How to Drill Concrete with an Impact Drill

How to drill a concrete wall with a drill

- How are concrete walls drilled?

- Diamond drills and other devices

- Practical Tips from Masters

- A few nuances of how to drill a concrete wall

In modern buildings, as a rule, walls and ceilings are concrete. Sooner or later, there may be a need, for example, to hang a lamp shelf or to repair plasterboard walls during repairs, then the problem arises of how to drill a concrete wall with a drill.

Concrete wall drilling pattern.

Difficulty in drilling can arise due to a number of reasons. Firstly, the structure of concrete panels is heterogeneous and includes iron reinforcement, cement-sand mortars and crushed stone, which makes drilling difficult. Secondly, concrete has high strength and is very difficult to process.

How are concrete walls drilled?

Before proceeding with the work, it is important to decide which drilling device is the best for the job. The choice, of course, is small, since there are two types of wall drilling:

The puncher will better cope with this work, since its function is precisely punching concrete or stone surfaces. Using this tool, you can make holes of large cross section, but even the highest quality impact drill is not able to drill holes more than 12 cm.

The scheme of the drill.

But when it is necessary to drill foam concrete walls, it is the drill that will be optimal, since the puncher will simply crumble the surface.

When working with concrete walls, it is absolutely forbidden to use a hammerless drill, because it will be pointless, and you can also ruin the tool.

When you have to make just a few holes and there is no hammer drill, you should not get it because of this, you can do with a drill. If there is a lot of work ahead, then buying a hammer drill is inevitable.

In the case when you still need to work with a drill, it is important not to forget that you need to use a drill bit for concrete and it is with a tip coated with a carbide compound.

Back to the table of contents

If there is a need to make a hole for a socket or switch, crowns designed for drilling concrete can be used. The cutting part around the circumference has universal carbide soldering.

Such elements have a cross section from 35 to 120 mm, but products with a cross section of 68 mm are in great demand, since sockets and switches have it. If drilling is carried out with a crown, it is important not to forget to turn off the function of impact punch. Holes with a maximum depth of 15 cm are drilled with this device. If a greater depth is necessary, it is recommended to use an extension nozzle.

Similar crowns are sold for electric drills. They differ from the previous ones in that, instead of soldering, they are equipped with a tungsten carbide alloy. The advantages of such a device are that if the concrete walls are tiled, then there is no point in replacing the nozzle, since it drills both tile and concrete surfaces well. But we must not forget that such devices can be used for drills with power above 1000 watts.

Most often, drills are used to operate the puncher, the cross section of which has limits from 4 to 80 mm. Many are faced with the problem of the correct selection of the diameter of the drill. But the most reasonable when buying a punch device is to buy a set of drills for concrete. But a quality kit costs a lot of money, in connection with this it is necessary to choose the same cross section as the dowel designed for this model.

Back to the table of contents

Everyone knows that the concrete wall and all similar structures have durable qualities and are difficult to drill, since most often during work you can stumble on the crushed stone included in the concrete composition of which the wall and ceiling structures are made. Holes in concrete slabs during construction are made quite often:

- during finishing works;

- when installing built-in furniture;

- when installing air conditioners;

- when installing electrical wiring;

- when installing plumbing devices.

During minor household repairs, you can do with a simple electric drill, not equipped with a shock function.

Sharpening a drill on concrete.

To do this, in the process of introducing the core drill into the concrete surface, it is periodically necessary to grind the concrete with a metal punch, which must correspond to the hole cross section. It is used when, when drilling, an electric drill starts to get stuck in concrete. Then they put the punch in the hole and beat it, using a hammer or sledgehammer, which helps to crush the compacted places and penetrate deeper. But the punch in this case needs to be slightly rotated, and then you can again begin to work with a hammerless drill.

These manipulations should be continued until the holes have reached the desired depth. This method is very lengthy, but suitable for several holes.

Of course, you can use universal drills with diamond tips. They will perfectly cope with metal, crushed stone, as well as with concrete structures. But it is important to consider that they are suitable only for an ordinary drill or device with the vibration mode turned off. Using diamond drills in the work, it should be remembered that they require cooling during operation.

But a good drilling effect can be achieved by using a hammer drill. Its advantages are in combining the functions of rotational motion with reciprocating motion. When drilling with such a drill, the tip of the drill is able to break the concrete composition, and the drilling process will be the least time-consuming.

Back to the table of contents

Before drilling a concrete wall, it is necessary to install a drill in the drill chuck. But first, it’s important to make sure there are no foreign objects in it. If such are the case, they must be removed with a soft cloth to avoid problems with further work. So, installing it in the cartridge, it is important to ensure that it is correctly placed. at a right angle and the tail has entered all the way.

The scheme of the device for drilling concrete.

The first difficulty that can occur when drilling a concrete wall is the emphasis on iron reinforcement. In this situation, the reinforcement is punched with a punch and then drilling is continued. When working with an impact electric drill, a metal drill can cope with similar difficulty.

It is important to note that when working with a low-power device (since it is not designed for continuous operation), after 15 minutes, let the drills rest for 10 minutes. This time will be enough to cool the device and the concrete wall. Before starting further work, it is recommended to moisten the drill with water, which will significantly increase its service life.

There are cases when, when drilling holes on the other side of the wall, pieces of plaster break off. With such problems, it is necessary to reduce the drilling speed to reduce vibration. Of course, working at this pace will take much longer, but the integrity of the wall will be preserved.

Another problem that can occur when a drill is stuck in the wall. In no case should you try to remove it by loosening the tool, since in this way you can break off its end. In this situation, the punch is disconnected, a smaller drill bit is inserted into it and they begin to drill a locked element, but they try not to touch it.

With the correct selection of the device and accessories, you can achieve high-quality holes even in the concrete wall. But first you need to acquire a little practice and theory, then the work will not create trouble.

How to drill a concrete wall with a conventional drill or punch: recommendations

How to drill a concrete wall with a conventional drill? such a question was asked by many masters when they had to hang shelves, cornices and more.

Concrete is a strong material and therefore lends itself extremely poorly to drilling. Even how to drill a wall in a panel house, the task may seem unsolvable.

Although, if you know certain secrets, this process can be greatly simplified.

Choose a tool

So, the first question that a home foreman should ask himself is not how to drill a concrete wall with fittings, but with what. The main assistant in this matter will be the puncher, because it is intended for stone and concrete. At the same time, even powerful drills can not cope with a wall with a width of more than 12 cm. Although, when it comes to foam concrete, it is preferable to drill, since the punch simply breaks it.

The quality of the drill also determines whether it will be possible to drill a hole in a concrete wall.

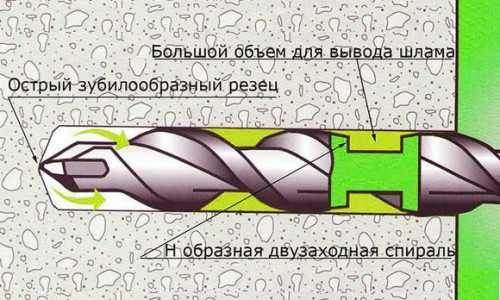

One of the best options is to use drills designed specifically for the impact drill. Their working part is a plate made of strong metal. With the help of these drills, the question of how to drill a thin concrete wall can be considered resolved.

There are also core drills that are diamond coated. They are very strong, use them in special drilling rigs, and therefore cost a lot. Therefore, they solve the problem of how to drill a hole in a concrete wall at home, it is impractical at least.

Crown application

Often you need to get a large diameter hole in the wall for a wall outlet. How to drill a bearing wall in this case? Then the crowns are used, in which there are metal solders around the circumference. Crowns are found in a variety of sizes, but 68-centimeters, which are designed specifically for sockets, remain the most popular. When working with these parts, the hammer must turn off the shock mode.

Video: How to Drill Concrete with an Impact Drill

There are such crowns for drills. But they have a spraying of a different nature. from a carbide-tungsten alloy. It is convenient to use them, since it is quite possible for her to drill a hole in the concrete wall and simultaneously make a hole in the tile. Such crowns are used only with powerful drills.

Drills. one more device than to drill a concrete wall. Their diameter is diverse. Experienced craftsmen are advised to make a selection based on the diameter of the dowels.

We drill concrete with a perforator

So, how to drill a hole in a concrete slab using a hammer drill? The procedure is simple:

- the drill switches to shock mode, after which drilling begins; the tool must be kept strictly at a right angle;

- after a while, the drill is moistened with water, this will help to avoid overheating;

- after it is possible to drill a reinforced concrete wall, the drill, without turning off the device itself, needs to be removed;

- to clean the hole obtained from dust, a drill is launched into it several times.

Can’t drill a wall? Has the puncher run into something solid? So, you need to try to make a hole in another place.

We manage a drill

How to drill a concrete wall without a perforator? The issue of using a conventional drill when working with concrete remains unresolved. So is it possible to drill a concrete wall with a drill, everyone decides for himself. The tool can break. And the procedure will take more time.

You can drill a hole in concrete with a drill if you use a special tool. a punch. It’s easy to operate: put the sharp end to the place where the hole will be, hit it several times with a hammer, after which you can start drilling.

It is important not to overheat the tools.

As soon as the drill stumbles upon an insurmountable barrier, you need to again use the punch until the desired goal is achieved. Here’s how to drill a concrete wall with a drill. Although it takes more time and requires a lot of effort, for lack of a punch, it can also be used.

Diamond drilling

This is another way to easily drill a concrete wall. However, it is used only by professionals with special equipment (high-power electric motor and the like).

How to drill a frame wall? This is not a problem, because diamond drilling allows you to get holes of large diameter and depth, and without dust irritating the eyes. In parallel, water is supplied directly to the drill, so that it is cooled. As a result, the resulting holes have a neat appearance, and the appearance of cracks is completely eliminated.

How to drill a tile so that it does not crack? Look here. What is a hole conductor? Find out in this article.

Concrete walls are drilled by this method, as a rule, by professionals from specialized companies. So to stock up on a diamond drilling rig for independent work does not make sense.

Read also :. Prices for installing locks on metal doors. Repair of ovens at home. Repair of interior doors. DIY plastic window repair. Do-it-yourself shower stall made of tiles in the photo and manufacturing tips. Door lock repair: how to do it yourself?

How to drill a concrete wall

When buying a drill for a drill, it is best to consult with specialists

The repair process in an apartment includes a lot of work related to creating holes in the walls: for this, a tool of various designs and capacities can be used. Many craftsmen and those who are going to carry out repairs themselves want to learn how to drill a concrete wall with a conventional drill and whether this is possible at all. A puncher is usually used for such work, but it is not always suitable for this, moreover, if you have to buy a tool, its cost is much higher than that of a drill.

Tool Selection Features

In most cases, it is better to use a hammer drill for drilling concrete: it has an increased power, is designed for punching hard surfaces, and allows you to make large diameter holes. The use of the tool is impractical in the following cases:

- the need to drill the wall to a depth of 10-12 mm;

- work with foam concrete, which crumbles during processing with a perforator;

- no more than 10-15 holes are required in the work.

Concrete Drill

Before drilling the wall, it is important to choose the drill itself: it should not be shockless, since such a variety is ineffective when drilling concrete, the nozzle and cartridge almost immediately become unusable. The nozzles themselves must be victorious, designed for concrete work, the tip. with carbide coating.

In some cases, a good solution would be to purchase a hammer drill: the device is more expensive than the classic model, but has a high power that can be adjusted.

What nozzles to choose?

Before you drill a hole in a concrete wall, you need to choose a nozzle of the appropriate design. The following varieties are used for work:

- Impact-type toothed crowns for drilling. When working with concrete, it is recommended to use varieties of separate soldering teeth made of the most durable metal alloys. Many crowns are equipped with SDS tails for installation in a drill with a quick chuck. Drills are well suited for concrete walls, but they can begin to break down when in contact with metal, so before drilling a reinforced concrete wall, it is necessary to check that there are no reinforcing bars in the place of work.

- Diamond crowns, which are designed for hammerless drilling. Such nozzles are more modern, with their help to make a hole in a concrete wall easier. The edge of the crowns has an abrasive structure and special cuts, in the production it is processed by spraying diamond chips or corundum. Before making a hole in the wall, it is only necessary to choose the desired nozzle length: varieties with a diameter of up to 100-120 mm are used in everyday life, larger crowns are used in professional works. A distinctive feature is the ability to drill without risk of damage to the fixture fittings.

- KS-crowns that have a cutting edge with crystalline diamond particles. Such nozzles are used for most solid walls, including drilling concrete slabs, external walls and stone structures with them.

Before working with drilling equipment, you need to choose a nozzle suitable in composition, thickness and length

Before drilling a load-bearing wall or partition, it is necessary to make sure that during the work no wires or cables, if any, are laid inside.

How to drill concrete with a drill?

Typically, such work is performed in the following cases:

- rough finishing of premises;

- installation of built-in furniture and appliances;

- installation of wiring and plumbing when communications are required to be concreted.

When using a winning nozzle during work, it is necessary from time to time to use a metal punch, which is selected to fit the size of the hole being formed. Such a tool allows the drill not to jam during deep immersion of the drill: the punch is placed in concrete and deepened by hammer blows to make a hole in the wall, breaking the seal.

This process is quite long, the use of diamond crowns can serve as an alternative: a drill equipped with such nozzles will not get stuck in concrete.

Work with an impact drill with a diamond crown

- Before drilling a hole in the wall, you need to install the right nozzle, after making sure that the tool is working and the drill is intact.

- Concrete needs to be drilled carefully, when using low-power equipment, the duration of continuous operation of the drill should not be more than 10-12 minutes. If the drilling is delayed in time, it is necessary to take breaks so that the motor of the device cools down.

- After drilling a concrete wall, it became clear in the supplement that it is necessary to process the nozzle for each new hole. You can wet the surface with water to facilitate the procedure and save metal from deformation.

The whole process of work can be seen on the video:

If you encounter a stuck drill, you can not remove it by force: this leads to breaking off the device, as a result of which the tip will remain in concrete. The nozzle must be disconnected, select a crown of reduced diameter and use it to pull out the stuck element.

Expert Advice

Before deciding how to drill concrete walls and start work, it is worth paying attention to the following recommendations:

- if the hole diameter exceeds 12 mm, and the depth is 10-11 cm, it is better to use a hammer drill or a hybrid device (drill-hammer);

- if the holes are made for plastic dowels, the depth should be 7-10 mm more than the size of the fastener, since concrete dust and small particles of stone remain inside;

- the beginning of work is recommended to be performed at low speeds, so that the nozzle does not move due to increased torque, and the shock mode is turned on when the drill passes 2-4 mm in depth;

- dust that appears during the drilling process can be removed with a vacuum cleaner, it is advisable to do this in the process, periodically stopping the drill and cleaning the hole from concrete particles;

- be sure to follow safety precautions during work: gloves must be worn to eliminate the risk of the handles slipping and safety glasses so that the crumbs do not get into the eyes and damage the mucous membrane.

Dowel drill size chart

In most cases, a concrete wall is drilled with a punch, without a drill. If, as part of the repair, you need to make no more than 15-20 holes or the wall is made of foam concrete, the use of a drill is the best choice, which will save time and money.

Before punching a hole, you need to make sure that the wiring does not pass in this place, and check whether the nozzle is suitable for such work (the duration and efficiency of work depend on which drill the drill will be equipped with). When deciding what to drill a wall with, one should pay attention to the winning crowns: such a drill using a drill can easily make a hole with a depth of up to 10-12 cm.

How to drill a concrete wall: technology features

The walls and ceilings of modern buildings are most often made of monolithic reinforced concrete slabs. It is well known that concrete is a material of increased strength, the handling of which requires knowledge of its processing techniques. In particular, a concrete wall must be drilled with a special tool: a drill or a perforator.

Drilling tool

Concrete Impact Drill

The organization of work on the manufacture of holes in concrete requires a special approach, involving the choice of the appropriate tool and special drills (the usual ones are not suitable in this case). The following toolkit is best suited for these purposes:

- The choice of drill perforator (hammer drill);

- drill bit made of an alloy of tungsten carbide and cobalt;

- diamond drill.

A puncher or hammer drill provides rotational-translational movement of the drill (drill), which greatly facilitates the drilling of concrete.

Unambiguously choose a punch, if you need to make holes more than 12 cm in diameter.

Some experts believe that in most everyday situations you can get by with a conventional drill that does not have a shock function. But in this case, to successfully complete the work, it will be necessary to use a special metal pin, the thickness of which is approximately equal to the diameter of the planned passage. Using this pin, the point of intended drilling is “stuffed” and the concrete is periodically broken as it immerses into the wall. Several small holes can be drilled with a conventional drill with a drill.

Drills, drills, crowns for concrete

Of great importance is the choice of components. Winning tip is T-shaped. If you want to get a really durable tool, get drills of domestic manufacturers, where the metal ratio is 9: 1, if you buy a drill made in China, know that there are less hard alloys there.

Strength depends on the ratio of its diameter and length. There is a pattern: the longer the drill, the thicker it should be.

Hardened drills have a black shade, golden color. titanium coated drills. Titanium is much stronger.

Drilling Concrete

For a drill, choose drills with a shank in the form of a polyhedron or cylinder, for a punch. drills marked SDS-plus, SDS-max. Drills for drill and punch are not interchangeable: they can be installed on another tool only with an adapter.