How to cut a cast -iron blank. How to drill a cast -iron pipe

How to cut a cast.iron pipe with your own hands

During the repair, many people try to replace all obsolete communications at once. It turns out that it is most difficult to work with sewer cast iron pipes that need to be dismantled. They used to be connected by cement, sulfur or aluminum. It turns out that the system was carried out for centuries. But then the end of the century came up. And at the same time, complex work begins.

At first glance, it may seem that removing cast.iron pipes is very easy. But here you need to work wisely. After all, having put too much effort, you can damage the riser, which unites several apartments at once. In this case, the anger of the neighbors is inevitable. Costs, time and a lot of work will begin.

Before starting the dismantling of an old cast.iron pipe, you need to familiarize yourself with some rules:

- turn off the water supply in the house;

- remove the hose from the drain tank on the toilet;

- Remove the toilet carefully;

- take out all devices and items from the premises that can interfere with the performance of work;

- cast iron. fragile material. Pipes that are far from the riser can be broken with a hammer;

- removal of pipes that directly approach the riser;

- Cuffs are installed on the bell. First, the bell is cleaned of lubricants.

Dismantling pipes from cast iron

So how to cut cast.iron pipes, let’s try to figure it out. If the pipe from cast iron used to be connected by gray, then the task is not easy. But here there is advice on how to make out cast.iron pipes. Like any other substance, sulfur should be destroyed under the influence of something. And these “something” is open fire. If the sulfur is heated with a soldering lamp, it becomes viscous. So disassemble the pipes is very easy.

Use open fire carefully so as not to make a fire. In addition, when heating pipes from the compounds, sulfur gas will be released. Therefore, you need to apply measures to protect your own health. You can heat the connection for several hours. In order not to suffocate during this time, you need to wear a gas mask. It’s not bad if there is a bucket of water nearby in case something caught fire.

Methods of cutting material

As with any metal, the methods of cutting cast iron are divided into thermal and mechanical. The choice of a specific tool depends on the design features. The equipment is given below, which cuts (or cuts) cast iron:

- pipeline;

- angle grinding machine;

- chisel;

- Kryzuvka for metal;

- lobby

- plasma installation;

- Gas cutters.

Now it is worth evaluating cutting using these tools with cast iron objects.

Mini-cut

Mini-cutting is a type of portable autogen to work on metal, but with an even smaller size.

In fact, a mini-cutting is a lighter with a gas cutter, which is located on top of the device.

At the same time, the characteristics of the apparatus are pretty good: the mini-autogen has a good pressure of the flame and the sufficient size of the gas tank, which allows you to do work with it even with windy weather.

But there is one nuance: prolonged combustion can greatly heat the upper part of the mini rezak, and the parts made of plastic can melt, and it is not possible to carry out repairs or replacement in most cases.

The mini-hot paper has the same principle of operation as the unit of standard sizes.

But due to the fact that, the volume of the cylinder with the gas is small, it must be periodically refueled (you can use the usual Tsang cylinder).

Of the minuses of the mini-glass, you can also note a small length of the outgoing flame, so working with some types of metal on them is extremely uncomfortable.

Basically, such mini-options are used by jewelers or craftsmen who repair air conditioners and refrigerators, as they are very convenient for working with their own hands with small items.

Cast Iron Repair Job: Machining a Replacement Casting and Brazing in Place

In everyday life, a mini-hot butter is used to ignit the fireplace in a private house or in the country.

Cold types of metal cutting

Metal cutting mechanically is a complex process, because metal products have high strength and hardness. Cold types of metal cutting include:

Cutting with guillotine.

With this method of cutting, special mechanical tools are used. scissors and knives for metal. The workpiece is installed on the desktop and fixed with a clamping beam. Then, using a special blade, cutting is carried out. The result is a perfectly even edge, without unnecessary edges, burrs and zabrin. Cut the material immediately throughout the width of the sheet, so the curvature of the cut is zero.

The following types of guillotine for cutting metal are currently used:

They do not differ from each other in terms of operation, but the last three types are supplemented by electronics, which ensures accuracy and safety of cutting. There are also machines that can cut metal not only across, but also along. Most often, the guillotine type of processing is used for procurement work.

Disadvantages of this method:

- It can be used not for all types of metals and has restrictions on the thickness of the workpiece. For example, hydraulic machines are designed for metal up to 6 mm thick.

- The workpieces obtained as a result of cutting often do not correspond to the desired size, since the accuracy of processing depends on the qualification of the operator.

- It is impossible to carry out figure cutting.

- Cutting copper with laser: Advantages and disadvantages of technology

- Types of metal cutting: industrial use

- Metal processing by drawings: convenient and profitable

Latu.saw cutting.

Currently, this type of metal cutting is very popular due to the low cost of equipment, good performance and simple maintenance. The cutting tool is a strip saw stretched on the pulleys.

Modern tape drifts (LPS) are supplemented by various equipment and electronics, thanks to which the unit is easily built into a specific production fishing line for a trimmer. The speed of cutting such a machine on average is about 100 mm/min and above.

The method of cutting on LPS allows you to achieve accurate compliance with the specified parameters, and the site of the section does not need to be additionally processed. The method is good for high.precision products and parts with a smooth surface. LPS is suitable for any metal, and the cut width is only 1.5 mm.

With this type of metal cutting, it is important to comply with a number of conditions:

- the exact choice of a step of the teeth of the cutting canvas in accordance with the cross section of the sawn profile using special tables;

- feed speed;

- Cutting speed.

LPS allows you to cut a metal blank at an angle, which is a great advantage compared to guillotine.

The disadvantages of this type of metal cutting include the inability to get a curly cut and limiting the size of the workpieces, depending on the capabilities of the machine.

Cutting metal with a circular saw and “corner grinding”.

With the help of a circular saw make accurate cuts of good quality. This tool allows you to control the cut angle.

Disadvantages of this type of cutting include a large amount of waste, low speed and a small cutting depth.

For cutting profile rental, you can use an angular grinder. There are no cranberries and oxides, few waste remains at the site of the cut.

But low performance with this type of metal cutting is its main disadvantage compared to other methods.

How to hold a corner grinder correctly

Many have a corner grinder, but most people do not know how to use it correctly and how to keep it. This leads not only to marriage in work, but also to severe injuries. Corner grinder is a rather dangerous power tool. The circle should be installed by the pattern up and clamped by a special nut.

A person with the leading right hand holds an angular grinding of the handle with his right hand. In this case, the circle should be located on the left side of the machine, and the protective casing should close it on top. The rotation is so that during cutting sparks fly to a worker. If the corner grinder jams the circle and the corner grinder will break out of the hands, then it will not go to the cutter, but in the opposite direction.

The left hand holds the car by the handle, which is wrapped in a threaded hole on the case. There are somewhat for special cases of use, but the right position of the handle is only the upper.

This position of the machine requires the use of protective equipment. To protect the eyes and open part of the face, these are protective glasses, and even better. a protective mask. To protect the open parts of the body from sparks and small fragments during cutting, it is necessary to put on a suit made of dense material.

Cutting modes during milling

The choice of the optimal cutting mode of cast iron allows you to achieve maximum productivity of the machine, based on its resource, as well as the necessary accuracy and quality of the resulting part, while minimizing the costs. The following factors that can be adjusted in the processing process affect the cutting mode of cast iron:

- The choice of tool feed;

- Used cutting tool;

- The rigidity of the technological system.

- The strength and speed of the cut;

- The depth of the removed layer (the thickness of the cast iron removed in one pass);

- Cast iron brand.

Carrying out work

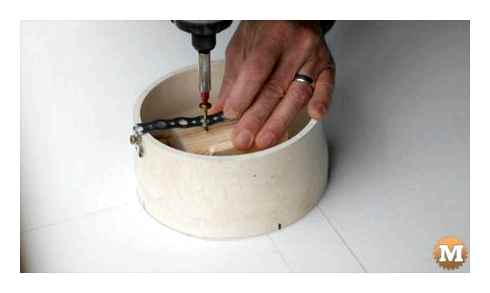

When performing processing by drilling, the following recommendations must be followed:

- Constant monitoring of the tool for the tool. With an increase in the load on the metal, defects may appear in the form of cracks and shells. As a result of the drill breakdown, the master can be injured.

- In the process of processing, overheating is not allowed. An increase in the temperature of the workpiece will lead to a change in the structure of the metal, as a result of which it becomes a fragile.

- Previously, the surface of the part is prepared before drilling, the drilling place will swing.

- If the diameter of the hole exceeds 10 mm, then it is necessary to apply the tool set. Start with small diameter, gradually achieving the right.

As a result of compliance with the technology for machining cast.iron parts, the master can achieve high accuracy holes.

Work with a chisel and a hammer

This pair of products will help divide cast iron in an inaccessible place. Dismantling work begins with pipes removed from the riser in places where you do not stick a corner grinder or hacksaw. Since cast iron is a fragile material, it is easily destroyed after point dynamic loads.

A good shock tool has a rubber or polymer nozzle to slightly soften the blow. This is necessary so that the pieces of cast iron do not scatter around, do not get into the riser and do not create a blockage.

How to cut cast iron pipe using a chisel

The chisel and the hammer work perfectly with the cast iron of the Soviet era, that is, connected by sulfur, aluminum and cement. As you move to the riser of free space for work, as a rule, it becomes larger, so further cast iron can be cut off with a more effective device. As with a corner grinder, when working with a chisel, it is recommended to close the areas of the body into which a cast.iron fragment can fly off.

The performance of the work is extremely small, but sometimes without them in no way.

Dismantling instructions

Destruction of the joints with a burner

If the joints of a cast.iron pipeline are fastened with gray, this complicates the task of dismantling. However, we have some tips on how to make out the cast.iron pipes of the sewage system in this case. Like any chemical substance, sulfur is destroyed with certain influences, namely, with prolonged heating with an open flame. High temperatures make it viscous and plastic, so that the removal of the substance from the surface becomes simple.

To dismantle the pipeline connected with sulfur, prepare a hammer and chisel, as well as a gas burner for heating. By the way, the burner can be replaced with a soldering lamp.

When the pipeline is heated with a lamp or burner into the surrounding space, a harmful gas will be released. sulfuries. In addition, open fire is also a danger. Therefore, measures to protect life, health and environment are required. Warm heating operations can last several hours so that the combustion products do not harm light, you will need a gas mask, and to prevent accidental fire and other interior elements, a protective screen of metal or asbestos is suitable.

Destroying joints without a burner

If you use the burner, we offer to familiarize yourself with the video presented below.

Dismantling instructions

It is advisable to start dismantling with the analysis of pipes located at a distance from the riser. This is not difficult and problems most likely will not arise if a chisel and a hammer are used, because cast iron is a very fragile metal.

So, consider how to remove the cast.iron sewer pipe:

A hammer break the plots to the cross

- Next, you need to gradually loosen it inside the riser. You can leave a segment of the pipe connected to the cross, then the operations to destroy the crosses will simplify. Some experts, on the contrary, remove cast.iron pipes to the maximum, extremely exposing the compounds.

- Put on protective agents and closing furniture with screens, you should proceed to heating the sulfur. The work will go faster if two people participate in the dismantling: one pays the joints with a soldering lamp or gas burner, and the second with a knife removes the viscous sulfur.

- Когда устранено большее количество серы с мест стыкования, крестовина извлекается из стояка.

Angle.grinding machine

It works quickly and comfortably, but not without minuses with a corner grinder. For example, she cuts only in a straight line. An attempt to make a curly cut will lead to a “snack” of a disk, its breakdown, a possible user injury. Therefore, the machine is used for cutting in a straight line. Another minus. the fire hazard of the method (abrasive disk metal = sparking). Before work, you will have to put on glasses, protection on your face and hands.

Cutting more efficiently than a jigsaw around, so more often users choose a noisy corner grinder. When buying a cut.out circle, prefer products on a bakelite bunch, because they are an order of magnitude stronger than ceramic analogues.

Drilling in conditions of industrial

In conditions of industrial production, if necessary, solving the problem, how to drill cast iron, appropriate machines with a working tool with special working surfaces of the corresponding sharpening are used. Must apply cooling liquids to ensure a given operating temperature.

In addition to drilling cast iron, it is imperative to ask a security issue during such works. It should be taken into account the possibility of the presence of a cavity, voids and similar defects in the array of the processed material. This is more often associated with a large amount of carbon in cast iron and a number of other components.

These sudden defects also lead to the fact that when processing the metal, a large amount of finely dispersed crumb and dust is released. Processing methods depend on the type of cast iron, but there are general rules and safety requirements.

As a result, in the course of work, generally accepted protective measures should be performed. Need to protect the respiratory system. Why is it necessary, in addition to the equipment of the place of work ventilated by the hood, to use a respirator or cotton-gauze “petal” for individual protection.

You should also protect your eyes. Safety requirements provide for the presence of protective screens, the use of protective glasses with closed side edges. Work in special work clothes, mittens and headdress.

Basic safety regulations

Before cutting a tree, it is necessary to familiarize yourself with the safety regulations before the corner grinder. The main of these rules is as follows:

- Be sure to use personal protective equipment (protective plastic glasses, fabric gloves), work in overalls.

- It is strictly forbidden to use disks having defects.

- It is recommended to hold the corner grinder hard with 2 hands.

- Constantly ensure that the electric cord is not near the rotating disk.

- Put an angular grinder only after a complete stop of the cutting element.

- Do not clean the protective casing.

- Do not work intoxicated.

You can not use equipment that is not intended for work with angular grinder. Cutting equipment for a disc circuit saw should not be used for the following objective reasons:

- The corner grinder has a higher rotation speed than the circular saw. The disk is designed for lower speeds, so at high speed it, cracked, can fly up. Flying fragments can harm health.

- The tree has a more viscous texture and inclusion in the form of knots, because of this, the teeth enter the material unevenly. If the disk is jammed, the tool can be pulled out of the hands, which is fraught with dangerous injuries.

- Due to the uneven loads, the equipment is overheated and failure is possible.

Recommendations for work

There are a number of small technical and operational subtleties that are important to consider in the process of processing the tree:

- Many, in attempts to make work more comfortable, get rid of the protective casing. But this is categorically impossible to do, since the casing is the only barrier in front of the operator and disk, the destruction of which can lead to injuries.

- A special device will help to increase the reliability of the physical maintenance of the tool. the supporting base. She will make a machine from a manual apparatus.

- To ensure a more tenacious grip, it is recommended to saw a corner grinding of a corner grinder in building gloves with rubberized lining.

- If the model of the angeling machine used is provided with the lock function, it should not be used. Complex situations may require instant disconnection of the device to minimize the damage, and the lock on will not allow this to do this.

How to cut slate without dust. Dangerous dust

Today, against the background of madness over the entire environment, the slate is considered perhaps the most dangerous roofing material. How. Asbestos, a dangerous mineral in its composition! Nevertheless, most of them have no idea how this substance works and how much it contains various objects and things that surround us. Please note that if you decide to get rid of everything that the asbestos contains, throw the money immediately! In their production, asbestos are used to increase the service life and strength of bills.

Seriously, however, Asbest is completely harmless to a person in a bound state in which he lives in food. Slate on the roof of the house or barn does not create dust, and if you are so worried about it, just paint it. Fortunately, shale paints that have high adhesion to such surfaces are now specially intended for this purpose.

That is, asbestos slate itself is no more dangerous than the same plastic roof, because asbestos is connected by cement, but if you begin to saw or grind it, the dust that enters our lungs can really cause chronic bronchitis and other problems that are related With hard work. Starting repairs to get rid of all asbestos.cement designs, you simply provoke the spread of such dust. It is not surprising that in the midst of the campaign to combat asbestos at the state level, the United States made a very reasonable decision. It is much safer to fight asbestos than to deal with it.

Therefore, do not rush to get rid of everything that ASBEST contains. Use as before. However, when performing any task, try to protect yourself. The easiest way to prevent dust from entering the lungs and eyes. This is to put on a respirator and protective glasses and be on the leeward side before cutting slate. If you have to work in a closed room, wet the slate properly before cutting it. Much less dust stands out from wet products during cutting. In addition, it is much easier to cut the product immediately after soaking. Therefore, experienced craftsmen put wet rags in the place of cutting before cutting slate for several hours.

When cutting, send those present to the room to breathe air. Even street was not as harmful as asbestos.cement dust. First of all, children should leave the room. Because of their low stature, they breathe air at a level where the most dust. And one more important security measure, as they say, for the future. Never throw away the remains of building materials or building garbage on the road. Over time, cars will be crushed pieces of the same sheet, and the air in hot weather will be filled with dust containing asbestos.

Work with a chisel and a hammer

This pair of products will help divide cast iron in an inaccessible place. Dismantling work begins with pipes removed from the riser in places where you do not stick a corner grinder or hacksaw. Since cast iron is a fragile material, it is easily destroyed after point dynamic loads.

A good shock tool has a rubber or polymer nozzle to slightly soften the blow. This is necessary so that the pieces of cast iron do not scatter around, do not get into the riser and do not create a blockage.

The chisel and the hammer work perfectly with the cast iron of the Soviet era, that is, connected by sulfur, aluminum and cement. As you move to the riser of free space for work, as a rule, it becomes larger, so further cast iron can be cut off with a more effective device. As with a corner grinder, when working with a chisel, it is recommended to close the areas of the body into which a cast.iron fragment can fly off.

The performance of the work is extremely small, but sometimes without them in no way.

Gas cutting

Two methods of gas cutting cast iron are distinguished:

In the first case, the finest stream of flame supplied under high pressure affects the workpiece. The combustion product is usually a mixture of oxygen with kerosene or diesel. By the way, an effective method in the elimination of technological accidents.

The second method resembles a gas acid, only a cutting element is a thin pipe made of hot steel. Its tip heats up to almost 1,500 degrees (welding/soldering iron/lamp), then oxygen is supplied through it, ignited at the output and heated to 2000 degrees. The received burning mixture easily copes with the thick cast iron.

Both methods are good, but there are minuses. it is important to have experience working with gas equipment. Responsible and accurate cutting is performed only by a professional. The second drawback is the release of gas harmful to the health during the operation of the cutter.

The method is suitable for working in the fresh air or in the garage. For example, the need to eliminate a cast.iron lock from swing gates. The cutter works quietly, you will not hide anyone.

Varieties of units

If you plan to make repairs and choose the device, then the next information will definitely interest you.

There are quite a lot of varieties of cutters. All of them have different devices and characteristics.

- The oxygen apparatus is an ejector installation, in which the burning stream forms an oxygen. Oxygen autogen is considered one of the most budget devices and is quite suitable for cutting with your own hands;

- A kerosene cut, as the name implies, works with the help of kerosene vapors. As a rule, they are used to cut a carbon steel with a thickness of not more than 20 cm. It is almost never used for cutting with your own hands, as it differs in a complex device and is used mainly in industrial work (the characteristics of the burner allow it to be used in coal or mining industries, underground, while a propane or acetylene cut there is undesirable);

- The propane apparatus is used in cutting products, which include non.ferrous and ferrous metals of different compositions (the most commonly propane autogen is used when cutting cast iron. batteries or pipes). Professionals pay attention to safety and reliability that the propane apparatus provides compared to the use of other units. Therefore, it is the propane autogen that is most often used when performing work with their own hands. In addition, if you use a propane metal cutting method, you can be sure that you are provided with efficiency and performance;

- Acetylene gas burner is used to process parts and sheets that have a large thickness. Separate valves are on all such burners, with the help of them you can set a high speed and power power during operation. There are even portable cutters, for the work on the metal of which you need an acetylene mixture. Since thanks to acetylene the flame reaches the highest temperature, then, despite the compact size of the device, they can even cut a very thick metal for them. Such a portable cutter is extremely convenient to use with your own hands and is in great demand with this.

But still, universal ejector devices are most popular. Universal autogens can cut the metal in any direction and under any inclination.

At the same time, they are extremely convenient to operate and are small in weight. One of the last developers of manufacturers is a gas.ignition gas cutter.

It is extremely convenient for using it with your own hands, since such a device is turned on by one click on the button.

But such an autogen is quite expensive, so if you need the device for a short period and for a small amount of metal cutting, then the purchase of such a burner will be inappropriate and wasteful. It is much better to buy a mini-cutter.