How to cut a pipe at an angle of 90

Using a ready-made miter box

How to use the miter box

A miter box will help you cut the plinth at a 45 degree angle. By the way, do you know how to use the miter box? The specialists of our portal have prepared for you a step-by-step.

How to cut at a 45 degree angle

Often, during repairs, you can face a situation when it is necessary to saw off a piece from a part, at an angle of strictly 45 degrees. Usually, this is needed to connect two parts at right angles, 90 degrees, such as: door trim, plinth, pieces of furniture and much more. An experienced craftsman, professionally engaged in repair work, can often do without special devices, and practically by eye is able to cut the necessary part evenly and clearly. But if you are a novice repairman, and you have a desire to do the work as efficiently as possible, without damaging expensive parts, then you just need to purchase a miter box. a special device that allows you to saw off material at a given angle without any special tricks.

To work, you need to have: a miter box, a hacksaw, a protractor with a pencil, a workpiece made of wood, a screwdriver with screws or a clamp.

Self-made miter box

- 1. First, you need to assemble the box of the future tool. To do this, it is necessary to drill holes in its side walls, for future fastening with screws and, having smeared the ends of the parts with glue, connect them in such a way that both walls are strictly perpendicular to the bottom and parallel to each other, after which we fix them with screws.

- 2. Using a protractor, mark an angle of 45 degrees with a pencil, if necessary, add additional lines for the grooves. The most critical part is the cuts, it is best to make them with the same hacksaw blade as you will be cutting products. It is necessary to cut by holding the blade, avoiding strong pressure on the tool, first we cut one side, then the other.

- 3. We start processing the material. With a clamp or screws, we fix the miter box on the working surface. At the place of the future cut on the plinth or board, we make a mark. How to cut at an angle of 45 degrees becomes clear if you press it tightly against the side wall and align the mark with the slot on the template. We insert the hacksaw into the groove and cut the workpiece, while the work of the blade is limited to cuts, which allows you to make the cut as smoothly and accurately as possible.

- 4. Before sawing the skirting board, make sure that the corner of the room is really straight and, if it is not, you need to adjust the cutting angle of the workpiece. To do this, measure the inner corner of the junction of the walls, and divide the result by two. If you do not have a professional rotary miter box that can change the cutting angle by the required amount, then to achieve the result, you need to saw additional grooves at the desired angle in a homemade miter box. This way you can cut the skirting board for the most accurate alignment.

Now you know how you can cut a workpiece at a 45 degree angle. Perhaps the time has come to move from theory to practical action. The team of the mebeldok.com portal is sure that everything will definitely work out for you. stay with us!

How to cut the corners of a ceiling plinth

This is an instruction manual on how to cut the corners of a ceiling plinth. Considered options for solutions, such as.

Used tools

There are several ways how to cut a pipe; for this, construction and industrial tools are used for metal processing. Of all the types, only the grinder allows you to get curved surfaces without further processing with the closest location of the edges.

Some tips for cutting pipes

Households sometimes require cutting to connect the pipeline at different angles or axially. The main tool for these works is a universal grinder and discs for metal.

Performing a longitudinal cut

To make a high-quality even longitudinal cut, you can use a simple device in the form of a metal corner. It is securely fixed on a flat wooden surface with screws and the pipe is pressed against it with a heavy load. An angle grinder makes a longitudinal cut of the pipe top, slightly resting the disc on the surface of the angle.

The corner can be attached to the pipe with clamps and a cut can be made along the upper wall of the corner in the same way.

Techniques for cutting pipes at an angle of circular cross-section

Round pipes of different diameters are cut at an angle when the direction of the pipeline is changed, while it should be borne in mind that a straight cut at the desired angle, unlike a rectangular section, will not lead to a tight joint of the edges. Therefore, special patterns are used, in which the marked edge has a curved shape, which makes it possible to obtain a high density of the connection.

DIY pipe miter box

Using a template is not very convenient. you have to make a cut along the line, holding the grinder on weight, which leads to large errors. If you have a welding machine, you can make a simple miter box. guides for the grinder’s disk, preventing it from going to the side.

For this, a previously made template is used, in the side of which a hole is drilled and a nut is welded. When working, a homemade miter box is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. A grinder with a disc for metal makes a cut, slightly pressing the disc to the side surface of the device. It is clear that with long-term work, the edges in the miter box are gradually grinded, and although the process occurs simultaneously on all edges, some errors will appear over time. Therefore, it is better to make the device from hard wear-resistant metal in order to increase its service life and obtain a more accurate tool.

How to cut a cast iron pipe

The main difference between cast iron and ordinary steel is its high brittleness and large wall thickness; its accurate cutting must be performed in the following sequence:

- A marking corner is drawn according to the template using a scribe, for

supports under the part put a wooden board or board.

- Perform a shallow cut of the surface with a grinder around the entire perimeter.

- Further, the groove is deepened in several passes until the two parts are completely separated.

Making a template for trimming a metal profile

If you need to cut a large number of pipes, you can make a template from a metal profile of a larger diameter on a paper sheet in the above way. The angle of inclination is checked with a protractor or a construction square. in this case, the two edges of the trimmed parts of the template are connected.

When working on the part to be cut, a template is put on in the right place and pressed tightly, the markings are applied with a sharpened scribe when tracing the template contour. The part is cut in several passes with a gradual deepening of the groove.

Collar insert

In order to obtain branches of metal pipeline lines in the form of tees, a collar insert is used, for which it is necessary to cut the edge of a round pipe adjacent to the walls of another at a right angle. To implement the method, proceed as follows:

- cut the edges of the workpiece at right angles as described earlier.

- On a round end surface, four equidistant points are marked with a marker, located at angles of 90 and 180 degrees to each other.

- Measure the size of the circle, the resulting diameter is divided by 3. From two diametrically located points, the resulting distance is laid, after which these points are connected to two other smooth arc, drawing a line with a marker.

- A cut is made according to the marking with a grinder and semicircular segments are separated, after which the part is ready for welding. With minor inaccuracies in the pairing, it can be sealed with a sledgehammer, attaching it to the round surface of another element.

Using a computer program

To implement this method of marking pipes for cutting, you will need a computer with special programs. First, you need to draw up a drawing, which indicates the transverse dimensions of the product, as well as the planned cut angle. Need to get a virtual template.

Print it out on a printer. And here it is worthwhile to understand that the larger the pipe diameter, the more sheets will be required to print it. Then you need to carefully cut out the details of the drawing from all pages and glue it, it is best to use stationery tape for this. It remains to attach the template to the pipe and apply the markings.

This method of solving the problem is highly accurate. All the necessary programs can be downloaded from the Internet, they are free to download and use. It will also be possible to find a template for cutting pipes at an angle. All that remains is to print and cut it. To carry out the marking, the piece is simply wrapped around the pipe.

Marking the corner with a paper sheet

Layout on paper is one of the simplest ways to accomplish a task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its section.

Then an angle of 45 degrees is formed on the smaller side. It remains to mark the cutting line with a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape so as not to accidentally erase it. This method is great for long, large pipes with a cut in the middle of the piece.

How to cut a pipe at an angle. marking options for round and profile pipes

When installing a pipeline, it is often necessary to cut the pipe at a certain angle. Accuracy plays an important role in this task. There are several easy ways to cut a pipe at an angle.

An incorrect pipe cut will lead to the impossibility of mounting a structure of the form that was originally conceived. For example, if you plan to rotate the system by 45 degrees, then you need to cut the pipe at 45 degrees. To complete the task, you will need tools for marking and a grinder (it can be replaced with a hacksaw for metal).

Method of marking with a container with water instead of a template

This marking method is suitable for small diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, tilt it towards the mark, and then pull it out.

As a result of such actions, a clear line of contact with water will appear on it, it must be highlighted. On it, the pipe is cut at an angle. This method is best suited for jobs where multiple striping is required.

How to cut a profile pipe at an angle

The marking of the profile pipe differs from the round one. Its manual execution can lead to significant errors. The best way to solve the problem is to create a cutting template from the same profile, but with a larger diameter.

A small section of a shaped pipe will be required. On it, using a protractor, mark an angle of 45 degrees. Now, with the help of a grinder, you need to cut off part of the workpiece along the marked line. The cut edges need to be sanded and defects removed. All that remains is to insert the original product into the bevel cutting template. Then you need to apply a marking along the cut line of the larger profile. And already the pipe itself is cut along it.

The text describes how to cut a pipe at an angle of 45 degrees. When the markup has already been completed, it is recommended to use a grinder. With its help, it will turn out to make an even cut. You can replace it with a hacksaw for metal. It will also be possible to cut the product by welding, but experience in handling the tool is needed, otherwise there will be irregularities. “How to Cut a Pipe Straightly. Cutting Tools and Techniques”.

For personal use

For cutting iron pipes in the household, the following tool is used:

Manual pipe cutters. Allows you to cut round parts with a smooth right angle cut by the cutting edges of the rollers. There are several varieties of products of this type, consisting of single rollers, as it is also called, their rows, fixed on a chain. In everyday life, such devices are found quite occasionally and are more suitable for professional work.

Bulgarian. It is a universal tool for trimming all iron parts with different angles; for work, special discs for metal are used, which are quickly grinded down during use. Therefore, there is an option to accurately cut the curved line with a disk of small diameter.

Gas-burner. A quick and effective way of cutting metal with a hot flame jet, there are disadvantages such as melted edges that complicate the upcoming welding. Gas torch is difficult to cut

product according to a cardboard template, which will burn, if a line is drawn, then in a stream of flame it will not actually be visible.

Spool filling, capacity

Before securing the line, the spool is removed: unscrew the screw that is in front of the spool and press the button located on it (if the clutch is rear).

Next, you need to open the forestry machine. Place the spool on the axle and tighten the screw. No force is required during installation. The fact that the spool is installed is indicated by the latch with a click.

Having closed the line layer, we start winding the line. For a smoother winding, it is recommended to tighten the line. To avoid problems during the operation of the reel, at least 2 millimeters should remain from the edge of the spool to the line.

The spool capacity is indicated by the spool manufacturer in the user manual.

How to cut a pipe at an angle. marking options for round and profile pipes

How to cook pipes at different angles of 45 and 90 degrees

Welding pipes is not easy, and even if you need to make sure that they do not flow during operation. But even if this is not necessary, then certain difficulties often arise if you need to weld one pipe into another at a certain angle.

It is quite difficult for an untrained welder to do this. To do this, you first need to mark the pipe, then cut it off exactly with a grinder and weld it into another pipe. What tricks are there? How to quickly and correctly cut a pipe at an angle?

Care and Precautions

- The line must not come into contact with the rotating parts of the reel.

- Leaving the spool in storage until next use, make sure it is dry.

- It is recommended annually to open the coil body and lubricate its mechanism with special grease.

- The coil should be used according to the instructions, otherwise, in the event of a breakdown, you will have to rely on your own strength: the warranty does not apply to damage caused by incorrect use of the BC.

- After use, the reel should be wiped with alcohol (open areas) and lubricated with grease on the line guide roller.

There are many parts in the spinning reel. “Inertialess”, since there is no inertia on the drum during casting, the position of the spool in the reel is fixed. This is a complex device

If you take good care of it and observe precautions, the BC will last for many years. When working properly, it is not recommended to disassemble the coil more often than once a year.

With the knowledge of how the spinning reel works, no breakdown will take you by surprise!

For the prevention of a spinning coil, see the video. Enjoy watching!

For industrial use

In the industry, for the transportation of liquids and gases, pipelines of a huge diameter are used, therefore, pipe cutting units have a large weight and overall dimensions. There are also manual pipe cutters of the rotary and clamping principle of action. At the beginning, the cutting rollers rotate on a round surface with the help of an adjustable handle, in the 2nd version, the cutting is carried out by arcuate plates, which are evenly shifted during rotation.

Cutting at 45 degrees

Usually, if you set a goal to turn the pipe by 45 degrees, use fittings, bends with a 45-degree angle of rotation, made of the same material as the pipes themselves, if the pipes are iron, then the turns are welded from steel. For HDPE pipes, there are electrically welded or cast bends at 45 degrees (in practice, it is almost impossible to find compression fittings with such an angle of rotation).

If you still need to cut a round pipe made of steel or various types of plastics, then a piece for cutting pipes at an angle is useful for this purpose, the shape of which is calculated manually or by machine. The task is greatly simplified if at an angle of 40 5 degrees you need to cut off an iron square profile.

For a quick cut, use an ordinary piece of paper folded sideways to mark the surface for the upcoming cut. Using folded paper, proceed as follows:

- carried out on the straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a sheet of paper folded sideways to the side surface with a sharp end to the strip in such a way that the upper edge of the cardboard triangle is flush with the upper side of the iron profile.

- draw a line with a pencil along the side of the sheet at an angle of 45 degrees, after which the cardboard corner is applied to the other side and outlined with a pencil (it is better to use a narrow marker).

For sawing, use a grinder with a disc for metal, first drawing a narrow line along the marking, after completion, evenly deepening it until the edges are completely separated.

When working with a grinder, you need to take into account the following factor. when the edges are completely cut off, the disc is possibly damaged by an acute angle

, which will lead to its wear, and in the absence of protection on the grinder, even to injury to the worker. Therefore, it is better not to cut the corner edges to the end, but to leave a narrow groove and then break off, then grinding the ledge.

Do-it-yourself pipe connection without welding

Small-sized frame structures are assembled without welding. In this case, the connection of the profile pipe without welding is carried out using a special device.

How to cut a pipe straight with a grinder?

When working with construction or plumbing tasks, you need to know how to cut the pipe straight with a grinder. In the article, we will consider quick and easy ways of how to properly cut a pipe with a grinder so that the result is perfect.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, you should properly cut the pipe with a grinder, so that you can easily connect it later. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper must be in perfect alignment with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cutting line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

How to cut a profile pipe straight?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to perform the action with a grinder, so the cut will be smoother.

How to cut a cast iron pipe?

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a way with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Work the grinder around the circumference of the pipe, making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cutting discs are used to cut cast iron pipes.

If you don’t have a grinder at hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then to cut the metal take a grinder, welding, hacksaw, gas welding.

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the steps taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

- The grinder is an inexpensive and affordable option, but it is considered not the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment.

- A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted using mechanical devices. It is important to note that the models of the machine differ in shape, so consider the ratio of dimensions to the pipe before use.

- Flame cutting is the most popular option for cutting large diameter pipes, sheet metal. The cut occurs due to the action of a high-intensity flame, the metal melts and leaves the cut zone with a gas flow. This method is convenient and effective.

How to cut a pipe lengthwise correctly?

A quick way to cut a pipe lengthwise using a grinder:

- Focus on the markup.

- Use for such a case the painter’s thread, which has found distribution when marking walls.

- Before starting work, fix the pipe and with small movements, carefully saw the pipe.

- Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc will not jump off the marking lines. Remember safety.

How to cut thin-walled pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of deformation of the material. Fillers such as sand are used for cutting. Actions can be carried out using a grinder, a special machine.

Summing up, we emphasize that cutting metal pipes is a complex process, but anyone who wants to enhance it can enhance it. With the advice of a professional, you can easily cut pipes in a variety of sizes and materials. Also remember to use a file or emery paper to clean the edges of the pipes after cutting. And the most important thing to remember when starting such actions is safety precautions. Wear a special suit (casing), mask or goggles when getting started. Hands should also be reliably protected from sparks, so use thick gloves.

How to cut a pipe straight at any angle

When doing repairs or laying new communications, you often have to look for an answer to the question: how to cut the pipe exactly? There are many simple methods that can achieve the desired result when cutting pipes from any material.

How to cut a pipe straight at a 90 degree angle

There are several nuances when cutting a pipe to the correct size. It should be borne in mind: the material of manufacture, the angle at which should be cut off. If the angle is right, then the marking is done as follows:

- Measure the required length, draw a line with chalk or a marker.

- At the level of the mark, wrap the pipe with masking tape or a sheet of paper. It is necessary to ensure that the edges of the tape coincide with each other. This will ensure a smooth cut.

- Cut off the pipe with a grinder. Exactly how the markings are made is possible only if the cut is made not at one time, but in several steps. After a small cut, it is necessary to turn the pipe by 20.40 degrees until a full turn occurs.

It is impractical to mark up with a tape measure. When wrapped around the pipe, it breaks, making it impossible to draw a circle evenly.

How to mark out at a 45 degree angle

It is more difficult to make 45 degree markings. Small diameter pipes can be marked with water. If the piece is small, then this option will do. A pipe is lowered into a container with water at an angle of 45 degrees. Water leaves a mark on the surface that needs to be duplicated with a marker.

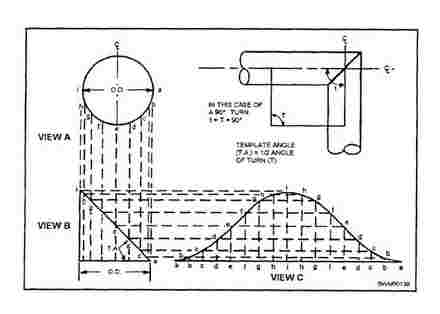

Using a paper template, you can mark any pipe diameter. It is done as follows:

- A circle is drawn on graph paper equal to the diameter of the pipe.

- The base of the circle will be the X axis. On it you need to draw a segment equal to the length of the circle, so that the middle coincides with the axis of symmetry of the circle.

- The resulting line must be divided into 16 equal segments.

- The line of symmetry of the circle, which will be the Y axis, is also divided into 8 segments.

- From the points that form the segments, you need to make projections: from the points on the X-axis, vertical, and from the points on the Y-axis, horizontal. The intersections of these projections must be connected with a smooth line.

- The resulting figure must be cut with scissors.

The template is wrapped around the pipe and secured with masking tape.

It is difficult to cut the pipe straight at an angle. As a rule, a sander with a large diameter wheel is used, even for cutting thin pipes. A large circle leads you less to the side.

An interesting way to cut a plastic pipe

There are many tools for working with plastic pipes. There are special scissors that cut pipes with a diameter of up to 75 mm.

You can use a hacksaw for metal or just cut it off with a grinder. But all of these methods have drawbacks. The scissors cut at a 90 degree angle. But how to cut an even plastic pipe if a different angle is required or the large diameter does not allow them to be used? If you cut with a hacksaw, the slippery plastic surface prevents cutting according to the markings. You can make a device that is devoid of the listed disadvantages.

This tool combines a pipe guide (miter box) and a nichrome thread cutter.

A nichrome thread is installed on the miter box at the desired angle. It is connected to the electrical network through a ballast resistor or rheostat. This will make it possible to select the desired temperature. After heating the red-hot wire, the workpiece must be lowered into the miter box. This will allow you to cut the pipe straight like clockwork.

Video

Here is a video of the simplest attachment for welding at an angle of 90 degrees.

And here’s another one, three-dimensional.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it evenly, you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting off such a pipe, you need to determine an algorithm of actions.

- We mark it in the same way as steel pipes.

- At the place where the cut is made, you need to put a wooden beam as a support.

- Next, you need to cut a few millimeters around the entire circumference.

- After that, a chisel is inserted into the groove and a sharp and strong blow with a hammer must be applied.

As a result, it will split along the line, forming a fairly even cut point, which, if necessary, can be additionally processed.

Preparatory stage

- If the installation of two elements is required, which together make up a right angle, then the preparation will consist in the correct cutting of the pipeline at 45 degrees. It is easy to do this: an ordinary rubber band is put on the pipe, fixed, its second edge is pulled along the pipe by 325 mm, the resulting contour is outlined with chalk. Cut at exactly the right angle.

How to Cut Pipe Angles Accurately – Kevin Caron

In all other cases, you will need to draw up a drawing and calculate a curve, along which you will then need to make a slice.

- The second common option: the pipe is connected by a cut-in into the second at a right angle. In this case, two cuts at 90 degrees are made in the segment with a grinder and the resulting wedge is cut out. Then, gradually cutting, form a round hole. At the end of the perpendicular fragment, a section is removed at the same angle. Gaps are inevitable, so further welding will be carried out in several stages.

It is recommended to make a drawing in order to achieve a tighter fit.

How to cut a pipe at 45 degrees

When installing a pipeline, it is often necessary to cut the pipe at an angle. over, the angle must have exactly the degree that is necessary for the structure. If the corner is made incorrectly, it is impossible to make exactly the dimensions of the pipeline that were supposed to be made. For example, the pipe will rotate 45 degrees during installation, therefore, you need to know how to cut the pipe at 45 degrees. To do this, we need marking tools, a grinder or a hacksaw for metal.

Cutting a shaped pipe using a pipe cutting device at forty-five degrees:

Last revised: 07/21/2015 By Alexander Krivinda

If the pipe is profiled

But, for example, we have a profile pipe, not a round one. Manual marking of a profile pipe can lead to a large error. The best way out of this situation is to make a template from the same larger diameter profile. Take a small section of a profile pipe and use a protractor to mark an angle of 45 degrees. We cut off according to the markings with a grinder and grind the edges so that we do not get hurt by the burrs during work. Then we just have to insert a profile of a smaller diameter into the template and, having made a marking, cut it off.

We cut a profile pipe at an angle in a homemade device In this article, we looked at how to cut a pipe at 45 degrees. Using one of the above methods, mark up and cut. For a smoother cut, it is better to use a grinder. When cutting by welding, experience is required, otherwise irregularities will turn out on the cuts. As a last resort, you can use a hacksaw for metal. There are many different angled pipe cutting attachments on the market today, but they are expensive to purchase. It is easier and cheaper to make a template for yourself once, and use it as needed.

How pipes are welded at right angles

When installing metal structures. from the frame of a children’s swing to a heating system, you almost always have to deal with welding. This process is much more complicated than it seems at first glance, and much more responsible: the reliability and durability of the product literally depends on the quality of the seam.

In its most general form, it means joining two segments of the same or different materials by forming a permanent connection. There are quite a few methods for such a connection. There are two main groups:

- under pressure. for example, ultrasonic, cold, press;

- fusion welding. a thermal method involving heating the fragments to be joined.

Fusion docking is divided into two types:

- electric arc. manual, submerged arc, in argon and so on. The edges of the pipeline sections are melted under the influence of the arc charge;

- gas. the familiar acetylene. In this case, the edges of the pipes to be joined are heated by a gas-oxygen flame, joined, and the gap is filled with the material of the molten bar.

The quality of such a seam is lower than that obtained by the electric arc method. But the latter is not applicable to a pipeline with thin walls. up to 3.5 mm.

The method provides a reliable strong connection, but one-piece. If we are talking about metal products, then this is an advantage.

Depending on the purpose of the pipeline, thickness and diameter, different joining methods are used. In general, there are three main groups.

- Butt joint is considered the most durable. A transverse joint is used. for welding the pipeline around the circumference, and a longitudinal joint. for connecting parts. Butt welding allows you to join segments along an axis. Different seams are used: single for pipes with a diameter of up to 500 mm, and double for pipelines with a nominal bore of more than 600 mm. In the photo. butt connection.

- Angle welding. used to join the pipe at different angles: 90 degrees, 45 degrees, 20 degrees. The reliability of such a seam is somewhat lower.

- Lap joint. splice is used only to align the pipeline with additional elements.

Welding a profile pipe: what electrodes to cook 2mm, how to weld with an inverter, how to do it correctly, by electric welding, like at 90 degrees

The profile pipe is one of the types of construction metal rolling, used in the construction of light metal structures:

- greenhouse frames;

- supports for fences for domestic use;

- sewerage and water supply systems, etc.

The widespread use of shaped pipes is due to a number of factors:

- affordable cost;

- wide range of sizes;

- ideally uniform thickness and smooth surface of rolled walls: outside and inside;

- low susceptibility to various kinds of deformations;

- small mass of finished products;

- reliability and durability.

The most popular type of heat treatment for this type of rolled metal is welding. We will consider how to properly cook profile pipes further.

The wall thickness of shaped pipes varies within a fairly significant range. However, it is precisely working with thin-walled products that requires certain skills and knowledge. Welding thin metal is a complex process with some difficulties and peculiarities. Thus, you need to know exactly how to weld 2 mm profile pipes.:

- welding is carried out with a current of 10 to 60 A;

- the diameter of the electrodes is from 0.5 to 2 mm.

- the connection is made in one pass;

- the quality of the seam depends on the speed of welding; the performer needs to have time to weld before the working edges begin to cool (although some brands, for example, rutile, can be welded with a separation).

There is also general information (for products with walls of any thickness) that will help the contractor understand how to weld shaped pipes:

- when exposed to high temperatures, profile-section pipes are more susceptible to deformation than round ones;

- melting the metal can fill and block the interior. Therefore, in cases where hollowness is important, you should monitor the absence of metal droplets inside the product;

- end connection contributes to high stress at corners, which occurs due to uneven heating and improper bead formation.

Square mark

If you have a square at hand, then you must first determine the exact line of the end of the pipe, including the profile one. By attaching the tool and smoothly shifting it over the surface, we get a cut line of 45 degrees. The same technique is used with a 30-degree angle.

Methods for marking and cutting metal pipes

The use of [metal pipes] in the production and installation of metal structures is associated with the need for cutting across, along and at an angle. And there is not always special equipment at hand. How to cut the pipe evenly with the help of available tools, we will describe in this article.

We cut the pipe at an angle of 90 degrees

To mark the section [water and gas pipes] at a right angle, you can use a sheet of A4 standard paper, wide electrical tape or construction tape. If you wrap a wide enough material around the pipe so that the edges match exactly when applied, you get a perfect cut line. If the tape or tape is firmly stuck to the metal, you can walk right along the edge.

BRILLIANT Idea For PIPE 90 degree Joint WITHOUT CUTOFF MACHINE…

It is important to be able to use the grinder correctly, hold it with some effort and follow safety rules. The described technique is the simplest, it is also suitable for cutting a large diameter pipe.

We use a sheet of paper or cardboard

You will have to do several operations with the sheet to get the desired angle. If you don’t want to get confused in the folds, just make it square and fold it diagonally to get the angle you want. You can do the same with any sheet, as long as its sides are equal to each other. The method is convenient in that it can be applied both to a pipe with a large diameter, and to [shaped pipes of square and rectangular cross-section].

Methods for cutting metal pipes at an angle

There are several ways to saw off the pipe or cut it into pieces. Of the available tools, the grinder is the best for this task. But the biggest problem remains the need to correctly mark the cutting lines. They can be different, most often it is necessary to maintain either a right angle relative to the pipe axis, or 45 degrees. Techniques vary somewhat depending on which products need to be cut:

pipes for water supply, gas and heating distribution;

profile products for assembling gates, canopies, and other metal structures;

large-diameter pipes. as a rule, this is rarely needed at home, where the widest clearance is only in the sewer;

pipes made of steel, cast iron, thin-walled pipes made of non-ferrous metals and soft alloys.

Both tasks can be solved quite simply, even without using a special pipe angle pattern.

We cut the pipe at an angle of 45 degrees

Most often, this has to be done when installing plumbing and heating and assembling frame structures. You can cut the pipe at 45 degrees with a grinder according to the markings, which are made either with a sheet of paper of the same A4 format, or use a regular school (drawing) isosceles square.

How to properly cut pipes from different metals

Accurate sawing and cutting of pipes depends not only on well-executed markings. The material is also of great importance. metal of different thickness and hardness is cut with different efforts and side effects. To properly cut a cast iron pipe, it should not be sawed through to its full depth. Cast iron is a brittle metal, therefore, several cuts are usually made, and then the specialist with one precise blow of the chisel beats off a piece on them.

To work with thin-walled pipes, you will have to very accurately calibrate the position of the grinder. In this case, the master must choose the right [discs for cutting metal with a grinder]. In an industrial setting, special pipe cutters, gas cutting machines and welding machines can be used to perform the same tasks.

Gas Pipe Cutting Safety

When working with gas pipes connected to the mains, it is important to observe safety measures. First turn off the gas supply valve, then make sure that there is nothing in the pipe. To do this, it is enough to open the burners of the stove and light the gas. when it runs out, the flame will go out.