How to cut mdf wall panels

How to fix mdf wall panels

The choice in favor of MDF panels should be made when you need to quickly, efficiently and at the same time inexpensively decorate the walls in the room. In particular, this material is good, provided that it is planned to lay an additional thermal insulation layer.

MDF is based on wood waste, which is mixed with an adhesive solution and then pressed. Such a structure of the material can be compared with chipboard boards, but unlike them, there are no harmful chemical compounds and various resins in the composition of MDF panels. The result is a high-quality, environmentally friendly product that can be safely used for interior decoration of residential premises.

There are two ways how to fix MDF panels to the wall. frame and glue. Each of these options is good in its own way, and their choice depends on the specific circumstances. For example, when there is a need to mask the existing communications, it is best to do this by means of an MDF frame mount. If the finishing work will be carried out on flat walls, then you can safely use the option with landing on glue.

Installation of wooden lathing

The installation of wooden lathing begins with the fastening of a vertical post. First, the rack is installed in the corner of the room, after which they move to the window and door openings (the racks are mounted in the direction from the floor to the ceiling). With the help of a construction plumb line, the verticality of the racks is checked.

Then the rack is applied to the wall, on which the appropriate marks are applied. future holes for fasteners. The distance between the holes (a drill is used to create them) varies from 50 to 70 cm. After that, “nests” are placed in the prepared holes for fixing, and their position is again marked with a marker or pencil. It is necessary to drill a hole two or three times the diameter of the future fastener, which is then inserted back. By the way, experienced craftsmen prefer to do it a little differently: they initially drill holes in the racks, while the marking is done directly through the racks.

All subsequent lags are mounted in the same way. It is noteworthy that logs are installed on top of the openings and under the windowsill, despite the “step”. Also, the slats are mounted outside and inside the window opening.

To eliminate ledges on the rails and at their joints, a plane is used.

The creation of the lathing during the installation of wall panels has the following advantages:

- The walls do not need preliminary preparation (if you wish, you can not even remove the old finish);

- A correctly installed frame will allow you to achieve maximum evenness of the walls;

- In case of unplanned repairs, the panels can be easily removed from the crate.

Features of metal lathing

When creating a metal frame, you cannot do without a profile, special fasteners (they are also “ears”) and connecting elements. Experts advise to purchase them for those who have to perform a large amount of work in a relatively short period of time. If one or two rooms need paneling, then you can refrain from buying them.

To fasten the metal frame to the wall, only self-tapping screws are used (for a concrete base, self-tapping screws with diameters of 4-6 mm are suitable, and if the wall is distinguished by enviable strength, then a smaller diameter of the fastener is allowed). By the way, self-tapping screws or dowels are attached simultaneously with the plastic “socket”, therefore, the hole in the wall must correspond to its diameter, and the protrusions are not taken into account.

Technology for attaching MDF panels to glue

Installation of panels is carried out on a prepared wall (remove all existing debris and dust) in several stages:

- On the wall, starting from the corner of the room, markings are applied, which will determine the places of joining of the panels themselves. To mark the vertical and horizontal boundaries of the finishing material, you can use a marking cord or a simple rope;

- The glue is applied to the inner side of the panel either pointwise or in a checkerboard pattern, after which you need to wait a while for it to set (as a rule, the time is written in the instructions on the package);

- After that, the panel is pressed against the wall and smoothed with smooth movements in the direction from its center to the edges;

- Using a level, you should check the evenness of the attached panel, after which all manipulations are repeated with the next panel. Depending on the manufacturer’s recommendations, the adjacent panel will be fixed with an overlap or butt-to-joint.

Installation of metal lathing

The principle of installing a metal crate is much similar to the installation of a wooden frame. First of all, the corner posts are fixed, after which they proceed to the transverse posts and posts in the openings. The step of the metal lathing is exactly the same as that of the wooden one. 50-70 cm. Narrow UD and wide CD profiles are used to assemble the racks. A building level or tape measure is used to verify horizontality and step. First, the metal slats are fixed to the racks, and then to the wall. Self-tapping screws act as a connecting element between the details of the lathing and the wall, but it is better to refuse from the dowel nails so that the profile does not “float”.

The disadvantages of this method of panel mounting include:

- The creation of a system of profiles, its subsequent fixation and leveling can cause certain difficulties for someone who, until that moment, was not particularly involved in repair or finishing work, therefore, most often you have to turn to professionals for help;

- Installation of the frame and its subsequent sheathing “eats up” several centimeters of free space in the room, which reduces its area;

- Installation of the frame is costly and time-consuming, and therefore you can not count on fast work.

MDF panels

Finishing wall panels based on MDF are available in three forms of production: rack, slab and sheet. Their surface can be finished with veneer or laminated (pasted over with foil), painted. The surface can be smooth or embossed, the color can be any, even in flowers. Most often, MDF panels imitate a wooden surface (it can be a natural wood color, lightened, tinted in different colors).

The option with brickwork is also popular, masonry is a little less common. There are also plain-colored colors and, although they are presented in even cheaper materials such as fiberboard and chipboard, they are still bought. There are reasons for this:

- MDF is one of the safest materials. It is formed from wood waste ground to fibers, and then pressed at a high temperature. Under these conditions, a natural binder is released. lignin, which is contained in wood fibers. If there is not enough binder, a binder previously isolated from other rocks is added. Therefore, MDF is considered a natural finishing material, it is allowed for use in children’s and medical institutions (the formaldehyde emission coefficient of this material is not higher than E1).

- MDF is not afraid of high humidity, reacts little to temperature changes. Therefore, MDF wall panels for interior decoration can be used in rooms with high humidity, but not where there is direct contact with water.

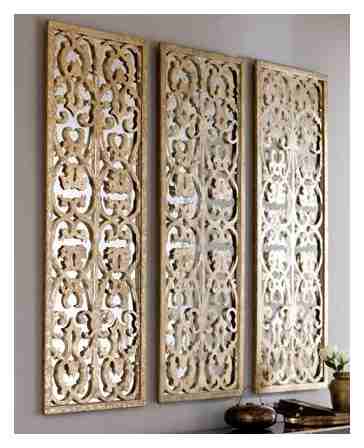

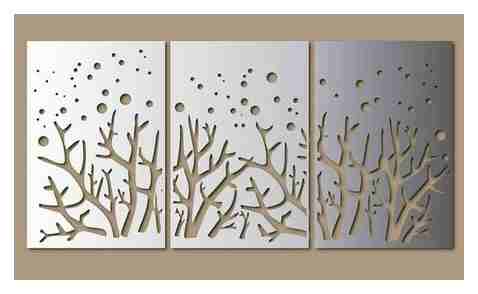

- You can form a relief of any complexity. Simpler patterns are formed during pressing, more voluminous and complex ones. using a router. This technology makes 3D volumetric wall panels MDF.

This material still has a drawback: it costs a lot. The price depends on several factors:

- Density.

- Material thickness.

- Difficulties in forming and painting.

The minimum price is from 30 per square meter, the maximum is up to several hundred dollars. But here you also need to understand that MDF wall panels have different purposes. There is for wall decoration. They have a high density and thickness (from 8 mm thick). Minimum price from 40. For finishing the ceiling. You can take thin ones (from 6 mm), since there is practically no mechanical stress. But the following fact must be taken into account: the thinner the MDF, the more often you need to put suspensions (fasteners). Otherwise, MDF panels can bend under their own weight. Fasteners cost money, so the savings, if possible, will be negligible. But spend more time at work.

What are the wall panels for interior decoration (release forms)

Wall panels are a profitable finishing option. They can be mounted on a base of any curvature and appearance. When installing them, a long and difficult process of plastering and putty is not needed. Wall panels for interior decoration are attached to the lathing of wooden bars or metal profiles, thereby hiding any irregularities. This finishing material is produced in three types: in the form of sheets, plates and slats. Let’s consider each type in more detail.

Wall finishing panels look dynamic in modern interiors.

Rack panels for wall decoration

They are small in width. but considerable length. They are connected to each other according to the thorn-groove principle. There are slatted wall panels for interior decoration, in which the joints are hardly noticeable, there is a pronounced relief. From the peculiarities of installation: the lathing should be located in the direction perpendicular to the direction of laying. If you will mount the planks horizontally, the lathing should be vertical.

They are made of MDF, chipboard, fiberboard and plastic (PVC) and are widely used. PVC slatted panels are popular for budget wall and ceiling decoration in bathrooms, kitchens. Their disadvantage is fragility. Under mechanical stress, the plastic bends, in rare cases it can crack. For places with high humidity, MDF panels can be used (except for places of direct contact with water). Fibreboard and chipboard slatted panels are more suitable for dry rooms. They are distinguished by a much higher resistance to loads. Good for wall decoration in hallways, corridors, living rooms.

Rack panels during installation are attached to the crate with self-tapping screws or staples from a construction stapler. There are also special fasteners: clamps. A clamp is attached to the crate, and it holds the rail with a protruding part. a tongue. In general, clamps are used to mount any type of interior wall panel. This is a convenient flush-mounted system.

Installation of slatted wall panels can be carried out in a horizontal, vertical, inclined direction. Least waste when mounted vertically or horizontally. Although the slatted panels have a considerable length (from 2.4 m), there are still joints. There are special docking strips for decorating them. Special finishing elements are used to decorate the inner and outer corners, starting strips are used to decorate the edge of the trim.

Vertically, horizontally, obliquely, the same width, different.

In general, it should be said that slatted wall panels for interior decoration are a good choice. Their appearance is combined with ethnic styles, loft, modern, some classical trends. In fact, it all depends on the appearance of the panel. They can imitate wood, ceramic tiles, stone surfaces. Honestly, the imitation on PVC wall panels is “so-so”. Even from a considerable distance, it can be seen that it is plastic. The woody relief looks more plausible on MDF slatted panels, a little worse on chipboard.

Chipboard wall panels

Chipboard panels for wall decoration are made of sheet and slab type. The material has a low resistance to humidity, so it is used exclusively in rooms with normal humidity. It also reacts poorly to the cold, therefore, it is not used on unheated loggias and balconies, baths, summer cottages.

Laminated or veneered chipboard wall panels for interior decoration look good in modern interiors

In the manufacture of chipboard, an artificial binder containing formaldehyde is used. In high concentration, this substance is dangerous, because the production of the material is controlled by the sanitary and epidemiological station. Each batch of material is tested, according to the results of laboratory tests, a hygienic certificate is issued with the specified emission class. Excellent indicator. Super E and E1 (like natural wood), acceptable. E2. Anything above (more than a number) at home is better not to be used.

Particleboard wall panels for interior decoration are available in laminated (covered with foil) or veneered. Their assortment is not so wide. the material is weakly plastic, therefore the plates are mostly smooth. Only a few manufacturers have modern equipment that allows you to shape the relief. But, even with new equipment, the maximum that can be formed is imitation of brickwork, ceramic tiles, wood texture.

Even in this version, you can also use chipboard wall panels with veneer

The fastening can be hidden. with the help of clamps. or self-tapping screws. When fastening with self-tapping screws, holes of a smaller diameter are pre-drilled in the material. And we must remember that reinstalling the same fasteners will not work. It is necessary to use a larger diameter, as the material is crushed / crumbled and not restored.

Panels for finishing the walls of the kitchen, bathroom, corridor, living room

The number of finishing materials is growing from year to year. But wall panels for interior decoration have been known for a long time. The first to use wood paneling for wall cladding, later other materials were added.

Gypsum panels for wall decoration

About 5 years ago, gypsum wall panels for interior decoration appeared on the market. This is an environmentally friendly finishing material, absolutely unreliable and hypoallergenic. Another advantage is its absolute incombustibility. It is as flammable as stones. All in all a good choice.

This is how they sell 3D gypsum wall panels for interior decoration

Production technologists allow making a relief of any complexity, so that such slabs have a figured front surface. They are also called 3D wall slabs. The types of relief are very different. Geometric patterns of varying difficulty, curved mowing lines, circles, floral motifs and all in combination. There are a lot of options and variations. The production technology has almost no limitations. And all this variety is available in two versions:

- Made from pure plaster of Paris diluted with water. They can only be used in rooms with normal humidity, since gypsum is hygroscopic. When wet, it collapses. Applications. corridors, living quarters.

- Moisture resistant with hydrophobic additives. The additives reduce the absorbency so much that this type of finish can be used in rooms with high humidity. With some types of additives, they can be mounted in places of direct contact with water. near bathtubs, washstands. They can be installed in bathrooms, as kitchen aprons.

In any case. moisture resistant or not. gypsum wallboards for interior decoration can be painted. This is perhaps the only option for painting. Any paint can be used. Its type is selected for the tasks: if it is assumed that wet cleaning is required, the paint must be resistant to washing, if gypsum panels mounted on the walls of the pool are painted, paint with a waterproof effect is needed (or varnished over it).

Installation of gypsum boards for wall decoration. with glue. If the surface is flat, you can directly on the wall, if there are drops, you need to either level the wall or mount the crate. Take universal glue, but see that it is suitable for the materials used and withstands a sufficient load. One plate weighs about 2-4 kg. Not too much, but not too little.

The seams between the slabs can be left, or a seamless surface can be made. The choice depends on the type of relief and the type of room. There are slabs that are clearly “square” so the seams look attractive. Just take into account that it is better not to do them in the bathroom or kitchen. unnecessary problems when cleaning. There are no such problems with living rooms. there is no strong pollution here.

Characteristics and area of application by type of material

We will not talk about PVC panels. There is a separate article about them with a detailed description of the technology of installation on walls and ceilings. At this point, we will consider wall panels for interior decoration from other materials. There are more than enough of them. There are the usual MDF and chipboard, there are exotic bamboo, glass, metal.

Wall decoration with decorative panels is becoming more and more popular

Bamboo trim panels

Not too common, but an interesting option is bamboo wall panels for interior decoration. They are made from bamboo cut into strips, which are then woven into slabs of different sizes. Then the material is pressed, painted and varnished. Such bamboo panels are suitable for ethnic-style interiors, moreover, with an oriental orientation. The resulting braid has different thicknesses. from 1 mm to 7 mm. Depending on the thickness, bamboo panels are glued to the ceiling (1-3 mm thick) or walls (4 mm and thicker).

There is also another technology for the production of bamboo wall panels. In this case, the stems are crushed to fibers, pressed at a high temperature. This is how 3D eco-panels are made from bamboo. Using the same technology, a similar material is produced from cellulose and cane. The variety of patterns here is no less than in gypsum counterparts, and the thermal conductivity is slightly less. Among the disadvantages. they do not belong to the category of non-combustible materials. And one more thing: they are produced in China, Thailand, there is no production in Russia yet.

The installation method for these volumetric finishing panels is with glue. The seams are putty and leveled. The surface can be painted, but first it must be covered with a primer. to reduce and level the absorbency and so that the paint is smoother. It is better to apply paint from a spray gun. the relief is difficult to paint over with a brush and completely impossible with a roller.

How to attach to the crate

In order to fasten mdf panels to the wall lathing, clamps are taken. special type staples.

The clamps are pushed into the cavity of the panel groove and fixed using a construction stapler.

It is best to use nails. Care must be taken not to damage the edges of the panel.

Use pliers to avoid this. We mount the rest of the panels. In the grooves of the panel, which is already installed, the crest of the panel, which will be the next in the row, is inserted.

A video about the installation of mdf panels on the wall can be viewed before starting work. Next, you need to fix the wall panels for interior decoration to the crate and perform the work in the same way in the required amount.

The last panel against the wall may not fit properly. If necessary, you can cut MDF panels with a jigsaw or wood saw.

It will not be difficult to cut it out, the main thing is to correctly measure the part that will be cut off. This will give them the correct length. Following the recommendations of the instructions on how to attach MDF to the wall, you can do such work yourself. We mount accessories.

In order for the interior from mdf wall mounting to look like a finished product, it is necessary to install mdf fittings. You can close the joints with a folding corner.

Apply glue to the inside surface and press firmly against the corner panels. After finishing work using mdf panels, the appearance of the walls will significantly change.

Large-format ceramic slab effect

Some tile panels are small. I alternate tiles, different in texture and color, you can lay out different patterns of any complexity.

Visually, this will allow you to achieve the effect of large format ceramic tiles.

Thanks to panels with dimensions 120 x 80 cm, panels can be covered faster. After reviewing the recommendations on how to mount, you can give the modules an excellent appearance.

The difference between wall panels is noted for such indicators as:

- sizes;

- texture;

- thickness;

- color;

- fastening principles.

With the right work, you can create the perfect interior. Interior wall decoration with natural materials is now in trend. However, natural materials are quite expensive, and work with them is time consuming. Therefore, synthetic materials are widely used.

Due to their high quality, they are difficult to distinguish from their natural counterparts. MDF panels repeat the texture of natural wood, create the look of a wood covering.

over, they lend themselves well to washing and cleaning. And the installation process is simple and fast. It is necessary to cut the panels of the required length and fasten them to the frame.

MDF reacts steadily to moisture. Here is about moisture resistant mdf for walls. There are special corners to match the color of the panels, they can change shape. With them, you can build a platband, inner or outer corners. Such material is used to give the interior a finished look. You can find out how to install mdf panels on walls from the recommendations.

Installation and installation technology of the first panel

To carry out installation work on the installation of MDF panels on the walls, you must start from the corner:

- we apply the first panel;

- we check the level;

- we fix the panel with self-tapping screws to the rails along the entire height.

A thematic video from the Internet will tell you how to attach mdf to a wall.

Description of MDF wall panels

Installation of MDF boards on walls can be done correctly, quickly and cheaply, without putty, priming, painting or wallpapering. Minimum debris, stylish and practical.

Wall panels have been known for over 10 years on the Russian market. During this period, their popularity does not decrease.

The advantages of using mdf panels are:

- a wide range of sizes and textures, glossy and matte;

- low cost;

- great quality;

- environmental friendliness of the materials from which the panels are made;

- optimally suitable sizes;

- ease of adaptation for rooms of any configuration;

- the ability to attach to a wooden and metal crate;

- indicators of mechanical, thermal and ultraviolet resistance;

- long service life without losing its original appearance;

- resistance to tobacco smoke;

- ease of cleaning and washing;

- ease of installation, if you need to fix mdf panels on the wall. You can repair a room in half a day, without dust, dirt, preliminary work and a large number of special tools.

This building material is suitable for both dry and damp rooms. Even when exposed to moisture, MDF furniture will not be covered with mold or mildew. Mounting MDF from wood will also be a profitable way to decorate the surface.

There is a wide variety of mdf panel designs:

- with photo printing. Here about the kitchen aprons with photo printing;

They are perfect for attaching mdf panels to the wall for any room in any style:

- living room;

- bedrooms;

- baths. Here about bathroom furniture;

- children’s;

- kitchens.

The versatility of the panels lies in the fact that they can even be fixed to the ceiling. Here about mdf for the ceiling.

Wall panels are:

In order not to have to purchase panels again, risking not guessing the shade, it is recommended to heed the following advice:

- Take 10% more materials for pruning and other unplanned circumstances;

- try to choose panels of the same batch for one room so that the shade does not change.

The cost of installation of MDF panels on walls will depend on the choice of materials.

Installing MDF panels on walls: DIY installation and lathing

Wall decoration consists of several stages. Installation of MDF on walls will require a preliminary selection of the necessary materials. The technology for mounting mdf panels on walls is quite simple if you follow the tips and tricks. To equip the room is within the power of everyone.

Everyone wants to have a stylish and comfortable home in order to emphasize their own individuality and create a unique atmosphere.

We mount the crate to the surface of the rail

It is necessary to start work from the corner. Laying must be done tightly. The thin part faces towards the corner. Fastening is carried out on the surface of the rail.

You can successfully complete the work on the installation of MDF panels on the wall with your own hands if you prepare the slats, the cross-section of which is 20 by 40 mm. They will need to be fixed using self-tapping screws and a screwdriver.

With the mounting level, we constantly check the evenness of the installed rails. If the surface of the wall turns out to be uneven, it is necessary to level the battens with the help of such building materials as:

- plywood;

- timber;

- assembly adhesive.

To fix the surface, use long screws or dowels. nails. This will depend on what materials the walls are made of. This process is also constantly monitored by measuring the evenness of the surface with a level.

The bottom of the batten should be positioned with a distance of 3. 5 cm from the floor. This will allow you to successfully fix the floor plinth in the future.

At the top, the lathing is mounted at the level of the ceiling.

- the crate is fixed in different positions:

- in the corners;

- along the window opening.

If the work is carried out where there is a high level of humidity, it is advisable to install elements of a plastic crate or metal. You can watch a video on how to mount MDF panels on a wall surface. If you use the “groove in groove” fastening method, over time it will be possible to easily disassemble the structure.

How to fix and install. installation

Tips for novice builders

If the installation is carried out in winter, it is necessary to first hold the wall panels indoors for several days to restore their dimensions. When choosing panels, it should be borne in mind that the narrower they are, the longer the work will take, but there will be less trimming.

It is necessary to determine how smooth the walls are. If the level shows good data, in this case, you will not need to make a wooden crate.

You can simply glue them to the cement with a special glue. In the case when the walls are not even, you will need to carry out the crate.

This situation is more common. What materials will you need for it? The lathing is made of soft wood. Consider in advance what the crate will be. In dry rooms, it is better to use wood, and in damp rooms, a metal profile. According to the same parameters, it is necessary to select fasteners.

Self-tapping screws. if a metal profile is used, fasteners from self-tapping screws for wood or staples, if you need to work on a wooden crate. In the space of the wall and lathing, a layer of heat or sound insulation can be laid.

In what ways is the mdf panel attached to the wall:

- with crate;

- without lathing.

Basic rules for cutting

So that the efforts on cutting PVC panels are not wasted, and the result of the work meets expectations, experts recommend adhering to a number of rules for working with plastic. These little secrets will help not only to significantly reduce the amount of spoiled material, but also save the master from unnecessary financial expenses and injuries.

When carrying out work in the heated season, do not start cutting panels that have recently been brought into the room. The plastic should naturally warm up to room temperature, which is achieved in at least 12 hours. The fact is that at low temperatures the plastic panel becomes fragile, and therefore it can crack and break off in large fragments.

Regardless of the chosen method of processing the material, it should be placed with its front side facing you, which will avoid deformation of the panel and difficulties during its further installation. When cut from the seamy side, you can find microcracks on the front part, which will manifest itself over time and significantly spoil the interior.

It is necessary to mark in advance the straight line of the planned cut, which can be done with a simple pencil and a stationery ruler.

To speed up the process of preparing the material for installation work, you can cut or saw several PVC panels at the same time. To do this, it is enough to fold them in a pile and create a two-point support. It is best to rest the opposite edge of the stack against the wall, which will help avoid shifting the products, respectively, as a result, parts of the same length will be obtained.

Choosing a cutting tool

Specialists in the implementation of repair work, who have to carry out the installation of PVC panels in their professional activities, know many secrets regarding the correct cutting of plastic materials up and down. After analyzing them, each owner who wants to make repairs on his own will be able to choose the most suitable professional tool for him or use the tools at hand.

The choice of a method for cutting panels usually depends on the tasks and capabilities of the master. Below are the types of cutting materials.

Cutter

If necessary, this tool can be independently made from available tools, for which it is enough to adhere to the following recommendations:

- it is necessary to prepare a metal strip, the thickness of which is at least 2 mm, and the width is 1 cm;

- then one of the edges of the workpiece should be cut off at an angle of 45 degrees;

- it is necessary to sharpen the edge of a homemade product using a grindstone;

- the opposite side should be wrapped with electrical tape, which will allow you to protect your hand from damage during work.

A professional cutter for plastic has a relatively low cost, so its purchase can serve as a profitable investment, because thanks to such a tool, the process of cutting PVC panels becomes not only more convenient, but also quite fast.

Power tool

For quick sawing of PVC panels, a power tool at hand is best. For this purpose, you can use almost any device, which will help to significantly reduce the time spent on preparing for installation.

Often, cutting is performed using the following devices:

- jigsaw;

- Angle Grinder;

- circulars.

To work with plastic material, it is allowed to use only low speeds, because with significant heating it begins to melt and release fumes that are toxic to the human body, and in this case the cut will turn out to be torn.

Using a jigsaw will help make the process of preparing PVC panels for installation much faster than using a hand tool.

However, with this method of processing, the following nuances must be taken into account:

- even before starting work, it is necessary to turn off the pendulum stroke;

- a file with as small teeth as possible should be used;

- you need to set the lowest speed of movement of the file, which will avoid excessive heating of the plastic at the cut.

How To Install Wood Paneling

Using a jigsaw is very convenient to cut stacks of panels, but you should make sure that their height does not exceed the length of the file installed in the tool.

The angle grinder is recognized as the most convenient and practical power tool with which you can cut PVC wall panels. By installing a cutting disc, you can make not only straight, but also curly cuts on the surface of the plastic. When processing plastic in a circle, the angle grinder turns on only at low speeds, which will avoid damage to the material due to melting of the edges.

In the absence of more practical and convenient tools, PVC can be cut with a knife.

To solve this problem, the following types of cutting products are suitable:

- Kitchen knife. This tool is suitable for cutting multiple panels in the process of repairing or replacing them. For large-scale wall decoration, such a procedure is unnecessarily long and painful.

- Construction knife. Among hand-held cutting tools, such a device is one of the best options for achieving a straight cut with relatively little effort.

- Stationery knife. Using a wooden ruler or square, this tool allows you to achieve a perfectly even cut of the panel, therefore, it is often used to cut them.

How to cut PVC panels?

- Material features

- Choosing a cutting tool

- Cutter

- Hacksaw

- Power tool

- Knife

- Basic rules for cutting

- Safety regulations

PVC panel is one of the most popular materials for interior decoration. Its use in the interior attracts not only by its appearance, but also by its affordable price, ease of maintenance and installation. Due to the listed characteristics, many people prefer PVC panels, rather than tiles, when decorating personal hygiene rooms.

Hacksaw

One of the universal devices for cutting any material is a hacksaw, which is sure to be found in the arsenal of any craftsman. It is she who will help, if necessary, cut the plastic wall panel. Such work will take longer than using a special cutter, but with significant volumes of cladding, this will not significantly affect the total repair time.

When using a hacksaw, you should listen to the following recommendations of experts:

- for working with plastic finishing materials, you should use a tool with small teeth, which is usually designed for working with metal or wood;

- to shorten the PVC panel, there is no need to apply strong physical forces, which can damage the material;

- you can cut several parts at once with a hacksaw by folding them in a pile and securing them to avoid bending or displacement.

To prevent the cut from being serrated, it is not recommended to use a tool with teeth set apart in different directions.

Material features

PVC panels are one of the modern types of finishing materials that are made by extrusion and are used both in the bathroom and in the living room. The main raw material in the production of such products is polyvinyl chloride, which is used to fill the mold. To give the panels the desired color, a certain amount of crushed natural chalk is added to their composition.

Decorating PVC panels can be done in one of the following ways:

- staining;

- thermal printing;

- offset printing.

Thermal printing is applied to the plastic surface using a special roller heated to high temperatures, which presses the film to the surface of the product. Thanks to this technology, it is possible to quickly and clearly apply a pattern without losing the brightness of the image. The panel itself does not need additional varnishing. Offset printing is used much less often due to its high cost.

Safety regulations

Like working with any building materials, processing PVC panels requires compliance with several safety rules. These recommendations are especially relevant if you plan to work using a tool that is connected to the power supply, for example, a jigsaw or an angle grinder. When cutting plastic with a power tool, there is a great danger that debris and sawdust can fly off the panels. Therefore, experts recommend purchasing safety glasses and gloves in advance, which should not be removed until the end of the work. These seemingly simple personal protective equipment can help keep your hands and eyes safe from injury.

These tips should help you decide on the choice of a tool, as well as create an interior of your own dreams and avoid most mistakes, because with a little effort, you can achieve the desired result, saving a lot of money.

How to easily and clearly cut a plastic panel is described in the video.