How to cut linoleum when laying is better

How to cut roll coverings correctly

Highlights when cutting linoleum during installation

To carry out work on cutting linoleum canvas, in addition to the purchased knife, you will need to prepare a square, a long ruler and a tape measure. To create a template, you need plain paper or thick cardboard.

When working, try not to rush and take all measurements several times. You need to cut with confident movements, applying effort. If necessary, you can draw up a diagram of the location of the canvases, and only after that start cutting them according to the calculated parameters.

DIY linoleum cutting technology will consist of the following:

- Before cutting the linoleum, it should be kept indoors for 7-14 days at room temperature. For a more precise date, refer to the instructions or paper insert supplied with the coating.

- Next, the roll is cut according to the length of the room, taking into account the allowance. For a canvas with a length of 5-6 m. 20 mm overlap, less than 10 m. 40-50 mm, over 10-12 m. 50-70 mm. This is necessary for the stock of material for trimming and natural shrinkage.

- The cut canvases should be left for 3-5 days until they are completely straightened. If “waves” remain on the surface, then you should not try to eliminate them using third-party methods. High-quality roll coating will straighten naturally.

- Then the cut pieces are laid out along the length of the room. If there are protruding communications and other decorative elements in the room, then you will need to prepare a paper template. After that, according to the template, the pattern is transferred to linoleum and cut off in the right places.

- If the room has the correct shape, then the linoleum is pushed up against the wall with an overlap and cut off at the junction.

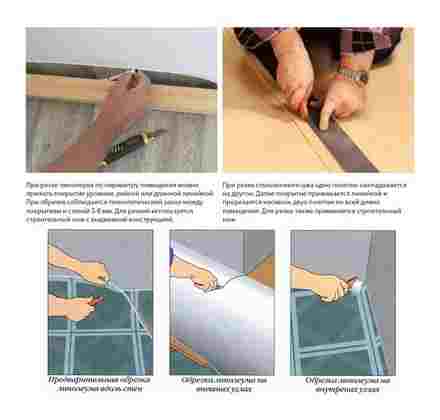

- For joining the canvases with a pattern, the first canvas is laid out on the floor surface. The second canvas is superimposed over the first until the joining edge forms a continuation of the pattern. Next, the edge is pressed with a long ruler and cut through both pieces.

Upon completion of the cutting, the linoleum must be shifted by one half of the room and the work surface must be removed from dust, debris and abrasive particles. After that you can start fixing and docking.

Linoleum cutting tool

The construction knife is a versatile tool for cutting roll coverings

Cutting PVC or natural linoleum can be done using the following tool:

- construction knife. has a retractable design, the ability to change and rigidly fix the cutting blade. In fact, this is an adapted and improved version of the stationery retractable knife, adapted for construction needs. Suitable for cutting both thin-layer and thicker roll coatings, but when working, you should carefully monitor the path of the blade;

- knife for cutting linoleum. has a curved or hook-shaped cutting element. Allows you to quickly and quality cut through linoleum, carpets and any other soft floor coverings. Suitable for both cutting a straight seam and curly elements in corner joints;

- floor cutter. available in various variations. For linoleum, a design is used with a disc cutting element fixed in a special frame with a handle. A conventional fixed blade cutter can also be used. Allows you to quickly and efficiently cut a flat edge along the entire length of the blade.

Additionally, you can mark such a tool as a “beveler”. It is used when laying natural linoleum when it is necessary to cut off the “broken” edge. In the case of PVC coating, it allows you to cut off the “fringed” edge if gross mistakes were made during cutting.

When choosing a working tool, one should take into account the type of coverage that is planned for laying. Household linoleum has a low density and thickness. An ordinary construction knife is enough to cut it.

expensive semi-commercial or natural linoleum is best cut with a specialized knife. This will cut through the dense sheeting and get a smooth cut.

The appearance of the tool can be seen in the photo above. for an entry-level branded product. It is better for a master finisher to purchase better equipment.

Among the manufacturers are Truper, Suntool and Romus. For DIY work, knives from Biber, Jettools, Fit are quite suitable.

How to properly cut linoleum when laying. the choice of tools and technology of work

Hello. There is nothing difficult in cutting linoleum. The main thing is to choose the right tool, since it is very difficult to cut a dense canvas even with a well-sharpened knife or stationery.

Docking two or more canvases

Cold welding is used to join two or more canvases.

Fixing linoleum to the floor can be done in several ways. Glue applied over the entire floor surface is the most reliable solution. Double-sided adhesive tape is used for rooms where fixing rigidity does not matter or linoleum is a temporary floor covering.

The adhesive mass is prepared for work according to the instructions on the package. A spatula is used for application. First, linoleum is fixed against the wall for a large width of the canvas (60-70%). The adhesive is applied to a clean surface in undulating movements without excess.

After that, the web is carefully lowered and rolled with a heavy roller. If there is no roller, then it can be replaced with a regular building level wrapped in a soft cloth. The surface must be carefully smoothed over the entire area.

Do the same with the second half of the room. To join the canvases, you will need to glue the tape along the entire length and remove the protective coating. After that, an adhesive mass is applied to the remaining part. After gluing, the seam should be carefully rolled.

If you plan to weld the seam, then it is necessary to cut a groove for the filling. Before welding, it is necessary to thoroughly warm up the hair dryer for several minutes, put on the nozzle and insert the cord.

Above you can watch a video on how to properly cut linoleum when laying flooring in an apartment. Pay attention to the sequence of actions when laying multiple canvases.

How to measure, cut and install Linoleum floors Part 1 of 3

How to cut roll coverings correctly

Highlights when cutting linoleum during installation

To carry out work on cutting linoleum canvas, in addition to the purchased knife, you will need to prepare a square, a long ruler and a tape measure. To create a template, you need plain paper or thick cardboard.

When working, try not to rush and take all measurements several times. You need to cut with confident movements, applying effort. If necessary, you can draw up a diagram of the location of the canvases, and only after that start cutting them according to the calculated parameters.

DIY linoleum cutting technology will consist of the following:

- Before cutting the linoleum, it should be kept indoors for 7-14 days at room temperature. For a more precise date, refer to the instructions or paper insert supplied with the coating.

- Next, the roll is cut according to the length of the room, taking into account the allowance. For a canvas with a length of 5-6 m. 20 mm overlap, less than 10 m. 40-50 mm, over 10-12 m. 50-70 mm. This is necessary for the stock of material for trimming and natural shrinkage.

- The cut canvases should be left for 3-5 days until they are completely straightened. If “waves” remain on the surface, then you should not try to eliminate them using third-party methods. High-quality roll coating will straighten naturally.

- Then the cut pieces are laid out along the length of the room. If there are protruding communications and other decorative elements in the room, then you will need to prepare a paper template. After that, according to the template, the pattern is transferred to linoleum and cut off in the right places.

- If the room has the correct shape, then the linoleum is pushed up against the wall with an overlap and cut off at the junction.

- For joining the canvases with a pattern, the first canvas is laid out on the floor surface. The second canvas is superimposed over the first until the joining edge forms a continuation of the pattern. Next, the edge is pressed with a long ruler and cut through both pieces.

Upon completion of the cutting, the linoleum must be shifted by one half of the room and the work surface must be removed from dust, debris and abrasive particles. After that you can start fixing and docking.

About styling

Naturally, before trimming the linoleum along the walls, it must be properly laid. This is not particularly difficult to do. It is important not to skip any of the steps in order to get an even and beautiful coating that will last you for a long time. The flooring procedure is as follows:

- Make sure the base is dry and clean.

- Irregularities are removed. the bumps need to be cut off, and it is advisable to seal the pits and grooves with putty or plaster mixtures. Plywood sheets need to be laid on the plank floors, which will create a flat plane.

- After that, the base is subjected to additional processing, which usually no one wants to do. a primer. It is better to do this, as it will save you from concrete dust and improve adhesion in cases where the canvas is laid with an adhesive method.

- The purchased linoleum is rolled out in the room where it will lie and left in this form for a while so that the material straightens out and the waves left after rolling the roll disappear.

Next, the pieces are adjusted to the base. If the area of the room does not exceed twenty-five square meters, the panels may not be fixed with anything. This works if there are no more than two pieces. In other cases, gluing is necessary. In both cases, it is better to roll out the canvases so that they go slightly onto the walls. This will allow you to more accurately align the pieces end-to-end and, if necessary, move the panels a few millimeters. Without increasing gaps near walls.

Cutting features

Before cutting out the linoleum, you will need all the cutting tools, rulers, a level, and duct tape. It is also necessary to prepare the surface before laying it:

- If previously there was carpet on the floor, then it must be carefully removed. After that, you need to clean the surface.

- If the floors are wooden, check the condition of the boards. If possible, replace bad boards. Cracks between them can be filled. If the surface cannot be repaired, then it is necessary to lay sheets of plywood or chipboard. It is carefully necessary to deepen the hats of the hardware.

- If you already had linoleum, then if the condition is not entirely bad, it can be used as a base for fresh linoleum. The main thing is to thoroughly degrease the surface.

- The easiest option is to lay linoleum on concrete floors. It must be remembered that all irregularities will be felt through the new material and cause discomfort, both physical and moral.

- Before laying and cutting, linoleum must be rolled out in the room. so it will become smoother and the smell will disappear.

If you buy it in the winter, then you need to try to leave the material on the street as little time as possible. he does not like the cold. Therefore, we bring the roll into heat and leave it first in a rolled state. After letting it lie down for a couple of days, the roll can be unrolled.

After acclimatization, linoleum can be cut out. You need to know and remember:

- It is better to put a plain canvas in the direction of the light. This creates the effect of a “monolithic” finish;

- The canvas must be placed in a pattern, parallel to the outer wall, with strict adherence to the pattern;

- The joint does not have to be in the center of the room. Often two joints are made, but at the edges of the rooms. This does not create a visual division of the room into two parts, and furniture can often hide the joints at the edges of the room;

- Indoor pipes can be a problem. To cut cutouts for pipes, you need to bend the material outward and cut the necessary slots at an angle.

Linoleum covers the entire floor surface. It is advisable to leave 5-10 cm on each side in reserve, then they can be cut. In cold temperatures, linoleum can shrink. Heat waves can cause heat waves. There is no need to throw away the scraps. they can be useful for minor repairs of the canvas.

After you have cut it along the wall and cut it along the holes, you need to let the linoleum lie on the floor. Only after that it is necessary to start laying it.

How to install and cut in sheet vinyl floors carpettoolz.com

Cutting linoleum with and without a pattern

Before cutting linoleum at home, it is required to unroll the canvas from a roll and leave it in this state for at least a few days at room temperature. This removes waves and creases before cutting the floor.

Then you can start cutting, which must be carried out in the following sequence:

- The first step is to mark strips on the surface of the material along which further cutting will be carried out.

- Pressing the linoleum tightly to the floor, using a tool, you need to make a small puncture with an incision in the place of one of the drawn lines.

- Then, a wooden block, a building level or a ruler should be laid end-to-end to the specified strip, and then carefully cut the linoleum completely.

- After that, near the ledge, you need to cut off an insignificant angle in the material and carefully lay it.

If there is a pattern on the linoleum, the actions must be performed as follows:

- Before cutting the canvas, it is required to fold it and level the junction of the pattern.

- If one strip of material is applied to another in length, then it is necessary to find the connection points of the pattern and mark them.

- When combining 2 canvases, trimming excess material is required in such a way that in the future the patterns can be joined.

Benefits of special knives

There are a large number of special tools for cutting linoleum at home. They are divided into several types:

- For cutting synthetic flooring;

- Universal knives with replaceable blades;

- Special, for precise cutting at joints and corners.

- Special knives are required to work with complex contours and corners. Hook and trapezoid knives are often used. These knives are called designer knives.

- Electronic knives are needed for chamfering.

How to lay sheet vinyl flooring

- A special place is occupied by the crescent cutter. It is not only convenient for them to cut corners or seams, but it is also very convenient for them to remove glue from the linoleum surface. The choice of such knives depends on the person’s desire to work and on the level of skill.

Tool selection

When choosing a product, it is necessary to take into account a number of the following criteria:

- Strength and reliability of the handle. If the instrument has this component of poor quality, then with strong pressure it can break.

- Availability of spare cutting elements, if the product is of the appropriate design.

- Durability and optimal blade thickness.

In addition, you need to take into account the indicators of the floor material that will be processed. In this case, pay attention to the thickness and strength of the coating.

Advantages and disadvantages

In general, we can highlight a large number of advantages in laying linoleum:

- Cheapness (the exception is natural, but the price pays off by the service life and service life);

- Service life from 7 to 30 years;

- Ease of laying linoleum, which one can do;

- Wear resistance. modern technologies allow even inexpensive material to withstand large and long-term loads;

- Does not support combustion (if it is made in accordance with GOST);

- Prevents feet from sliding on the floor;

- Heat and sound insulation;

- Easy to transport;

- Easy to cut and stack;

- Does not require special conditions and facilitates cleaning the premises;

- Wide range of colors and patterns.

The disadvantages include only those that appear when choosing low-quality linoleum or low-quality laying it on the floor:

- Formation of irregularities, “repetition” of the floor relief;

- If air enters and does not remove, a hump may appear;

- The weak points are the seams. With improper care of them, the service life is reduced by one and a half to two times.

- Linoleum is susceptible to mechanical damage. When heavy objects are found for a long time in the same place, visible dents appear, which are difficult to correct.

- Elasticity and flexibility are lost over time;

- In some types of linoleum, over time, the release of harmful odors and substances begins, so before laying, be sure to find out everything about the material and its properties.

For information on how to lay linoleum, see the next video.

How to cut linoleum?

The main types of cutting tools successfully used in cutting linoleum are of three types: retractable construction knife, flooring knife and linoleum cutting knife. Sometimes, in the absence of the above tools, a clerical knife can be used, provided that a stock of replaceable blades is used.

However, such a knife can only be suitable for cutting thin linoleum. The cutting angle with such a knife should be kept the same. Otherwise, there is a high probability that the knife will “lead” to the side, and, instead of a straight edge of linoleum, you are guaranteed to get a “fringe” effect along the edge of the cut material.

The choice of tool for cutting linoleum very much depends on the thickness, density of the coating and the complexity of the shape that must be given to the various parts of the material that is used.

A retractable construction knife is better suited for cutting thick types of linoleum, as it has a stronger structure than a clerical one. Although the design principle of this knife is the same, however, the thickness of the blade and the guiding elements are made taking into account the greater load on the cutting surface.

Such a knife will be able to qualitatively cut linoleum of any thickness. The tool itself can be used for other functional tasks when repairing your apartment, but it will not always allow you to accurately cut the coating for parts of the material that are installed end-to-end. Uneven seams can be conspicuous.

The flooring knife is a very durable and easy-to-use tool that allows you to cut any type of flooring used for flooring. However, its technical design will allow high-quality cutting of material only in a straight line.

The linoleum cutting knife is a specialized tool with a fixed curved blade designed for cutting linoleum of any available density. If it is on sale, then it is better to opt for it. It is a knife equipped with a front-loading retractable blade and several working positions.

How to cut linoleum

If you decide to start making changes in your apartment, starting them from the kitchen, then you will definitely need to change or lay linoleum. The modern quality of materials allows you to use linoleum in the corridor or hall.

Having made the necessary measurements, you will be faced with the task of cutting the material correctly. The appearance of the final work on the improvement of the floor of your premises will depend on the quality and accuracy of cutting.

Most often, linoleum sellers offer you to purchase a special knife when purchasing material. Those who have not encountered the features of cutting this finishing material mistakenly assume that this operation can be performed using improvised tools, the list of which includes knives (kitchen, pen, stationery), scissors (gardening, tailors), etc.

Of course, for such operations, there are specialized tools, the use of which guarantees you high quality joints between parts of linoleum prepared for flooring.

The cutting technique of linoleum itself also affects the quality of the connection of its individual parts. The easiest and most common way to cut the material in the same way to eliminate gaps in the joints is to overlap the edge of one piece of linoleum when cutting. Cut both pieces of material at the same time, then you can avoid gaps with a width of 1 mm or more.

The inaccuracy of the joints between the parts of the linoleum will lead to the accumulation of dirt in the crevices, which will lead to rapid wear and the violation of the integrity of the entire coating. This cutting technique requires increased attention to the quality of the cutting surface, since any mistake made during this process will damage both pieces of material, and, as a result, increased labor or financial costs.

How to properly cut linoleum?

When cutting linoleum, we will need other tools: a square, rulers of different lengths, a spatula with teeth. The procedure for cutting and laying linoleum:

To level the coating, linoleum must be rolled out and left to level for a while.

It is necessary to cut material blanks taking into account the allowances for cutting and shrinkage of the coating (from 2 to 6 cm, depending on the length of the material).

After cutting the linoleum into ready-made pieces, they must be left for 4-5 days in the form of a stack of sheets, for full straightening.

You can adjust the dimensions of the covering directly on the floor if there are no additional protrusions in the room and the room has the correct shape.

Cut linoleum at the base of the corners should be “V-shaped”, pressing it to the floor with a ruler or corner, cut along a ruler.

When using linoleum with a complex visible pattern, perform face-up cutting operations to evaluate the quality of the joint pattern of the applied coating.

Linoleum should be cut along a long line, starting from one side of the wall.

After cutting the first piece, secure the edge of the cut material with any heavy object. Mark a joint line over the finished piece. Put the next piece on the finished one, cut both along the marked line, butt the new piece back to back.

High-quality raw material, the right tool, precise cutting of the coating, butt-to-end linoleum installation and a good fit when the material shrinks will bring you maximum satisfaction with the work performed, and the room will sparkle with new colors. The new coating of your floor also depends not only on the tool you choose, but also on the patience when cutting the linoleum.