How to cut aluminum angle at 45 degrees

How to cut a 45 degree angle correctly

Sometimes a part or a product needs to be cut at a certain angle. As a rule, you need to trim baguettes, fillets, platbands, baseboards and other similar interior elements at a 45-degree angle. Everyone can cope with this task. The main thing is not to rush, not to be nervous, and everything will turn out.

Buy prefabricated corner elements

Of course, the easiest way not to bother with trimming a particular part, and buy ready-made, not in need of treatment and trimming. These details and elements are now commonly available in large supermarkets or smaller stores.

For example, with regard to the baguettes or fillets, they sell special corner elements that fit perfectly into the corner and do not need to be trimmed. They simply need to be glued in place and pressed down well.

The method of joining trimmed platbands without trimming

Roof strips today are often not trimmed at an angle to be joined together, but the junction is made at right angles. This method of connecting the platbands does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

Trimming at an angle with the mitre saw

If it is still necessary to cut at an angle a particular part, it is worth stocking the chisel. the simplest device, which looks like a small box. The chair has slots that are designed for a saw or a long sharp knife. Of course, these slots are made so that they form an even and accurate angle of 45 degrees.

However, a plier can have many cuts at once, at different angles. This is convenient, because with a single device, you can cut any parts at different angles.

Chisels that are adjustable are also available. Slots in such a chair can be adjusted, allowing the master to set exactly the angle that is required at the moment. In particular, it is quite easy to translate the slots of such a chair to a position of 45 degrees.

Now the workpiece can be trimmed elementary. Baguette, platband or plinth are placed in the jig, and then the saw is inserted into the slots and the excess is cut off elementary. The angle ends up being perfect, exactly 45 degrees.

What to do if there is no plane? Very simply. You need to make a template, which will not be difficult to transfer the necessary markings on the workpiece. As a template you can choose thick cardboard or something else that will be appropriate in this case.

The 45 degrees grid. The template of an angle of 45 degrees

Frequently the domestic handyman has an urgent need to make some measurement or marking at a certain angle, and either an angle piece or protractor are not at hand. In this case several simple rules will help him.

If you urgently need to plot a right angle and do not have a square, you can use any printout. The angle of the paper sheet is a very precise right angle (90 degrees).). Cutting (punching) machines in printing houses are set up very precisely. Otherwise the initial roll of paper will begin to cut crookedly and askew. So you can be sure that this angle is exactly right.

And if there is not even a printed edition or it is necessary to construct an angle on the ground, for example when marking a foundation or a sheet of plywood with uneven edges? In this case the rule of the golden (or Egyptian) triangle will help us.

A golden (or Egyptian, or Pythagorean) triangle is a triangle with sides that relate to each other as 5:4:3. According to Pythagoras’ theorem, in a right triangle, the square of the hypotenuse is equal to the sum of the squares of the cathetuses. Т.е. 5×5 = 4×4 3×3. 25=169 and it is undeniable.

Therefore, in order to construct a right angle, it is sufficient to draw a straight trimmer line of length 5 (10,15,20, etc.) on the workpiece.д. divisible by 5 cm). And then, from the edges of this line start to measure out on one side 4 (8,12,16 and t.e is a multiple of 4 cm) and the other is a multiple of 3 (6, 9, 12, 15, etc.).д. is a multiple of 3 cm) the distance. Should produce arcs with a radius of 4 and 3 cm. Where these arcs intersect each other and there will be a right (90 degree) angle.

Such angles are usually used for making rectangular frames. The material from which the frame (baguette) is made is sawn under angle of 45 degrees and joined. If you don’t have a plane or protractor handy, you can get a 45-degree angle pattern as follows. It is necessary to take a sheet of writing paper or any printed matter and bend it so that the line for the bending trimmer passed exactly through a corner, and the edges of the bent sheet coincide. The obtained angle will be equal to 45 degrees.

House lamp out of wood with their own hands

Angle of 60 degrees is required to build equilateral triangles. For example, you need to saw such triangles for decorative work or accurately set the power bend. Angles of 30 degrees are rarely used in their pure form. However with its help (and with the help of the corner in 90 degrees) the corner of 120 degrees is made. And this is the angle needed to build an equilateral hexagon, a figure very popular with carpenters.

To construct a very accurate template of these angles at any time you need to remember the constant (number) 173. This results from the ratio of the sines and cosines of these angles.

Take a sheet of paper from any printed publication. Its angle is exactly 90 degrees. From the corner on one side measure 100 mm (10 cm).), and the other is 173 mm (17.3 cm). Connect these points. So we got the template, which has one corner of 90 degrees, one of 30 degrees and one of 60 degrees. You can check on a protractor. everything is accurate!

Remember this number. 173, and you can always build 30 and 60 degree angles.

When marking the workpieces or drawings on the parts besides the corners themselves it is very important and their ratio. This is especially important when making rectangular details or e.g. when marking foundations, when cutting out large sheets of material. Incorrect construction or marking brings later a lot of unnecessary work or to the appearance of a large number of waste.

Unfortunately, even very exact marking tools, even professional ones, always have a certain error.

Meanwhile, there is a very simple method of determining the rectangularity of the part or construction. In a rectangle the diagonals are absolutely equal! So, after the construction it is necessary to measure the lengths of the diagonals of the rectangle. If they are equal, everything is all right, it really is a rectangle. And if not. you built a parallelogram or rhombus. In this case it is necessary to “play” a little with neighboring sides in order to achieve exact (for this case) equality of diagonals of the marked rectangle.

Cutting at 45 degrees. How to saw at an angle of 45 degrees

During home repair work you may need to saw materials at an angle of 45 degrees. Usually this is done to join two parts “in the whisker”, that is, the corner of 90 degrees (frames, skirting boards, door trims, etc.). For the result of the work to please you, it is important to absolutely precisely fit the adjacent parts of the blanks. To do it without a special device. a jigsaw. is extremely difficult, especially for a beginner.

Prepare an angular template, which will help you easily make a precise cut of the workpiece of wood at an angle of 45 degrees. This device is an inverted U-shaped profile with slots on each side for the hacksaw. Usually they are arranged at angles of 45, 60 and 90 degrees. The more complex saws are additionally equipped with arbitrary fixed slots, or have a pivoting design. it allows you to set the saw in the optimal position.

Buy a ready-made joinery tool at a building supply store with a wooden, metal or plastic tray. For the novice craftsman, this is the best option. If you want, you can make a simple crosscut with your own hands from three boards or plywood strips (thickness. about 1,5-2 cm).

Drill a few holes in the walls of the future jigsaw, apply joinery glue to the ends, and assemble the box (tray) of the jigsaw. Secure the corner template with screws. The walls of the tool should lie strictly parallel one to the other; the bottom and each sidewall make clear perpendiculars.

Mark a 45 degree angle with a pencil, add additional groove lines if necessary. To make sure you are not making the right calculations, use a protractor.

The most responsible thing is the cuts. It is recommended to perform them with the same hacksaw that will later be used for sawing in the finished jigsaw. Start sawing without exerting too much pressure on the tool, hold the blade. First cut through one side and then the opposite side.

Start processing the lumber. Secure the crosscut on a workbench or work table with a screw clamp (clamps for fixing parts) or with screws. Then mark the future sawing on a slat (plank, baseboard) and put the workpiece into the box. Press it firmly against one of the side walls of the template, aligning the marks with the corner slot of 45 degrees.

Insert the hacksaw into the slots of the jigsaw and cut the workpiece. The saw’s operation will be limited to fixed cuts and you will make a smooth and accurate cut.

When sawing baseboards, make sure the corners of the room are really right. If the walls are very uneven, the angle of the kerf on the workpieces should be corrected. Mark the place of the joints of the inner walls with an angle meter and divide the result in half (the joint of the baseboards “in the whisker”). To make an accurate cut, it is recommended to make grooves with a given angle in a homemade jigsaw. Another option is a store swivel tool, which allows you to change the angle from 0 to 180 degrees in increments of about 15 degrees.

How to cut (grind) a tile at a 45 degree angle?

Everyone calls this action differently: flush, sharpened, undercut, burr, kremlin corner. The meaning is only one.

For quality cutting the end part of the tiles at a 45 degree angle, you will need an electric tile cutter (tile cutting machine) or, at the very least, a grinder (tips) with a disk on the tile.

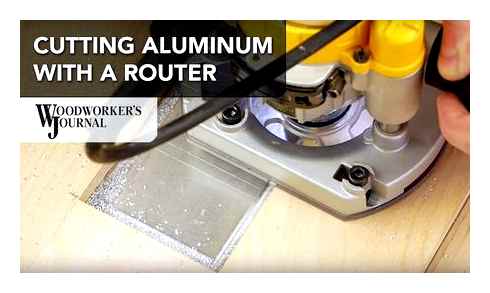

The easiest way. This is the mill

The grinder is more difficult to achieve a quality result, but, in principle, it is also possible. This is the easiest way to sharpen a tile corner at 45 degrees with your own hands at home.

The process of grinding and milling the faora in the video below.

First of all, you must have a good diamond tile disk.

Place the tile along the edge (perpendicular to the workpiece) and grind its back (clay) at a 45 degree angle.

If this turns out to be a little rough, you can go through the large uneven burrs of the disc again, and to get a cleaner and smoother edge, you can use this (pictured below) sanding attachment with sandpaper or diamond “turtle”.

Velcro grinding wheels are wiped off. New ones are removed and attached. The Velcro base itself is wrapped around the threads of the grinder. Diamond nozzles have a much longer service life, but they are also many times more expensive. If you’re constantly laying tiles, it makes sense to get one with diamond turtles. If you are doing your first and last renovation in your life, it is quite possible to do it with the sanding wheels.

When working with this stuff, you need a grinder with adjustable speed (at least speed!), Otherwise, the edge of the tile will melt and burn rather than burst.

You can buy great “shells” here!

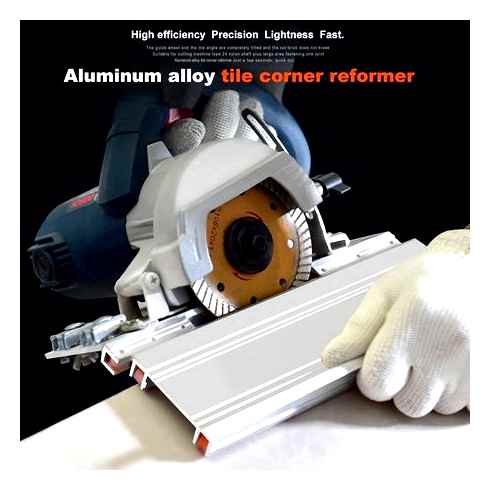

Electric Tile Cutter

Electric tile cutter, or as it’s also called, tile. Wet cutter. It has a water-cooled disc, and this very water dampens all possible dust. The tile cutter cuts along one clear fixed track and minimizes human error such as hand shaking and so on.

The tile cutter has two working positions. Cut flat and cut at a 45° angle (you can actually set any angle from 0 to 45°, but this often makes no sense).

Metal scissors

An even simpler tool that is easier to work with. The principle of operation is elementary. the profile is marked, then cut along the line.Advantages:

- cutting is faster than with a hacksaw;

- Cheap scissors;

- With a good tool and experience, a good result is possible.

View metal scissors on AliExpress → Disadvantages:

- In the transition over the edges of the profile is possible departure from the line marking, damage to the workpiece or its bending;

- You have to practice and spoil a few “rough” blanks before you can work perfectly accurately.

Metal scissors

Even simpler tool that is easier to work with. The principle of operation is elementary. the profile is marked and then cut along the line.Advantages:

- The cutting is faster than with a hacksaw;

- cheapness of scissors;

- Good results are possible with good tools and experience.

READ Metal scissors on AliExpress → Disadvantages:

- At transition through edges of a profile the departure from a line of a marking, damage of preparation or its bending is possible;

- You have to practice and ruin a few “rough” blanks before you can work perfectly accurately.

How to cut a tile at 45 degrees?

To make a corner of two tiles look nice, when cutting the tiles, you need to leave the glaze out a little bit (0.5-1mm). That is, only the clay is cut. If you go over the glaze (the face of the tile), it will be “torn” and chipped. It’s immediately obvious, it’s not pretty.

We ran into this problem regarding the trimming of corrugated tiles. But about that later.

Many of you may have seen this “art,” but more often than not everyone thinks it should be. And a tiler with twenty years of experience assures us that it can’t be otherwise.

Even if there is a need to cut the corner of the tile not from the “factory” edge and you need to cut the icing, but there is a way to make it beautiful.

First, you need to cut the tiles evenly first (depending on the size you want), and then, again, cut them to 45° before reaching the glaze. This cut will be much cleaner and prettier.

You can also trim the edges of the glaze with fine sandpaper, which will make it even smoother.

Second, you can still cut a corner out of the beautiful edge (factory end), trim the opposite edge with sandpaper and hide in the other direction. It will be less noticeable.

For example, we once acted in contact with a toilet. Because a good angle is more important than the bottom seam. What’s more, he turned out to be very neat, too, and if you don’t know he has a haircut, you’ll never pay attention to it.

How to choose the right angle grinder for cutting metal

How clean cutting metal with an angle grinder will be depends on the performance of the machine and the ease of its use. The power and diameter of the cutting wheel are taken into account when choosing a tool.

Picture : Angle grinder “Zubr” power of 800 watts

For work with metal workpieces, we recommend a 125 mm capacity model with a 800-1000 W spindle speed of 10 000 rpm.

Picture : Einhell BT-AG 1000 W angle grinder

Also pay attention to the ergonomics of the machine. The tool must rest comfortably in your hand. Preferably, the handles should be made of rubberized plastic or rubber. They dampen vibrations and reduce slipping. Finger recesses on the handles are desirable.

Safety

The angle grinder is an electrical cutting tool and great care must be taken when working with it. For example, before changing cutting or grinding attachments, always make sure that the machine is unplugged from the mains. If the plug is plugged in, there is always a risk of injury from accidentally pressing the start button.

When cutting and grinding soft materials such as aluminum, be aware of their toughness. To get the job done, you don’t want to disregard the rules for using cutting wheels. For example, a wheel that is too wide can overheat the metal and cause the discs to jam or slip. This ultimately results in injury.

Safety

The angle grinder is an electrical cutting tool and great care must be taken when working with it. For example, before changing cutting or grinding attachments, make sure that the equipment is unplugged. If the plug is plugged in, there is always a risk of injury from accidental activation of the start button.

When cutting and grinding soft materials like aluminum, you must be aware of its toughness. In order to perform the work, you should not neglect the rules of operation of the cutting wheels. For example, an excessive width of the wheel can cause overheating of the metal and consequently cause the discs to jam or slip. This ultimately leads to injuries.

Safety precautions when cutting metal with an angle grinder

Sawing metal pieces requires special safety precautions. Even with proper safeguards and care in design, the tool can still cause accidents, including injury from flying splinters, fire due to sparks, etc. п.

Picture 1: Personal protective equipment: goggles, earmuffs, gloves, helmet

- Wear personal protective equipment (PPE): canvas gloves, respirator, goggles.

- Do not grind using the side of the wheel.

- Do not use bent or severely deformed tools.

- Make sure the metal cutting wheel does not cross with power lines, lubricants or other foreign bodies.

- Do not plunge too deeply. this could damage the wheel and tool.

- Before starting the equipment with a newly mounted disc, test it in idle speed.

- Clamp the part you are working on in a vise. If you hold it in your hands, you can injure your hand with the cutting tool.

- Wait until the machine stops moving completely before removing and replacing the disk.

How to clean aluminum cookware: tools and accessories

Of course this is not all; many other methods are used for cleaning, but this is the most popular and effective. Some people prefer to buy a special detergent for aluminum, but most people save money on this. You can polish aluminum just as well at home.

Electric jigsaw

Before working, it is important to make sure that the tool is fixed with a saw specifically for metal. Of course, a blade for wood will also cut aluminum, but the quality of the cut will leave much to be desired. Profile cutting begins at the back, then one by one cuts the side edges.Advantages:

- electrical equipment facilitates the work of the user;

- quality, close to perfect (there will be no burrs, bevels, other defects on the product);

- quickness of work;

- multiple use (with the right saw);

- The electric jigsaw is cheaper than similar devices for cutting aluminum profiles.

Assortment of profiles for drywall

When installing gypsum plasterboard, it is almost always necessary to construct a metal frame, the creation of which uses a special aluminum

profile. It comes in the following varieties:

The first two types of profiles are among the basic. During the installation of the frame, it is necessary to trim each type, since only in some cases is it necessary to use the entire length of the rail. Basically, the profile must be cut into several parts to create a crate for the construction to be performed.

READ Makita wood grinders

Electric tool

These include an angle grinder, a drill, an electric jigsaw, and a circular saw. The first two tools with a metal disc installed quickly cope with a smooth cut profile. An angle grinder produces a significant level of noise, as well as a huge amount of flying sparks in different directions. Instead you can use a drill, which has a similar mode.

A small sized circular saw can completely replace the angle grinder and slightly increase the ease of use, but its cost is more expensive and not in all situations the purchase is justified, especially if the tool will be used lightly.

The most suitable option is considered to be an electric jigsaw, which, thanks to its design features and the top handle, provides a secure hold. Especially its use can be appreciated when cutting profiles in a huge volume.

You can also use a pendulum saw, which is a convenient high-speed tool, but because of its high cost is used mostly only by professionals.

Circular saw

Analogous to a hand saw, but more powerful. Has the following features:

- performs longitudinal, transverse, inclined cutting;

- can saw from any place of the workpiece (not just from the end);

- Modern devices prevent overheating, timely turning off or giving a signal to the operator;

- the user can select the speed based on the thickness of the workpiece.

Advantages:

- Durability of tooling. a disk for working on metal (better. on aluminum);

- rapidity of work;

- maneuverability;

- Ability to cut at an angle of up to 45 degrees;

- Cost comparable to more suitable counterparts (end saws for aluminum).

- The equipment is usually bulky and weighs a lot, making it difficult to work;

- the price will seem high if the tool is purchased for one-time work;

- ).

Circular saw

In the example shown is a table saw Yilmaz KY 305. This is a special device for cutting small-section metal profiles with small wall thicknesses. Mechanical clamp captures the workpiece, the cutting angle of up to 45 degrees (any side), it is possible to choose a fixed angle (0, 15 deg., 30 degrees and t.д.).Advantages:

- allows you to cut larger workpieces (up to 130×65 mm;)

- compactness;

- The possibility of angular cutting;

- High speed and accuracy of work;

- equipment availability (saw blade 300 mm).

Saws for cutting aluminum profiles

Saws for aluminum cutting: main characteristics and types

Saw blades for cutting aluminum must be chosen according to the specific working tasks. Circular saws are more recommended. Unlike saws designed for straight cuts, this tool can be readjusted for different angles.

How to choose a saw

If you have not yet dealt with such tools, in the process of selecting and purchasing seek help from consultants. Every store that sells tools has them, or this function is performed by salespeople. But it is not superfluous to ask about some technical characteristics and peculiarities of the saws at first. It will help to communicate with professionals on the same language.

If you need a saw for simple jobs that will be done occasionally. buying a professional complex tool does not make sense. If the work to be done is complex, which involves precision and accuracy, the capabilities of the machine must be studied more carefully. First of all, you need to pay attention to the power, on which the pace and quality of work depends. Consider also the maximum dimensions of the workpieces with which the saw can work. Find out what the base is made of, if there are electronic adjustments.

Design Features

The design of the aluminum cutting saw is not particularly complicated. The working unit consists of a motor with a gearbox, the saw blades and the handle, on which the trigger is placed.

Motors are most often located to the right of the cutting disc, but can also be in the rear. They are divided into two types:

- Collector. They are characterized by high torque, but need regular replacement of the collector brushes.

- Asynchronous. This motor works without collector brushes, runs quieter and lasts longer.

The discs are driven by a motor through a gearbox. There are two types of gears:

- The gearing is quite noisy, but doesn’t slip under high loads.

- Belt transmission is quieter. During operation, vibration from the disc is dampened, which contributes to precise operation and prolongs the life of the motor. The belt wears out, can fly off in sudden load changes.

READ Setting the Husqvarna 137 carburetor

The saw can also be operated without a gearbox, in which case the torque is transmitted to the discs directly from the motor. Reliability is a plus, low torque is a drawback.

In order to increase the cutting width the saw

is equipped with a traction function. The name comes from the fact that you have to pull the blade toward you while working.

Circular saw blade for sawing aluminum profiles

of aluminum on a Jet JMS-10S mitre saw with a 297 saw blade.080.10M by CMT Utensili.

Electronics

Many saws are not equipped with electronic speed control. Few have a wide range of electronic adjustments. Having this adjustment allows you to control the cutting process and adjust the saw’s operation for a specific material.

Maintaining a constant RPM under load is also rare. This option is important in works for which speed is important. If you press down hard, the speeds tend to drop noticeably. In this case the speed can be corrected electronically.

Additional Features

The saws are equipped with a laser so that the line for the profile trimmer can be seen more clearly. If you have to deal with long pieces of work, the table extension option comes in handy. There are different clamping devices, stands for mounting on the floor.

READ What kind of saw blade is good for cutting laminated wood particle board?

Types of Saws for Cutting Aluminum

There are several kinds of saws for profile sawing. The classification depends on the task in hand.

- Single-headed. These tools are designed for cutting profiles in PVC products. There are saws with bottom, frontal and pendulum feeding of the cutting head. All models must be equipped with cooling and air preparation systems. Single-head saws can be additionally equipped with chip collection systems, roller conveyors, additional clamps.

Double-headed. These saws are meant for cutting of basic profiles in the PVC and aluminum construction. Blowing pistols and air treatment systems also need to be present on these models. They can be equipped with additional cooling systems, intermediate supports, digital sensors, electronic control systems, chip collection systems. There are varieties here as well:

READ Board Saw

at the same time. For aluminum profiles the IP modification is used, which is characterized by a hydro-pneumatic disc feed, a cooling system and a hydraulic brake.

Which saw blades are right for cutting aluminum?

Blades for cutting aluminum sheets or profiles are somewhat harder to find than blades for wood, for example. It must be characterized by high strength and high carbon content in the alloy. There are monolithic blades and blades with high-strength alloy steel blades.

The teeth in aluminum cutting discs are also special, and the shape must be suited to the task at hand. making a cut in aluminum. They must be straight. Teeth are usually treated with a thin layer of diamond grit. Number of teeth selected depending on the type of cut. A saw blade with the maximum number of teeth is used for cross-cutting. For longitudinal cuts, it is better to use discs with fewer teeth, up to 60