How to cut drywall at home on your own. On the wall

Drywall cutting

Beginners in construction do not know how and how to cut drywall in the best way. After all, any work, whether it is the creation of a ceiling design, partitions or a complex decor element, requires knowledge of the rules of cutting GKL and strictly following them in practice. The tool for these purposes use different. It all depends on the chosen cutting method. So, how to cut drywall at home, they will tell the recommendations below.

A mandatory list of tools for sawing gypsum fiber with your own hands includes three groups of object

Devices for marking on a sheet of GKL. a simple pencil, roulette, long ruler.

Actually cutting-drinking devices.

- Knife. You can cut a gypsum plate with a clerical knife, as well as a specialized construction with a double.sided interchangeable blade (suitable for more dense materials).

- Hacksaw. It is better if it is a metal processing tool than a tree.

- Electric. Ideal for cutting rounded elements. The chip on the ends of the drywall leaves the least of all high.quality metal files with a small tooth.

- Electric drill. Need to make holes. For the gaps of a large D, round crowns will be required (with which the core of the door snapling locks is cut) and feathers.

Edges for processing edges:

This list clearly shows how the home craftsmen cut drywall. Of course, he is far from complete. The arsenal of experienced craftsmen may include professional equipment, for example, a special cutter for GVL. However, for those who first work with the material, this set is quite enough. To better understand how to cut drywall, it is necessary to clearly represent the structure of this material.

The structure and purpose of drywall

Plasterboard sheets are a layer.up combination of two types of materials. gypsum (internal contents) and dense cardboard sheets glued to it on both sides. It is clear that if the cardboard layers are damaged, the rest is not difficult to cut.

Therefore, in order to be able to quickly cut a sheet of GKL, it is not enough to know what is better to cut drywall. It is important to know the basic principle of this action: after the continuous even halzing of drywall is carried out immediately, the second step is immediately followed. the leaf is pulled.

Cut drywall, like any hard porous material, is easy. It also lends itself well to drilling.

The functions of the material allow you to distinguish it into varieties: moisture.resistant, fire resistant, standard, increased strength (for example, hypercardon or gipper performed using KNAUF technology), acoustic gypsum cardboard, etc.

6 new updated texture wall painting techniques

Despite the large assortment of the Civil Code, the panels of any of its varieties are good to divide into parts through the available improvised material.

The principle and rules of cutting drywall

Attention! The kitchen designer earned on our site. You can familiarize yourself with it and design your dreams for free! The designer of the wardrobe designer may also be useful.

The principle and rules of cutting are based on an understanding of what you are dealing with, so you should first study the structure of the material. But in this case, the name speaks for itself. two outer layers are formed by cardboard, serving the basis of relative strength, and gypsum with fillers is made between them. Different types of drywall are used for various purposes: standard, waterproof, fire.resistant. The first is used in all cases, excluding the skin and ceiling sheathing (moisture.resistant drywall is used here) and structures that are in the immediate vicinity of the fireplace or other heat source (in this case, there is fireproof material).

Minimalist Custom Closets Finishing Drywall. Home Renovation

Preparation and application of markings

Place a GKL sheet on a flat horizontal surface and apply tags using a simple pencil, roulette or ruler. Suitable for this procedure marker and a fountain pen, but their traces are visible under putty.

Directly before or while working, select a tool that will be cut. There are many ways to fulfill the intended means of your funds. In fact, you can cut drywall with any sharply subjected object, but this will require certain skills. Consider the main tools of those that can be used.

Cut the drywall with a mounting knife

Cut the drywall with a hacksaw

It doesn’t matter which side you cut drywall on. But the very place of the cut is important. If you saw the sheet from the edge, the fishing line for the trimmer will turn out to be flat, but it will take a lot of time. The through hole is best made with a jigsaw, otherwise it will turn out to be uneven.

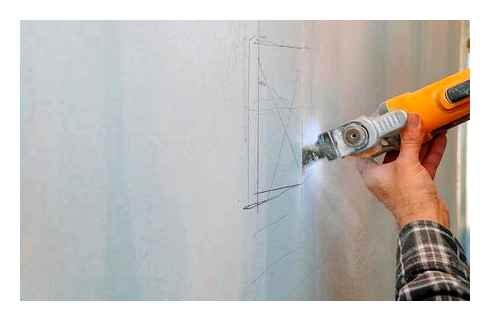

Cut a drywall with an electrician. an option for the lazy

If you do not know how to cut drywall at home and be afraid to experiment, then it is better to entrust the processing of the material to an electric tool. Lobzik is an optimal tool for cutting drywall, since it allows you to make a canvas of any shape and can make holes inside the drywall sheet. The curved lines will turn out to be the most accurate, and the edge will be much easier to process using a rubbish for drywall.

Consider step.by.step instructions on how to cut drywall using an electrolobian: 1. We draw a fishing line for a trimmer, according to which it will be necessary to cut the material. It is better to use a black marker to make it clearly visible. 2. We install a drywall sheet on several bricks or stools so that there are no objects under the cutting line (they can be hooked). The sheet should lie balanced, not to be tense at the spray points. the cut quality will improve significantly. 3. Install the lobby at the beginning of the line, turn on the laser sight (if this is available on the tool) and lead exactly along the desired path. Or bring a drywall to a tripod with an electrician. four. The edges are demolished at 45 degrees, for plastering the surface. Can even be done with sandpaper if the processing area is not too large. 5. If you do not have a rubbish or corners are poorly obtained, then a cutter for drywall will become an relevant tool. It can be put on an electric screwdriver or drill, the cone is installed between the sheets and draw at the junction. The cutting knives will remove the edges of each sheet at the same angle. it is very convenient with large volumes of work, where you need to quickly and efficiently process many sheets. Perhaps you wanted to ask how to cut a gypsum-shaped drywall under the door or window opening? Here you can not find a universal tool, it is necessary to use a hacksaw and a jigsaw, since with only a jigsaw or a hacksaw alone you can not get an internal angle of 90 degrees.

Electrician will be an ideal tool for you if there is nothing to cut a profile for drywall, since it is suitable for metal. You need to buy several files “for all occasions” and it will be possible to cut not only drywall, but also metal, wood, stone and other materials. Now let’s watch the video cutting of drywall with a painted knife without noise and dust:

Cut the drywall with a mounting knife

In the mounting knife, interchangeable blades. There are canvases for cutting different materials, a proprietor of the metal part outside the handle is regulated. There are the same stationery models, but to work with drywall, they are low.power.

You can even cut drywall with a clerical knife

Costs a mounting knife from a few hundred. The tool is good when it is decided how to cut drywall at home in a straight line. Figure lines with an assembly knife is possible. Let’s start:

- Draw drywall according to pre.made marks.

- Put a steel profile for drywall or a metal ruler to one side of the marking. They will not let the knife go aside during cutting.

- We put the blade to the edge of the marking and lead along it with a pressure about 3 kilograms.

The knife should not pass through the sheet. Correctly cut drywall is to lead a blade with a deepening of about half a centimeter. The rest break along the line when we bent the panel with your hands.

The cut should be at the top. To bend drywall, you need to operate. You can just put the sheet on the floor, or you can put on chairs or the edge of the table.

Cut the drywall with a hacksaw

Hacksaw is also a type of saw, but already manual. There is a tool, usually a few hundred. The canvas of the hacksaw is different. You need even with small teeth. This is a scabbard for metal.

Cut the drywall with a hacksaw

When working with drywall, it gives the most even cut. The thinness of the saw canvas allows it to be easily bending inside the sheet, passing exactly along curved markup. Launch the process:

- Having placed a drywall and making a drill or knife in its corners for the entrance of the sheath of the hacksaw.

- Inserting a hacksaw into a slot and drinking to the opposite point.

- Having processed the edges of the cut with improvised means.

On which side to cut drywall with a hacksaw does not matter, but in which place is important. When cutting the sheet from the edge, the tool gives an even, neat fishing line for a trimmer, although you have to spend a solid time. The through holes on the canvas of the drywall of the hacksaw gives uneven. It is better to use the jigsaw here.

Cut the drywall with an electric jigsaw

Lobzik-a tool with a re-trim of a file. Simply put, we are talking about a miniature type of electric saw. In working with drywall, it allows:

-The most accurate edges without zazubin and contour drops

Cut the drywall with an electrician

We cut a gypsum cardboard with an electrician along a pre.outline contour. Since gypsum dust will be knocked out from under the blade, we make the tags with a black marker. It is visible under whitish sediment.

Mark the sheets from the back. However, drywall is only the basis of structures covered after tiles, wallpaper, plaster. Therefore, the side of the marking is not fundamental. Let’s start work:

- We put a gypsum sheet on stools or bricks, leaving the space under the cutting line free. Also, there should not be tension on the fishing line for a trimmer saw. His torn forces worsen the quality of the cut. The basis of drywall is based on the flexibility of the material. Without support, the sheet can break under pressure in unforeseen places.

- Install the lobby at the start of the cutting line or bring the drywall to the tripod of the tool, because it is not only autonomous, but also stationary. Also, in a number of jigsaw there is a laser sight. It helps “go” exactly by marking. In case of work in the twilight, backlight will help out. She is not on all lobes either.

- It remains to turn on the jigsaw and smoothly.

- In the finale, treat the edges with sandpaper or a jacket, file.

I understand how to cut drywall with a jigsaw only if you have a tool.

Cut the drywall with a mounting knife

In the mounting knife, interchangeable blades. There are canvases for cutting different materials, a proprietor of the metal part outside the handle is regulated. There are the same stationery models, but to work with drywall, they are low.power.

You can even cut drywall with a clerical knife

Costs a mounting knife from a few hundred. The tool is good when it is decided how to cut drywall at home in a straight line. Figure lines with an assembly knife is possible. Let’s start:

- Draw drywall according to pre.made marks.

- Put a steel profile for drywall or a metal ruler to one side of the marking. They will not let the knife go aside during cutting.

- We put the blade to the edge of the marking and lead along it with a pressure about 3 kilograms.

The knife should not pass through the sheet. Correctly cut drywall is to lead a blade with a deepening of about half a centimeter. The rest break along the line when we bent the panel with your hands.

The cut should be at the top. To bend drywall, you need to operate. You can just put the sheet on the floor, or you can put on chairs or the edge of the table.

How to cut a profile for drywall

You can cut the profile for this material using the following tools:

It is not recommended to use corner grinding at home, since many sparks are formed when working with it. They can lead to fire. Ordinary metal scissors will be enough. They can easily cut iron without creating excess chips or garbage. When drywall is attached, the profile will not be visible. Therefore, you can cut it in small pieces for convenience. It is important to tightly install the profile to the wall. Then the design will be strong.

The main advantages of choosing this particular material is the ease of installation. Therefore, it is in great demand in the market of finishing materials. For interior decoration of premises, this is optimal and profitable. Now you know how you can cut drywall, and what tools you can use. And you can install it yourself, and change your house beyond recognition. Without spending extra money on professional specialists.

Direct lines cut

Put the sheet on the horizontal and even surface. Draw the lines along which there will be a cut. Attach a metal ruler and fix it so that it does not move. Take a knife and draw several times along the planned line. This is done so that the incision becomes deeper and more even.

Experienced experts advise not to neglect a ruler. For a person inexperienced, it will be difficult. Will have to spend a lot of time so that the edge turns out to be neat. This is easier and faster to achieve with the ruler. After the cuts become quite deep, drywall should be put on the rib and slowly tapped on the back. A pair of shock is enough for the sheet to break through the line. It remains to cut the cardboard layer with a knife.

Making curves of parts

The most time.consuming and long.term process is to bend the parts of drywall. Correctly bend the Civil Code, profile is a task that requires accuracy and patience.

First, a rectangular workpiece is cut off. To mark the part correctly, using a flexible roulette, the length of the arch along the bend is measured.

The facial coating of drywall is denser than the opposite, so the binding of the workpiece is performed so that the rear coating is stretched.

After watching a video, you can understand without words how simple everything is:

It is possible to bend a wide detail only with the help of a template. It is made of wood.fiber slab, plywood or the same drywall.

One side of the part is rolled with a needle roller with such pressure so that the needles penetrate into the thickness of the sheet 3-5 mm. After that, the surface is wetted with water until softening. This process is long, and you should not rush. In this case, the pattern must be gradually bend the detail. After it falls into the shape, it is fixed and left to dry out.

For gentle arches with a large radius, where the steepness is small, you can do without wet bending. Transverse incisions are made with uniform step, as a result of which the accordion is obtained. After fixing, such a surface is plunged to hide the ribs of the bend.

For arched structures, bend the profile. To do this, it is cut with scissors with a pitch of 3-10 cm, depending on the steepness of the bend. Make triangular incisions correctly.

To work with drywall, you can get by with an ordinary tool that is found in any home workshop.

The creation of arches and niches from drywall in inexperienced people causes many difficulties. For example, often during the repair you have to cut drywall sheets. To do this more efficiently and quickly, it is worth knowing which tools are better to use and how to cut better. Before learning how to cut drywall, it is worth preparing the necessary tools.

How to cut round and rectangular holes

Very often in the sheet you need to make holes for pipes, sockets or switches.

To do this, on the sheet you need to mark the places of their location using roulette.

Rectangular holes:

- Accurately measure the distance of the edges of the hole from both sides of the sheet, as well as from its top and bottom. Apply the outline of the cutout.

- Then you need to make 4 holes on the sides of the marked rectangle with a thick drill with a thick drill. an electrician saw should be held in them. They should be located inside the rectangle as close as possible to the cutting lines.

- Insert the file alternately into each of the holes and cut the opening. You need to work extremely neatly, strictly along the drawn lines.

- Having received a hole, check how well a switch or socket box passes into it.

- If necessary, finalize the edges with rashpil.

Round holes:

- For this purpose, you can use the nozzle for a drill or hacksaw of a small size.

- Apply the center of the future opening to the sheet.

- Fasten the crown of the required size in the drill cartridge.

- The drill of the crowns must be installed in the center of the hole and drilled, smoothly pressing the drill (with a strong press, the nozzle can get stuck in a gypsum). Better use the average tool speed for this.

If there is no drill and nozzles, then you can make a round hole with a knife, but it is not so convenient.

We do the hole with a knife like this:

- Apply the contours of the future hole on both sides of the sheet (and do not make a mistake).

- Then cut a layer of cardboard on both sides with a knife.

- After that, you need to lightly tap the gypsum with a hammer, knocking it out.

- Check how well a box or pipe enters the formed hole.

Any curved figures with smooth lines are cut out according to the marking using an electrician. In its absence, you can use a hacksaw for metal, but it is very inconvenient.

How to bend drywall

In order to mount arched structures above the doorways or niches, you need to somehow bend the drywall so that it does not break.

For these purposes, manufacturers of drywall produce special sheets of the CTP (arched), which have a thickness of 6.5 mm and are easily amenable to deformations.

Such material is somewhat more expensive than usual. For its installation, special arched profiles are used, equipped with cuts on the side walls. Thanks to these cuts, the profile can be easily bent in the necessary way, and then fix the flexible sheet in it.

Since the thickness of the flexible sheet is small, to enhance the structure, two layers of drywall should be used: the draft layer is made of a conventional sheet, and the front from the arched.

But if you were not able to buy a CHA, that is, methods of bending and ordinary wall drywall. For different situations, different technologies for the effect on the sheet are used.

If you need to get only a small bend, then this can be like this:

- Prepared gypsum cardboard workpiece with a roller or brush is wetted with water on one side.

- It is left for 10-15 minutes so that the water is absorbed into the gypsum layer.

- After that, the sheet is screwed in the intended place. Do it carefully so as not to damage the material weakened by water.

- After the evaporation of water, the material gains its original strength and at the same time holds a given form well.

If the radius of the bend bend is small enough, then it can be bent as follows:

- I process the sheet on one side with a needle roller.

- Then, using a sponge, it is impregnated with water for an hour. Make sure that the paper on the back of the sheet does not get wet, otherwise it can break when bending.

- Then carefully bend with the template and fix the ends of the sheet with clamps.

- The structure is left in this form until it dry completely.

If the roller with needles is not at hand, then you can use another option (dry bend):

- Instead, a knife is used, which make cuts on the sheet, placing them in the direction of the perpendicular line of bending.

- The distance between the cuts should be 10-50 mm. The more often the cuts, the less the bending radius.

- The side on which the cuts are made should always be inside the bend.

Thus, having previously studied all methods of cutting and bending GKL, select the most suitable for yourself and act exactly using technology.