How to cut a circle with an electrician in the countertop. Instead of a compass

How to cut an even circle as an electrician

A compact and convenient tool that greatly simplifies the process of cutting wood, metal and many other materials. The design of the electrician is relatively simple, but has certain nuances, the knowledge of which significantly increases the efficiency of using the device. In this article, we will talk about the device of an electric jigsaw, we will conduct a brief instruction on its operation and share a couple of interesting tricks.

The next small introduction is compiled with the aim of answering the question “what is an electrician” and “how it works”. Since this is only a superficial analysis of the tool, we will not plunge into the technical depths, but we will only touch on external functionality. We assure that the information provided will fully clarify the general understanding of the concept of the device and form a clear picture of the principle of its operation.

First of all, you should pay attention to the forms of electrolobsics. They can be bracket or straight with a mushroom.shaped handle. The first option is the most common and very convenient, but for the sake of justice it is worth saying that working with a mushroom handle can be quite comfortable (especially in a figure cut).

Regardless of the shape of the handle, each jigsaw has a start button and its latch (for work without holding). Also, any device of this type, has a sole that can be stamped or cast (on more expensive models). For the cut at an angle, the sole can be tilted using a key or lever installed on professional devices. Saw canvases that make an average of 50 moves per second are installed in a special clamp, which can be a columnar, screw or quick.and.resigned.

Most modern models are equipped with a pendulum function (to accelerate the cut), the regulator of which is located on the left side of the case, next to the file. If we consider the device of an electrician in more detail, note that some models can be equipped with backlight, vacuumber, laser pointer and other useful devices. About these and other functions, we talked in detail in a separate article.

For more sophisticated users who are versed in the structure of the power tool, the following electrical circuit was posted. The model of the domestic manufacturer presented in the analysis, clearly demonstrates all the components of the “fillings” of most standard devices.

How to insert a file into an electrician

With intensive use or when working with various types of materials, there is often a need to replace the saw canvas. Types of file mounts on different models of jigsaws may differ. To give the most detailed answer, consider each type of clamp separately.

Column clamp. Perhaps the simplest fastening of a file in an electrician, most common in inexpensive copies. Consists of a block with two screws installed on the front side of the tool. Is universal, as can I fix saw canvases with any shank. When tightening this mount, you should be neat and make sure that the saw rises exactly. To do this, tighten the screws, evenly, a little bit, and ideally check the evenness of the installed canvas with a square.

Screw clamp. A more convenient and reliable mount, although it has only one screw installed on the side. To figure out how to change the file on the jigsaw with this type of clamp, you do not need to be seven spans in the forehead. All that is required is to loosen the fastener element with a screwdriver or key, remove the old file, install a new one and tighten it back. The main thing is not to tighten the screw too strongly, otherwise the canvas can “play” when working.

Quickly sound mount. The most convenient peel clip, found on more or less expensive models. Does not require a key or screwdriver and is suitable only for paintings with certain types of shanks (depending on the model of the tool). To install a file, just take a special lever with your finger and insert a new canvas into the groove. There are several types of levers: frontal, lateral and radial (demonstrated in the next video).

How to cut a hole under the sink in the countertop?

When you have experience in a certain case, then you do not notice difficulties, everything seems simple and understandable. But when you start some operation for the first time, even minor trifles raise questions. How to cut a hole in the countertop under the sink, where to start?

Start with the designation of the place where the sink will be located on the surface, because at least three options:

- how the water will be brought to the tap;

- how the mixer will be installed;

- how the drainage system is carried out;

- Will there be enough space for additional equipment (filter, soap dish, garbage capacity, etc.

After understanding and presenting a complete picture, you can start directly to the question of how to cut the sink in the countertop. It’s good if it is rectangular, and if it is round or oval or generally complex geometric shape, while cut the countertop under the sink?

A template will help you, or rather, you can’t do without it. Some manufacturers, in order to facilitate the task of future owners of sinks, immediately complete with the purchased product offer a ready.made template.

But if you are not lucky with this, don’t be upset. Since you have already tuned in and imagine how to cut the countertop under the sink, it will not be difficult to make a sink template on your own.

Take a cardboard or dense watman, and circle the contours of the future hole under the sink with a pencil on the sheet. Then cut the necessary details with scissors. Please note that it is necessary to navigate by external measurements, not forgetting about the gap when cutting.

So, when the template is ready, you can proceed to the next step. marking.

Draw a fishing line for a trimmer for the future saw on the surface of the stove with a simple pencil. To do this, place the template where the sink will be in the future and circle the contours of the desired hole.

Some fix the template to the surface and immediately begin to saw. Experts recommend abandoning this method and be sure to mark the pencil. Why? Because, how to cut the countertop under the sink, if the template moves all the time? There is a chance of cutting with a cardboard, which will distort the required dimensions.

Do not want to make a template at all? You can turn the sink with the front side to the surface of the countertop and circle its contours with a pencil.

Now it is necessary to make holes under the sink with a drill so that the jigsaw can enter. over, for:

- rectangular shape. 4 holes (in each corner);

- triangular shape. 3 holes (in the corners);

- oval or round shape. one hole (anywhere).

Thus, the surface is prepared directly for sawing. If there is an opportunity and allows space, it is preferably a plate of a future desktop during the process of the sawing process to unite.

So, how to make a hole for the sink in the countertop, depending on the material of the product? Let’s talk about this next.

How to cut a countertop under a sink?

Most often, the question of how to cut a hole under the sink in the countertop is asked by the owners of the laminate slab, since in this case it is the easiest to make a cut. But the subtleties must be taken into account:

- Work on marking is a repetition of the passed (important information);

- saw an electric jigsaw, inserting it into the holes prepared by the drill;

- The canvas of the jigsaw is perpendicular to the sawing surface, tightly pressing the tool;

- Sprinking the countertop from the side of the laminate to avoid the formation of chips and cracks;

- it is imperative to maintain a sawn.out part, since it can break off under its weight and a crack in the stove.

Tip: Do not be lazy and as the cutting line moves, stop and fasten with tape on both sides (outside and inside) the place of the cut so that the cut part of the countertop is tightly held to the last millimeter.

How to cut a countertop under a round sink? In the same way, with a jigsaw, slowly, passing the canvas along the marking line, gluing drank with tape.

Place the sink in the resulting hole. Fits? The sink should freely enter. If tight, go with rashpil and sandpaper. Peel the formed cut from sawdust, and cover with a thin layer of sealant.

And how to cut the countertop under the sink if the material is artificial stone?

In this case, you can use the drill for metal as a tool for drilling holes, and the cut to make a cutter. Or you can use the same jigsaw, but then the cut is made with an indent from the marking line per centimeter, and then bring the fishing line for the cutting trimmer to the desired size by the cutter. These precautions are necessary to exclude the formation of cracks and chips.

Когда отверстие выпилено, обработано, примерка раковины прошла отлично, переходят к установке мойки и подключению сантехнических коммуникаций.

Is it possible to cut a hole for a sink in a tabletop of glass or natural stone yourself?

Theoretically, of course, you can. But a counter question arises, whether the sheepskin is worth the definition, especially taking into account the high cost of the cut material?

For glass and natural stone, you can’t get by with an ordinary jigsaw and a cutter, you need special equipment, which is also not cheap, but only one will need it once. In addition, you will have to prepare a specially equipped place where the cut, since both glass and the stone are heavy, they need reliable supporting stands.

How to correctly cut a countertop under a sink of glass or natural stone is known by E-STOUN professionals.ru with extensive experience and skills. They can trust them to arrange a dream kitchen.

Cutting instructions

Before starting work, you need to drill a hole for the canvas of the jigsaw in the faner.

To cut out even circles with a jigsaw quickly and beautifully, it is not necessary to be a specialist in this area, but for a beginner it can be a very difficult task. In this matter, the main thing is patience and, of course, the presence of the necessary related tools, such as the jigsaw, saw, compass, simple pencil and surface polishing devices.

The first thing to do is draw a circle on the surface of the material with which you will work. It will be best to use the compass or choose a suitable circle and circle. It is necessary to circle with a pencil so that traces from it can be erased in the future.

If you need to cut a circle inside the surface, then you should make a through starting hole. Next, you need to insert the blade of the jigsaw or saw into this hole and fix the free end of the file with a clamp. It is recommended to cut in a sitting position. First of all, it is necessary to fix the file in the jigsaw using the key, and it should be borne in mind that the files of the file should be directed down. You need to cut it in the direction from top to bottom. The tool should be kept exactly to avoid Zazubrin and bevels.

The main thing in this process is not to rush and cut smoothly without sudden movements.

In the process of cutting, it is necessary to take small breaks, as the file can overheat and break. Here is a circle and ready. Now it is recommended to align the edges with a file, erase the marking left with a pencil and polish the part. If necessary, you can varnish.

Of course, cutting a jigsaw requires a certain dexterity and skills, but everything comes with experience. Therefore, compliance with the recommendations described above should help a beginner master in mastering this interesting and exciting activity.

Sizes and shapes of sinks

These indicators belong to the main characteristics. It is worth deciding on the very beginning, so that later everyone is comfortable and comfortable in the kitchen space. The most common and in demand is considered:

You can opt for other forms: oval, with rounded corners, triangular, pentagonal, hexagonal, trapezoidal, intricate. It all depends on your needs and preferences. The number of bowls can also vary. There may be two, three or in one copy. They can have both the same and different sizes.

How to cut a circle in a granite counter top

Various forms of sinks for the kitchen

Rules for working with an electrician

To understand how to cut a circle in wood correctly, it is important to study the features. This carpentry tool helps to cut ovals, wave.shaped patterns, figures with uneven outlines, non.standard carved caskets, shelves with a through plan

In order for the interaction with the jigsaw to be organized and safe, it is important to adhere to the rules:

In order for the work with the jigsaw to go quickly and safely, do not forget to fix the product before work.

- In order to avoid inconvenience, special stands should be prepared in the work. A slot is made to the middle of the backup, somewhat resembling a lock hole.

- The stand is fixed with clamps or screws to the workbench.

- At the time of work, you need to sit down, arrange the file strictly vertically relative to the floor and perpendicular to the surface.

- The workpiece is placed in the middle of the stand, holding it with the left hand, with the right you can saw plywood. The location of the sawdust should be in the middle part of the hole of the background.

- The tool does not tolerate strong pressure: a small touch and gradual movement up and down, and it will begin to work effectively.

Electrician. a very useful power tool. The use of the right file, a little experience and confidence, and most importantly. the correct position of the body, you can do everything with it. You can do many things that cannot be done on other tools. The machine is used to cut straight lines, curves, profiles and trimming the circle. Great for cutting wood, metal and plastic.

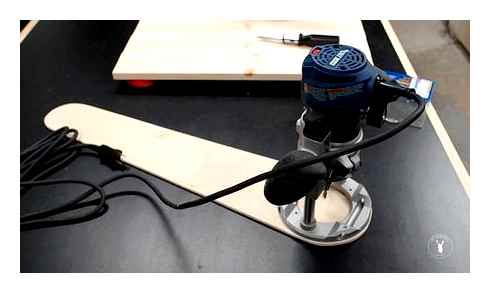

The master showed how to cut the ideal circle with an electrician. He made a wooden device. Its design is unpretentious, and the device itself is easy to manufacture. To get an idea of this, see this image.

12 mm plywood sheet. Wooden strip. Nails.

First of all, measure the size of the base of the base of the liner machine. The next step is to cut the plywood sheet in the form of L, as shown in the image.

After cutting the sheet, plywood in the exact size of the next step cut a wooden strip to attach this sheet with nails. This strip is used to hold the electrician in its position.

Make sure that there should not be any type of opening between the strip and the base plate of the electrician.

The next step is to drill small holes on the sheet. The distance between these holes is equal, for example, 1o cm. These holes are used for cutting different diameters of the circle.

After that he painted him so that he looked good. Now he is ready for use to cut the perfect clamp circle.

Used for cutting round discs of various diameters.

For a better understanding, see the video below.

Often the question of how to cut out of plywood with a plywood lobby is at a dead end by novice masters. After all, to do this is much more difficult than a simple straightforward cut, no saw will help here.

Most often, a jigsaw helps to cope with the task of figured sawing. Litzes are manual and electric. The hand.lobby consists of a frame with clamps for a canvas and handle. The main disadvantages of the manual jigsaw: low mechanical strength of the canvas and a small frame size. As a result of this, the canvas is often torn and it is impossible to cut on a large indentation from the edges of the part. Such jigsaws are usually used to process wooden products. Electrics are ordinary, in which the saw is located vertically, and for art cutting, where the steel canvas is a cutting element. Electric jigsaws are usually used when working with thick material.

How to cut a countertop under a sink

Preparing the countertop for the installation of the sink is not very difficult, but quite painstaking, requires zeal, free time and personal work. A properly cut hole is the key to elementary installation of the sink, and as a result, getting the pleasure of washing dishes.

To make the hole neat and correct, you need to follow the following rules:

- We take a clean cardboard sheet of the necessary parameters, which will go to make a template.Conscious manufacturers are found that such a template is made on their own and put into commodity packaging. It remains to take the scissors and walk along the contour. If such a template is absent, then a sink is taken, turned upside down, put on a cardboard laid on a flat horizontal surface, a sink contour is circled with a pencil and a template is cut out. If there is no finished template and you did not buy a cardboard sheet, then you can put an inverted sink on the countertop and circle it.

Pencil with a pencil where the sink will crash

Cut the hole for the sink through the painting tape

You can look more about how to cut a hole for the sink

Tool characteristics

Electrics are divided into household and professional. Using household tools with a power of 350-620 W, perform a small amount of wood on wood with a thickness of up to 70-80 mm, sheet steel up to 4 mm thick. Professional power tool is intended for a large amount of work, provides continuous operation within 8 hours, performance does not decrease. The tool is designed to work with wood material with a thickness of 80-130 mm, steel material up to 10 mm thick, aluminum up to 20 mm, has a power of 580-750 W.

Household models have a smaller set of additional functions. Important working functions. the speed of the course, power, the method of attaching the canvas for sawn, pendulum movement, equipping the file rotation by the file, regulation of the number of moves to optimize work with different materials. Lobziki single.speed without adjusting the stroke is used for sawing wood.

Electrician is often used during finishing work, for curved cutting, creating internal holes, curly parts in the manufacture of furniture, while the material with which they work is required to fix it. To fix the material, you can apply clamps, on the material it is preliminarily marking the sawdust, then they turn on the tool and begin to cut out. The principle of operation is to convert the rotational movement of the shaft into the progressive movement of the working mechanism. saw. The file is strengthened on the rod. a round plate, on the quality of which the durability of the part depends

When choosing a power tool, it is worth paying attention to the round shape, thickened rods

Rectoline cut when using the guide tire

First, experienced craftsmen place the workpiece on the desktop. Then install a jigsaw in a special shoe. Then the tool with an additional device is placed in the bus. Next, position the peel on the marking. After that, fix the tire and turn on the electrolobian, which is moved along the guide. While the master does not make any great effort. He only needs to move the tool on which an exclusively high.quality cutting canvas is installed. Otherwise it will not work to perform an even section.

This video tells about the features of a flat cut by an electrician:

Straight cut when using a parallel stop

Many electrician are sold along with a parallel emphasis. Such models are often chosen by professionals. It is possible to perform high.quality cut when using a parallel stop if:

- The material with a flat surface is cut, since the shoe should move only on such a plane;

- It is used exclusively high.quality jigsaw, which does not take aside during operation;

- a rigid and strong additional device is used;

- the shoe is tightly pressed to the surface of the cut material.

Even if a specialist uses a lobby, which did not initially enter the parallel emphasis, he will always be able to use it, since there is a slot in the sole of each such tool. It is it that allows you to fix the bar of an additional device.

How to cut plywood, wood, metal: tools for using the tool

A jigsaw is a very common tool among amateurs and professional joiners, so it is important not only to choose it correctly, but also to know the rules of use. To answer the question of how to cut it with a jigsaw, it is necessary to take into account a number of nuances related to the specifics of the electrician and stages of the sawing.

The choice of a suitable tool

Several recommendations from experienced specialists will help you choose the right tool for work.

To cut at home a fairly domestic or semi-professional D-shaped jigsaw, which is controlled by one hand. The greater the power, the harder the electrician, and it will be more difficult to saw it evenly.

Step speed regulator, electronic stabilizer and pendulum course will greatly facilitate the cutting process. The presence of a plastic lining on the sole will reliably fix the car on the cutting canvas. Useful functions are built.in blowing and backlight.

It is worth paying attention to the mounting of the canvas. Some models have a restriction that does not allow the use of any saw.

It is not recommended to saw boards with a jigsaw, for this there are circular saws and hacksaws. Although a powerful tool can cope with the task, it is unlikely to achieve a perfectly even saw.

Each model of the jigsaw varies in shape, so before purchasing it is worth holding the tool in the hand, and if possible and test it directly in the store.

The choice of cutting canvas

Fabric for jigsaws differ in the length and frequency of teeth. It is worth giving preference to proven brands, in this case there is a quality guarantee for metal, and the saw will be even. Files are classified according to the configuration of teeth:

- On standard models, the teeth of the same size are located at an equal distance and in one direction;

- The so.called saw with a missed tooth is distinguished by the absence of cloves, so that the speed of the sawing increases, the canvas heats less and sees, and the chips are removed from the surface to the side;

- In the case of double teeth, the speed of the cut below, but the quality of the cut is better. The chips are removed from the cut;

- In reverse paintings, part of the teeth is directed upward. Using such a tool, you can cut a laminated wood-bruise plate and other wood without chips with a jigsaw, since the upper teeth cut the material with the reverse movement.

The specific thickness of the canvas depends on the material with which you have to work, but the basic for the manual model are. ,

The marking of the line drank

In order to cut off the material with a jigsaw, it is necessary to correctly outline the fishing line for the trimmer of the saw and securely fix the blank on the surface. If you have to work with a long canvas, it is worth using a flat rail as a guide and two clamps for attaching it and working material. It is necessary to act in a certain sequence.

First, you need to mark the wood-cutting stove using a ruler. To do this, the required distance from both sides is measured, the marks are connected, forming a fishing line for a cutting trimmer. For the manufacture of a curly line, it is advisable to draw it on paper, and then transfer it to a tree with a copy of the carbon.

To cut a circle with a jigsaw, the marking is applied with a construction pencil or a black marker to the surface on a pre.made stencil of thick paper or cardboard. In this case, the sawing of the material begins with the drilling of the hole in the center. The blade should move from the center to the marking line, and then along the perimeter of the circle.

Important! The jigsaw is inherently provided for curved cuts, cutting it exactly in a straight line is quite difficult. You need to constantly monitor the line and direct the tool a little to the side.

In order to avoid chips on the finished surface, the file during operation is not carried out at the mark, but near it. The laser guide on the jigsaw will help to saw smoothly.

Fastening of the material

So that the cutting line for the trimmer of the cut is even, the working surface should be as stable, hard and strong as possible. When working at home, this can be an ordinary table with reliable legs and a flat countertop.

The board is fixed on the surface using clamps, fixed on both sides with moderate force. The processed sheet must be placed in such a way that when working, the tool does not rest against the surface. So that in the process of the saw on the saw there is no pressure, the protruding edge hanging from the surface can be weighted using the attached cargo.

SPILE technology

Begin to saw after fixing the workpiece and marking. To do this, you need to turn on the electrician, set the maximum speed level and adjust the pendulum course, putting on the number 1.

It is necessary to bring the file to the marking line, press the side of the platform to the guide and start work. Moving the jigsaw forward, it is necessary to monitor the location of the platform. It is impossible to get away from the guide.

When a few centimeters remain until the end of the canvas, it is necessary to carefully hold the free edge, avoiding fault. The process can be considered completed on this.

So that the cut does not turn out to be a curve, it is worth remembering a number of nuances:

- In the process of work, you can not press on an electric jigsaw, otherwise the saw will break;

- Cutting a steel sheet, it is necessary to choose a tool with maximum power and work at high speed. when heated, steel is softened and becomes more pliable;

- By processing plastic, laminate, organic glass or stainless steel, it is necessary to provide additional cooling of the file and periodically take breaks so that the tool can cool down;

- So that the plastic does not melt in the process of processing, it is necessary to set the minimum speed with a frequency of 1000 revolutions/minute;

- Figure cut will turn out even when choosing a narrow saw with small teeth;

- Having finished the work, the electric device should be cleaned of sawdust and put in a special cover.

How to cut a circle with an electrician?. Tool system

With the development of building technologies, new materials and tools appear. The power tool allows us to significantly facilitate the work of the builder or home master, and some work cannot be performed at all without its use. One of these tools is an electrician.

Wood threads with an electrician may require the tool the presence of a penny of the canvas. This means that during operation the canvas makes not only progressive movements down and up, but also as if crushing the material in front.

It is recommended to use a pendulum course only if it is necessary to make a direct cut. With the help of this tool, in the presence of the desired paintings, you can make direct and patterned cuts in many materials: different wood, brick, glass, ceramic tiles, non.ferrous metals, plastic, drywall, steel (even stainless) and others.

The saw changes very quickly, unlike a regular hacksaw. Figure sawing with an electrician wood rose to a new height with the advent of this tool. With the help of a jigsaw, holes can be cut inside the part, as well as saw at an angle.

Consider how to cut an electrician. First of all, make sure you have new sharp files. There is always a wide range of various paintings on sale. Dumb canvases will greatly load the engine, which is not recommended, and the edges will turn out to be torn.

Next, it is required to fix the sawing workpiece. If the part is well fixed, the cut will turn out more accurately and more precisely. When cutting, do not put pressure on the jigsaw towards the cut, it is necessary that he walks freely. If you still have to crush, then the canvas is stupid.

It is necessary to cut not along the marking line, but next to it, this will make a cut more precisely. If possible, you need to put the workpiece with the front side down. The working course of the canvas occurs when upwards, respectively, the cut from the lower part of the part will be more accurate.

A thread with an electrician at an angle is carried out when fixing the supporting plate in the right position. On most models, you can set the cut angle: 15, 30, 45 degrees. First, it is better to cut the unnecessary board to check the angle by the transporter, and then proceed to the shallow option.

How to cut a paper circle without using scissors, compass or pencil (Trick!)

Drinking a wood jigsaw has an undoubted advantage, which consists in the fact that when processing thin or sensitive blanks, the cuts are very high.quality, without burrs and torn edges.

Before cutting spheroidal forms inside the part, for example, a hole for the right handle, first you will first need to drill it with a drill to fit the canvas. Then you need to insert the canvas and turn on the tool. It is necessary to hold the carved part so that the canvas does not eat.

When working with this tool, some safety rules should be followed. Before sawing an electrician, you need to make sure that the power cord is zaizoli everywhere. Avoid direct contact with the canvas of the jigsaw. The canvas must correspond to a certain type of sawed material.

Before using an electrician, read the instructions for operating and care for the tool. Lubricate and clean your tool, this is a guarantee of its long and impeccable work.

How to cut a circle with an electrician?

Electrician is a well.known manual type tool designed to cut out patterns on various surfaces. In its significance, it is just as important as a drill or a peorator.

They can make straight and curved openings in the wood of any breeds and other unnatural materials, accurate cuts of geometric shapes with complex trajectory. Find out the question of how to cut a circle with an electrician, the tips and recommendations listed here will help.

Properties of locksmith tools

The jigsaw is intended for household and professional needs. The first species devices are small in power and are designed to carry out work in small volumes. The purpose of using special equipment is the professional orientation of the tool, its productivity and a long period of work.

Usually household appliances have a standard set of functions:

Electrician is used to finish surfaces, cutting out of uneven edges, openings of internal position, and furniture. The processed material is reliably fixed on the basis.

Marks are made in advance, then the holes are cut. Roting vibrations of the shaft are converted into a progressive nature. The saw is fixed on the rod, its quality determines the period of use of the product.

Choosing a device, preference should be given to round forms and thickened rods.

The jigsaw is distinguished by such positive qualities as:

- Cutting holes in any samples.

- A simple device allows you to quickly replace the saw.

- The ability to make a cut round or rectangular species.

- Simplicity of use.

- Does not require special knowledge and skills.

- The presence of a significant number of saws with a different step border of action, the forms of the teeth allows for various types of work in the conditions of one device.

- Reliable fixation of the sawn.out sample allows you to cut any distances from the edge of the product with a jigsaw.

- The universal device allows you to drink to any depth.

- At the time of work, the material is practically not damaged.

- The shortened movement of the canvas provides a slowdown in the work of the device.

- The possibility of injuries.

- The probability of failure of the cord.

- Checking the battery charging level.

The released new items are equipped with improved functions: reducing the number of vibrations, improving performance indicators, equipment of the device with convenient functions. Depending on the method of fixing the cutting part, there are saws:

A jigsaw in some way can replace a milling cutter, a hand hacksaw, a circular, a chain saw, a machine for grinding angles. The tool is necessary in any household, it allows you to carry out woodcarks.

The master cuts out perfect circles with a jigsaw

Electrician. a very useful power tool. The use of the right file, a little experience and confidence, and most importantly. the correct position of the body, you can do everything with it. You can do many things that cannot be done on other tools. The machine is used to cut straight lines, curves, profiles and trimming the circle. Great for cutting wood, metal and plastic.

The master showed how to cut the ideal circle with an electrician. He made a wooden device. Its design is unpretentious, and the device itself is easy to manufacture. To get an idea of this, see this image.

12 mm plywood sheet. Wooden strip. Nails.

First of all, measure the size of the base of the base of the liner machine. The next step is to cut the plywood sheet in the form of L, as shown in the image.

After cutting the sheet, plywood in the exact size of the next step cut a wooden strip to attach this sheet with nails. This strip is used to hold the electrician in its position.

Make sure that there should not be any type of opening between the strip and the base plate of the electrician.

The next step is to drill small holes on the sheet. The distance between these holes is equal, for example, 1o cm. These holes are used for cutting different diameters of the circle.

After that he painted him so that he looked good. Now he is ready for use to cut the perfect clamp circle.

Used for cutting round discs of various diameters.

For a better understanding, see the video below.

Комментарии и мнения владельцев

In fact, you do not need to cut out this small piece, look at your video, which you cut out on the board three times, but you just need to cut this angle, just ignoring a small part.

thanks a lot! I have to cut circles with a jigsaw at work, you get tired of drawing with a pencil on a wood.fiber slab and then you need to cut it very accurately along the line, your eyes get tired of failure. I will not write about marriage, there is little marriage. I will make myself and apprentices such a sole, there are some kind of ideas.

The disadvantage of this idea is that the diameter of the cut circle is not controlled smoothly. There is an idea to make an adaptation composite for accurate adjustment of the diameter, but it will already be in the metal. In fact, it is strange that the kit did not attach such a device in the factory design. Now everyone has to collective farm in their own way.

Features of work

The tool is produced with built.in protection systems, pneumatic and electric drives. The introduction of innovative technologies helps to improve the functions of electrolobsics, reduce vibrations, noise, increase productivity, equip the tool with convenient functionality. Tools can be classified according to the method of fastening the saw: saws with a part with a hole, saws with a cross.shaped detail, smooth saws. Electrician can perform some functions of the milling cutter, hand hacksaw, saber, circular, chain saw, angling machine; The tool is a good help in the household.

In the process of the jigsaw, the current, which comes from the power source, sets the engine of the electrician. A rotational movement to the gear is transmitted through the engine and the gearbox that fixes the stem. The rotational movement of the shaft is transformed into the reciprocating motion of the working mechanism (up and down), the saw performs the piercing of the material. The tool is indispensable when wood carving. Files are attached with screws or cloth devices, this allows you to conveniently and quickly change the canvas without using a special tool.

The principle of operation

Wooden elements of the interior decor with a wave, ovals, a variety of curved figures, original caskets with carved jewelry, unsurpassed shelves with through ornament are performed by an electrician. In the process, some rules are required to follow. For carving there are special stands that allow you to comfortably produce cuts. To the middle of the stand, it was made drank for convenience, in appearance resembling a keyhole. The stand is attached to the workbench using clamps, screws. It is necessary to work with a jigsaw sitting, technological operations are performed in such a way that the saw is in an upright position relative to the floor, it is perpendicular to its plane. The workpiece is located on the stand, it is held with the left hand, the right hand works as a jigsaw. The sawing area should always be located in the middle of the cut of the stand. You should not press the tool too much, carefully move the device up and down the device.

In this case, the work of the file is controlled, which is directed strictly along the marked contour. In order to expand the fishing line for the trimmer to expand smoothly, you need to carefully turn the device to the right (to the left). When performing sharp turns at right angles, it is required at the rotation point to work in one place, do not move it forward, but slowly unfold in the right direction. When cutting a circle inside the workpiece, a hole is drilled in the middle of the circle, then the upper screw fixing the saw is removed from the power tool. The saw is inserted from the bottom into the drilled hole, clamped by the screw at the mounting site. Further cutting of a round element is carried out. After that, the screw is spinned again, remove the file. In the process of cutting, pay attention to the degree of tension of the file, with weak tension, it performs poor.quality work. If it is pulled, it is easy to break a file. It should be fixed with screws so that she does not have the opportunity to slip, but the thread should not break.

A high.tech hand tool makes it possible to independently manufacture various extraordinary interior decor items, gifts, extravagant figures.