How to cut wooden corners on slopes. To plastic panels

How to glue a plastic corner to a plastic panel

A corner for framing is made by hot flexion of the PVC of the sheet. Decorative element makes it possible to choose colors that are suitable for any interior. Application area:

- Window slope inside the house or apartment.

- As an external material for protecting external or internal angles.

- Door or arched opening.

- To protect the angle of wall when decorating with wallpaper.

- Corner protection when finishing with plastic in the bathroom.

- Draping of the joint when decorating external cladding with siding.

A plastic element is a good protector from mechanical exposure, but, like any material, it has advantages and disadvantages:

- The installed corner is used as a finish of the seam at the adjustment site of the finishing materials.

- Long service life. up to 25 years.

- Installation is performed independently, you can stick a corner without preliminary preparation.

- The plastic element is easy to cut, produced by multi.colored.

- Acceptable price.

Why do you need plastic corners on slopes among the shortcomings, the following turned out to be significant:

- Plastic fragile material, so it is necessary to cut it with special tools. it is possible to manifest cracks.

- The combustible finishing element does not tolerate high temperatures.

How to use corner linings for plaster

Of course, it is important to correctly install corner overlays. There are its characteristics and stage for this work, their knowledge will help easily cope with this task

Description of work with different angles and slopes will be told further.

Finishing the internal corners

You can finish the internal corners in turn, or perform work at the same time, in any case perform the following actions:

- Spray is pounced and a primer is applied, equal to the wall by rule, acting from the corner and further. Followed by the corner, making the mixture on the mixture.

- The cell is applied to the edge to the surface, at an angle of 30-40 degrees. Then it is brought to the inner corner, laid on the wall and is grouted up and down. Further, Kelma is attached to the freshly plastered wall with the base, and pressed by the edge.

- Tightly pressed on the tool, thus, it is cleaned. After drying the primer, apply an cover.

- The covering is efficiently aligned with a grater. At the end of processing the corner part of the walls of the gerk is located so that its edge is on the plastered side, and the corners slightly touching the fresh plaster.

- The device move up and down the entire corner, as a result, they get a strictly verified rib between the walls.

You can finish the internal corners in turn, or perform work at the same time.

Finishing the outer angles

With this part of the finish, they also act in one of two ways. At the first, they resort to the use of metal angular profiles, it helps to process both sides at once. The second involves the processing of walls in turn.

- The metal profile is attached with a plaster mixture, after its drying, the surface is primed.

- The corner rail is fixed on the thin layer of the mixture. The mixture is lubricated from the floor to the ceiling. If necessary, the profile is cut off with scissors for metal, so that its length corresponds to the length of the wall.

The metal profile is attached with a plaster mixture, after its drying, the surface is primed.

Roading slopes

Slopes are 90-degree corners of door and window openings. When placing slopes, the same depth and thickness of the plaster are observed. In order for this to work out, they act in stages:

- First, the surface is cleaned and primed;

- The plaster is applied to the dried surface of the slopes;

- Install corners for slopes for plaster, and soak them from above;

- On a dried surface, the slopes are cleaned.

When placing slopes, the same depth and thickness of the plaster are observed.

Types of installation

Installation of wooden slopes on windows in a wooden house can be performed in several ways, so you need to determine and think over the nuances in advance. Slopes of wood can be mounted 12 hours after installing a window box. The construction foam manages to dry during this time, forming the strength of the form. Since the mounting foam is subject to rapid destruction, the finish of the window should not be postponed for a long time. Thanks to operational work, the installation of wooden slopes will show the highest quality results.

You can do the installation of slopes on the windows with your own hands in the following ways:

-

In the first method, the foam is the material of filling the voids. Initially, all panels are measured, adjusted to the desired dimensions using cutting. Pay attention to the corners: it is important that they differ in perfect evenness. Further, the panels are fixed with self.tapping screws in the area of the corner connection. Slopes should be fitted into frame grooves, after which free places are filled with mounting foam. Drop it, taking into account the fact that the sealant at the time of complete drying will increase the volume by 3 times.

Corners for protection

Varieties

Note. Metal corners should not be confused for attaching wooden structures with decorative protective ones, since the first option belongs to the category of fastener accessories.

- To protect the integrity of the cladding, as well as as a decorative element, external or internal corners of wood can be used, although there is no difference between them, since the wood on both sides is the same. Installation, as a rule, is carried out on adhesive compounds of the type of carpentry, silicone sealant, “liquid nails”, and in some cases this is done using self.corrosion screws. Below we present in the table several options for a corner of different wood species, on which the price of the product also depends.

Note. In addition, the wooden corners also include the skirting board (filler) of the same material, but it is used exclusively for internal joints of the wall and floor or wall and ceiling.

- Excellently imitates any breed of wood of a folding profile of wood.fiber slab, four versions of which you see in the upper photo. Its main advantage is that its plate can be bent at any angle that is necessary in each case without any restrictions.

All restrictions are in the standard size of such a decorative product. they are made strictly 2600 mm in length, but the width of each side can have two options. 22 × 22 mm and 28 × 28 mm.

- Perhaps the most common can be called plastic corners under a tree or under any other material, but all of them are made of polyvinyl chloride (PVC) and the angle have either 90⁰ or 85⁰ to increase the fit of the fit.

In addition to color, such profiles can also differ in size. their length is 2700 mm or 3000 mm, but the width of the sides has much more options and can be 10×10 mm, 15 × 15 mm, 20 × 20 mm, 25 × 25 mm, 30 × 30 mm, 40 × 40 mm, 50 × 50 mm and 60 × 60 mm. The installation of decorative elements is carried out on “liquid nails” or silicone sealant.

Corgol of the infantry metal (UP)

- The corner of the infantry metal, although it serves for decoration, is not such an object, since this is a hidden profile and is set for a clear shape and stiffness of the corner of the corner. Its parties have 25 mm in width, and the length can be 2500 or 3000 mm, which is quite enough for standard residential premises.

Note. There is also a flexible oral corner that is made by PVC. But the instructions recommend using it for arched structures, most often it is drywall, to create a clear curved edge.

Installation nuances

There are situations when, during facing work, you cannot avoid the use of wooden corners, for example, in external trim, this is the installation of a block house, where you will definitely have to close joints with profiles with your own hands-other options simply do not exist.

In such cases, fasteners are carried out only with the help of self.tapping screws or, in extreme cases, nails are the most reliable fixation, which is not scary of wind gusts and deformation of the material (no glue for external work is used).

But here it is very important that the joint has strictly 90⁰. otherwise it is better to use two separate plate (boards or flat rails).

If the house made of wood and the interior decoration are the same, then even with plastic windows you will not decorate the sloping with putty or wallpaper. homogeneous materials look much more beautiful.

But, as we have already mentioned, the joint of 90⁰ is important, which will not be here, because the slope almost always has a dumb angle, therefore, it is better to sew polished boards on both sides, as shown in the upper photo and it will no longer be important for you, on how many degrees there will be a turn.

Fasteners on the inside are not necessary to produce with nails or screws. here you can well use various adhesive compositions.

For internal joints, it is much more convenient to use floor and ceiling skirting boards, although in the upper version they are more often called fillets, but can have exactly the same cross section for the ceiling and for the floor.

How To Cut & Install Vinyl Siding on a Gable End Roof

Fixation here is more often carried out on nails or screws, although the use of various adhesive compositions is not excluded. this is already at your discretion. It can be noted that the balcony frame uses metal corners for wood, but, as we have already said, this applies to fastener accessories, and not to decoration.

How to stick corners on slopes correctly: step.by.step instructions

Glue plastic corners at a temperature above 15 degrees when closed doors and windows.

- Prepare the surfaces: align, clean, wipe it from dust, degrease. If textured wallpaper is glued on the wall, it is better to cut a thin strip for better adhesion of glue with a stationery knife.

- Take the corner and attach to the upper part of the opening. Apply marks from the inside. Measure the width of the shelf. Add the resulting number from one and the other from the serifs. Diagonal between cuttings. It will turn out an angle of 45 °. Cut the inside of the corner under 90 °.

- Measure the corners to the side parts of the opening in the same way.

- Apply glue in the center of the corner with a continuous line or zigzag. Do not spare him, but do not overdo it. The glue should fill the entire interior of the corner, but at the same time not to appear around the edges after installation on the slope.

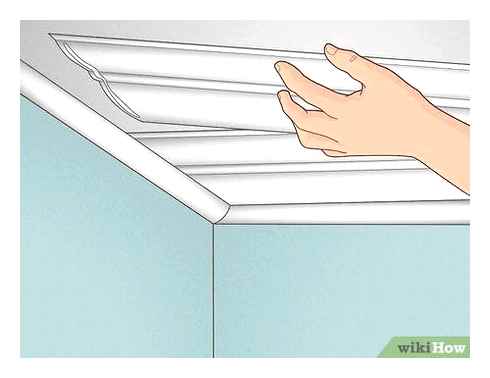

- Set a corner on a slope. Keep in mind that some types of glue should achieve the desired viscosity in the air. In this case, the corner is attached to the wall 3-5 minutes after applying the composition. Read the instructions carefully.

- Press the part with your hand or install supports.

- If excess glue performed on the edges of plastic, remove them. Try not to smear glue on the surface. Traces can be removed with a solvent.

- Withstand the corner under pressure as much as it is written in the instructions.

What to fix for

The choice of the method of fastening the corners to protect the walls of the walls depends on the material of the corner, on which surface they will be attached. Most often used glue. over, in the leaders “liquid nails”. This is a universal composition, but before buying, check that a specific brand can glue the materials you need.

You can plant a corner on glue if it is even, without large flaws. If there are pits/hollows, you are unlikely to glue it. In this case, you can use silicone. If you glue white corners, silicone can be taken white. It is better to take transparent to color. Not everywhere it is advisable to use acidic. Although it is cheaper, it can damage metals or paint.

In both cases, the wall and corner should be clean, dry. The composition is applied to the corner, it is pressed to the corner, fixed with stripes of painting tape. We grab it after 40-60 cm. If everything is even, it is possible after 60 cm, if you need to repeat the form, after 40 cm or even more often.

How and how to glue the PVC corner to the wallpaper

Leave in this state until the glue dries or the silicone hardens. See the exact time on the packaging. Then the painting tape can be removed. It differs from the usual adhesive tape in that even from paper wallpaper it is peeled off without damage to the surface. But to be confident, try to glue and peel off in an inconspicuous place.

A corner of foamed rubber-M-shaped and universal on a self-adhesive basis

There is another option for how to glue the corners on the wall with wallpaper, painting. You can use bilateral tape. Glue it first to the corner, then, taking off the protective coating, press it to the corner. There are corners to which the adhesive tape is already glued. Some types of foamed rubber or plastic (usually flexible or universal).

Cons and pluses of slopes from sandwich panels

The main advantages and disadvantages

The specified type of slopes is performed using mounting foam. high.quality sealant on a polyurethane basis. The material is distributed in the center between two small sheets from the PVC structure.

- No additional processing and decoration of the surface after installing the slopes is not required, because the plane is characterized by a structure that is exactly similar to metal.plastic products.

- Drywall over time is subject to cracking and wetting under the influence of moisture presented in the form of condensate. Sandwich panels for window slopes always remain waterproof and do not destroy.

- If the insulation of sandwich panels is needed, then this is more likely in the measures of reinsurance, because the material does not miss the cold at all. Experts often carry out such measures with the aim of immobilizing and strengthening the design on the window.

- Cleaning the sandwich panel is not difficult, a rag moistened in soapy solution, dust, dirt and even coffee spots are rubbed. If this has not helped, it is allowed to use the detergent that is usually washed, but without the presence of abrasive substance.

- The installation is reduced to a simple and understandable procedure, thus, even a beginner in construction will be able to cope with the installation.

- The life declared by the manufacturer ranges from 15 to 20 years. The slopes are not afraid of hail, strong wind and rain.

It’s time to discuss the minuses of sandwich panels

Rather, they are associated with the low quality of the proposed material, so when buying, pay attention to the manufacturer, do not be afraid to ask the seller-consultant inconvenient questions and demand to show certification

Turn to the quality of the panel material

This is in your interests, because low.quality panels under the influence of sultry weather and high temperatures acquire a yellow tint, which cannot be eliminated and deformed, therefore they are considered extremely unreliable and brittle.

Much depends on the diligence and responsibility of the one who set to install the slopes from the sandwich panels. A careless attitude, haste and mismatch of the installation technology can subsequently lead to the formation of voids between panels and the windowsill.

Sandwitch slopes device

Studying the device of the internal structure allows us to conclude that slopes from sandwich panels are very similar to the usual plastic

If you pay attention to the functional component of these two copies, then you will understand that their technical characteristics are also identical

To make slopes from sandwich panels with your own hands, you will have to collect a few components of the product into one, namely:

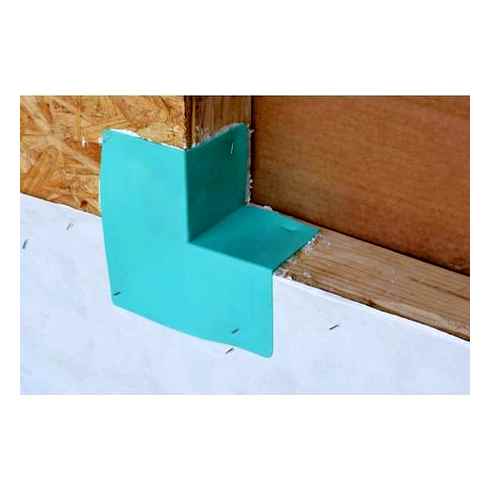

- Profile made of plastic, presented in the P-shaped form. Its other name is the starting profile, because it is from its installation that the installation of the device originates. Fixation occurs directly around the perimeter of the window box, creating the right connection of the slopes with each other and with other important windows of the window.

- A sandwich panel is a composite where polyurethane or polystyrene is located in the center between the plates made of plastic. The thickness of the panel can be very diverse. from 10 to 32 mm inclusive. Which model is suitable in this particular case depends on the free area coming from the edge of the window box to its end. Experts recommend using a universal device, the thickness of which is 24 mm.

- Platband-plastic profile taking F-shaped. The difference from the starting profile is that the platband additionally has a protruding wide part, blocking the joint, which forms during the installation of the structure between the sheet and the angle of the window, which is located on the outer side.

Masters use other methods of arranging sandwich panels. In most cases, brackets fixing the front of the panel due to the attachment of platforms from the type of rail are used. This type of slopes is called European, and the assembly process is more like a designer that allows you to turn the installation of slopes from sandwich panels into a light and fast procedure.

Gluing

The installation of the corner is not difficult if you approach the case without haste. First of all, it is necessary to accurately measure the length of each of the external angles of the slope. After that, blanks are made from the corner. Their size should exceed the length of the slope by 3 cm. This is necessary so that in the process it is easier to fit the elements to each other. This factor must be taken into account when buying corners, t. to. With a large number of windows, it may be necessary to have in stock one additional bar with a length of 270 cm. After cutting the elements, it is necessary to try on them in their place. It is necessary to start installation from the upper bar, t. to. It is easier to fit the side corners to her.

It is installed in its place and marks on the corner along the edge of the slope. After that, the excess part must be cut. But it is necessary not to cut a whole corner, but only that part of it, which will fall directly on the slope, and not on the wall. If the corner goes with a lock, which is designed to fix in a sandwich panel or lining, then the lock is cut at an angle of 45 degrees so that it does not rest against the castle of the adjacent corner. In the same way, the side corners are trimmed. The protruding parts must be shared over that the elements from the lower corners overlap the protrusions from the upper. The next step is cutting the elements at a place at an angle of 45 degrees. Due to this, the excess part is cut off, and the perfect angle of adjacence is provided. Read more this method for the installation of the corner for slopes of the windows is discussed in the video below.

If the fixation is carried out by sticking, then the adjustment of the elements can be carried out in this way with the only difference that there is no need to mess with the lock. If the slopes by the window are made qualitatively, then the trimming of the ends can be performed using the cushed, and not in place, which will partially facilitate the task. Glue to the surface of the plastic corner should bend to bend

It is important to choose the amount that when the lining is pressed to the slope, its distribution under the shelves occurs uniformly

The protruding the remnants of the glue must immediately be removed with a damp washcloth or a rag that does not leave a pile. Before polymerization, the corners must be firmly fixed in order to achieve this can be used by painting tape, which fixes them directly to the surface of the wall and slop. There is a small trick that must be observed when gluing the corner at the site of the wallpaper. The canvas of the wallpaper under the corner should be cut so that the corner can block them. This is done so that after gluing the lining does not fail the wallpaper along with the product.

In some cases, the installation of the lining can be made using small screws. It is worth doing only when the rest of the methods are not suitable. The option with self.tapping screws is applicable to such strips that have a thickness of 1.4 and more than millimeters. In this case, it is necessary to accurately outline where the screws will be located. A drill with a diameter that slightly exceeds the diameter of the cutting edge of the screws drunk holes. The upper part is additionally expanding so that the self.tapping head is partially or completely drowned. To completely hide the heads of self.tapping screws, furniture pads or stickers are used. Fixing places will remain visible, so this method is better to use as a last resort.

A few words about tools and materials

Floor skirting boards are now made of wood or polyvinyl chloride (PVC), in other words, from plastic. The ceiling fillets have a little more list:

The assortment of ceiling skirting boards is much wider than that of the floor.

- Polyurethane. these skirting boards have good elasticity and can bend radial and other curved surfaces, but they need to be cut to clear corners in any case;

- Foam. the easiest budget option, the price of foam plinths is low and they are cut very easily;

- PVC. the principle is the same as the floor skirting boards, but the lineup is much wider;

- Wooden. similar to the floor, only there are still wide models;

- Gypsum-with the advent of polyurethane and foam, gypsum ceiling fillets faded into the background, firstly, they are heavy, and secondly, fragile. But in fairness to mention them is worth.

Since it is impossible to correctly cut the ceiling skirting board and its flooring with a good tool, we will dwell on this issue a little more.

The best, almost ideal tool for cutting any skirting boards and not only is a trim saw with a rotary bed. The high.speed disk makes smooth and exact sections, and the bed in these units turns to any corner. The problem is only in the serious cost of this tool.

The end of the saw is almost the perfect tool for cutting skirting boards and not only their.

It is believed that one of the best hand tools for the exact cut of small bars is a training saw. In principle, this is true, but I will tell you honestly, really high.quality saw, even with the current assortment it is not easy to find. If you still decide to buy a similar tool, then take a saw with a small tooth.

Theoretically, polystyrene and polyurethane can be cut by any sharp and durable knife. But at the same time you need to have a firm hand and at least a little experience in cutting foam. Plus wide fillets with a knife is very problematic to cut.

Without experience, making a clear cut with a knife is very problematic.

Personally, in the absence of ending, I use only a hacksaw for metal. It is suitable for cutting absolutely any material, from foam and to wood. By the way, they often ask the question of how to cut a plastic skirting board for the floor, and so. take a hacksaw for metal and you definitely won’t make a mistake.

For cutting skirting boards, a hacksaw for metal is considered one of the best tools.

Three working methods for pruning plinths

In floor and ceiling skirting boards, the instructions for cutting are almost the same. But if on the floor of the crooked corner you can cover something, then on the ceiling this is already a problem, so we will pay more attention to how to cut the ceiling skirting boards.

Classic knocking method

Classic knock is a P-shaped bed with slots in opposite sides. A suitable part is put in this bed and is sawn through the slots in the sides. The idea is not new, the instrument is already several hundred years old, but, despite the simplicity of how to correctly cut the angle of the ceiling skirting board with the help of such a cashed, not everyone knows.

How to cut a ceiling skirting board in the corner with the help of a classic chusla, not everyone knows.

Совет: потолочные плинтуса при подрезке прикладываются к тому борту стусла, который находится ближе к вам, а напольные плинтуса наоборот, нужно прикладывать к дальнему от вас борту инструмента. Это не догма, но так работать гораздо легче.

It’s easier to work with floor skirting boards, as the knock lies on a horizontal plane easier for you to navigate in the position of the skirting board. People are most often mistaken when cutting a ceiling fillet, it is simply incorrectly invested in the tool. There is a simple but important rule here.

Важно: борт потолочной галтели, который касается стены, должен быть направлен к верхней кромке борта стусла, а та часть плинтуса, которая граничит с потолком, кладется на дно стусла.

At the corner, as you know, 2 sides, and so, in order to less mistakes, accustom yourself to ensure that the bar, which will be mounted on the right side of the corner, put into the knock on the right, and the bar, which is attached to the left, put it in the hand on the left. Details about the intricacies of the use of classical cushed is described in the video in this article.

In addition to the classic P-shaped, there are two more types of such designs-this is a professional and rotary tool. As for the professional option, it is used only by masters. The device is quite bulky, but it turns at any angle and has a hacksaw, which can be fixed in the right position.

Professional knocking with the possibility of fixing hacksaws and details.

The rotary device can be safely called “” stupid. Of the advantages, there is only the possibility of a clear fixation of the angle of turning the bar. On the one hand, they simply work. put a corner, put it to the baseboard and cut off. But on the other hand, you need to get used to such an instrument, if you do not have an experience with a hacksaw, then you should not take a rotary knock.

Совет: при выборе классического П-образного стусла, во-первых не берите китайскую продукцию. А во-вторых старайтесь покупать модели с возможностью жесткой фиксации детали внутри, одна из таких моделей показана на фото снизу.

With a stall with the possibility of fixing the part inside it is much more convenient to work.

Temple cutting method

Most often, both ceiling and floor skirting boards need to be cut under 45º. If a specialized tool is not nearby, then improvised knock can be drawn on a notebook leaflet. From the school geometry course, we know that the diagonal of any square in relation to the base has an angle of inclination 45º.

Then you need to draw a square and hold 2 diagonals in it. this will be the desired 45º. You just have to properly attach the baseboard to the leaf and mark. True, in order to cut off the plinth without guides to cut off a good eye and a faithful hand.

The method is universal applied

Cutting under 45º is a common option, but what to do if you need a different angle, and only a hacksaw and a pencil are available? It turns out that there is a very simple way out of this situation. Plus, this method is universal, it is suitable for both external and internal angles.

over, I can assure you that those angles that visually seem straight a couple of degrees have deviations. As a result, you buy a good tool, cut out clearly 45º, and when joining the gap between the skirting boards “crawls out”. Here this problem disappears. And then, using an example, we will consider how to cut a ceiling baseboard in the inner corner.

How to Cut a Mitered Bridle Joint | Wood Corner Joints

Take a filler, apply it on one side of the corner and with its help draw 2 lines, along the wall and on the ceiling.

Совет: чтобы линии были малозаметными их можно проводить не карандашом а, к примеру, гвоздем или острием ножа.

Important nuances

If you tried, as you could, but a small gap at the junction of it still “got out”, do not be upset. In wooden filters, such a gap is easily covered with furniture wax. To cover the gap on skirting boards made of polyurethane, foam, plastic or gypsum, putty is perfect. Naturally, the color of the composition should coincide with the color of the skirting board.

All the cracks in the area of ceiling fillets are closed with putty.

Wide ceiling fillets are certainly beautiful, but they can only be mounted on perfectly even walls. If the plane of the wall in relation to the ceiling goes in a wave, then it is better to buy narrow polyurethane fillets, they are elastic and will smooth out this drawback.

Most questions arise about how to cut the wallpaper for a ceiling baseboard. There is nothing complicated here: the wallpaper is glued with a small skirting board and when the wall is completely glued, take a large spatula, put it in a corner and cut the excess with a knife with a knife.

But keep in mind. neither a knife nor a spatula can be torn off from the wall until you pass the entire plane. That is, they put a spatula from the corner, cut off the wallpaper along the length of the blade, and then without tearing the blade from the wall, move and cut, until you reach the next corner.

Plastic, wood or wood.fiber plate. What to choose?

After making sure that the installation of corners is not just a whim, but a necessity, we will study the construction market to make the right choice. These products are divided into types depending on the material from which they are made. Yes, the corner can be plastic, wooden, bamboo, from traffic jams or wood.fiber slab. Each type has its pros and cons, we will consider them in more detail.

Plastic corners are made by hot folding from a sheet of polyvinyl chloride. They mainly have the same width of the shelves. From 10 to 40 mm in steps 5 mm. However, there are asymmetric samples, for example, 10×25 mm, but regardless of this parameter, the angle between the parties is 90 degrees. If you need to convert the arched hole, this is done using a special flexible profile. Their advantages can be called a relatively low cost, they do not need painting, unlike one tree.

The next type. Cork corners. Such decorative elements are often used for arched openings, but this does not mean that their use is limited by this area. They can also be used to decorate slopes of various shapes. The cork has a number of advantages, including strength, fire resistance, practicality and environmental friendliness. In principle, this material has practically no shortcomings if your pet does not want to sharpen claws, it will damage the surface.

It is also worth noting wooden and bamboo products that will always be a sign of excellent taste and will fit into almost any interior. In addition, we must not forget about their environmental friendliness. However, such elements are slightly more expensive than their analogues from other materials, and, in addition, they often need painting. Even with natural wood, you can compare the material such as a wood.fiber plate, but it is much lower, because wood dust is used to create it.

Photo gallery: materials for finishing

It is clear that the assortment is quite large, and there is something to choose from. But what is guided by this? Of course, no matter how much we want, but almost always the budget is limited. Therefore, first of all, we must proceed from our financial situation. As mentioned above, plastic products have a very reasonable price, while their appearance is not much inferior to the analogues of natural materials. But, in addition to the price, it is also worth paying attention to the fact that these decor elements harmoniously fit into the design of the room.

Varieties of plastic corners

The most common are PVC elements that resemble the letter L, curvilinear. The second option is more often used for arched openings.

There are other options. For example, T-shaped. Apply to conceal joints formed during the installation of the slope on the window. The middle part is inserted into the gap between the wall and the window slope, covering the place of the design of the structural elements.

Samples

There are removable options. Apply less often, more expensive than the rest of the accessories. If you need to carry out repair work (wallpaper glowing), the corner lining can be dismantled, at the end of the work, installed back, clicking on the fixing element.

The wider the side of the corner covering the surface, the greater the load withstands.

Corners to protect wall angles: selection options

This method of design of the walls of the walls. protective corners. does not like everything, but there are no special alternatives. In any case, on the walls of the wallpaper glued, the corner is still better protruding and torn paintings.

Only one solution to the integrity of the wallpaper without the use of decorative corners is available. to make not an acute slope angle, but rounded. In this case, there will be no task with its decoration. It will be possible to simply wrap the wallpaper canvas without cutting it. But you need to remove the angle completely, you will have to cut it again, but, it means that the question will arise again about protecting the joint of the wallpaper on the corner.

It is fundamentally true to choose a decorative corner so that it does not look alien. There are special tricks for this.

The interior in the appropriate style looks good

It is necessary to choose corners to protect the angles of the walls based on the overall design of the room. There are several standard solutions:

Or tone with wall decoration, or tone with doors

Tone with doors. The material is better to choose the same. wood, wood.fiber plate. And pick up the coloring one in one. This technique is often consumed in hallways and corridors, where many doors go out. In the rooms it is more appropriate to select the walls of the walls. In that with skirting boards.

Use one of the additional colors (read about the combination of colors in the interior here), which will not only at the corners, and in the framing of the paintings or in the upholstery of panels, decorative medallions, etc.D. 1st color and textures with flooring.

In general, select corners to protect the angles of the walls, you need to attach to the design of the room. This can be done after furniture is placed and textiles are hung. In this case, it is easier to present the final result. Since the picture in our heads can be very different from reality.

If you can’t choose an acceptable color for you, and you need to protect the corners in the apartment, direct attention to transparent plastic corners. They are of various types. hard, flexible, with different widths of the wall

Plastic, wooden or from wood.fiber slab. which one to choose?

After making sure that the installation of corners is not just a whim, but the need, we will study the construction market in order to make the right choice. These products are divided into types depending on the material from which. So, the corner can be plastic, wooden, bamboo, made from a cork or a wood.fiber slab. Absolutely every type has its pros and cons, consider them in more detail.

Plastic corners are made by hot bending of a sheet of polyvinyl chloride. Basically, they have the same width of the shelves. from 10 to 40 mm in steps of 5 mm. However, asymmetric specimens are found, for example, 10×25 mm, but regardless of this parameter, the angle between the sides is 90 degrees. If you need to transform the arched opening, then this is done through a special flexible profile. Their advantages can be called a relatively small cost, they do not need painting, unlike the same tree.

The next type is corners from the cork. Such decorative elements are often used for arched openings, but this does not mean at all that their use is limited only by this area. They can also be used for decoration of slopes of various shapes. The traffic jam has a number of advantages, among which strength, refractory, practicality and environmental friendliness. In principle, such a material has practically no minuses, except that if your pet wants to sweat claws about it, this will damage the surface.

It is also worth noting wooden and bamboo products, which will always be signs of excellent taste and fit into almost any interior. In addition, one must not forget about their environmental friendliness. True, such elements are somewhat more expensive than their analogues from other materials, and besides, they often need painting. Even with natural wood, you can compare such material as a wood.fiber plate, it only costs significantly lower, because wood dust is used to create it.

Photo gallery: materials for finishing

It can be seen that the assortment is quite extensive, and there is something to choose from. But what to be guided by this? Of course, no matter how much we want, but almost always the budget is limited. Therefore, first of all, we have to proceed from our financial situation. As mentioned above, plastic products have an acceptable price, while their appearance is inaccessible to analogues from natural materials

But, besides the price, you should also pay attention to the fact that these decor elements harmoniously fit into the design of the room

PVC corners are widely used and are used in the following areas:

decoration of internal window slopes, where they are used as additional protection and decor element; shelter of mounting foam in the inner angles from the outer side of the window and protecting it from the harmful effects of the ultraviolet rays of the sun; framing the door, slopes and arches; prevention of damage to corner ledges during operation walls covered with wallpaper; additional reinforcement of the joints of the GPL; the design of the angles obtained after laying tiles in the bathroom; as finishing elements for other types of plastic coating.

Products differ in profile, which is produced in several cross.sectional variants. Widespread corner with the same sides, used to strengthen slopes. The novelty that appears in the market is in demand. a self.adhesive option. The material is practically no different from the usual profile, but has more flexibility.

Due to the presence on its surface of the sticky base, there is no need to buy glue. It is produced in rolls of various lengths, but the maximum value in one package does not exceed 50 m, therefore, for each specific case, you can purchase the most suitable type of packaging.

In the case of decorating arches, the profile with different sides is more in demand. T-shaped is necessary to hide the angle between the wall and the slope, when connecting various finishing materials that differ from each other in texture and pattern. Laid on the floor when laying tiles, it ennobles the irregularities of the tile in places of its contact with the floor surfaces or walls.

Another popular option is a removable profile equipped with a latch, which has increased flexibility, good protective functions, so it is very convenient to work. In addition, plastic corners, depending on the type of closed corners, are distinguished by external and internal.

How to cut PVC panels?

is one of the most popular materials for the interior decoration of the room. Its use in the interior attracts not only the appearance, but also an affordable price, ease of maintenance and installation. Thanks to the listed characteristics, many people prefer PVC panels, not tiles, when decorating personal hygiene rooms.

This tool can be called the main. A jigsaw well has a minimum of shortcomings. You can cut the panels along and across. You can cut figures with ovals and other broken things.

The jigsaw has a feature. He tears the edge of the panel in places where it remains to cut very little. At this time, very often panels burst (especially in the cold).

Therefore, it is worth using a file with a minimum tooth. For ourselves, we chose a Bosch metal canvas with a tooth of 0.8 mm. This saw will protect you as much as possible from a torn section.

If the jigsaw works at high speeds, you can cut such a file very quickly. This saw for metal, from cutting plastic products, it does not stupid.

The main plus of the jigsaw is universality. Cut the PVC panels, you can both along and across. In any spatial position.

The downside of the jigsaw is weight, the presence of a wire. With an incorrectly selected canvas. torn cut.

There is one secret

When you have to harvest a lot of sticks, frame size. For example, it is necessary to cut off at once 20-30 pieces.

And so as not to cut one piece each time, but increase the speed. You can resort to one secret.

You will need clamps (bench presses) as in our photo. Take several at once, usually 5 pieces. Consider that they do not stick out a friend-drill and clamp them with bench presses. Two pieces on each side of the panel.

And saw calmly. In this way you can cut to 5 panels. You can cut off more, but the Bosch saw does not give such an opportunity.

You will expel the cutting process five times and make your work simpler.

The wood.fiber slab, XDF, wood.fiber slab, plywood, etc. cut it.

We offer a rectilinear and figured sawing according to your sizes of all types of sheet materials: laminated woody stove, wood-fiber slab, plywood, wood-fiber slab, wall panels, countertops, etc.D. The work uses the most advanced technologies for the manufacture of furniture parts on Italian and German equipment with diamond discs.

| Cut the wood.fiber plate (laminated) | ||

| For physical. persons | For furniture. Org. | |

| Sprinkled material with a thickness of 8 mm, 10 mm, 16 mm | 20.4 /m.P. | 17 /m.P. |

| Sprinkled material with a thickness of 22 mm, 25 mm | 22.8 /m.P. | 19 /m.P. |

| Sprinkled material with a thickness of 32 mm, 38 mm | 30 /m.P. | 25 /m.P. |

| Sprinkled corners | 48 /pc. | 40 /pcs. |

| Drank a groove under a wood.fiber slab | 36 /pc. | 30 /pc. |

| Quarter | 42 / pc. | 35 / pc. |

| SPIL under 45 gr. | 48 / pc. | 40 / pcs. |

| Gluing details | 360 | 300 /m2 |

| Twisting details | 240 /m2. | 200 /m2. |

| Radius up to 500 mm (16 mm). direct cuts | from 144 /pcs. | 120 /pc. |

| Radius up to 500 mm (25 mm). direct cuts | from 168 /pcs. | 140 /pc. |

| Radius up to 500 mm (32 mm). direct cuts | from 228 /pcs. | 190 /pcs. |

| Radius more than 500 mm (16 mm). direct cuts | from 228 /pcs. | 190 /pcs. |

| Radius more than 500 mm (25 mm). direct cuts | from 300 /pcs. | 250 /pc. |

| Radius more than 500 mm (32 mm). direct cuts | from 360 /pcs. | 300 /pc. |

| Production of a radius template | 240 /pc. | 200 /pcs. |

| Radius on a table of 28 mm | 360 /pc. | 300 /pc. |

| Radius for a table of 38 mm | 432 /pc. | 360 /pc. |

| Mill under the loop | 60 / pc. | 50 / pcs. |

| Kinda milling under the door-wreck | 108 / pc. | 90 / pc. |

| Card Cards (Catting 2) | 36 / pc. | 30 / pc. |

| Cut a wood.fiber plate with a plastic coating, veneer, acryline | |

| For physical. persons | For furniture. |

Classification

There are many PVC accessories in the building materials market.

- The most common. with equal widths of the sides of 2×2, 5x5cm.

- Material with asymmetric sides, more often used to ennoble arched openings. Common size. 10x20mm.

- T, F-shaped. Used to mask the joining elements of the slopes of the opening and walls.

- Elements on the latch. Installation is more convenient, several times faster.

Dimensions

Differ in length (2m 60cm. 3m), width (1cm. 10cm).

Dimensions

- When installing the arched opening, the bar with asymmetric sides will help (5×17, 10×20, 15×25 mm).

- If you need to brush two surfaces, mask the seam, a T-shaped element (12×10, 18×10, 20×10 and 22x10mm) is suitable.

- To strengthen the slope, wide products will be required (20×20, 50x50mm).

- For window opening. planks 10×10, 15x15mm.

Peculiarities

Thanks to the qualities, the material has become popular, is in great demand:

- Used as a masking agent. After the finish of the slope, it forms a right angle.

- With proper operation, it will last a long time. Operational period. tens of years.

- Anyone will cope with the installation of the element, even without experience.

- High moisture resistance.

- Not subjected to rot, mold formation. It is possible to install in rooms with high humidity.

- Helps create even corners on plastered surfaces.

- Metal fittings strengthens the design.

- Products made of wood, plastic, metal, do not harm health, do not emit aggressive substances into the atmosphere.

- Thanks to the small mass, the construction of the window, doorways will not be loaded.

- Resistance to mechanical damage. When exposed to sharp objects, minor scratches remain, it can be removed when grinding the surface.

- Not inclined to collapse, change color from exposure to direct sunlight.

The material has a fraction of stiffness, but can break from significant mechanical influences. It is not recommended to install plastic corners from the side of the street, fragility increases.

You can not have plastic items near easily ignited materials, heating equipment. When burning, plastic emits toxic substances.

Installation of corners on window slopes or doors

Having dealt with what such products are made of, what are their features and having decided on the choice, you should study how to install corners on slopes. Detailed instructions are given below.

What glue to use

In addition to the corners themselves, we will also need an adhesive with which we will attach the selected element. When choosing it, it is worth remembering that quite often, especially if it is necessary to glue a narrow product, the glue seeps from under it and, of course, falls on the walls. As a result of this, the latter can be damaged, which, accordingly, will negatively affect the appearance of the room as a whole. Therefore, you should choose such an adhesive composition, the excess of which can be removed from the surface.

Basically, the corners are glued to new slopes, but nevertheless, check that the surface is relatively flat, since no decoration will be able to hide large hillocks. It should not have foreign objects like nails, screws, etc. D. It also needs to be degreased, for this purpose, white spite.

How to cut it correctly

Before discussing how to fix the corners on slopes, you should find out how to cut them correctly. After all, this stage of everything is the most time.consuming and, perhaps, even the most important, since it depends on how their edges will joke, and this directly affects the aesthetic appearance of the entire room. It is best to cut with a hacksaw with a small tooth. First you need to measure the length of the opening, then apply the marks to the corner so that the segment corresponds to this parameter. Then the part that will fit directly to the slope is cut strictly according to the marks, and the one that to the wall is at an angle of 45 °.

To cut the corner, use a hacksaw with small teeth

How to glue

Finally, we got to the main question of how to stick corners on slopes. However, before proceeding directly to fixation, it should be carried out, so to speak, fitting. After making sure that everything is cut correctly, you can move on. Apply to the inside of the corner, at the junction of the sides, gluing a solution with a step of approximately 10 cm. At this stage, an indispensable assistant will be a mounting gun. After that, quickly press the product to the surface and fix it in this position with a painting tape. You should start with a horizontal slope, and then proceed to the side. Remove the excess sealant from the surface of the walls with a damp cloth and let it dry well. You can remove adhesive tape only after 24 hours.