How to cut metal with a hacksaw for metal correctly. Removing burrs

Hand hacksaw for metal. Faithful assistant home master

The general theory of sawing with a hacksaw for metal looks something like this:

The theory of sawing with a hacksaw. Introductory course

Therefore, we will not study theory, but we will go immediately to practice:

On this video, the whole story on how to saw, in fact, is presented, but now there will be a postscript, a number of additions and amendments are presented (plus a brief retelling of the video).

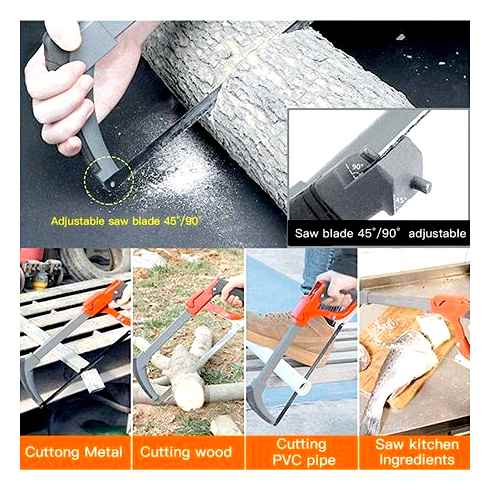

So, let’s start with the fact that it is necessary to cut with a hacksaw for metal horizontally, grabbing the tool with two hands. Why it would be nice to use a hacksaw with a well.expressed handle for grip with a second hand.

Drinking horizontally inconveniently, because for this it is necessary that the workpiece is fixed at chest level, and to saw standing standing. However, workbench, as a rule, are tables at which you need to sit, and if you saw, then standing and from top to bottom. Therefore, hacksaws are often made one.handed and sawed at an angle of 45 °.

To adjust the pressure on the saw (the more firmly metal, the volume must be loaded more, put it on it so that the teeth are bite into the flesh; and vice versa. if the teeth are cut too much, for example, into aluminum, then you need to reduce the pressure): a) change The angle of inclination during sawing, b) put your hand on top to increase weight, c) expand the canvas back.

The saw often stucks in the propyle when the end of the canvas is reached. This is due to the fact that the canvas has a wavy wiring of the teeth (so that it was wider than the canvas and it does not get stuck in the cut), but over time, the amplitude of this wave is reduced in the center of the canvas, and there is almost no at the ends.

Teeth grow more in the center of the canvas

This distortion arose on the basis of sawing this canvas previously not its entire length. Fix (increase breeding in the center or reduce at the ends) now this is already impossible due to the fact that the teeth are hardened. So moral: from the very beginning of the operation of a new canvas, you must always cut all its long.

The following problem: if you saw a thin sheet of metal, the thickness of which is less than the distance between the teeth, the saw gets stuck:

Too thin detail gets stuck between teeth

If the metal is firm (iron). you shift the hell, and if the soft (aluminum). a huge piece of metal is ripped off, torn edges are formed, the edge bends.

Subtle detail sawing a strong slope

Drink at an angle to form a cut of such a length that at the same time there are at least two teeth (the length of the drink ≥ two distances between the teeth).

Next topic: sawing a thin.walled aluminum pipe:

We install the canvas with teeth back, twist the pipe in the direction of the teeth (otherwise the canvas will get stuck on the neighboring edge of the cut, and with the use of force. to break).

Well, even before the heap The canvas of the hacksaw on the metal can be restored, the teeth, for example, is in this way:

Initially, this diamond disk was more diameter and this drill with this disk, being pressed thus, was located strictly parallel to the line of teeth of the canvas, and the disk, respectively, perpendicular. And it was right-in the new hacksaw, the front boundaries of the ends. Now a small negative angle is formed. a little less, but also norms.

information: the canvas can be drilled with a regular metal drill (from steel HSS). Because in the production, the whole canvas is not very hard, on elasticity, but the teeth are hardened separately by induction heating with rapid cooling for hardness, so these teeth can calmly saw the drill.

How to choose the right canvas for a hacksaw for metal

Saw equipment in the form of consumables for hand hacksaws must be selected based on the following indicators:

Type of tool. Case for metal are different, so before buying a hacksaw canvas, you need to measure the distance between the fixers of the tool body. If the tool has an option to adjust the frame, then you can buy any length of the headset of the processed material. if you plan to saw soft types of steel, like aluminum, copper, brass and others, then there is no need to buy expensive canvases, because carbon devices of low hardness will cope with such blanks. As the main material from which the equipment is made, is the steel type X6VF for domestic and HCS for foreign. If you need to cut more durable materials, like steel, cast iron, etc.P., Then the equipment from high.speed steels is used, the thickness of the metal, which is subject to processing, as well as the quality of the cut seam

Here you need to pay attention to TPI. the number of teeth per inch. Everything is simple here. if you need to get a high.quality seam when sawing thin blanks, then you need to choose a equipment that has a TPI value of more than 24

At the same time, the duration of sawing material increases several times. If the cut quality is not the main thing, but the speed of achieving the result is more important, then you can choose canvases with TPI less than 24 teeth per inch. The more teeth on the canvas, the higher the TPI of the teeth tpi. the devices under consideration have an appropriate deviation, which affects the speed of obtaining the result, as well as the thickness of the cut. GOST R 53411-2009 regulates that the canvases are produced by three types of wiring: with a deviation for each tooth, through one tooth and two adjacent ones through undiluted links. It is almost impossible to visually identify the size of the wiring of the links. For the option of wiring the links “for two adjacent through one”, the deviation does not exceed 0.15-0.25 mm. For other cases, the discrepancy is from 0.6 to 0.9 mm. You can measure the size of the wiring using an electronic caliper, only at the same time the detected value will be 2 times greater than indicated above

These are the main parameters that need to be taken into account in order to choose a competently mechanical canvas for your tool. Since the price of the device is relatively low, you can buy a set of devices from different materials, and test them in action. Will help make the correct conclusion when choosing paintings for manual hacksaw video below.

The service life of the devices in question depends on such a parameter as the type of coating. The presence of the coating allows you to increase durability. Manufacturers cover consumables for manual saws with chemical instrumental impurities, as well as nitroemalevo type NC-25 and NC-132. Nitroemalevo coating is less high.quality, since with an increase in the load, cracks occur.

It is interesting! The uniformity of the divorce of the links plays an important role in the process of cutting the metal. This is especially true for high.quality products, the uniformity of wiring teeth on which should be no more than 45% of the step parameters at a length of 10 mm. Using a micrometer, it is possible to measure equivalent of teeth, the value of which should not be more than 0.1-0.15 mm.

The use of a hacksaw for metal with a high.quality canvas is relevant today in the following cases:

- When you have to cut a water pipe, which is under pressure, for example, for a tender insert. It is dangerous to use the power tool in this case, so a manual saw is taken in operation

- When cutting plastic blanks. The use of corner grinding and other power tools will lead to member of the material, so it is important to use manual hacksaw

- When there is no electricity or work is performed away from electricity

From this list it is clear that it is important to always have in the arsenal not just a hacksaw, but also interchangeable canvases for it, which will allow you to use the appropriate set depending on the task

How to install a canvas in a knife on metal

Scabbard for metal is a hand tool that is used to cut profile metal and pipes. The simplest hacksaw for metal consists of a machine and a hacksaw cloth.

The machine, in turn, consists of a frame, in which a handle has a device that has a device for fixing the canvas, and on the other hand, a device for fixing and adjusting the tension of the canvas.

The stretch device, on the one hand, has a groove for inserting and fixing the canvas, and on the other hand, a screw with a ram which is tensioning the canvas.

Fabric for hacksaw on metal differs from each other with a width, long, thickness, distance between teeth and their height. The use of a particular canvas depends on the thickness, hardness and shape of the material that needs to be cut.

The manufacturers of paintings made sure that you could choose a canvas for yourself for the material that you need to cut, whether it be aluminum, copper, bronze and even a plastic.

The dimensions of the canvas, namely the length, width, dimensions and brand of steel, can be found on the purchased hacksaw.

Real Hardware Hacking (with a hacksaw): My New Wearable Computer

How to install a canvas in a knife for metal?

As shown in the first figure of the article: teeth down (if the canvas is one.sided) and teeth are directed forward, from the handle. When you saw, you put pressure down and forward. the teeth of a hacksaw, down and forward should be directed in the same way.

To install, release the tension screw, remove the old canvas from the pins, put on a new one and tighten so that the canvas from the click of the nail rang like a string. The main thing here is not to overdo it and not break the canvas.

Experimentally you will find the optimal tension.

The tension is carried out using a ram on the adjusting device, that is, by tightening the ram you will pull on the canvas. So when tearing a hacksaw canvas, you need to find a middle ground. Also, make sure that the canvas is installed smoothly, without distortions, since the bias will entail an uneven drink during cutting.

How to saw?

Since you were interested in the question of installing the canvas, it means that the advice will not hurt about the method of using a scabbard for metal. Get with one hand (right, if you are right.handed or left, if left) by the handle of a hacksaw, the other. beyond the opposite handle the vertical edge of the arc of a hacksaw. Put the canvas on the fishing line for the trim of the cut.

Direct the canvas strictly in the direction of the cut line. The angle of inclination of the hacksaw. The canvas should almost lie on parts, usually at an angle of 30-45 degrees. So there will be less vibration, noise and smoother a fishing line for a trimmer cut. Cut across the material, with an angle of 90 degrees, is only in emergency cases, for example, when turning the cut line.

The smoother you need a fishing line for a trimmer cut, the smaller the angle of inclination.

The first movements must be made with a slight effort so that the canvas crashes into the material and does not slide to the sides of the cutting line. When making smooth movements, strictly progress, press the hacksaw to the part when moving forward and loosen the pressure when returning to the original state. When the canvas clings to the material, you can work in full force.

The scope of movement is maximum, from the edge of the canvas to the edge, without hitting a hacksaw on a part with an arc. No need to “stamp on the spot”. so you quickly rub the canvas on one section and you will have to throw it away, because it is impossible to use a flawed sheet.

Keep the arc Khspuvka evenly, do not let it bow in different directions. The direction of cutting corresponds to the plane of an arc of a hacksaw, so the boltka is contraindicated here. In addition, the canvas easily breaks with sharp jerks of the hacksaw to the side.

The properties of the material of the canvas are such that it holds the longitudinal force of stretching very well, but very fragile for bending.

Dimensions

Currently, 300 mm is considered the standard length for the canvas. There are also hacksaws in which this indicator is 150 mm. Shorter options are used only in cases where a large hacksaw is not suitable precisely because of its size or the master needs to do a very thin job.

If we talk about teeth in the canvas for metal, then they are very small. This choice is due to the fact that it is small teeth that are best coped with the task of sawing metal products.

Masters of working with this tool pay attention to the fact that the canvas is the most important element, but it is worth paying due attention to the handle of the tool.

In some types, it is made very unsuccessful, and it will be inconvenient to work with such a device, even if the metal canvas corresponds to all the qualities.

Differences in the tools

As mentioned earlier, saws are conditionally divided into professional and home. The main advantage of a professional tool is that its design is more rigid, and also makes it possible to carry out work at an angle of 90 and 55 degrees. Home devices are most often flimsy, and during the work they are constantly “stormy”.

In this case, even a high.class metal canvas does not guarantee a quality saw. However, here it is already necessary to build on the frequency of using this tool. Home saws are much cheaper, and it is worth purchasing only if the hacksaw is rarely used.

If you use this tool quite often, then you should not save.

It is worth mentioning a separate type of saw-a hacksaw. The main difference between this tool and an ordinary hacksaw is that it is intended to work with a broken hacksaw canvas for metal.

Product design

Constructive performance of this tool almost the same for all models. The saw is a C-shaped arc, between the lower edges of which the canvas is fixed or pulled. The working and main part of this tool is the same hacksaw canvas for metal, which has many small teeth.

The handle is one of the three main details of the device, plays a significant role in terms of convenience of using the tool during prolonged operation. The most successful in terms of execution and comfort of use are two.component composite handles with rubber inserts.

Fabric on hand hacksaws for metal. the right choice, types and installation

Among manual cutting tools, a metal hacksaw continues to be popular.

The main advantage of this tool is that it can always be used when the power tool is useless or its use is limited by the technological task.

To use a hacksaw, you will need to install a metal canvas in the tool. Only before installing the cutting element, it must be correctly selected.

Crossbow canvases for metal tools

It is necessary to consider a hacksaw canvas for metal by classify this type of consumable for three types:

- For manual hacksaws (they are large and small). After the appearance of a corner grinder or corner grinder, as well as disk, saber saw and jigsaws, manual hacksaws lost their popularity, but at the same time did not disappear completely

- For machine units. these include tape saws that are used in industry (designed for the machine). For strip saws, canvases that have the corresponding parameters are used: length, thickness, manufacture material, sharpening and shape of teeth. At home, such units are used only if it is necessary to conduct high.precision cutting of metal parts. For such units, a special strip canvas is used, the teeth of which have spraying from carbide materials. In tape saws, not only equipment for cutting metal is used, but also on wood. Ribbon saws need additional water cooling during operation, which extends the life of the devices, and also reduces the load on the drive mechanisms of machine units

- Autonomous electrical units are tools that displaced manual hacksaws. These include saber files and electrolobsics. A canvas of appropriate shapes and technical parameters are available for a saber saw. For the jigsaw of the canvas for metal, they also have the appropriate parameters, therefore, when choosing them, gently consider for which type of tool consumable cutting materials are intended

In the material, we will examine in detail the canvases for metal for hand hacksaw, which you can buy in any construction store, on the market and even in online stores. By the way, the advantage of buying on the Internet is that the buyer has great choice, in contrast to the purchase in a store where the assortment is limited by two or three models.

Types of cutting snacks for metal

Cutting headset for hand saws for metal are produced in three types:

- Single. have the total length of paintings up to 265 mm. However, the main parameter on such equipment is the distance between the fasteners, which is 250 mm

- Single standard are the most popular models of paintings that have cutting teeth from only one part. The gap between the fasteners is 300 mm, and the total length of the canvas is up to 315 mm. If you buy a canvas canvas, then take into account (measure) you need not the total length of the canvas, but the distance from one fastener to another. Typically, manufacturers indicate the sizes on the side of the equipment

- Double. completely identical to the previous type of size, only the cutting parts on such devices are located on both sides. This allows you to increase the life of the headset, since with abrasion and dulling of teeth on one side, you need to turn the canvas and continue its operation

The canvas for metal metal has a thickness of 0.63 mm, and double-0.8-1.25 mm. On the headset, this parameter is indicated by the letter S. The difference is also available in the width or height of the paintings. For a single headset, the height is 12.5 mm, and for double-20-25 mm.

GOST R 53411-2009 regulates such main indicators as a step of teeth and their number, which are indicated by the letters P and Z. These indicators affect the quality and speed of cutting metal parts and blanks. The length of the devices in question is also 150, 350 and 400 mm.

What are made of

The modern canvas for a hacksaw for metal is made of the following types of steels:

- Carbon. differ in low strength indicators, so you can use them for cutting non.ferrous and soft metal. The headset of this class has HCS labeling, and the degree of strength does not exceed the values of 44-46 HRC.

- High.speed. have high indicators of resistance to abrasion and wear of teeth, but their disadvantage is fragility. High-speed saws are marked by the HSS designation and have a degree of hardness up to 73-78 HRC. There are canvases made of high-speed steel with diamond spraying, which have a degree of hardness up to 82-84 HRC. a piece

- Bimetallic. received this name due to the use of two types of steel. Their production made a splash in the market, quickly displacing their analogues. The basis of bimetallic paintings includes materials such as carbon steel, on which a strip of high.speed steel is welded. Such types of devices are indicated by the letters of BIM, and in terms of strength they are such as high.speed, only due to the use of carbon steel as the main material, they have high strength and resistance to deformations

- Alloyed instrumental steels are modernized models of carbon analogues that are made by alloying carbon chromium, tungsten, vanadium, silicon, etc.P. The alloy allows you to achieve high strength indicators, and the degree of hardness is slightly lower than that of high-speed steel, and is 67-67 HRC.

The hardness of the manual sawfish characterizes the sensitivity of the equipment to the tension of the bend, therefore, depending on the used cutting devices, it is necessary to take into account the force attached to the hacksaw during operation.

Typically, the amount of force should not exceed the indicator of 60 kg, which is characteristic of the equipment that has the size of a step of teeth equal to less than 1.4 mm. If the size of the teeth is more than 1.4 mm, then the load should not be more than 10 kg.

Fabric on hand hacksaws for metal. the right choice, types and installation

Among manual cutting tools, a metal hacksaw continues to be popular.

The main advantage of this tool is that it can always be used when the power tool is useless or its use is limited by the technological task.

To use a hacksaw, you will need to install a metal canvas in the tool. Only before installing the cutting element, it must be correctly selected.

Crossbow canvases for metal tools

It is necessary to consider a hacksaw canvas for metal by classify this type of consumable for three types:

- For manual hacksaws (they are large and small). After the appearance of a corner grinder or corner grinder, as well as disk, saber saw and jigsaws, manual hacksaws lost their popularity, but at the same time did not disappear completely

- For machine units. these include tape saws that are used in industry (designed for the machine). For strip saws, canvases that have the corresponding parameters are used: length, thickness, manufacture material, sharpening and shape of teeth. At home, such units are used only if it is necessary to conduct high.precision cutting of metal parts. For such units, a special strip canvas is used, the teeth of which have spraying from carbide materials. In tape saws, not only equipment for cutting metal is used, but also on wood. Ribbon saws need additional water cooling during operation, which extends the life of the devices, and also reduces the load on the drive mechanisms of machine units

- Autonomous electrical units are tools that displaced manual hacksaws. These include saber files and electrolobsics. A canvas of appropriate shapes and technical parameters are available for a saber saw. For the jigsaw of the canvas for metal, they also have the appropriate parameters, therefore, when choosing them, gently consider for which type of tool consumable cutting materials are intended

In the material, we will examine in detail the canvases for metal for hand hacksaw, which you can buy in any construction store, on the market and even in online stores. By the way, the advantage of buying on the Internet is that the buyer has great choice, in contrast to the purchase in a store where the assortment is limited by two or three models.

Types of cutting snacks for metal

Cutting headset for hand saws for metal are produced in three types:

- Single. have the total length of paintings up to 265 mm. However, the main parameter on such equipment is the distance between the fasteners, which is 250 mm

- Single standard are the most popular models of paintings that have cutting teeth from only one part. The gap between the fasteners is 300 mm, and the total length of the canvas is up to 315 mm. If you buy a canvas canvas, then take into account (measure) you need not the total length of the canvas, but the distance from one fastener to another. Typically, manufacturers indicate the sizes on the side of the equipment

- Double. completely identical to the previous type of size, only the cutting parts on such devices are located on both sides. This allows you to increase the life of the headset, since with abrasion and dulling of teeth on one side, you need to turn the canvas and continue its operation

The canvas for metal metal has a thickness of 0.63 mm, and double-0.8-1.25 mm. On the headset, this parameter is indicated by the letter S. The difference is also available in the width or height of the paintings. For a single headset, the height is 12.5 mm, and for double-20-25 mm.

GOST R 53411-2009 regulates such main indicators as a step of teeth and their number, which are indicated by the letters P and Z. These indicators affect the quality and speed of cutting metal parts and blanks. The length of the devices in question is also 150, 350 and 400 mm.

What are made of

The modern canvas for a hacksaw for metal is made of the following types of steels:

- Carbon. differ in low strength indicators, so you can use them for cutting non.ferrous and soft metal. The headset of this class has HCS labeling, and the degree of strength does not exceed the values of 44-46 HRC.

- High.speed. have high indicators of resistance to abrasion and wear of teeth, but their disadvantage is fragility. High-speed saws are marked by the HSS designation and have a degree of hardness up to 73-78 HRC. There are canvases made of high-speed steel with diamond spraying, which have a degree of hardness up to 82-84 HRC. a piece

- Bimetallic. received this name due to the use of two types of steel. Their production made a splash in the market, quickly displacing their analogues. The basis of bimetallic paintings includes materials such as carbon steel, on which a strip of high.speed steel is welded. Such types of devices are indicated by the letters of BIM, and in terms of strength they are such as high.speed, only due to the use of carbon steel as the main material, they have high strength and resistance to deformations

- Alloyed instrumental steels are modernized models of carbon analogues that are made by alloying carbon chromium, tungsten, vanadium, silicon, etc.P. The alloy allows you to achieve high strength indicators, and the degree of hardness is slightly lower than that of high-speed steel, and is 67-67 HRC.

The hardness of the manual sawfish characterizes the sensitivity of the equipment to the tension of the bend, therefore, depending on the used cutting devices, it is necessary to take into account the force attached to the hacksaw during operation.

Typically, the amount of force should not exceed the indicator of 60 kg, which is characteristic of the equipment that has the size of a step of teeth equal to less than 1.4 mm. If the size of the teeth is more than 1.4 mm, then the load should not be more than 10 kg.

Crossbow canvas for metal. How to choose and how to put?

Do not forget that the production of a working habits is carried out in accordance with the established standards in GOST 53411-2009.

The specified information in this regulatory and technical documentation determines the selection of two main groups: for machine and manual cutting.

It should be borne in mind that the machine canvas for metal is extremely rare, since such equipment is extremely rare. For manual hacksaw, the following execution options are issued:

- A single hacksaw canvas for metal with a distance between the fasteners of the element 250 mm. over, the total length indicator is 265 mm. This version of the performance is suitable for the tool that is used in the absence of the need for great performance.

- Single execution options with a distance between two fasteners of an element of 300 mm. The total length indicator is 315 mm.

- For greater performance, a double hacksaw cloth is installed. The length of this version of the execution, as well as the previous.

When choosing, attention is also paid to the width indicator, which is 0.63 mm for a single execution option, for a double 0.8 mm. Tooth height in the first case is 12.5 mm, in the second 20 mm.

The value and step of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend on. The following alloys are most widespread:

A hacksaw canvas with a tungsten carbide has recently been quite common, since it is characterized by increased wear resistance. It should be borne in mind that spraying can have the most different colors, blue options are found on sale, ordinary steel dark gray.

The hacksaw tungsten in question is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to the bending load. That is why with careless metal cutting, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength of strength by heat treatment. At the same time, it is worth considering the following:

- The main part of the product is characterized by the hardness of the surface layer near HRC 44-46.

- Depending on the type of material used in the manufacture, the hardness of the tooth varies from the HRC limit from 64 to 67. This indicator is characteristic of alloyed alloys. High-cutting steel is characterized by the fact that it has HRC hardness in the range of 73-78 units.

Do not forget that significant changes in hardness cause the sensitivity of the product to bending. The tool is designed for various loads, it should not exceed 60 kg with a step of 1.4 mm, as well as 10 kg with a tooth step of less than 1.4 mm.

A fairly large number of varieties of such a product determines that with the selection of a suitable version of execution there are no serious problems.

The principles of choice of canvas

It is important to choose the right option for the performance of the product to a specific operational condition. If the surface does not have the required properties, then it will not last for a long period. The selection criteria can be called the points below:

- The most important selection criterion can be called the distance between two fasteners. In some tools, this indicator may vary thanks to a special device.

- The next selection criterion is the strength of the cut metal. If the work provides for the cutting of common soft alloys, for example, copper or aluminum, then the product is selected with the least hardness of the surface layer. X6VF steel is very common, in paintings of imported origin, hCS marking is used. You can also process durable metals for which a hacksaw canvas is suitable for high.speed steel, import marking HSS,

- The thicknesses of the cut metal and the quality that must be achieved after processing is also taken into account. Abroad, the PPI indicator becomes a defining criterion. the number of tops of the teeth per inch length. To ensure high quality, PPI is required more than 24, if the priority of performance is required, then the option is selected with an indicator of less than 24.

- When choosing, attention is paid to the quality of breeding cutting. This parameter must comply with the norms that are established in the previously given GOST. There are three main execution options: breeding for each, through one tooth or two adjacent.

Many are looking for a hacksaw canvas, which can last for a long period. It should be borne in mind that the quality of the applied coating affects the operational period. The use of inexpensive substances becomes the reason why, when heated, a large number of cracks appear on the surface.

The quality is also affected by the uniformity of wiring. A good hacksaw canvas for metal is not more than 45% for a length of 10 mm. Also, a visual inspection allows you to determine how equal in height individual teeth. Exact results can be obtained when using a micrometer or other measuring device with high accuracy.

About saws

The saw canvas refers to consumables. in the process of work, it is stupid, it grows down. Deformations are possible due to non.calculated loads. The main division of the cutting tool is by the type of material processed:

150mm. Marking by the abbreviation HCS. The inscription “on wood” or “For wood” is performed on the lateral surface.

Increased accuracy is facilitated by a decrease in tooth size to 3mm, a small divorce to the sides. Clean for wood inscription.

one.5mm), wave.shaped wiring. Inscription “Metal” or “Metal”. HSS marking. Plastic. Medium tooth (

3mm), small wiring. Inscription “Special for Acricilic”.

Files are produced by ceramics, glass, drywall and other materials. Differ in geometric parameters and cutting part. instead of teeth, an abrasive coating is applied. Universal models working with wood, metal and plastic are presented. Figure cut is carried out with narrow saw canvases.

Kryzuovka for metal: types, scope of use, GOST requirements

Among the variety of locksmithing tools, a metal hacksaw is a high degree of probability of the most famous representative of this group of manual tools. About what species are, and where it is used, as well as how to choose, and for popular models. this is the topic of this article by the editorial office of HomeMyhome magazine.ru

The classic version of the hand hacksaw for metal, familiar to many since childhood and school bench

Features of application and types with photos of models

All hacksaws for metal can be classified according to two parameters:

All manual models, regardless of the design and type of use, must comply with the requirements of GOST 17270-71 “Scabbard manual frames.

Specifications (as amended by N 1-4) ”, and electrical counterparts-GOST IEC 60745-2-11-2014“ Manual Electric machines. Safety and test methods. Part 2-11.

Private requirements for saws with a reciprocating movement of a working tool (jigsaws and hacksaw saws) “.

The appearance of the modern hacksaw of the brand “Sturm!””

Household and professional hand hacksaws for metal

The main purpose of such a tool, regardless of the nature of its use, is the sawing of metal blanks for a given size and a certain shape (grooves, seams, etc.D.). The distinguishing features of the models used by professionals are:

In a special place are mini-brows (hacksaw-handbags), which can be used in hard-to-reach places, which is achieved by a special design of this type of tool.

Structurally, a knife.haired woman in a classic form consists of the following elements:

- Frame. is performed in the form of an arc and serves to fix the hacksaw canvas;

- Handle. serves to reliable fixation of the tool in the user’s hands.

Note! Professional models are equipped with two.component handles that allow you to work as a tool using both hands.

All the parameters that the manual hacksaw frames must comply with are regulated by the requirements of GOST specified above.

Note! The quality of the cut and the speed of its execution using a hand hacksaw on metal depends on the type of hacksaw.

The speed of work and their laboriousness depends on the correct choice of the hacksaw cloth

When working with manual hacksaw for metal, certain rules must be observed, which will save strength and not damage the hacksaw, namely:

- The hacksaw should be firmly fixed in the frame of the hacksaw. For its fixation, special nuts are used, placed on the tension mechanism of the tool.

Important! Before fixing the hacksaw canvas, the hacksaw frame must be pushed to the width corresponding to the length of the web.

- When sawing the movement of a person using the tool, should be uniform, without jerking.

- During the work in the workshop using a locksmith vice, the employee’s body must be placed, in relation to the axis of the sawing workpiece, at an angle of 45 °, and the hands are bent at the elbow at a right angle (see see. The drawing below).

- The tool should be held with both hands, pressing to the surface of the processed metal during the reciprocating movements of the hacksaw cloth.

The scheme of the correct location of the employee during work with a hand hacksaw for metal

Important! The workpiece firmly fixed in the vice will reduce the likelihood of a hacksaw canvas during sawing.

On the domestic market of a manual locksmith instrument, a large number of different models of scabbard for metal are presented. Here is some of them:

The company “Enkor” produces a tool under such brands as: “Corvette”, “Enkor”, “Encor-plast” and “Accumaster”.The Osa 20980 model is equipped with a special screw that provides the tension of the canvas and rubberized handles.

| Plastic | There is | 300 | Not | 0.56 | 395 × 145 × 25 |

Review of the Enkor model “Osa 20980”:

Read more for the Ozzovik: http: // otzovik.COM/ReView_2473309.HTML

The appearance of the Gross Piranha 77602 model

The country of the production of this model is Taiwan, and the birth of the brand is Germany. The design of the frame allows you to perform saw at an angle of 45 and 90 ° in relation to its plane.

| Metal | There is | 300 | There is | 0.672 | 400 × 130 × 30 |

Hacksaw for metal manual its purpose is the views and how to choose

The demand for hand hacksaws for metal remains relevant, since this type of tool has many advantages and only one drawback. This is the first tool that was invented by a person for cutting metal blanks.

Today, in the arsenal, every honor of himself has at least one option among different types of this tool.

Hand hacksaw for metal is popular in that the tool is always ready to work in the absence of a corner grinder and electricity.

Structural parameters of manual knife stabs for metal

The hacksaw for metal looks quite simple:

- The base or frame of the “P” of the figurative shape is mainly from metal

- Handle of different forms for handmade

- Metal canvas for manual hacksaw or cutting element fixed along the edges of the frame

These are the main elements that make up hand hacksaws for metal. An important detail is a canvas having a characteristic type of teeth. Small teeth are intended specifically to work with solid materials.

The canvas is fixed on the frame. For the manufacture of the frame, alloy steel is used. Frames are of different types, shapes and designs. Professional manual devices have the function of adjusting the angle of tilt of paintings. There are such frames that are able to part. This function in the tool allows you to install cutting elements of different lengths.

The handle is also an important node, as it is able to ensure the convenience and comfort of the use of the tool. The handles are of different shapes, and are also made of such materials. wood, metal, plastic. The simplest handle is made of wood, and the bonds of the two-component composition are considered as maximum and comprehensive: metal and rubber insert.

A canvas for a hand hacksaw for metal is a thin tape that is made of hard types of steel, and has a different length. On one or two sides there are a clovice.shaped teeth.

The hacksaw is the most fragile element of the tool, therefore, when working, it is important to control the rigidity of its fixing.

Cutting elements for hand files are made according to the method of heat treatment of teeth, which allows you to extend the service life of the product.

It is important to pay attention! A manual hacksaw canvas is not intended for sharpening, so when erasing the teeth, its replacement is required. For today, canvases of bimetal and hot metal (nickelled stainless steel) are produced. They differ in color: the bimetallic canvas is painted in different colors, and a completely red.hot color has a dark color.

When choosing a canvas, attention is paid to its length. The length of the canvas can be from 10 cm to 70 cm. Classic mechanical hacksaw for metal metal allow you to use canvases of 30 cm long, since it is precisely these dimensions of the tool that are as comfortable and convenient for work.

Why do we need hacksroots manual for metal

Hand hacksaw for metal is intended for sawing metal materials. This is not the only purpose of the tool, since it has established itself well in relation to materials such as plastic, wood-brown plate, foam, polystyrene foam, plexiglass, ceramics, laminate.

The peel under consideration for sawing metal is a very necessary tool on the farm, because in the absence of a corner grinder, it can always help in the current situation. to saw off the hat of the oxidized bolt or to cut off the steel wire.

A big drawback of such an instrument is a high cost of physical strength and time. The presence of small teeth is reflected in the time to achieve the result. To obtain a result from the master, an application of not only titanic power is required, but also patience.

The result of prolonged and stubborn work is the as-only result, which sometimes exceeds a cutting grinder.

Types of hacksaw

There are the following types of scabbard for metal:

- Home. The simplest options that are in the set of each master. Such devices are considered an obsolete option, but their production continues to this day. The advantage of these tools is the simplicity of the design. The handle is made of wood, and is located in the same plane with the canvas

- Professional are intended for use in prolonged work. Such products are equipped with a more convenient handle, which in addition can be rubberized. Some expensive models are equipped with a mechanism for adjusting the angle of location of the cutting part during operation

- Mini-cuts or handle-drin on metal has a special shape that differs from the first two types. Such products are intended for use only when difficulties arise with access to the cut part. The device has the shape of a knife with an additional sheet fixation point. The handle is made of plastic and metal with rubber

How to cut with hand hacksaw for metal correctly

A hand file for metal requires the following operating rules from the master:

- Accepting the right rack to the master. With your feet you should rest on the floor well, and the work by the device is performed exclusively by two hands, so initially to be sure to ensure that the workpiece is securely fixed in the sponges of the vice

- Reliable fixation of the canvas. The hacksaw cloths are very fragile, so if the product is “fidgeted” from side to side with poor fixation, then at one point it will simply break

- Correct movements with a saw. To cut the part, you need not only to hold the tool correctly, but also to work with it. The instrument pressed to the sawed part is performed when moving forward, and when returning to the opposite position, the press pressure is weakened. If you do not reduce the pressure of the press with the instrument with the instrument, then the teeth of the canvas will quickly dull

It is important to pay attention! The canvas on the frame of the hand hacksaw for metal should be fixed in the position of the direction of the teeth in the opposite direction from the handle.

The choice of the tool or what you need to pay attention to

To choose the best hacksaw for metal manual, pay attention to the following parameters:

How to install a canvas in a hacksaw for metal. a metallist directory

A metal hacksaw is considered a fairly common manual tool, which is designed to divide the workpiece into several separate parts of a certain size. Its design features are characterized by the fact that it is possible to carry out the periodic replacement of the worker is tight.

When processing metal, it is very likely to quickly wear the cutting edge. Therefore, the function of replacing the tape was provided, for which it takes a small amount of time. There are simply a huge number of different paintings, consider the features of the choice and many other points in more detail.

Types of hacksaw paintings and their design

Do not forget that the production of a working habits is carried out in accordance with the established standards in GOST 53411-2009.

The specified information in this regulatory and technical documentation determines the selection of two main groups: for machine and manual cutting.

It should be borne in mind that the machine canvas for metal is extremely rare, since such equipment is extremely rare. For manual hacksaw, the following execution options are issued:

- A single hacksaw canvas for metal with a distance between the fasteners of the element 250 mm. over, the total length indicator is 265 mm. This version of the performance is suitable for the tool that is used in the absence of the need for great performance.

- Single execution options with a distance between two fasteners of an element of 300 mm. The total length indicator is 315 mm.

- For greater performance, a double hacksaw cloth is installed. The length of this version of the execution, as well as the previous.

When choosing, attention is also paid to the width indicator, which is 0.63 mm for a single execution option, for a double 0.8 mm. Tooth height in the first case is 12.5 mm, in the second 20 mm.

The value and step of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend on. The following alloys are most widespread:

A hacksaw canvas with a tungsten carbide has recently been quite common, since it is characterized by increased wear resistance. It should be borne in mind that spraying can have the most different colors, blue options are found on sale, ordinary steel dark gray.

The hacksaw tungsten in question is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to the bending load. That is why with careless metal cutting, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength of strength due to heat treatment. At the same time, it is worth considering the following:

- The main part of the product is characterized by the hardness of the surface layer near HRC 44-46.

- Depending on the type of material used in the manufacture, the hardness of the tooth varies from the HRC limit from 64 to 67. This indicator is characteristic of alloyed alloys. High-cutting steel is characterized by the fact that it has HRC hardness in the range of 73-78 units.

Do not forget that significant changes in hardness cause the sensitivity of the product to bending. The tool is designed for various loads, it should not exceed 60 kg with a step of 1.4 mm, as well as 10 kg with a tooth step of less than 1.4 mm.

A fairly large number of varieties of such a product determines that with the selection of a suitable version of execution there are no serious problems.

The principles of choice of canvas

It is important to choose the right option for the performance of the product to a specific operational condition. If the surface does not have the required properties, then it will not last for a long period. The selection criteria can be called the points below:

- The most important selection criterion can be called the distance between two fasteners. In some tools, this indicator may vary thanks to a special device.

- The next selection criterion is the strength of the cut metal. If the work provides for the cutting of common soft alloys, for example, copper or aluminum, then the product is selected with the least hardness of the surface layer. X6VF steel is very common, in paintings of imported origin, hCS marking is used. You can also process durable metals for which a hacksaw canvas is suitable for high.speed steel, import marking HSS,

- The thicknesses of the cut metal and the quality that must be achieved after processing is also taken into account. Abroad, the PPI indicator becomes a defining criterion. the number of tops of the teeth per inch length. To ensure high quality, PPI is required more than 24, if the priority of performance is required, then the option is selected with an indicator of less than 24.

- When choosing, attention is paid to the quality of breeding cutting. This parameter must comply with the norms that are established in the previously given GOST. There are three main execution options: breeding for each, through one tooth or two adjacent.

Many are looking for a hacksaw canvas, which can last for a long period. It should be borne in mind that the quality of the applied coating affects the operational period. The use of inexpensive substances becomes the reason why, when heated, a large number of cracks appear on the surface.

The quality is also affected by the uniformity of wiring. A good hacksaw canvas for metal is not more than 45% for a length of 10 mm.

Also, a visual inspection allows you to determine how equal in height individual teeth.

Exact results can be obtained when using a micrometer or other measuring device with high accuracy.

How to install a canvas on a hacksaw for metal

The design of the tool in question allows you to quickly replace the hacksaw cloth.

Kryzuvka for metal how to put the canvas correctly?. metals, equipment, instructions

Metal cutting is laborious, in need of serious patience, and requiring good tools.

One of the most common tools is a scabbard for metal. Basically, the type of hacksaw is approximately the same, the mechanism of replacing the canvas is different.

Two fasteners of the canvas are common, this is a threaded clamp, the canvas is fixed and pulled by a special nut with a lamb.

Another type of mount is a lever mechanism. The scabbard for metal in this case is removed and installed with the participation of a small lever.

In the latter case, according to manufacturers, the removal and installation of the canvas occurs faster. But the cost of such a hacksaw is much more expensive.

It is so difficult to imagine a person who would work without looking up with a hacksaw all day, and the speed of replacing the canvas would be very important for him.

Therefore, the choice of the mechanism of fastening the hacksaw for metal depends solely on your desire, no more. Well, from the completeness of the wallet too.

Knife canvases on this day. The choice is primarily between domestic and imported manufacturers.

Domestic canvases do not differ in quality, they quickly dull, the teeth fall out. But their cost is five, and sometimes fifteen times lower than foreign.

The canvases for metal are still distinguished as hot and bimetallic. The latter more flexible, less often break, but also more expensive than hot.

Carebout canvases differ in the number of teeth, they come from 18, 24 and 32 teeth.

For the cut of more solid material, you need to take a canvas with a large number of teeth, and vice versa.

If you take the canvas for metal with a small number of teeth for the cut of solid material, then it will be much more difficult to saw.

It is necessary to install the canvas in a hacksaw for metal correctly, the teeth must be directed in the opposite direction from the working.

Only in this case, less strength will spend less strength to work with a hacksaw and it will go easier and faster.

How to cut metal with a hacksaw?

To be honest, I don’t know any special secrets, but there are some nuances that should be observed.

About 30 years ago, when it was not particular who was not particularly about fortunes and grinders who heard all the work with the metal with an ordinary hacksaw for metal. And manual drill.

Firstly, I would advise you to choose a hacksaw, as in the second photo. This option is more convenient to work. It’s just more convenient to hold it in your hands and the handle will not slide in the hand.

When installing the canvas, you should pay attention to the correct location of the teeth. As shown in the photo, they should go away from the cutting. When cutting, you need to use the force when the saw comes from itself. Returning the saw back, you need to raise the handle slightly and loosen the pressure on the saw itself. So the teeth will remain in working condition longer.

It is also worth paying attention to the tension of the canvas when installing it in the saw. If the canvas is slightly stretched or too pulled, then with the slightest fluctuation of the saw, it simply breaks.

Well, so that the canvas does not gnaw, you can drop a couple of drops of oil into the section of the section.

Well, do not forget that the metal that is cut can simply be broken down. That is, sometimes it is enough to saw off half, for example, pipes or a corner, and simply break the rest, by bending in one and the other side.

There are no secrets. You need to remember a few important points and the metal will be dissipated like an oil on a knife.

You need to select a saw with a comfortable handle and strong. Choose a canvas not from cheap, but with spraying on the teeth of a durable composition. The canvas placed in the saw so that the teeth of the canvas are with the direction from you.

When performing a split, you need to actively use force when driving a saw from yourself and just without loading to move from yourself.

Try to perform the cut with the position of the canvas with the maximum area of contact of the teeth of the canvas with the surface of the object, which must be cut or filled with.

As for the split of the pipe, it is enough to put the pipe to half and a little more, as it can break clearly under your little effort. Much depends on the thickness of the pipe and its age.

As many colleagues have already noted, when performing work using a hacksaw for metal when cutting (sawing) it is necessary to pay attention to the following points:

- durable and with a comfortable handle of a saw frame;

- high.quality and appropriate step for a specific metal (depending on the viscosity and hardness of the metal) hacksaw canvases;

- The direction of the teeth is installed from yourself;

- hand movements should be smooth and with a wide amplitude.

As for the nuances, I can say that the hacksaw.material with high hardness and fragility and is afraid of overheating. Therefore, make constant stops at work and the saw will serve you for a long time.

The secret of your friend is more likely not in the way to work with the tool, but in the tool itself. The handling of a hacksaw for metal is taught at school (many did hammers, corners, etc.D.), for this there are no special secrets: put the canvas correctly and hold evenly when you saw.

But in my practice there were special canvases for metal (I don’t remember exactly where: either with the fur. saws, or from what other machine, but not the point.

), which lightly cut the pipes in the apartment and other metal objects that were easier to cut with a hacksaw than for the sake of this case to spin a corner grinder.

I can offer several recommendations that will accelerate the sawing of the metal with a hacksaw:

- use a hacksaw with a strong frame made of composite materials.

- For work, buying canvases is better bimetallic, with hardened teeth.

- For metals of various hardness, select a canvas with the corresponding number of teeth:

For soft metals, the number of teeth should be minimal-16-18pcs/inch.

for solid metals. maximum (32 teeth per 25mm).

Crossbow canvas for metal. How to choose and how to put?

Types of hacksaw paintings and their design

Do not forget that the production of a working habits is carried out in accordance with the established standards in GOST 53411-2009.

The specified information in this regulatory and technical documentation determines the selection of two main groups: for machine and manual cutting.

It should be borne in mind that the machine canvas for metal is extremely rare, since such equipment is extremely rare. For manual hacksaw, the following execution options are issued:

- A single hacksaw canvas for metal with a distance between the fasteners of the element 250 mm. over, the total length indicator is 265 mm. This version of the performance is suitable for the tool that is used in the absence of the need for great performance.

- Single execution options with a distance between two fasteners of an element of 300 mm. The total length indicator is 315 mm.

- For greater performance, a double hacksaw cloth is installed. The length of this version of the execution, as well as the previous.

When choosing, attention is also paid to the width indicator, which is 0.63 mm for a single execution option, for a double 0.8 mm. Tooth height in the first case is 12.5 mm, in the second 20 mm.

The value and step of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend on. The following alloys are most widespread:

A hacksaw canvas with a tungsten carbide has recently been quite common, since it is characterized by increased wear resistance. It should be borne in mind that spraying can have the most different colors, blue options are found on sale, ordinary steel dark gray.

The hacksaw tungsten in question is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to the bending load. That is why with careless metal cutting, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength of strength by heat treatment. At the same time, it is worth considering the following:

- The main part of the product is characterized by the hardness of the surface layer near HRC 44-46.

- Depending on the type of material used in the manufacture, the hardness of the tooth varies from the HRC limit from 64 to 67. This indicator is characteristic of alloyed alloys. High-cutting steel is characterized by the fact that it has HRC hardness in the range of 73-78 units.

Do not forget that significant changes in hardness cause the sensitivity of the product to bending. The tool is designed for various loads, it should not exceed 60 kg with a step of 1.4 mm, as well as 10 kg with a tooth step of less than 1.4 mm.

A fairly large number of varieties of such a product determines that with the selection of a suitable version of execution there are no serious problems.

What are made of

The modern canvas for a hacksaw for metal is made of the following types of steels:

- Carbon. differ in low strength indicators, so you can use them for cutting non.ferrous and soft metal. The headset of this class has HCS labeling, and the degree of strength does not exceed the values of 44-46 HRC.

- High.speed. have high indicators of resistance to abrasion and wear of teeth, but their disadvantage is fragility. High-speed saws are marked by the HSS designation and have a degree of hardness up to 73-78 HRC. There are canvases made of high-speed steel with diamond spraying, which have a degree of hardness up to 82-84 HRC. a piece

- Bimetallic. received this name due to the use of two types of steel. Their production made a splash in the market, quickly displacing their analogues. The basis of bimetallic paintings includes materials such as carbon steel, on which a strip of high.speed steel is welded. Such types of devices are indicated by the letters of BIM, and in terms of strength they are such as high.speed, only due to the use of carbon steel as the main material, they have high strength and resistance to deformations

- Alloyed instrumental steels are modernized models of carbon analogues that are made by alloying carbon chromium, tungsten, vanadium, silicon, etc.P. The alloy allows you to achieve high strength indicators, and the degree of hardness is slightly lower than that of high-speed steel, and is 67-67 HRC.

The hardness of the manual sawfish characterizes the sensitivity of the equipment to the tension of the bend, therefore, depending on the used cutting devices, it is necessary to take into account the force attached to the hacksaw during operation.

Typically, the amount of force should not exceed the indicator of 60 kg, which is characteristic of the equipment that has the size of a step of teeth equal to less than 1.4 mm. If the size of the teeth is more than 1.4 mm, then the load should not be more than 10 kg.

The principles of choice of canvas

It is important to choose the right option for the performance of the product to a specific operational condition. If the surface does not have the required properties, then it will not last for a long period. The selection criteria can be called the points below:

- The most important selection criterion can be called the distance between two fasteners. In some tools, this indicator may vary thanks to a special device.

- The next selection criterion is the strength of the cut metal. If the work provides for the cutting of common soft alloys, for example, copper or aluminum, then the product is selected with the least hardness of the surface layer. X6VF steel is very common, in paintings of imported origin, hCS marking is used. You can also process durable metals for which a hacksaw canvas is suitable for high.speed steel, import marking HSS,

- The thicknesses of the cut metal and the quality that must be achieved after processing is also taken into account. Abroad, the PPI indicator becomes a defining criterion. the number of tops of the teeth per inch length. To ensure high quality, PPI is required more than 24, if the priority of performance is required, then the option is selected with an indicator of less than 24.

- When choosing, attention is paid to the quality of breeding cutting. This parameter must comply with the norms that are established in the previously given GOST. There are three main execution options: breeding for each, through one tooth or two adjacent.

Carpentry electrical.burning

The carpentry electrofiger cuts out a thicker sheet layer than a locksmith, for example, a 12 mm thick steel sheet and a profile material 8 mm thick. This is explained by the greater power of the tool (on average about 550 W) and a longer stabbings of the hacksaw.

Cutting speed

On electronics, you can set the cutting speed that is optimally suitable for a particular material, and thereby ensure the safety of the hacksaw cloth. The use of a very flexible bimetallic canvas allows you to cut parts even a flush with the surface of the wall. However, long straight sections with electronics is hard to perform.

Relief of cutting

The hacksaw canvas will slide better if it is wiped with a soap solution or a special emulsion to cool cutting tools. In addition, the greased canvases remain sharp longer and not heat up so quickly.

The advantage of the carpentry electro.burning is the ability to cut the material, including metal, with a flexible narrow canvas without hard fixation of the tool itself.

Shliovaly machine

Processing and cutting thick.walled profile products, as well as sheets with a thickness of more than 2 mm. this is the scope of the angular grinding machine. Usually the work is carried out on hand. To those who often perform transverse cutting of products, it is recommended to purchase a suitable rack.

Hard consolidation

Cutting the material with the machine requires some skill and can only be carried out using special grinding circles. The processed part must be securely fixed. During operation, you should not allow the distortion of the machine.

Safety

You can work with a corner grinding machine only in protective glasses, mittens and non.flammable clothes. You can use the pro-pivot respirator and sound insulating headphones. If the work is carried out in closed rooms, then flammable substances should be isolated, since sparking occurs during cutting.

The corner grinding machine can be cut the thickest profile material. The capabilities of the machine limits only the diameter of the cutting circle.

Chisel

Such works, such as, for example, breaking holes in thick sheets, cutting rusted nuts, cutting thick wire, are best done with a chisel.

The instrument blade should have an angle of pointing 40-60 degrees, be sharply sharpened and well-hardened. If the cutting edge after several strokes is stupid or deformed, the tool is clearly unsuitable for further work.

The most used flat chisels and cruisers. The cutting part of the flat chisel has the same width as the handle. Kreutz Maycele has a blade across the handle and much already. For cutting curved openings, the blade can be slightly stuck around the edges, giving it a convex shape.

Follow the safety rules

Working with a chisel, put on protective glasses: bouncing pieces of metal can be hard to injure eyes! It is also necessary to work on a thick (15-20 mm) steel lining and be sure to use the mittens.

The chisel is placed on a fishing line for a trimmer of marking with a small slope. under the blow of the hammer, the blade cuts the material.

Types of hacksaw paintings and their design

Do not forget that the production of a working habits is carried out in accordance with the established standards in GOST 53411-2009. The specified information in this regulatory and technical documentation determines the selection of two main groups: for machine and manual cutting. It should be borne in mind that the machine canvas for metal is extremely rare, since such equipment is extremely rare. For manual hacksaw, the following execution options are issued:

- A single hacksaw canvas for metal with a distance between the fasteners of the element 250 mm. over, the total length indicator is 265 mm. This version of the performance is suitable for the tool that is used in the absence of the need for great performance.

- Single execution options with a distance between two fasteners of an element of 300 mm. The total length indicator is 315 mm.

- For greater performance, a double hacksaw cloth is installed. The length of this version of the execution, as well as the previous.

The value and step of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend on. The following alloys are most widespread:

A hacksaw canvas with a tungsten carbide has recently been quite common, since it is characterized by increased wear resistance. It should be borne in mind that spraying can have the most different colors, blue options are found on sale, ordinary steel dark gray.

The hacksaw tungsten in question is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to the bending load. That is why with careless metal cutting, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength of strength due to heat treatment. At the same time, it is worth considering the following:

- The main part of the product is characterized by the hardness of the surface layer near HRC 44-46.

- Depending on the type of material used in the manufacture, the hardness of the tooth varies from the HRC limit from 64 to 67. This indicator is characteristic of alloyed alloys. High-cutting steel is characterized by the fact that it has HRC hardness in the range of 73-78 units.

Do not forget that significant changes in hardness cause the sensitivity of the product to bending. The tool is designed for various loads, it should not exceed 60 kg with a step of 1.4 mm, as well as 10 kg with a tooth step of less than 1.4 mm.

A fairly large number of varieties of such a product determines that with the selection of a suitable version of execution there are no serious problems.

Classification of saws by type of holder

Crossbrushes for metal use several types of holder:

The pulp of the saw canvas makes the torture more rigid, which in turn provides a saw of high reliability and durability. Of course, there are some locksmith operations that do not require tension from the saw.

Hacksaws with a stretch fabric is the vast majority of sawing metal. In such hacksaws, the canvas is attached between the ends of the bracket holder. Saws of this type are equipped with a mechanism of thin adjustment of the sawing canvas.

Hacksaws with a canvas without a tightness have a marked area of application. In such saws, the canvas is simply inserted into the handle, and approximately in the center of the canvas there is a stubborn video or supporting bracket.

In saws without an tight.fitting, the cutting part from the center to the opposite handle of the end simply hangs freely. This is done so that a thin gear passes freely in hard.to.reach places. Yes, the reliability of such saws is low, but in return hacksaws without a tightening of the canvas provide the ability to cut in cracks and gaps.

What else you need to know about the types of scabbard for metal.

Operation and manufacture of hacksaw for metal

You can cut a metal workpiece in different ways. using power tools, industrial equipment, heat treatment. Classic tool for cutting parts. Kryzuvka for metal. With its help, you can saw blanks of metal and other materials.

Kryazuvka for metal

Characteristics and purpose

The main purpose of the hacksaw is to saw off different materials. The main one is metal, but since there are a lot of small teeth on the blades with its help can be separated:

- plastic;

- ceramics;

- polyvinyl chloride;

- Styrofoam;

- wood-cutting stoves;

- laminate;

- plexiglass;

- wood.

When choosing a hand tool, you need to pay attention to the canvas. The blades are made according to the requirements of GOST R 53411-2009. This document describes the standards according to which the canvases for hacksaw are divided into three groups, have differences in size:

- Double. The distance between the holes for fixing in the clamps is 300 mm (permissible error 2 mm). The length of the blade is 315 mm. Teeth height. 20 mm. Thickness. 0.8 mm.

- Single. The distance between the fasteners for fasteners is 300 mm. Permissible error. 2 mm. Total length. 315 mm.

- Single shortened. The distance between the fasteners for fasteners is 250 mm. Total length. 265 mm.

The height of single paintings is 12.5 mm, the thickness is 0.63 mm.

Orgage in packaging (Instagram / Rezka_stekla_soln)

Design

- Fabric for hacksaw on metal. This is a removable element. With its help, blanks are cut from different materials. Is a metal tape on which the wedge.shaped teeth are located.

- Machine or frame. Is an arc that is made from different metals, alloys. The frame is needed to fix the canvas. It can be standard cast or sliding.

- Handles. It can be located in different places.

Modern manual tools can be equipped with additional mechanisms to increase comfort during operation, expand the functionality.

Khspovka canvases (Instagram / Enerteh.by)

Types of hacksaws

- Household. Standard manual tools to perform rare homework. The handle is made of wood, and on the front of the frame the adjusting screw is installed.

- Khosuvka-handrails. A compact tool designed to saw metal in hard.to.reach places. Suitable for fixing broken sawy canvases.

- Professional models. Their main difference is the high quality of materials from which the main parts of the design are made.

It is also necessary to pay attention to the separation of hacksaws according to the type of drive. They are electric and manual. Electric are divided into battery, network.

The former allow you to work without connecting to the network, which makes them more universal, but the batteries are gradually discharging, require charging, which reduces the time of work with the power tool.

Battery models are equipped with special systems to suppress vibrations.

Household hacksaw (Instagram / Ploskogubtsy.ru)

Types of hacksaw paintings

A hacksaw canvas is considered the main part of a hand tool. The productivity of the tool, the accuracy of the cut depends on its type.

13 Ways to Cut Metal

It contains a large number of small teeth. Large teeth to cut the metal will not work.

Blade lengths. 150-300 mm. The canvas can be made of different materials:

Thin from tungsten

Stan strings are made from tungsten carbide. Their length is 30 cm. They are suitable for fixing in the framework of standard hacksaws. String diameter. 2.7 mm. With its help, you can perform accurate cuts. The string is suitable for straight and curved cuts, cutting circles.

Diamond string

The basis of such a string is alloy steel, on which diamond spraying is applied. Coating thickness. 2 mm. The string is fixed in the clamps with the help of rings.

High.quality diamond string should quickly saw different materials. When operating its surface and the working area, you need to moisten with water to avoid overheating.

It is better to choose an arc with a handle and fix a diamond string on it. Such a hacksaw is cheaper than a professional manual tool, but with its help it will be possible to cut metal, concrete, stone, ceramics, etc. D.

Diamond string (Instagram / Abraziv_ykt)

The principles of choice

When buying a hacksaw for metal, you need to take into account a number of criteria. It is important to study the strengths, weaknesses of the tool, understand the manufacturers.

Criteria

- The material from which the pen is made. Comfort when working with a hacksaw will depend on this. It is better to choose handles with rubber lining.

- Club shape, their size. They should not be large to cut the metal without problems.

- The size of the canvas. Depends on the length of the cut blanks.

It is better to put aside a tool with a hollow handle, because with strong pressure it will break.

Mini-Nogovka Metal (Instagram / Wedotools)

Advantages

- simplicity of design and its maintenance;

- low weight;

- performance of work in any conditions;

- reliability, durability;

- the possibility of sharpening;

- application for sawing different materials;

- Convenience in work.

Manufacturers and prices

Assortment of hacksaws (Instagram / Stroi_it)

Principles of operation

In order for the cutting of the metal to be more effective, when working with a manual tool, it is necessary to adhere to some rules:

- You need to hold the tool with two hands so that the canvas does not bend. Benches are better to fix in a vice.

- The convenience of using the tool can be increased if you change the cut angle.

- Pressure when moving forward must be increased, when moving back. reduced.

- It is important to practice in advance in fixing the canvas in the clamps. It is important that it does not move when sawing.

Before starting to work with a hacksaw, you need to check the sharpening and integrity of the teeth, their location relative to each other. If there are irregularities, teeth diverge in different directions, you need to replace the canvas.

Hacksaw for metal manual its purpose is the views and how to choose

The demand for hand hacksaws for metal remains relevant, since this type of tool has many advantages and only one drawback. This is the first tool that was invented by a person for cutting metal blanks.

Today, in the arsenal, every honor of himself has at least one option among different types of this tool.

Hand hacksaw for metal is popular in that the tool is always ready to work in the absence of a corner grinder and electricity.

Structural parameters of manual knife stabs for metal

The hacksaw for metal looks quite simple:

- The base or frame of the “P” of the figurative shape is mainly from metal

- Handle of different forms for handmade

- Metal canvas for manual hacksaw or cutting element fixed along the edges of the frame

These are the main elements that make up hand hacksaws for metal. An important detail is a canvas having a characteristic type of teeth. Small teeth are intended specifically to work with solid materials.

The canvas is fixed on the frame. For the manufacture of the frame, alloy steel is used. Frames are of different types, shapes and designs. Professional manual devices have the function of adjusting the angle of tilt of paintings. There are such frames that are able to part. This function in the tool allows you to install cutting elements of different lengths.

The handle is also an important node, as it is able to ensure the convenience and comfort of the use of the tool. The handles are of different shapes, and are also made of such materials. wood, metal, plastic. The simplest handle is made of wood, and the bonds of the two-component composition are considered as maximum and comprehensive: metal and rubber insert.

A canvas for a hand hacksaw for metal is a thin tape that is made of hard types of steel, and has a different length. On one or two sides there are a clovice.shaped teeth.

The hacksaw is the most fragile element of the tool, therefore, when working, it is important to control the rigidity of its fixing.

Cutting elements for hand files are made according to the method of heat treatment of teeth, which allows you to extend the service life of the product.

It is important to pay attention! A manual hacksaw canvas is not intended for sharpening, so when erasing the teeth, its replacement is required. For today, canvases of bimetal and hot metal (nickelled stainless steel) are produced. They differ in color: the bimetallic canvas is painted in different colors, and a completely red.hot color has a dark color.

When choosing a canvas, attention is paid to its length. The length of the canvas can be from 10 cm to 70 cm. Classic mechanical hacksaw for metal metal allow you to use canvases of 30 cm long, since it is precisely these dimensions of the tool that are as comfortable and convenient for work.

Why do we need hacksroots manual for metal

Hand hacksaw for metal is intended for sawing metal materials. This is not the only purpose of the tool, since it has established itself well in relation to materials such as plastic, wood-brown plate, foam, polystyrene foam, plexiglass, ceramics, laminate.

The peel under consideration for sawing metal is a very necessary tool on the farm, because in the absence of a corner grinder, it can always help in the current situation. to saw off the hat of the oxidized bolt or to cut off the steel wire.

A big drawback of such an instrument is a high cost of physical strength and time. The presence of small teeth is reflected in the time to achieve the result. To obtain a result from the master, an application of not only titanic power is required, but also patience.

The result of prolonged and stubborn work is the as-only result, which sometimes exceeds a cutting grinder.