How to drill a canvas canvas hacksaw.

How to drill a hole in a ribbon saw. How to drill potato steel, methods. The basic principles of sharpening

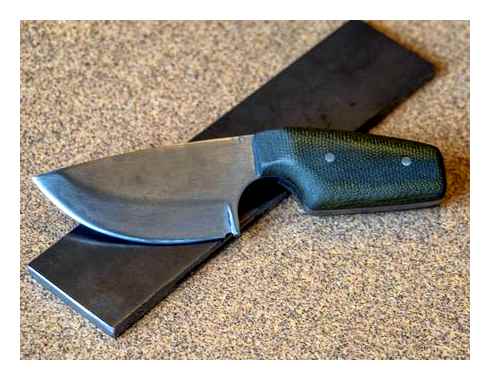

How to drill the high.speed steel of the p6M5 or HSS brand according to the European designation? For example, we made a knife from a canvas from a mechanical saw, and it is necessary to drill holes with a diameter of 5-6 mm under the pins for installing and fixing the linings of the handle in it.

The same operation may be needed for drilling the canvas of the hacksaw on metal from steel 1x6VF, from which you can make some useful products. A piece of the canvas from a mechanical saw of steel 9XF is suitable not only for the manufacture of knives, but, for example, non.standard key fobs.

How to drill a hacksaw on wood

And even if they already thought about many disc saws, chainsaws and jigsaws, there should still be a wooden saw in the arsenal of the wizard. How to choose a hacksaw, what to pay attention to and which brand to give preference and even a little story. All this is waiting for you below.History reference

Thanks to archaeologists, we know enough about pollen. The first documented records of manual dust belong to ancient Egypt and date about 3000 g. BC.e. There is only one riddle, because they used dust. Even the frescoes inside the pyramids diverge: some demonstrate saws for carpenters, others disassemble stone.cutting, while others demonstrate torture with a hand saw.

The hacksaws of that time were made of copper, and with the advent of iron they became much stronger. Although the shark teeth were found on some islands of Indonesia. If you improve them a little (increase the handle and add your teeth), you will get an excellent near.fight weapon.

By the way, every nation is trying to answer authorship. For example, in China it is believed that someone Lu Boon invented a hacksaw. But the Greeks consider the Ovid: the poet wrote that the invention of the hacksaw was the work of the dedica nephew named Talos.

How to choose a hacksaw for wood

Each hacksaw has its own characteristics that determine its use. Choosing this tool for yourself, you must decide in advance for what operations it will be used. For example, for the cross section of the fibers or in the longitudinal direction, cut the tree branches or dust of the floorboards, cut the wood stove or perform only the beginning of the section, and then continue to work with another tool.

How to Hang Your Canvas | MYPICTURE

-

The length of the canvas.This is a very important indicator, and to prove this, we will consider a small example. Suppose you need to cut a cross section with a width of 200,000 mm and a blade with a blade length of 350 cm at your fingertips. At first glance, it may seem that there should be no problems, since the length of the blade exceeds the length of the material. However, the incision is performed by reciprocating movements, and on this length the blade of the saw canvas does not leave the incision completely. The hacksaw will quickly clog, and you will complain about bad sharpening or “wrong” material.

It can be seen that with a length of 40 cm, only about 30 cm of the canvas will work. The shape of the handle interferes.

- The number of teeth and their size. The smaller the tooth with a hacksaw, the cleaner the cut. But there is a drawback: cutting with a hacksaw on the tooth will take more time. However, this cannot be completely called the disadvantage, since such hacksaws are usually used for small blanks. The abbreviation TPI (Theyeth Per Inch) is used to determine the number of hacksaw teeth. Literary translation: the number of teeth per inch, that is, the number next to the TPI abbreviation means the number of teeth located one after another at a length of 2.54 cm. The larger the teeth, the less inches, the faster and rude cut. With TPI 7 should be 7 teeth. Yes, all together.

- Tooth shape. Classical form. triangular. But with the development of technology, other forms began to be applied. In particular, the trapezoidal form has become especially common. Sharpen the saw if it has such teeth is very problematic, and not every master can do it. Trapezoidal teeth hardened with hacksaws.

- Steel and hardening. The brand of steel affects the severity and, therefore, the cleanliness of the cut and the duration of the operation. And it also depends on the steel brand, can you sharpen a hacksaw on a tree, consult a master or throw it away and buy a new tool. It is very difficult to polish the hardened teeth from a hacksaw and, as a rule, do not even sharpen them. Dismantling the blade or its sharpening is not a problem.

- Lever arm. It seems simple: the handle looks like a handle, but it should be comfortable. With an external inspection, take a hacksaw if you are ready to work with it. Think about whether it will be convenient for you to keep a hacksaw and keep in mind that you just keep it now, and on your hand, on your fingers and on your hand in general there will be some tension. The number of corns depends on the convenience of the handle, and you always want them to be absent. Rubber handle is much better than plastic.

- Objective. A wood hacksaw can be transverse, longitudinal (along the fibers) or combined. If you buy a hacksaw in a single copy and for unchigning work, it is better to have a combined version. If you consider yourself a master, the answer is obvious: the hacksaw is small. Marking on canvas will tell you everything.

- Price. Like most tools, the quality of the hacksaw is determined by its cost. If you do not know how to choose, start insisting on the price. The more expensive, the better. Naturally, when it comes to brand, and not about a Chinese fake. Dear hacksaw will last longer, and you will need to sharpen it less often or without sharpening. This is cheap, but high.quality hacksaw. Such a rarity.

- The ability to measure the angle. This is not a very important indicator, but it should be remembered. Usually, using a manual saw, you can quickly mark the angle of 90 ° and 45 °. Of course, this is not the best way for accurate measurement, but the error (if any) is small. Accuracy is not so hot, but for gross marking it will be done.

How to drill a saw canvas

Of course, steel should be drilled before heating. And if you come across a hardened workpiece (especially thick). let it go, drill holes with a regular drill and, if necessary, re.approve. But this option is not always possible and justified, sometimes unusual situations arise in which you need to drill (surge) steel, already very hot.

Well, for example, the knife blade is broken, or you decided to make a knife from a piece of saw. It is a pity to throw away such valuable material; Experienced masters usually give such things a second life.

Yes, this is not technologically advanced, but the masters came up with many different ways to drill hot steel or make holes in it. This requires less effort, based on the capabilities and materials you have, as well as on what you need. Instead of a hole, you can be satisfied only with a gap with a grinding machine into which you can insert a screw and fix the part. To make a slot less, you need to do this on both sides and use the cutting disc of the smallest diameter, that is, almost worn out.

Before drilling, you must study steel, how strong (tiny) it is strong, and from here you need to choose methods. If, in the end, the steel bends at least a little, and then breaks (this can be determined by a broken end or by posting a file), it can also be drilled using a conventional concrete drill with winning soldering. However, the drill should be sharp. Sharpening of the drill, the angle of inclination is also very desirable to change (fix), do as a metal drill, then the drilling process will go much faster.

But it is useless to sharpen victory on ordinary sandpaper, you need to do this only with the help of a diamond circle, then this can be done easily and without effort. And if there is no diamond circle. Just take a new concrete drill with winning soldering.

When drilling solid steel, it is necessary to press the drill enough and drill at high speed (if the drill is blurred or not sharpened, like metal), after lubricating the spraying place W-40 or oil. It will be easier to make a hole if you first drill a smaller diameter drill, and then more. The resistance area will be less, which means that the drill will be easier to move to the material.

For example, thin steel under the knife can be drilled with hot or winning rods, you need to grind like a drill, and a few pieces at once (make a visor and sharpen 2 sides) and change as they become dull. A couple of minutes and the hole is ready.

From my own experience, I’ll say that it is good to make holes in hardened steel using broken wells from the entire alloy, I had a couple with a diameter of 6 mm. Having imprisoned it as for metal, he dripped the oil and. Everything goes like clockwork, at a speed of about 600-1000 rpm.

The next method is long, requires several hours, but reliable. The hole in the steel plate can be easily etched with acid: sulfur, nitrogen or chlorine, also 10-15% is suitable. We make a rim of paraffin the desired diameter and shape, lower the acid there and wait. The hole is slightly larger than the diameter of the side side, this must be taken into account. To speed up the process, the workpiece can be slightly heated to about 45 degrees.

If you have a welding machine, it can also be used. The hole can simply be burned in the workpiece or locally “release”, and then drill. Run the edges of the merged edges and order.

Or I managed to get out of the situation in the following way: by marking the place of drilling, you could see, and then, tapping the electrode, heating the metal to the red color in the place of drilling. and then, without waiting for the metal to cooled, I drill steel with an ordinary metal drill. Then I clean the points from welding around and order. And if they manage to drill the hole before the metal cools down. then immediately in the water he will also harden in this place.

In the same way, if you had to slightly expand the hole in the steel plate. He did not take a hot steel folder. Then I was heated by metal with welding, even to cherry, and. Until I caught a cold. straightened it with a round saw. Even if the steel was already almost gray, the file still took it.

Of course, there are special drills for this, but they are expensive. about 4 per piece. These are tubular diamond drill for high.carbon steels.

A pen drill designed to drill glass is also suitable, although not entirely perfect. Use the oeinated drill carefully, do not crush much so as not to break. The plates are thin there, and fragile win.

You can also make a hole in the steel plate by firing, at high speed and using a special carbide tip. To do this, make a special “training”. From a winning plate (you can use a tooth from a circular saw) we make a round blank and sharpen it under the cone. Insert into an electric drill and cut the hole in the stove at high speed. The whole operation takes only a few minutes.

If the steel is not very tiny, for example, a hacksaw or spatula, you can easily break through the hole of the desired diameter using a peorator through the fasteners of the same or slightly larger diameter.

It will be much easier to drill stainless steel if you add soldering acid to a drilling ground.

And if there is access to an enterprise where there is an electric device, then on such a machine the holes can be made without problems, in a matter of minutes.

Well, now all the methods of drilling hot steel. There will be a few more, I’ll add. I have written somewhat since I wrote this article, so come in. And if you have your own unique unique method of drilling hot steel, write.

To improve the main characteristics of the metal, it is often extinguished. This technology involves increasing the hardness of the product due to severe heating of the metal and its rapid cooling. In some cases, after heat treatment, it is necessary to drill. Increasing this characteristic, drilling hot metal becomes more complex. Consider all the features of hot steel drilling in more detail.

The task is to drill a large hole in a tree. Solution. wood crows.

I welcome all visitors to my site, on which I talk about various types of tools, give advice and recommendations for choosing and working by one or another tool. Today we will look at the tool with which you without any problems drill a large diameter hole in a non-thick tree, most often it is plywood, a wood-fiber plate and a wood-piece plate.

Tool. ring saw on wood, most often sold in sets in various saw diameters. This is very convenient. I bought one such set and you can drill holes of any large diameters, of course, if the saws that go in the set you need diameter. Photo of such a set:

The nuances of drilling

The technology under consideration has a large number of features that must be taken into account. Hot metal drilling is carried out taking into account the following points:

- Before carrying out work, it is necessary to pay attention to the hardness of the surface. This parameter is used to select the most suitable drill. Hardness can be determined using various technologies.

- During drilling, a large amount of heat is released. This is why the cutting edge wear out quickly. In this regard, in many cases, coolants are fed into the cutting zone.

- When cutting heavy materials, it is necessary to sharpen the cutting edge from time to time. For this, a regular grinding machine or a special tool is used. As an abrasive, only a circle with a diamond coating is suitable.

There are many ways to cut hot steel. Some of them greatly simplify the processing. Only taking into account all the nuances can I improve the quality of the hole.

We make a high.quality knife from a saw in two and a half hours

From the side it seems that making a knife is easy, that it is only a sharpened steel strip and a wooden handle. But when it comes to practice, the picture changes dramatically. The main thing in this process is knowledge and experience. When you know, everything is simple when there is no experience, everything is complicated.

I recently posted on the Internet a photo with seven blades taken in one day in the Stakhanovo impulse.

Alexander Kudryashov in a comment asked to tell how I am doing even and symmetrical descents.

In response, I joked: “It’s simple: you take a“ magic marker ”, draw even descents, pronounce wonderful words, and even descents are ready”.

But is it really a joke? Joke, of course, but the truth is somewhere nearby.

Later I suggested coming and in practice to see how the right descents are made and the whole knife is entirely. And this proposal was accepted.

According to my idea, Alexander was supposed to participate a little in the manufacture: choose a blank for the blade, a handle material, the preferred length of the blade and handle. From our experiment, Alexander was supposed to leave with a ready, solid, and most importantly, working knife.

Alexander Izdodny arrived, in light pants of sand.colored and fleece jacket of the color of the coyote, which did not suit at all for the upcoming work. He had to give him working pants and a camouflage shirt in case he got dirty. Everything came perfectly. we are with him alone.

In the workshop, work went according to a pre.planned plan. As a material for the blade, an old kind mechanical saw from a quick.cutter was chosen. Why?

This is a well.known and repeatedly tested steel of industrial hardening. Yes, it is difficult to process, but due to red resistance (the ability to withstand heating for a long time without reducing hardness) does not require cooling.

The thickness of the mechanical spike is 2 mm, this is enough for most working knife tasks. The knives of the mechpil are light, they hold sharpening well and, importantly, are completely legal: the small thickness of the blade celebrates any suspicion of involvement in the cold weapons.

In general, there are many brands of high.speed steels, but the manufacturer does not always indicate a specific brand, often limited to the stigma of HSS (High Speed Steel). New saws rarely come across and are more expensive.

For a knife.item, the novelty of the mechanized vehicle does not matter, therefore, for the manufacture of a knife, you can use both a new saw and a pretty worked and even broken. The result will be of little resemble the source material. Of the shortcomings, one can note the tendency of steel to paint during lateral load and its exposure to corrosion.

Alexander chose a suitable canvas of a quick.cutter furpil (HSS Made in USSR). I cut off the excess and made the contour of the future knife on the emery, then processed the workpiece with a kratsovka. a rotating steel brush, giving it a noble black shine, and painted the blade part on both sides with a blue wide marker designed for warehouse work.

On the paint of the marker with a caliper, he marked the lines of future descents, paying special attention to the synchronism of their exit to the butt. The resulting lines circled with a “magic marker” with silver paint, which is nothing more than aluminum powder in a polymer binder.

Why exactly them? Very simple. This paint withstands high temperatures, lies well on the metal and holds firmly. Paints of ordinary colored markers are burned out, erased, and crumbled. And Serebryanka holds on. That’s all the magic.

I installed the blade on a special device for the removal of descents (a reduced version of the adaptation from Chapay, made independently from the steel corner). Marked the place where the descents will begin, and recorded with a manual vice.

I performed the metal removal of the metal with yellow cubitron II from 3M with grain P24 on a machine with an abrasive ribbon (on a greenhouse). For uniformity, I began to shoot metal from the marker mark at the future handle and moved to the tip with uniform slight pressure.

At the same time, it is very important evenly, in parallel, without distortions to apply a future blade to the tape. I let Alexander stand a little at the machine at the initial stage, using special devices. Railing out. a process requiring experience.

Having a little not reaching the silver lines of the “magic marker”, I changed the tape to the abrasive P60 and began to align the fishing line for the trimmer of the descents. Made several movements from an ear to the handle, creating a right angle at the beginning of the descents. Then work began on the risk of descents.

For this, there was enough work on abrasives P80 and P120. Apply for very solid high.speed steels of abrasive P180 and smaller unjustified. This is not Cubitron II, and at such tight steels abrasives work poorly and not for long. At the same time, it is important that the finish processing of the blade is made on one tape, otherwise the parties will look different.

A quick.cutting knife does not require constant cooling during processing, and this is one of the pleasant moments in its manufacture. Of course, the knife should not overheat, because the increased temperature of the steel leads to rapidly clogging the abrasive with sticky particles of metal. to suction.

Excessive clamp of the metal to the abrasive is undesirable for the same reason. A tape clogged with metal, which no longer “gnaws”, but “licks”, you can refresh. To do this, remove the clogged with metal, the licked tops of the abrasive and free the grains lying deeper.

To do it is simple. It is necessary to take the high.speed canvas of the mechpila and easily, like a file, draw them obliquely, towards the moving tape at the place of bending (on the contact video). This action will not give Abrasive pristine aggressiveness, but it will refresh it and will allow you to work again.

How to drill a saw canvas

Of course, steel should be drilled before heating. And if you come across a hardened workpiece (especially thick). let it go, drill holes with a regular drill and, if necessary, re.approve. But this option is not always possible and justified, sometimes unusual situations arise in which you need to drill (surge) steel, already very hot. Well, for example, the knife blade is broken, or you decided to make a knife from a piece of saw. It is a pity to throw away such valuable material; Experienced masters usually give such things a second life.

Yes, this is not technologically advanced, but the masters came up with many different ways to drill hot steel or make holes in it. This requires less effort, based on the capabilities and materials you have, as well as on what you need. Instead of a hole, you can be satisfied only with a gap with a grinding machine into which you can insert a screw and fix the part. To make a slot less, you need to do this on both sides and use the cutting disc of the smallest diameter, that is, almost worn out.

Before drilling, you must study steel, how strong (tiny) it is strong, and from here you need to choose methods. If, in the end, the steel bends at least a little, and then breaks (this can be determined by a broken end or by posting a file), it can also be drilled using a conventional concrete drill with winning soldering. However, the drill should be sharp. Sharpening of the drill, the angle of inclination is also very desirable to change (fix), do as a metal drill, then the drilling process will go much faster.

But it is useless to sharpen victory on ordinary sandpaper, you need to do this only with the help of a diamond circle, then this can be done easily and without effort. And if there is no diamond circle. Just take a new concrete drill with winning soldering.

When drilling solid steel, it is necessary to press the drill enough and drill at high speed (if the drill is blurred or not sharpened, like metal), after lubricating the spraying place W-40 or oil. It will be easier to make a hole if you first drill a smaller diameter drill, and then more. The resistance area will be less, which means that the drill will be easier to move to the material.

For example, thin steel under the knife can be drilled with hot or winning rods, you need to grind like a drill, and a few pieces at once (make a visor and sharpen 2 sides) and change as they become dull. A couple of minutes and the hole is ready.

From my own experience, I’ll say that it is good to make holes in hardened steel using broken wells from the entire alloy, I had a couple with a diameter of 6 mm. Having imprisoned it as for metal, he dripped the oil and. Everything goes like clockwork, at a speed of about 600-1000 rpm.

The next method is long, requires several hours, but reliable. The hole in the steel plate can be easily etched with acid: sulfur, nitrogen or chlorine, also 10-15% is suitable. We make a rim of paraffin the desired diameter and shape, lower the acid there and wait. The hole is slightly larger than the diameter of the side side, this must be taken into account. To speed up the process, the workpiece can be slightly heated to about 45 degrees.

If you have a welding machine, it can also be used. The hole can simply be burned in the workpiece or locally “release”, and then drill. Run the edges of the merged edges and order.

Or I managed to get out of the situation in the following way: by marking the place of drilling, you could see, and then, tapping the electrode, heating the metal to the red color in the place of drilling. and then, without waiting for the metal to cooled, I drill steel with an ordinary metal drill. Then I clean the points from welding around and order. And if they manage to drill the hole before the metal cools down. then immediately in the water he will also harden in this place.

In the same way, if you had to slightly expand the hole in the steel plate. He did not take a hot steel folder. Then I was heated by metal with welding, even to cherry, and. Until I caught a cold. straightened it with a round saw. Even if the steel was already almost gray, the file still took it.

Of course, there are special drills for this, but they are expensive. about 4 per piece. These are tubular diamond drill for high.carbon steels.

A pen drill designed to drill glass is also suitable, although not entirely perfect. Use the oeinated drill carefully, do not crush much so as not to break. The plates are thin there, and fragile win.

You can also make a hole in the steel plate by firing, at high speed and using a special carbide tip. To do this, make a special “training”. From a winning plate (you can use a tooth from a circular saw) we make a round blank and sharpen it under the cone. Insert into an electric drill and cut the hole in the stove at high speed. The whole operation takes only a few minutes.

If the steel is not very tiny, for example, a hacksaw or spatula, you can easily break through the hole of the desired diameter using a peorator through the fasteners of the same or slightly larger diameter.

It will be much easier to drill stainless steel if you add soldering acid to a drilling ground.

And if there is access to an enterprise where there is an electric device, then on such a machine the holes can be made without problems, in a matter of minutes.

Well, now all the methods of drilling hot steel. There will be a few more, I’ll add. I have written somewhat since I wrote this article, so come in. And if you have your own unique unique method of drilling hot steel, write.

To improve the main characteristics of the metal, it is often extinguished. This technology involves increasing the hardness of the product due to severe heating of the metal and its rapid cooling. In some cases, after heat treatment, it is necessary to drill. Increasing this characteristic, drilling hot metal becomes more complex. Consider all the features of hot steel drilling in more detail.

Knife.cutting wood. select tooth size

Even if you already have a hacksaw on your farm, it is quite possible that it will not work for your purposes, so sooner or later it may be necessary to go for a new saw. In choosing this tool, knowledge about its structure and features will be useful to you. If the saw has a teeth of a straight shape, it will be easiest to saw wood across, for sawing wood along the fibers you will need a tool with tilted teeth. In accordance with their inclination, the saw-cut will be transverse or longitudinal. If you often make, you will need both options.

The hacksaw with large teeth saws the fastest, but with it you will not achieve the even edge of the cut. To work in the garden or quickly cut rude boards, such a saw will suit you quite. For a cleaner edge of the saw, a tool with a small tooth is used, but it turns out to work with such a hacksaw. sawdust is more difficult to remove from the sawing.

For sawing large.fiber wood across the fibers, a saw with large teeth is best suited, for the usual needs of sawing, choose the middle tooth, and if you need accurate work, select a hacksaw with a small tooth.

With a very small tooth, the carpentry hacksaw is used by professional carriers, in the farm it is unlikely to be useful. There is also a mechanical hacksaw. this is a small machine with a mechanically movable blade, these are used in industries for sawing metal pipes and other metal elements, in the home workshop it will be replaced by a hacksaw for metal.

How to drill P6M5

Or not all high speeds are equally useful in general, everything is in the photo. I bought on the market yourself you know why the mechpila canvas, and could not scratch the glass (the habit is so stupid). Drilled with a regular HSS drill 4mm of the battery drill of a second 40. No Комментарии и мнения владельцев and owners’ opinions.Relax 02/02/2006 18:57

Generally knowledgeable people with electrolyte holes in such canvases makechief 02-02-2006 19:01

Why get used to electrolysis, if the hole of the ideal shape can simply be drilled, like in a piece of wood it was not a “non.kafe”Serjant 02/02/2006 19:04

Vest impareively knowledgeable people do not soar their brains with electrolyte. And take a carbide drill on concrete of the desired diameter. They pull it to a more acute angle and calmly drill any Rapid on 450 rpm. a maximum of 15 minutes with a drill overflow (2-3 times you have to drag)

Andrey, the fact that you drilled this saw is not surprising. Near the holes in the saw, the metal is released. and hardness there is a maximum of 55 ec. Retreat to the right at least a couple of centimeters (I judge by this photo), and hell will take a drill metal. The carbide.shaped curtailed

The drilling technology P6M5 and other fast.cuts is described here: https: // www.Knife.ru/forum/read.PHP?f = 1i = 32906t = 32274

A fabric of 40 mm width and 500 mm long was sore thoroughly. For a long time. Not me. A piece of the canvas rested from the workshop where the metal was sawn. The purpose of the experiment was as follows: it could or could not shoot 2 holes in this piece of steel. It turned out to be a might. To conduct the experiment, a drill was bought on concrete with a diameter of 6 mm. There was a drilling machine with a range of 400 to 2500 revolutions per minute in stock. The first hole was scrolled for 40 seconds at 595 revolutions per minute. But the doubt crept in that so fast. Having scratched in the back of the head, I realized that the metal in this place was simply released. It was decided to scroll the second hole. Cooling the drill, began to drill. Half a millimeter drill somehow. Then she refused to drill how much I did not strangle him. The drill dull. You just can’t stop us. The sharpening took half a minute. I inserted the core into the cartridge, the bullying continued to get dark: in general, the sharpening of the drill took place 4-5 times and the hole still scrolled, in 13 minutes. At this time, the drill is a renewal. I used simple water as cooling. He dipped a piece of steel there, wiped it with a rag and dripped machine oil into the formed hole. Pressed on the drill moderately. A piece of wood plate used a piece as a lining. Oddly enough, it drilled better with butter, at the same time and the drill was cooled. For insurance, it is advisable to press the workpiece with the lining to the table. For example, clamp. So use my modest experience.Chief 02/02/2006 19:14

I am Andrey, oh well, it’s not a pancake about that, it’s definitely not taking it, the drill glides but I would have blown up, I started to swear Although, we can come in handy, they will know that you can just drillSerjant 14-02-24 with the edge 19:18

Ouch!. I corrected whose business card with your nickname lies? Your boss?Nakhal 14-02-2006 20:52

In the pancake! Live and learn. And I am her old fashioned way, welding on a thin Elektrum Quickly, simply and without songs.Stingy 02/02/2006 21:40

So I correctly understood that it was recommended to drill “win”?And the angle of sharpening, how to remove under metal? Otherwise you need to do a hole in HSS and titanium.Maple 02-02-2006 23:27

To serjant: At the end of this branch https: // www.Knife.ru/forum/read.PHP?F = 1i = 32906t = 32274 there is a phrase: “I sculp nimvarus cub from P6M5, I will write an article and photos I will throw.”It was in 2003, and then I have not climbed this forum yet. So Cub was? If possible with a photo.Chief 02/02/2006 23:30

No, with a nickname, comrade. sergeant, everything is easier. Luger (IHBT) is busy here, the first thing that has come up was a nickname here. The laurels of Bush are not pretended to be claimed on 02/15/2006 09:43

The fact of the matter was was broken and thrown onto the closet. It is still lying around somewhere.

There is a comrade with the same nickname on Nayf ru and his name is Sergey. I confused you with himHunt11 02-02-2006 10:40

And chemistry is a hole for an hour. Only the edges are unevenmaple 02/15/2006 10:51

It’s a pity, I myself made Nimravus’s saw, but threw the descents, converted the uniform and it was no longer he, used both in the tail and in the mane, as a result, broke Grinya 15-02-2006 14:18:18

It is released near the fastening holes (or not hardened xs), is taken by a file, with the hardness of the working part simply not comparable. You retreat to CM 5 and again try to drill with nameless HSS and battery drill, the difference on the drill. It is not for nothing that people are cheap.Chief 02/15/2006 15:36

Duc I wrote that I tried. the working part of the saw is slipping the glass. the crumbs are already flying. So in vain I raised dust.OSM 16-02-2006 09:30

I made a hole in a saw with an arrow.shaped drill for glass, with a diameter of 4 mm. Time. seconds. It is possible and electrolysis, only longer, but if you do not drill and saw it, it is very convenient.Egorb 02-02-2006 11:06

quote: Originally posted by OSM: I made a hole in a saw with a switch.shaped drill for glass, with a diameter of 4 mm. Time. seconds. It is possible and electrolysis, only longer, but if you do not drill and saw it, it is very convenient.

I doubt, especially in seconds. I did not succeed, or rather partially drilled, and then the surfacing on the drill broke.Nakhal 16-02-2006 15:12

Yes, welding her! And under the influx at the edges of the hole, the pad is selected slightly.Serjant 16-02-2006 16:30

and then throw the piece. Because it will burst at the most crucial moment right through the gluttonous opening.OSM 02/17/2006 10:30

quote: Originally posted by egorb: I doubt, especially in seconds. I did not succeed, or rather partially drilled, and then the surfacing on the drill broke.

do not doubt. It is in seconds. After the first hole he drilled the second with the same success, and noticed that the spear seemed to be a little, but the third hole was not required for them to drill, so I don’t know how much it was enough.Sergey Kalugin 02/17/2006 13:17

Когда у меня было много времени и ХОРОШИХ заготовок для ножей приходилось брать угловую шлифмашинку с совсем маленьким кругом и прорезать маленькую полоску вдоль ручки. 5-7 cm. and sprinkled on the edges on the bolts to fasten the handle. the pen almost does not weaken. a little easier. Made in 1 minute.

The use of lubricants

The steel of the p6M5K5 brand is the material of domestic production, where the tungsten is less, only 6 %, but its deficiency is compensated by the use of the Cobalt element (up to 5 %). Cobalt also contributes to the equipment of the equipment, the ability to withstand increased thermal loads for a long time when working with hot materials.

Among the foreign analogues of high-speed steels suitable for the production of drilling metal drills, it is worth noting the HSS-Co brand. This, in fact, is the same tool as the previous one, where there is a similar composition of the main elements of the alloy.

Any porcelain drill is also suitable for obtaining holes in a purest metal, only their winning attacks need to be dragged.

tricks, how to drill thin drill

Drills are special tools, thanks to which you can quickly make holes in the materials. To fix them, a cartridge located on a drill or electric screwdriver is used. For the manufacture of such special tools, stamps of solid steel are used. Thanks to this, they can be actively used while working with materials such as metal, stone, concrete, brick, tree.

Almost every person in the workshop has a set of drills (usually for working with metal). However, in some cases, the user can operate exclusively thin drill to perform various work. For example, if it is necessary to make a large hole in the metal sheet, and there are no large diameter tools in stock. There are a large number of diverse tricks, the use of which will allow more effectively the use of thin drills during various work.

How to drill a hacksaw canvas for metal?

To improve the basic characteristics of the metal, its hardening is often carried out. Such a technology involves increasing the hardness of the product due to severe heating of the metal and its rapid cooling. In some cases, after heat treatment, it is necessary to drill. Due to the increase in such a characteristic, the drilling of a hot metal becomes more difficult. Consider all the features of the drilling of a potato steel in more detail.

We drill a hole in the potato steel

The spread of the issue of how to drill hot steel can be associated with the fact that when using conventional technology, the tool is quickly blurred and comes into unsuitability. That is why you need to pay attention to the features of the drilling of a hot alloy. Among the features of the technology, we note the following points:

- You need to properly prepare a hot blank.

- In some cases, a special tool is required.

- Cooling liquid is used.

If necessary, you can make a drill for hardened steel with your own hands, for which certain equipment and skills are required. However, in most cases, purchased options are applied, since it will better cope with the task when cutting potato steel.

Nuances when drilling

The technology in question has a fairly large number of features that need to be taken into account. The drilling of a hot metal is carried out taking into account the points below:

- Before the work, attention should be paid to the hardness of the surface. According to this parameter, the most suitable drill is made. Firmness can be determined when using a variety of technologies.

- During the drilling, a large amount of heat is released. That is why the rapid wear of the cutting edge occurs. In this regard, in many cases, a fluid for cooling is supplied to the cutting zone.

- When cutting the hardworked material, from time to time, it is necessary to sharpen the cutting edge. For this, a regular sharpening machine or a special tool is used. As an abrasive, an exclusively circle with diamond spray is suitable.

There are a variety of methods of cutting potato steel. Some of them greatly simplify the ongoing processing. Only when taking into account all the nuances can I improve the quality of the resulting hole.

Useful techniques for drilling

A wide variety of technologies can be used to work with potatoes. The most common technologies are characterized by the following features:

- Surface treatment with acid. This technology is characterized by prolonged use, since a fairly large amount of time is required to reduce surface hardness. Sulfur, chlorine or other acid can be used for etching. The procedure provides for the creation of a side that will restrain the used substance in the cutting zone. After prolonged exposure, the metal becomes softer, it will be possible to drill when using the usual option.

- You can use a welding machine to achieve a set goal. When exposed to high temperature, the metal becomes softer, which greatly simplifies the procedures.

- Most often, a special drill is used. On sale there are options that can be used for processing rocky steel. During their manufacture, metal with increased resistance to wear and high temperature is used. However, the complexity of manufacture and some other points determine that the cost of a special tool is quite high.

In addition, to achieve the goal, a punch is often acquired. With it, you can make a small hole, which will simplify further drilling.

Using lubricants

When drilling potatoes, serious friction occurs. That is why it is recommended to purchase and use various lubricants. Among the features of this processing method, we note the following points:

- First, the drilling zone is processed. A small amount of lubricant is applied to the surface where the hole will be located.

- Oil is added to the cutting edge. A small amount of substance is required to process red steel, but it must be added from time to time, since when the tool is rotated, it scattered.

- During operation, it is recommended to take breaks for cooling the cutting surface and the processed surface.

When drilling hot steel, serious friction occurs. That is why it is recommended to buy and use different oils. Among the features of this processing method, we note the following points:

- To begin with, the drilling zone is processed. A small amount of oil is applied to the surface where there will be a hole.

- Oil is added to the cutting edge. A small amount of substance is required for processing hardened steel, but it must be added from time to time as the tool rotates as it rotates.

- During operation, it is recommended to take breaks to cool the cutting surface and the processed surface.

This is because oil can reduce the temperature of the cutting edge.

Similar materials

A tool that is always useful

You are a happy owner of a suburban site? Have already acquired a cozy house, multi.story.

Self.tapping screws, grouse and other screws

At first glance, all the screws are similar. But it is worth going to a specialized store. eyes run up

Carpentry and carpentry saws

Measured tapping of an ax and scraping a saw. sounds are almost forgotten. But sometimes I want to do so.

Garden saws

In early spring, the kidneys on trees and bushes have not yet swelled, all gardeners are in a hurry to the cottage with acute.

Electrician: saw canvases for different materials

If you need to saw off, cut off, cut, a tool equal to an electrician is difficult to find. Wide.

Electric saw AL-KO EKS2000/35: Test drive

The main word that can be selected for the characterization of the AL-KO EKS2000/35 electric vehicle is dynamics

Chainsaw: features of work and safety precautions

Chainsaw. an instrument with increased injury hazard. Therefore, you need to handle it delicately and.

Laser level: how to align the pillars in height

The traditional level is not always suitable for alignment. What an alternative exists?

Tools: an electrician that does not chop wood

A saw canvas for an electrician can be different. Why?

How to drill holes in wood

Is it possible to drill holes in a tree with rod on metal?

Tools: Chainsaw work

Chain saws are of two types: electric and gasoline. Chainsaws. more powerful than electric, and.

Tools: hacksaw with interchangeable canvases

Which tool is better. specialized or universal. We will talk about using a hacksaw.

Railing mounting with wooden rods

If you do not want to use ugly brackets to attach the railing to columns, replace them.

We drill a hole in the potato steel

The spread of the issue of how to drill hot steel can be associated with the fact that when using conventional technology, the tool is quickly blurred and comes into unsuitability. That is why you need to pay attention to the features of the drilling of a hot alloy. Among the features of the technology, we note the following points:

- You need to properly prepare a hot blank.

- In some cases, a special tool is required.

- Cooling liquid is used.

If necessary, you can make a drill for hardened steel with your own hands, for which certain equipment and skills are required. However, in most cases, purchased options are applied, since it will better cope with the task when cutting potato steel.

How to drill potato steel at home

To improve the basic characteristics of the metal, its hardening is often carried out. Such a technology involves increasing the hardness of the product due to severe heating of the metal and its rapid cooling. In some cases, after heat treatment, it is necessary to drill. Due to the increase in such a characteristic, the drilling of a hot metal becomes more difficult. Consider all the features of the drilling of a potato steel in more detail.

We drill a hole in the potato steel

The spread of the issue of how to drill hot steel can be associated with the fact that when using conventional technology, the tool is quickly blurred and comes into unsuitability. That is why you need to pay attention to the features of the drilling of a hot alloy. Among the features of the technology, we note the following points:

- You need to properly prepare a hot blank.

- In some cases, a special tool is required.

- Cooling liquid is used.

If necessary, you can make a drill for hardened steel with your own hands, for which certain equipment and skills are required. However, in most cases, purchased options are applied, since it will better cope with the task when cutting potato steel.

Nuances when drilling

The technology in question has a fairly large number of features that need to be taken into account. The drilling of a hot metal is carried out taking into account the points below:

- Before the work, attention should be paid to the hardness of the surface. According to this parameter, the most suitable drill is made. Firmness can be determined when using a variety of technologies.

- During the drilling, a large amount of heat is released. That is why the rapid wear of the cutting edge occurs. In this regard, in many cases, a fluid for cooling is supplied to the cutting zone.

- When cutting the hardworked material, from time to time, it is necessary to sharpen the cutting edge. For this, a regular sharpening machine or a special tool is used. As an abrasive, an exclusively circle with diamond spray is suitable.

There are a variety of methods of cutting potato steel. Some of them greatly simplify the ongoing processing. Only when taking into account all the nuances can I improve the quality of the resulting hole.

Useful techniques for drilling

A wide variety of technologies can be used to work with potatoes. The most common technologies are characterized by the following features:

- Surface treatment with acid. This technology is characterized by prolonged use, since a fairly large amount of time is required to reduce surface hardness. Sulfur, chlorine or other acid can be used for etching. The procedure provides for the creation of a side that will restrain the used substance in the cutting zone. After prolonged exposure, the metal becomes softer, it will be possible to drill when using the usual option.

- You can use a welding machine to achieve a set goal. When exposed to high temperature, the metal becomes softer, which greatly simplifies the procedures.

- Most often, a special drill is used. On sale there are options that can be used for processing rocky steel. During their manufacture, metal with increased resistance to wear and high temperature is used. However, the complexity of manufacture and some other points determine that the cost of a special tool is quite high.

In addition, to achieve the goal, a punch is often acquired. With it, you can make a small hole, which will simplify further drilling.

Using lubricants

When drilling potatoes, serious friction occurs. That is why it is recommended to purchase and use various lubricants. Among the features of this processing method, we note the following points:

- First, the drilling zone is processed. A small amount of lubricant is applied to the surface where the hole will be located.

- Oil is added to the cutting edge. A small amount of substance is required to process red steel, but it must be added from time to time, since when the tool is rotated, it scattered.

- During operation, it is recommended to take breaks for cooling the cutting surface and the processed surface.

Special oil allows not only to simplify the drilling, but also to increase the service life of the tool used.

This is due to the fact that oil can reduce the temperature of the cutting edge.

Spiral drills are quite widespread, which are represented by a vertical rod with two grooves. Due to a certain location of the grooves, the cutting edge is formed. Among the features of the choice, we note the following points:

- The winning drill was quite widespread. It can be used to work with various red.hot alloys. However, the surface with too high firmness with such a tool cannot be processed.

- The choice is made according to the diameter indicator. It should be borne in mind that getting a hole of large diameter is quite difficult. The option of executing a larger diameter is much more expensive due to the use of a large amount of material in its manufacture.

- Attention is paid to the angle of sharpening, the purpose of the product and the type of material used in the manufacture. For example, cobalt performance options are characterized by higher resistance to high temperature.

- It is recommended to pay attention to the products of extremely well.known manufacturers. This is due to the fact that Chinese execution options are made when using low.quality materials. However, such a proposal is much cheaper and can be used for short or disposable work.

- When choosing a drill, you can navigate on the marked marking. It can be determined by which materials used in the manufacture of. The diameter of the hole that can be obtained when using the tool is also indicated.

How to drill a hacksaw?

Question to connoisseurs: what drill you can drill a hole. in the canvas of a mechanical saw. From such saws. They also make shoe knives.

Учим HTML5 Canvas за 30 минут!

The best answers

I burned! And drill, well, if only with a diamond!

if the winning drill does not help you can. burn errosion. There are still Elbor drill

IMHO is useless to drill, just burn or etch

As far as I remember, these canvases are made of red-hot steel- 2 options at home: 1 release metal- heat the red-hot and allow to cool- and drill to health with anything, but then the strength of the canvas, to put it mildly, will suffer (harden to the original version of the house is almost impossible )

2 drill a tube with diamond spraying at low speeds and with the addition of oil (such glasses are usually drilled)

Can be on the machine using abrasive paste (abrasive powder water). But this is a troublesome business. Better to burn.

NGRARY Drowning the drilling with a gas burner to raspberry color and drilling and quickly as a conventional drill

The answers of experts

Modern hacksaws are usually hardened only in the place of teeth

Heat this place for gas. stove and drill with an attack, drill to hot, cooling drill in oil.

Drill with a winning float.If not a blade, but where the handle is, then you can let go, heating to red and cool slowly. Then you can drill a simple steel drill.

If the hacksaw is not thick, 0, 5 mm, you can pierce a beard, placing a nut with a hole a little larger than the diameter of the beard under the canvas.

It is taken by an old Soviet drill from alloy P18, steamed from the aircraft factory, with oil, at low speeds (P6M5.He won’t take from the store)

The canvas of hardening and only the working surface (teeth) cannot be drilled and cannot be drilled. With a total width of a canvas 15 mm, this is a plot of about 5 mm. Above the teeth can be drilled with butter (soap) at low speeds and first with half a diameter. Here is the main difficulty- not to rush and not “plant to get a small drill. Slowly, in 5 7 minutes, you will succeed, but at low speeds!! ! You will rush- the result is zero! The canvas is generally not to be drilling! Then the nominal size of the drill and with soapy solution will be treated with a clean. Well, the tasks of you, I have already done an ungrateful job!

[Link is blocked by decision of the project administration] there people drilled the canvas with a diamond drill, concrete drill, electric arcs, burned with a coal electrode, and used electrochemical etching. Most methods are described in sufficient detail.

Try with a regular drill with strong pressure at medium speeds, not a drill, but on the machine, the part will quickly heat up and the hole will actually be served through the red.hot metal

Burning tungsten rod, at high speeds, about 10,000 rpm

But the tubular drill with diamond spray did not try?

Any metal, regardless of hardness, can be “drilled” with electrophoresis in a few hours. The problem at the same time is to reliably cover the surface with varnish or glue to the hole. You can also combine electrophoresis with drilling with a coal electrode to remove reaction and coal products

And what if you apply a technology like etching of printed circuit boards, cover with acid.resistant varnish except the desired hole, and etch in acid.