How to cut a profiled sheet for a roof

Features of cutting corrugated board

Today, corrugated board is a demanded material that is used in a wide variety of construction work, it can be used to make fences, gates, cover roofs, and make the strongest overlapping of houses. From corrugated board you can build garages and outbuildings, cover external and internal walls.

A professional sheet is a rather thin product; it can be easily damaged when cutting. In addition, the metal is coated on top with a layer of galvanized and polymer, which makes it impossible to use conventional methods of cutting sheet metal.

High-temperature methods are also not suitable, since the coating, despite its strength and resistance to many factors, easily burns out under the influence of high temperatures. That is, as a result, not only the coating will be damaged, but also the sheet itself.

An angle grinder with an abrasive wheel is also not suitable for cutting, as it severely spoils the coating, and this again leads to the formation of corrosion. In this case, you can only use a special blade with carbide teeth, which is used for cutting metal surfaces.

Hacksaw for metal

Most often, cutting of corrugated board is carried out using a hacksaw for metal, which is more economical and convenient.

- The advantages are that cutting with a hacksaw is carried out very quickly and accurately, no chipping or burrs remain along the mowing line of the cut. Using a hacksaw allows you to do all the work by hand yourself, since it does not require significant physical effort. Most often, it is a hacksaw that is used when working with small roofs, fences, gates, the material of which has a small thickness.

- Of the minuses, it should be noted that the profiled sheet is very easy to cut along a straight mowing line, but it is impossible to make curved cuts with it. Therefore, when using a hacksaw, you should also provide for the presence of another tool. In addition, when working with a hacksaw, it is necessary to prepare a special cutting table on which it will be possible to strengthen the material for cutting. But here it should be noted that all the disadvantages of using a hacksaw are much overlapped by the advantages.

Jigsaw (manual or electric)

This tool is used when it is necessary to obtain curved surfaces that cannot be achieved with a hacksaw. You can use an electric jigsaw or a manual jigsaw for this, which depends only on the convenience of the work. With the help of a hand tool, cuts can be made in small areas, but large volumes are available only with an electric tool. As a difference, there is no.

Hand jigsaw device

The electric tool is used for corrugated board, which has a corrugation height of twenty-five millimeters, combined with a short length. Such cutting is carried out across or along the sheet, but the profiled sheet must be pressed strongly so that it does not rattle.

The work is carried out at high speeds, the file must be fine-toothed, special for metal. When choosing a high speed, a reciprocating mode with a longitudinal inclination of the tool file is recommended.

The advantages of working with a jigsaw are the low cost of such work, but there are also disadvantages. Among the shortcomings, it is necessary to highlight the inconvenience of working with a cross-cut of corrugated board, which has a high corrugation from twenty-five millimeters. In addition, the jigsaw is not recommended for cutting thin strips, since the proper quality is not ensured, the cutting time is very long.

When using a jigsaw, the edges of the metal sheet and polymer coating are quite burned, that is, after cutting, it is necessary to process the edges with special enamel. There is a lot of noise during operation.

Metal scissors

In some cases, ordinary metal shears are used to cut corrugated board, which allow excellent cutting across the wave. Here it is necessary to note such advantages of work as:

- the ability to quickly, easily and efficiently, if necessary, cut very thin and even strips;

- cutting across the corrugation wave without damaging the material.

Types of metal scissors

- along the sheets of corrugated board are cut very poorly, since the flexibility in this direction is low;

- when using scissors for metal, the edges of the cuts are slightly uneven.

But still, it is often just simple metal scissors that are used when carrying out small work on the construction of flooring, in the construction of garages, gates, fences. Usually they cut small volumes of material.

Cutting corrugated metal roofing with an grinder

The more convenient it is to cut the profiled sheet?

Consider how to cut corrugated board, what are the advantages and disadvantages of the tools designed for this.

How and what to cut corrugated board?

In any work using corrugated board, questions often arise about whether it can be cut and how this can be done without damaging the sheet itself and the polymer layer. In our article we will try to figure out what to cut corrugated board, what tools are needed for this and how you can process the cut edges in order to avoid the appearance of traces of corrosion.

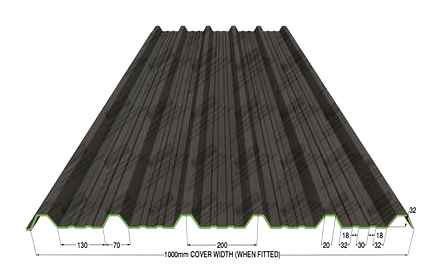

Corrugated sheet structure

angle grinder: use or set aside?

As we said before, the angle grinder can only be used with certain types of cutting discs, which are called exactly that on the market: cutting discs for profiled flooring. These are thin discs with a thickness of one millimeter to 1.6, its teeth are made of carbide materials.

Angle grinder device

After cutting, all edges must be immediately treated with special paints to avoid corrosion. Some people prefer to cut the entire bundle of profiled sheet at once using diamond-coated disks, but experts do not recommend doing this, since there is a high risk of metal damage.

There is only one advantage when working with an angle grinder. the speed of performing all operations. Cutting the profiled sheet will become quick and fairly easy.

There are many more cons. An angle grinder is in any case an abrasive tool that is quite capable of damaging the profiled sheet. This happens for the following reasons: during cutting, hot metal particles fall on the polymer coating and burn it, and this is a prerequisite for the appearance of foci of corrosion on the surface.

Of the negative aspects of using an angle grinder, it should be noted that the edges of the metal become torn, which leads to additional work to remove such burrs on the surface. In addition, when cutting, an unpleasant, strong squeal is heard, which delivers a lot of negative emotions, especially if there are neighbors.

How to cut corrugated board?

Decking has a lot of advantages, one of which is the ease of processing this material. Since the profiled sheet has a small thickness and light weight, it can be adjusted directly on the construction site. And for this you do not need to purchase a special machine for cutting corrugated board, a portable hand tool is quite enough.

But, despite the apparent simplicity, cutting corrugated board has its own characteristics. This is explained by the fact that, unlike conventional sheet metal, a profiled sheet is a layered cake made of a metal base and multilayer protective and decorative coatings.

The destruction of protective coatings when cutting corrugated board will inevitably lead to active corrosion and significantly reduce the service life of structures made of profiled sheet. Therefore, it is very important to know how to properly cut corrugated board in order to prevent significant damage to the zinc layer and protective paint.

Table of contents of the article (click to open)

How to cut corrugated board with a jigsaw?

If you can’t decide how to cut the corrugated board, then we advise you to choose a jigsaw if, of course, you do not have any other tools already purchased. As a rule, this is the best choice for those who decided to independently engage in the installation of roofing in the country or the construction of a fence from a profiled sheet. It is desirable that it has a laser guide.

This tool is the most versatile of what you can cut a profiled sheet without spending serious effort and special skills. In addition, it can be used for carpentry work, and in order to cut down a few dry branches in the garden.

In addition, the jigsaw is very easy to maintain and use. The speed of work is high, the probability of injury is minimal; if the file breaks, it can be easily replaced, and even a beginner can handle cutting. All these qualities make the jigsaw almost the ideal tool for this task.

Now let’s dwell directly on the technology of its use:

- Before cutting the corrugated board with a jigsaw, draw the line for the cut. To do this, you can use a regular marker.

- Secure the sheet so that it is at least 10 centimeters from the surface and does not move when cutting. For this, you can use ordinary goats.

- Now you can start cutting directly. Don’t rely on the eye. use the laser pointer to keep the line of the cut straight and exactly what you want it to do.

- Try to press the jigsaw tightly against the sheet where possible. This will reduce the risk of file breakage.

- Despite the fact that this tool for cutting corrugated board is quite safe and has many mechanisms that protect a person from injury, be extremely careful. Hold the sheet by the edge, and do not rest your hand on it. over, do not keep your hand on the mowing line of the saw, even if the tool is still at a decent distance.

If you follow all these rules, you can easily cope with cutting corrugated board yourself. And you will do it quickly and without serious harm to cover the sheet.

Is it possible to cut corrugated board with an angle grinder?

The greatest harm to the protective coating of the corrugated board is caused by heating to a high temperature that occurs during the cutting process. Therefore, the use of gas-cutting equipment for these purposes is completely excluded. For the same reason, you cannot cut corrugated board with an angle grinder.

The fact is that when cutting with a high-speed tool with abrasive wheels, the metal in the place of the cut simply burns out. Together with it, the protective coating also burns, and not only along the mowing line of the cut, but on both sides of it. The width of the damaged area, as a rule, is 3-5 mm, which leads to the occurrence of the so-called edge corrosion.

In addition, sparks flying out from under the abrasive circle are dangerous. Due to the high temperature, they can damage the polymer coating at a distance of several tens of centimeters from the incision site.

Cutting corrugated board with an angle grinder is possible only in one case. if, before cutting the corrugated board, the abrasive wheel is replaced with a cutting disc for corrugated board with fine teeth. However, even in this case, it is not recommended to use this tool, since such a measure will simply reduce the amount of damage, and not remove it at all.

How to cut a profiled sheet to maximize the preservation of the protective properties of its coating?

Many builders prefer to use an electric saw with a profiled sheet cutting disc. This tool has a number of advantages:

- The rotational speed of a circular saw is almost 2 times less than that of an angle grinder, therefore, the metal of the profiled sheet under the action of the teeth of the disc for cutting corrugated board does not melt, but is removed in the form of small sawdust.

- The ability to quickly cut a large number of sheets

- You can buy a disc for cutting corrugated board in any building supermarket, in the same departments where abrasive cutting wheels are sold.

However, be very careful when using a power tool with a rotating wheel, as metal pieces formed during cutting can cause injury. Therefore, this tool requires certain skills to work with it and is not suitable for beginners.

If you need to cut a small number of sheets, then a classic tool for cutting corrugated sheets is perfect for you. a hand hacksaw for metal. It is extremely easy to use, allows you to make an incision of absolutely any shape and is safe even for a person with zero construction experience. Of course, it is also possible to get injured from using a hand hacksaw. however, this outcome is extremely unlikely compared to other tools.

But this method also has its drawbacks. The main one is the large amount of time needed to complete the work. In addition, you will need a special table for cutting corrugated board.

Another option is to use a hand or electric saw. With the help of them, the work will be done faster, however, with their help, you can cut corrugated board only along a straight mowing line.

Unlike the previous method, cutting the profiled sheet with a jigsaw allows you to make curved cuts of any shape. This adjustment is often necessary when installing roof coverings in the places of passage through the roof of ventilation and chimneys. However, before cutting the profiled sheet with a hand or electric jigsaw, you need to carefully mark the sheet so as not to be mistaken with the dimensions of the cutouts.

The disadvantage of this method is that cutting the corrugated board with a jigsaw is possible only with a profile height of no more than 20 mm. When cutting higher profiles, the blade tears metal and often breaks.

Finally, if it is necessary to adjust the profiled sheets of small thickness, you can use the scissors to cut the corrugated board. It can be either ordinary manual shears for cutting sheet metal, or special electric shears for cutting profiled sheets.

Shears for corrugated board can be of three types. cutting, knife and slotted. The most accurate cut is obtained if you use slotted shears for the profiled sheet. They are equipped with a special head that allows you to make an accurate cut without any deformations and distortions.

Electric shears are very popular among professional builders. They are considered one of the most convenient tools for cutting profiled sheets.

In addition to conventional manual and electric shears, nibblers are also used. They cut the profile sheet in two parallel straight lines, which avoids bending the sheet. Before cutting the corrugated board, using a special handle, the matrix holder can be turned at an angle of 90 ° to the cutting line of the cut. This allows you to cut a profile that is bent at right angles without burrs.

The only drawback of these tools is their high cost and, most importantly, an extremely narrow field of application. If cutting corrugated board is not your daily routine, then it makes no sense to buy nibbling or electric shears.

Many roofers use such a tool for corrugated flooring as drill bits. If you have certain skills and use a cordless drill, such a nozzle is very convenient for cutting and adjusting the profiled sheet in hard-to-reach places.

As you can see, the choice of possible instruments is quite large, and each of the options is optimal for a certain situation and loses to analogs in another. Therefore, it is quite difficult to say unequivocally what is better to cut corrugated board without reference to a specific task. How to cut a profiled sheet in each individual case is decided by a specialist, taking into account the complexity of the shape of the cut, the ability to access it and his personal skills and preferences.

Corrosion protection of edges

Even the use of special tools for cutting corrugated board does not guarantee complete protection against damage to the covering of the corrugated board. Only in profiled sheets of galvanized steel of the 1st class of zinc coating thickness, the presence of molecules at the cut creates a barrier that prevents metal oxidation.

Therefore, in order to avoid shortening the service life of the corrugated board, it is imperative to apply a special anti-corrosion mastic to the cut edges. In addition, you can also paint these places with paint in the color of the protective coating of the profiled sheet. Fulfillment of these simple requirements will reliably protect the edges of the corrugated sheets at the fit points, ensuring the reliability of the corrugated sheet throughout its entire service life.

Helpful article? Save it on social networks so as not to lose the link!

Shears for metal for profiled sheet

The corrugated board can be easily processed using conventional metal shears. Use a hand tool or a modification with a mechanical and electric drive.

Scissoring has the following benefits:

How to: Cut a Trimdek Roof Sheet | Metal Roofing Online

- allows you to cut the material into strips;

- cross cut is performed without deformation of the edge;

- fitting work is carried out directly at the installation site;

- allow you to cut geometric shapes of different shapes from the profiled sheet.

- inconvenient to use if the cut (line) is located near the base of the wave;

- long sections are not straight;

- when cutting a sheet with the edge of the blades, a burr is formed.

We use scissors only for adjusting the sheets in place. Cutting a lot of material takes a long time.

Electric scissors

It is the most convenient tool for cutting sheet metal. It combines the precision of a hand saw, the speed of an angle grinder or jigsaw and the quality of a circular saw. Electric scissors can cut almost any broken and smooth curves, holes, grooves and other geometric shapes. The battery-powered modification allows installation and adjustment of corrugated board without power supply directly on site. The disadvantage is the high cost of the device.

How to cut corrugated board. an overview of all the possibilities

Cutting thin sheet profiled steel is a process that requires the fulfillment of two conditions:

- relative accuracy of the cut;

- minimal damage to the surface and edge of the material.

We fulfill these requirements using a hacksaw, a grinder (angle grinder, impeller), electric jigsaw, circular saw, scissors.

Cutting the profiled sheet with a hacksaw

This is not the most convenient way, but it is considered acceptable for the prompt execution of work, cutting out small elements, cutting edges and other operations. Not every tool design can be used to cut sheets. So, a hacksaw on an arc frame will require bending one of the sides of the sheet to pass along the mowing line of the cut. For work, it is better to use a canvas fixed by a console.

- cut is obtained without burrs, smooth;

- operation time is minimal for cutting small sheets;

- no electricity supply required;

- work can be carried out directly at the installation site.

- difficult to make curved cuts and change the trajectory;

- for precise work, a rigid fastening of the sheet is required;

- impossible to cut holes.

We choose a hacksaw blade designed for cutting metal with a minimum size and maximum tooth frequency.

Circular saw for cutting corrugated board

A circular saw resembles a turbine in its principle of operation, but in comparison with an angle grinder it has a number of advantages:

- cutting speed is 2 times lower, which makes it possible to exclude melting of polymer soybeans and burnout of zinc;

- under the influence of the saw teeth, small chips are formed, which are easily removed;

- accurately carries out straight-line cuts at high speed;

- discs for cutting thin sheet metal at a cost commensurate with the abrasive material for a grinding machine;

- there is no spark;

- the cut is smooth without burrs.

The use of the tool requires working skills. Maximum efficiency is achieved when cutting profiled sheets on a workbench or in special clamps. Not applicable for cutting complex geometric shapes, holes.

Jigsaw for cutting metal sheets

The tool is used to cut straight and curved segments. For work, we choose a special blade for metal with a minimum pitch and tooth height. In addition, the width of the saw should not exceed 4 mm if it is necessary to cut small radius curves.

- for a profiled sheet with a height of no more than 40 mm;

- for longitudinal and cross-cutting of small sections;

- when cutting along a wave of long sections, we use a manual clamp to eliminate sheet vibration.

- limitation of the processed sheet in thickness due to the length of the saw blade;

- low cutting speed and high noise level;

- fluctuations in the material from the saw stroke, which affects the accuracy of the cut.

The jigsaw is recommended for cutting holes, grooves and other complex geometric elements.

Cut the corrugated board with an angle grinder

Cutting the profiled sheet with an angle grinder is performed with a special disc. The use of an abrasive tool is not recommended, as it leads to negative consequences:

- the polymer layer is destroyed by heating the metal at the cut;

- the galvanized layer burns out;

- sparks generated during operation damage the surface of the material over a large area.

High-quality cutting of the profiled sheet with a turbine depends on the skills of working with the tool. For cutting we use high speed, which eliminates burrs, but causes strong vibration, affecting accuracy. We use an angle grinder exclusively for cutting straight long segments. Such operations are performed at high speed. It is not easy to cut complex shapes, and the joining of angular cut lines depends on the skills of using the tool.

The main disadvantage of cutting corrugated board with a grinder is considered to be an inaccurate coincidence of the mowing line of the cut with the markings. Compliance with safety regulations precludes the use of the tool directly on the installation site. It is forbidden to cut the profiled sheet, holding the impeller in one hand.

Cutting Sheet Metal~Irwin Tools Metal Cutting Circular Saw Blade Review. LIKE BUTTER!

Non-standard equipment

Sheet material is factory cut using plasma or laser cutting. Such equipment is stationary and allows you to perform large-scale precision work. The laser allows you to cut holes from 1 mm in diameter, cut mowing lines of any configuration. The work is carried out automatically. Cut drawings are entered into a computer system that controls the process at all stages.