How to cut an opening in concrete for the stairs. Comments

Classes in reinforced concrete slabs

Residents of cottages, panel and brick houses in most cases ask to make an opening in the floor slab for arranging staircases that were originally not provided for by the project, on the lower floor. Less often. to the attic. Sometimes they order to stop the opening in the slab in the basements.

In addition, the corresponding openings are cut during redevelopment with the unification of the premises vertically, as well as for the installation of additional communications between the floors.

In commercial premises, an opening in a tile floor is sometimes necessary for arranging elevators and escalators.

How to make an opening under the stairs in the floor slab

The fact is that if the stairs (marches) are made in accordance with the accepted quality standards, when the length, width and height of each stage are combined in a certain proportion, then climbing the stairs will not cause unpleasant sensations or fatigue, which means that it will not be especially remembered.

Thus, the norms that the stairwells (marches) must correspond to the reinforced concrete floor slabs take into account not only the parameters necessary to guarantee the strength and stability of the building structure and the diamond cutting of concrete, but also the notorious human factor.

How to make a staircase in a concrete floor

In their structure, stairwells (marches) of reinforced concrete floor slabs are a single structure ninety.centimeters width, including from three to eighteen steps laid on a single supporting concrete base. Sometimes, depending on the necessity, stairwells (marches) may even include staircases on the second floor.

Diamond cutting of the stairs in concrete, like steps, from reliable, practical, durable, frost.resistant and stable material. heavy concrete (monolith).

Make an opening in the foundation under the stairs

When ordering the design of the march, you should also know that you will have to provide the initial parameters of the ratio of the width, height and length of both steps and the marches themselves included in the project of the stairs necessary for the construction of the facility.

The material was prepared by the engineering department of the company Buvomchik

- Diamond drilling holes

- Diamond drilling holes

- Stroke of walls without dust

- Diamond cutting of openings

- Strengthening openings with metal

We work throughout and the region

How to make an opening under the stairs in the floor slab

The fact is that if the stairs (marches) are made in accordance with the accepted quality standards, when the length, width and height of each stage are combined in a certain proportion, then climbing the stairs will not cause unpleasant sensations or fatigue, which means that it will not be especially remembered.

Thus, the norms that the stairwells (marches) must correspond to the reinforced concrete floor slabs take into account not only the parameters necessary to guarantee the strength and stability of the building structure and the diamond cutting of concrete, but also the notorious human factor.

How to make a staircase in a concrete floor

In their structure, stairwells (marches) of reinforced concrete floor slabs are a single structure ninety.centimeters width, including from three to eighteen steps laid on a single supporting concrete base. Sometimes, depending on the necessity, stairwells (marches) may even include staircases on the second floor.

Diamond cutting of the stairs in concrete, like steps, from reliable, practical, durable, frost.resistant and stable material. heavy concrete (monolith).

Make an opening in the foundation under the stairs

When ordering the design of the march, you should also know that you will have to provide the initial parameters of the ratio of the width, height and length of both steps and the marches themselves included in the project of the stairs necessary for the construction of the facility.

The material was prepared by the engineering department of the company Buvomchik

- Diamond drilling holes

- Diamond drilling holes

- Stroke of walls without dust

- Diamond cutting of openings

- Strengthening openings with metal

We work throughout and the region

How to make a passage for the stairs in the ceiling

Modern cottages and bunk apartments are not without a staircase. In addition to functionality, it gives luxury to each home. How to create a unique interior with a capital staircase? Planning this element requires special knowledge in the construction topic. If there are some skills of such work, then you can do without the hands of professionals. The main thing is to determine important points: what staircase is needed for a particular house, what passage is needed for it, how to dismantle passages for stairs in the ceiling and how to calculate all sizes.

What are the staircases

In new houses with the planning of the stairs, all ceiling passages must be designed in advance. In a new building with concrete overlap, workers leave an area under the stairs equal to a standard slab. Such a passage will have a reserve. As a rule, it is slightly more than the necessary space under the stairs. The absence of a hole after the completion of construction will not be a large obstacle. In the stoves you can make it yourself with the help of a corner grinder.

Wooden ceiling is not so demanding. If the opening was not planned in advance when building the building, then this.

There are several varieties of staircases:

The passage in the ceiling should be safe and convenient when walking up and down. The most standard and popular. rectangular option. He is very in demand among residents of the private sector. This type requires a minimum of design efforts. Takes less time and effort to create it. The length parameter directly depends on the device and size of the planned staircase.

A more complex type of structure on the ceiling is in the form of a circle. Such a passage is used for screw options of stairs. In the performance of this opening, the main thing is not to miss one moment: to arrange the upper steps below the circumference itself.

The semicircular passage is ideal for screw and marching stairs.

The device of the ceiling opening in the form of a diverse polygon is more difficult, but the result is worth.

How to plan the location of the opening and stairs and not make a mistake in the calculations

When erecting a stairs, it is worth relying on SNiP (building codes and rules). What should you pay attention to before installing the stairs:

- Make a project (for example, in the AutoCAD program);

- Calculate the parameters of the opening;

- Calculate the area under the stairs;

- Choose a safe and comfortable version of the stairs;

- Pay attention to the presence of doors near the planned staircase and make sure of their unhindered opening;

- Plan the location of the lamps illuminating the stair march.

The staircase erected should enter the space allocated for its construction. The minimum requirements for the execution of such interior elements:

- The width of the flight of stairs. 1 m

- Passage height. 2 m

- Stage width. 0.2 m

- The width of the intermediate landing. 1 m

For the stairs leading to the attic or the only room, there will be enough opening 0.6-0.7 m wide. Other options for combining the premises will require a larger volume.

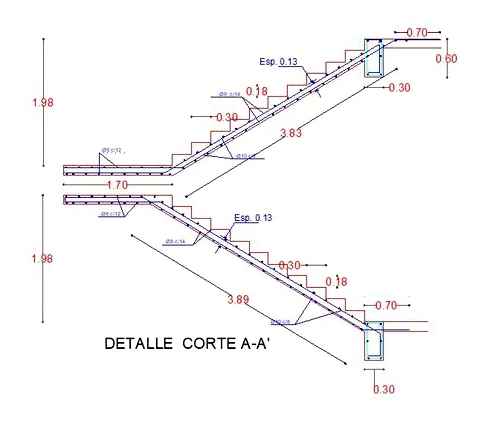

It is important to determine the design features of the stairs. the number of steps, levels of slope and geometry. The following data are taken into account for this:

Knowing the parameters of the steps and the height of the span, you can calculate the level of the end of the stairs (upper step) with the following method:

- The distance from the floor to the floor is measured. the interval is taken from the floor of the first to the floor of the second floor and the size of the floor thickness is deducted;

- From the resulting result, the height of all steps is alternately taken away;

- Stop taking further when the result is less than 2 m. This figure will show that the number of deduced steps fits under the ceiling, and the remaining steps will go beyond the ceiling passage.

When planning the rotary version of the stairs, it must be taken into account that the width of the passage in the ceiling depends on the level of the race of the turn, and the length is identical to the length of the second march. The opening diameter of the screw variant of the stairs will be equal to the size of the round structure.

It is worth adding about 5 cm to the margin to the marked surface of the future opening, this will finally arrange the staircase and put its appearance in order.

Working with the opening

The technology of work with the opening depends on the material from which the ceiling is made. Distinguish between wooden and reinforced concrete floors. Another amount of work on the passage in the ceiling depends on the degree of readiness of the hole. During the construction of the house, the opening may be planned in advance or not. In the second case, you will have to dismantle some elements. There is a disassembly of the floor and ceiling and cutting beams.

Passage in a wooden floor

When the opening along the beams is located, you need:

- Remove parts from two beams;

- Insert short transverse elements between the free ends of the cut parts;

- Fix them with squares for additional structural elements located along the length of the aisle. The size of the short beams should be identical to the main.

In the case of the opening near the wall of the stone, one of the ends of linear elements can go into it and is fixed with the solution.

Mark the area on the ceiling. Add 5 cm on each side. Make amplifying elements to the long side of the passage. Insert the supporting elements on the smallest sides of the opening and install adjustable jack racks. Using a special tool, make holes in each corner of the floor (lower side);

Rise to the top floor, find holes. Retreat 10 cm from drilled points along the opening with the aim of installing transverse elements. Sprinkle on two sides of the hole, creating an angle of 90 degrees. Then create cuts relative to the floor boards;

Removing cut boards is carried out by bar. Fairy scrap will help to finally bring the work to the result;

Sawing a beam is worth a flush with the opening. A partner should support it from below. This will create the perfect work with a saw. We do not remove the scraps, they will come in handy for layout of double transverse elements. Cut the two fragments of the beam in size and fasten them with a chess pitch using nails or bolts of 10 cm;

Features of punching holes under the stairs

The size of the future opening, its shape and location are designed depending on a number of factors. The main ones are:

- structural scheme of the structure (transverse / longitudinal cross, etc.P.);

- type of floor (monolithic / concrete with varying degrees of reinforcement, etc.).

For example, if you are dealing with an overlap with an intended reinforcement. then, when it is destroyed even a small part, the bearing capacity of the structure will be reduced to naught, and no gain will help here. In this case, the overlap is more advisable to completely dismantle.

But in the vast majority of cases, cut a fragment in the ceiling without dismantling it, possibly. But be sure to arrange the reinforcements before starting work. Its main types:

- The edge of the cut is strengthened by metal structures. welded to the reinforcement;

- The edges of the floor on the cut are held by support columns.

As for the tools for direct work, the technology of diamond cutting is best suited here. The opening in the flooring under the stairs will be cut out by an electro-or a gas station, the working part of which is a “toothy” disk with fragments from the strongest technical diamonds. This method exceeds the usual outfit in all parameters using a peorator and jack of a hammer. “Diamond” guarantees:

- low noise and vibration;

- relatively small pollution of the room;

- perfectly flat cutting of the opening;

- high speed of work.

Specialists of Spetsstroymontazh have extensive experience working with all kinds. And the technology of diamond cutting is our unconditional “horse”.

In addition to the purely physical work, our organization, which has the allowance of SRO, will help you collect and draw up the necessary documentation, develop and implement the project. With us you will save your strength, time and money.

How to make an opening in reinforced concrete overlap? Is it possible to make an opening in reinforced concrete overlap?

The opening can be made in iron. concrete overlap, if this allows the design of the ceiling itself. In other words, if it is an old house, where the ceiling plates are narrow and long, then the creation of the opening will be almost impossible, since the opening of this size will violate the design of the plate, and it will have to be strengthened in such a way that, firstly, this is not consistent with the redevelopment, but secondly. it will become very costly.

But in houses with monolithic ceilings, just now everyone is making openings for placing stairs, when forming a transition to two floor, and more, apartments and private houses. In this opening you can even place an elevator.

Technically, it is necessary to ensure the support of the cut part of the plate from below, and then cut out or cut it, drill around the perimeter, and lower the fragment of the ceiling overlap down. Next, chop it and take out the garbage.

Openings can be of various shapes and size.

In some cases, a significant strengthening of structures with a metallic rental is required.

Special diamond disk saws are used to cut concrete. You can use another improvised tool (professional large corner grinder with two handles). Cutting is required during the cutting process.

This video showed a stationary cutting of concrete, when the saw was motionlessly fixed on the floor of the ceiling through a special bed.

The second video shows a device for drilling holes in the ceiling, the Veda inside the ceiling is still present and the reinforcement.

If the reinforced concrete overlap does not have a stiff rib or the next level, or something heavy is not installed on the floor slab, then the opening can be done, there will be nothing terrible in this, but we must also remember that the reinforced concrete overlap is while there is ribs while there is ribs stiffness or reinforcement in it, if the structure is disturbed, then the plate can collapse, and even after making the opening, this ceiling cannot be loaded in other places.

For example, if in the overlap A-1 or A-2 make an opening from one side to the other, then the stove collapses, the same can be with the plates A-3 and A-4 if you cut the stiffness rods.

The opening itself can be cut in two ways:

I like the second option more, since the edges are originally even and do not require further processing.

How To Remove A Brick Load Bearing Wall. New Opening

When you cut the opening, it will fall from a height of at least 1.8 meters, and this is fraught with destruction in the house, since the opening will be very heavy, because it is from concrete and metal structures. Therefore, before cutting the opening, it is necessary to ensure safety so that the cut out the piece does not fall.

An opening in reinforced concrete overlap can only be done if there is a certain experience in the construction and coordination of this type of work with the competent authorities, since during the manufacture of the opening you weaken the reinforced concrete plate, which can lead to the collapse of the balance of the plate or the destruction of the room, and this is fraught with damage to health. people and even death. Therefore, do not do this work yourself, use the help of specially trained people with a license (resolution) to perform this type of work!

The manufacturing process itself comes down to the following stages:

- Plan and approval.

- Removing part of the reinforced concrete overlap.

- Strengthening the remaining part of the slab.

- Checking and evaluation of construction work.

Here is one of the options for strengthening the reinforced concrete floor slab:

- collapse of part of the removed slab.

- collapse of part of the remaining slab.

- Together with the collapse of the stove, weaver of the floor slabs is possible.

- Together with the collapse of the floor slab, a “departure” of the vertical pillar of the floor system is possible.

How to make an opening under the stairs to the second floor

How to make an opening under the stairs to the second floor? Consider the technical aspects of diamond cutting openings under the stairs. The construction of a building of any type, regardless of its number of storeys, suggests the presence of stairs in a country’s country house, for the creation of which, as you know, stairwells (marches) are needed in reinforced concrete floor slabs.

And although each of us often sees these, at first glance, simple elements of the staircase, but with the right approach to creating openings under the stairs to the second floor, rarely anyone can name the exact number of steps in one span on the stairwell.

ο the operator’s operational departure to the customer’s object within 24 hours.

ο order cutting services for the stairs: 7 (495) 991-81-26

ο will make openings under the stairs without dust and cracks!

How to make an opening under the stairs in the floor slab

The fact is that if the stairs (marches) are made in accordance with the accepted quality standards, when the length, width and height of each stage are combined in a certain proportion, then climbing the stairs will not cause unpleasant sensations or fatigue, which means that it will not be especially remembered.

Thus, the norms that the stairwells (marches) must correspond to the reinforced concrete floor slabs take into account not only the parameters necessary to guarantee the strength and stability of the building structure and the diamond cutting of concrete, but also the notorious human factor.

How to make a staircase in a concrete floor

In their structure, stairwells (marches) of reinforced concrete floor slabs are a single structure ninety.centimeters width, including from three to eighteen steps laid on a single supporting concrete base. Sometimes, depending on the necessity, stairwells (marches) may even include staircases on the second floor.

Diamond cutting of the stairs in concrete, like steps, from reliable, practical, durable, frost.resistant and stable material. heavy concrete (monolith).

Make an opening in the foundation under the stairs

When ordering the design of the march, you should also know that you will have to provide the initial parameters of the ratio of the width, height and length of both steps and the marches themselves included in the project of the stairs necessary for the construction of the facility.

How to Repair Broken Concrete Stairs. Quick and Easy

The material was prepared by the engineering department of the company Buvomchik

- Diamond drilling holes

- Diamond drilling holes

- Stroke of walls without dust

- Diamond cutting of openings

- Strengthening openings with metal

We work throughout and the region

Floor slab and opening for the stairs

Recently viewed 0 users

No registered user views this page.

Height, width and length of the bar for the kitchen: Determine the dimensions correctly

The best articles on the website of the IVD

- Construction and repair

- Foundation

- Roof

- Walls

- Window

- Doors and partitions

- Ceiling

- Balconies and loggias

- Internal constructions

- Floor

- Water supply and sewage

- Heating

- Ventilation and air conditioning

- Gas and energy supply

- Lighting

- Plumbing equipment

- Safety and home automation

- Bans, saunas, pools

- Construction Materials

- Decoration Materials

- Tools

- Technique

- Laws and finances

- Technonikol

- Design and decor

- Flat

- Bedroom

- Kitchen

- Canteen

- Living room

- Bathroom, bathroom

- Hallway

- Children’s

- Attic

- Small rooms

- Workplace

- Wardrobe

- Library

- Decoration

- Furniture

- Accessories

- Vacation home

- Landscape

- Redevelopment

- Catalog of houses

- Magazine

- News

- Developments

- about the project

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Contacts

- about the project

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Contacts

You are a professional architect of an IT?

You are a professional architect of an IT?

Site IVD.Ru is a leading Internet project dedicated to the reconstruction and design of the interior of residential premises. The main content of the site is the archive of the magazine “Ideas of your home”. exclusive copyright articles, high.quality illustrations, practical tips and lessons. A team of professionals in close cooperation with famous designers, architects and leading experts of the publishing house works on the project.

On our site you can choose comprehensive design solutions; view detailed reviews of the market of building and finishing materials, furniture, equipment and equipment; compare your own ideas with design projects of leading architects; directly chat with other readers and editors on the forum.

You are a professional architect or designer?

Cutting in a wooden floor

To do this, you will need the following tools:

It is quite difficult to cut the opening in the fatery of the structures. In addition, there are certain restrictions on vibration influences that can lead to cracks.

If the opening is created indoors, the beams forming it will be fixed between the beams of the inter.story floors. The sequence of work is as follows. At the very beginning, you need to cut the ordinary block of the ceiling in the place where the hole will be made under the stairs. If the opening has insufficient size, you can cut another beam, but you can not cut more than 2.

After that, you need to install paired beams in parallel by ordinary. Short paired beams forming a staircase will be attached to the first. Further, short ones are attached to them, the function of which is to ensure additional stiffness of the hole in the space. The height and thickness of the paired beams must correspond to the dimensions of the main.

All parts are fastened with each other with the help of metal corners and self.tapping screws. You can purchase a special fastener profile. If the opening is located near the brick wall, the beams should be attached at one end to the wall according to the above technology.

Dimensions and price for stairwells:

| product name | Length (l) mm | Width (b) mm | Height (h) mm | Mass (kg) | Price with VAT) |

| Host marches lm 15-12 | 3160 | 1150 | 1500 | 1.65 | 11600 |

| Host marches lm 18-12 | 3760 | 1150 | 1800 | 1.97 | 15300 |

| Host marches LM 28-12 | 3261 | 1200 | 1400 | 1.2 | 6200 |

| Stairword marches ml 24-60-10 | 2934 | 1050 | 1200 | 1420 | 7900 |

| Stairword marches ml 24-60-12 | 2934 | 1200 | 1200 | 1620 | 8400 |

| Stairword marches ml 24-60-13 | 2934 | 1350 | 1200 | 1800 | 8900 |

| Stairword marches ml 27-60-10 | 3269 | 1050 | 1200 | 1530 | 8400 |

| Stairword marches ml 27-60-12 | 3269 | 1200 | 1200 | 1740 | 9400 |

| Stairword marches ml 27-60-13 | 3269 | 1350 | 1200 | 1940 | 9 900 |

| Stairword marches ml 30-60-10 | 3605 | 1050 | 1500 | 1700 | 9 900 |

| Stairword marches ml 30-60-12 | 3605 | 1200 | 1500 | 1850 | 11400 |

| Stairword marches ml 30-60-13 | 3605 | 1350 | 1500 | 2000 | 12 400 |

| Ski marches ml-33-60-10 | 3940 | 1050 | 1650 | 1800 | 10 900 |

| Ski marches ml-33-60-12 | 3940 | 1200 | 1650 | 2200 | 11 900 |

| Ski marches ml-33-60-13 | 3940 | 1350 | 1650 | 2500 | 12 900 |

| Ski marches ml-36-60-10 | 427 | 1050 | 1800 | 2050 | 15 900 |

| Ski marches ml-36-60-12 | 4275 | 1200 | 1800 | 2360 | 16 900 |

| Ski marches ml-36-60-13 | 4200 | 1350 | 1800 | 2500 | 18 900 |

| Stairword marches 1 lm 30.eleven.15-4 | 3030 | 1050 | 2500 | 1480 | Contractive |

| Stairword marches 1 lm 30.12.15-4 | 3030 | 1200 | 2500 | 1700 | Contractive |

| Stairword marches 1 lm 27.eleven.14-4 | 2720 | 1050 | 1400 | 1330 | 6300 |

| Stairword marches 1 lm 27.12.14-4 | 2720 | 1200 | 1400 | 1520 | 7100 |

| Stairword marches LM 30.54-10 | 5160 | 1050 | 1500 | 2900 | 16 400 |

| Stairword marches LM 27.54-10 | 5360 | 1050 | 1600 | 2850 | 15 900 |

Z-shaped staircases

| product name | Length (l) mm | Width (b) mm | Height (h) mm | Mass (kg) | Price with VAT) |

| LM 30.54-10 Ave. | 5160 | 1050 | 1500 | 2900 | 16 900 |

| LM 30.54-10 p. | 5160 | 1050 | 1500 | 2920 | 15 900 |

| LM 30.60-10 pr. | 5760 | 1050 | 1500 | 3150 | 17 900 |

| LM 30.60-10 p. | 5760 | 1050 | 1500 | 3180 | 16 900 |

| LM 30.56-10 Ave. | 5360 | 1050 | 1500 | 2900 | 19 900 |

| LM 30.53-12 pr. | 5060 | 1200 | 1600 | 3280 | 18 900 |

| LM 33.53-10 Ave. | 5060 | 1050 | 1600 | 3050 | 19 900 |

| LM 30.56-12 pr. | 5360 | 1200 | 1600 | 3700 | 20 900 |

| LM 33.56-12 pr. | 5760 | 1200 | 1600 | 3900 | 21 900 |

| LM 33.56-13 pr. | 5760 | 1350 | 1600 | 4100 | 22 900 |

| LM 33.60-13 pr. | 5760 | 1350 | 1650 | 4250 | 23 900 |

Stairplay device in a wooden floor

The sequence of manufacturing the staircase in a wooden floor is the following.

The device of the flight of stairs in a wooden floor:

- a. in the middle of the ceiling;

- b. against the wall;

- B. beam conjugation device.

- First, in the place where the staircraft is planned, it is necessary to cut the ordinary block of the ceiling. If the sizes of the stairs should be larger than the hole formed after cutting one beam, you can shorten another beam, but not more than two.

- In parallel to ordinary beams, two paired beams are installed.

- Short paired beams are attached to paired beams, which form a staircase.

- Short, trimmed to the already installed beams are fixed: they will provide an additional rigidity to the opening.

The thickness and height of paired beams should be equal to the dimensions of the main beams. Beams are interconnected by metal corners and self.tapping screws or using a special mounting profile.

If the flight of stairs is located near the brick wall, the beams must be fixed at one end in the wall using the above technology.

Stairwinding device in reinforced concrete overlap

The opening under the stairs in the inter.story flooring consisting of standard reinforced concrete slabs must be considered in advance before the manufacture of the ceiling.

Stattering device in a reinforced concrete floor:

The stairway in this ceiling is framed by steel profiles (corners, cherries, double boars). Usually, during the construction of the building, a gap is left under it, the size of which is equal to the width of the standard reinforced concrete slab. The stairs occupies much less space than provided, so the holes remaining on one or two sides are frozen.

Metal beams must be placed along the floor slabs, fastening them together with welding. The frame formed from metal profiles should be based on the walls in the same way as the floor slabs. After its installation, you can proceed to reinforcing monolithic sites.

In order to hide the metal of the structure, you need to raise the frame 2-3 cm relative to the lower line of the floor slabs. During the manufacture of a monolithic area, a concrete solution will start under steel profiles and hide the metal. The monolithic mount will be reliable if you have a short-powered to the lower shelf of the metal profile and fix the mac-mac grid on them with a bar thick of at least 3 mm.

Floor slab and opening for the stairs

Recently viewed 0 users

No registered user views this page.

Height, width and length of the bar for the kitchen: Determine the dimensions correctly

The best articles on the website of the IVD

- Construction and repair

- Foundation

- Roof

- Walls

- Window

- Doors and partitions

- Ceiling

- Balconies and loggias

- Internal constructions

- Floor

- Water supply and sewage

- Heating

- Ventilation and air conditioning

- Gas and energy supply

- Lighting

- Plumbing equipment

- Safety and home automation

- Bans, saunas, pools

- Construction Materials

- Decoration Materials

- Tools

- Technique

- Laws and finances

- Technonikol

- Design and decor

- Flat

- Bedroom

- Kitchen

- Canteen

- Living room

- Bathroom, bathroom

- Hallway

- Children’s

- Attic

- Small rooms

- Workplace

- Wardrobe

- Library

- Decoration

- Furniture

- Accessories

- Vacation home

- Landscape

- Redevelopment

- Catalog of houses

- Magazine

- News

- Developments

- about the project

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Contacts

- about the project

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Advertising on the website

- Advertising in the magazine

- Terms of use

- Contacts

You are a professional architect of an IT?

You are a professional architect of an IT?

Site IVD.Ru is a leading Internet project dedicated to the reconstruction and design of the interior of residential premises. The main content of the site is the archive of the magazine “Ideas of your home”. exclusive copyright articles, high.quality illustrations, practical tips and lessons. A team of professionals in close cooperation with famous designers, architects and leading experts of the publishing house works on the project.

On our site you can choose comprehensive design solutions; view detailed reviews of the market of building and finishing materials, furniture, equipment and equipment; compare your own ideas with design projects of leading architects; directly chat with other readers and editors on the forum.

You are a professional architect or designer?

Device, cutting of the opening in the railway plate

When installing ventilation equipment in buildings, lack of descent into the basement, entrance to the attic in new buildings, the opening device in the floor slab is performed in the finished floor or ceiling, the area of which is significantly reduced. For turns on the stairs, the gap is left to the wall on the upper and lower steps not less than the width of the complex structure, which, in addition to the function of safe descent-ascent, plays an important role in the style of the room.

Idilla LLC will solve the problems in the reconstruction of houses, perform the installation of openings in the floor slabs, hardening and stabilization of cornices, balconies, beams, stairs, jumpers. The company works with floors of ceilings in multi-storey buildings of the P-44, II-49, I-49, I-155 series, private buildings, industrial buildings, manufactures openings according to MNIITEP, OJSC Mosproekt, Balarhproekt LLC, Mosilniya Project in accordance with the requirements for the construction of structures.

Normative documentation determines the ultimate-permissible norms of vibrational influences on the design, so the masters perform work using diamond technology. We organize water collection, mark the area, saw concrete into pieces by diamond cutting, remove, store. The cost of the order depends on the depths, the share of manual labor, the price of work using diamond technologies is more expensive than traditional, but percussion tools do not apply in such works.

We weld steel beams located along the plates, the frame should rest against the walls and ceilings during the opening of the opening, the operation is carried out on the ground, we pull the formwork with a rope to the installation site, fasten it to the beams. Twist wire loops using installation, pressing the shield to reinforced concrete structures. We cover the shield with a plastic wrap to prevent the solution of the solution, carry out the reinforcement of the site and fill the solution.

The frame rises approximately 30 mm above the surface of the inter.story ceiling, concrete when flowing under metal profiles will close steel. For greater reliability, we fasten the grid on the lower shelf of the steel profile. In the budget version, the welded metal frame is replaced by the formation of the hole with metal corners with support on the floor slabs. Note that the features of reinforcement of the floor slabs limit a change in geometry.

The company purchased production tools and leading companies for processing materials with high density, offers services in grinding and processing metal, stone, concrete. We carry out cutting, drilling holes, the opening device in the floor plate, cut through the seams in the floors and asphalt. Due to the presence of the installation of diamond drilling, stone.cutting machines, an anger.cutting machine, schonazhchikov, drones, gas stations and electric carriers, cable saw and tools for tools, the company is ready to perform a complex of work of a large volume.

We carry out the element of the element of the structure and the industrial building in constrained conditions, the cable cutting of volumetric reinforced concrete structures, the drilling of ventilation in buildings, the drilling of fictions in the basement, the foundation, the basement. Engineers will help calculate the preliminary cost of the order, time and scheme of execution, the price of services is low, exit for the inspection is free. The work belongs to the category of complex and dangerous, requires the use of physical strength and skills in execution, concrete fragments can be reused in construction.

| Walls | Price |

| In the brick | from 1800 per m2 |

| In drywall | from 1000 per m2 |

| In the foam block | from 6000 per pcs. |

| In concrete | from 7000 per m2 |

| In the bearing wall | from 9000 per m2 |

| In the bearing with strengthening | from 10,000 per m2 |

| In a monolith | from 9000 per m2 |

| In the plate of ceilings | from 10,000 per m2 |

| An opening for the stairs | from 11000 per m2 |

We deliver construction garbage to containers, sort, transport to landfills and utilize, carry out concomitant work. We are constantly expanding the list of proposed orders, save the time and money of customers, the owners will be able to solve all dismantling issues by contacting one company. A system of discounts is valid. The use of modern tools, technologies and experience of masters allow you to perform work in an accelerated rhythm.

Address: st. Ratnaya, house 8, building 3, office 4

Stairplay device in a wooden floor

The sequence of manufacturing the staircase in a wooden floor is the following.

The device of the flight of stairs in a wooden floor:

- a. in the middle of the ceiling;

- b. against the wall;

- B. beam conjugation device.

- First, in the place where the staircraft is planned, it is necessary to cut the ordinary block of the ceiling. If the sizes of the stairs should be larger than the hole formed after cutting one beam, you can shorten another beam, but not more than two.

- In parallel to ordinary beams, two paired beams are installed.

- Short paired beams are attached to paired beams, which form a staircase.

- Short, trimmed to the already installed beams are fixed: they will provide an additional rigidity to the opening.

The thickness and height of paired beams should be equal to the dimensions of the main beams. Beams are interconnected by metal corners and self.tapping screws or using a special mounting profile.

If the flight of stairs is located near the brick wall, the beams must be fixed at one end in the wall using the above technology.

Stairwinding device in reinforced concrete overlap

The opening under the stairs in the inter.story flooring consisting of standard reinforced concrete slabs must be considered in advance before the manufacture of the ceiling.

Stattering device in a reinforced concrete floor:

The stairway in this ceiling is framed by steel profiles (corners, cherries, double boars). Usually, during the construction of the building, a gap is left under it, the size of which is equal to the width of the standard reinforced concrete slab. The stairs occupies much less space than provided, so the holes remaining on one or two sides are frozen.

Metal beams must be placed along the floor slabs, fastening them together with welding. The frame formed from metal profiles should be based on the walls in the same way as the floor slabs. After its installation, you can proceed to reinforcing monolithic sites.

In order to hide the metal of the structure, you need to raise the frame 2-3 cm relative to the lower line of the floor slabs. During the manufacture of a monolithic area, a concrete solution will start under steel profiles and hide the metal. The monolithic mount will be reliable if you have a short-powered to the lower shelf of the metal profile and fix the mac-mac grid on them with a bar thick of at least 3 mm.

Cutting in a wooden floor

To do this, you will need the following tools:

It is quite difficult to cut the opening in the fatery of the structures. In addition, there are certain restrictions on vibration influences that can lead to cracks.

If the opening is created indoors, the beams forming it will be fixed between the beams of the inter.story floors. The sequence of work is as follows. At the very beginning, you need to cut the ordinary block of the ceiling in the place where the hole will be made under the stairs. If the opening has insufficient size, you can cut another beam, but you can not cut more than 2.

After that, you need to install paired beams in parallel by ordinary. Short paired beams forming a staircase will be attached to the first. Further, short ones are attached to them, the function of which is to ensure additional stiffness of the hole in the space. The height and thickness of the paired beams must correspond to the dimensions of the main.

All parts are fastened with each other with the help of metal corners and self.tapping screws. You can purchase a special fastener profile. If the opening is located near the brick wall, the beams should be attached at one end to the wall according to the above technology.

Piery staircase opening device

The open staircase opening can be square, rectangular or round. It is provided at least 20 cm more than the diameter of the stairs itself.

First, the circle is outlined on the floor surface, then with the help of the plumb line they transfer the marking and similarly indicate the second circle on the ceiling. Next, two jack racks are installed and drilled in the center of the opening in the inter.story floor through a through hole. from the bottom up. After that, the pin is inserted on the top floor into the resulting hole and applied with a pencil and rope circle to the floor surface.

Staircase marking under the screw staircase

It must be remembered that the diameter of the circle should be drawn taking into account the thickness of the beam, which will frame the opening. Next, cut the floor along the contour of the staircase and knock out unnecessary pieces of floor boards, without affecting the bearing beams of the ceiling.

After the ceiling, the oil beam is installed in the framing of the ceiling, cutting the remaining load.bearing beams and fixing it with the help of metal gear plates or corner overlays.

The staircase can be given an interesting shape or use various decorative railings and decoration elements.