How to Grease Lawn Mower Spindle (Super Simple Process). Grease for lawn mower

How to Grease Lawn Mower Spindle (Super Simple Process)

The blade spindles on a lawn mower turn about 3000 times per minute. During this operation, the moving parts create a lot of friction that, in turn, creates a great amount of heat. So to prevent the friction from causing excessive wear and potential seizing, manufacturers use grease as a lubricant inside the spindles.

In addition, manufacturers like John Deer recommend adding grease to the spindle after every 25 hours of use to prevent such problems. That all sounds fine, but how do you add grease to a spindle? Let’s take a look.

Greasing Lawn Mower Spindles (The Short Explanation)

To grease a lawn mower spindle, you need to inject a suitable grease into the spindle via the attached hydraulic grease fitting. Here are the steps you will need to follow.

- Locate the hydraulic grease fitting

- Clean the hydraulic grease fitting

- Fill the grease gun with suitable grease

- Connect the grease gun to the hydraulic grease fitting

- Inject the grease into the spindle

- Disconnect the grease gun

- Clean the hydraulic grease fitting

Why It’s Important to Periodically Grease Your Lawn Mower Spindles

As I mentioned, a lawn mower spindle can generate a lot of friction and heat during operation, especially when the lawn mower works for long periods at full speed. As grease is used, it starts to break down and burn off. Over time, there is less and less grease left in the spindle, which is why it’s a good idea to grease mower deck spindles.

So, the less grease or lubrication available, the harder the spindle and the lawn mower have to work. Therefore not only will the spindle suffer, but so will your lawn mower. Parts that can be affected are the spindle mounts, the deck belt, the clutch, and the engine itself.

Here are just a few problems you might run into and some extra repairs you might need to do if you don’t keep on top of greasing mower spindles.

Best Grease for Lawn Mower Spindles Other Equipment You’ll Need

Grease comes in a variety of different grades for different applications. Some are designed for light use, and some are specially designed for heavy high-pressure use. I use a general-purpose grade 2 grease suitable for lawn mower spindles. There really is no need to use high-grade greases as these are designed for different applications. After all, we’re talking about lawn mowers and not combine harvesters.

So the easiest way to find the right grease is to head down to your local lawn mower shop and see what they have available. They’ll more than likely have the best grease for lawn mower spindles.

Along with the grease, you will need a grease gun to inject into the lawn mower spindle. There are two things you need to make sure match up with the grease and your lawn mower. The first is the size of the tube of grease. Lawn mower spindle grease comes in a variety of different size tubes, so you’ll need a gun to match. I recommend asking for a standard-size tube, not the big one or the little one.

Then you can get yourself a standard grease gun. Next, you’ll need to make sure that the grease fitting on your lawn mower spindle matches that of the gun. Usually, the fitting is a standard-size Zerk fitting. So, double-check the grease fitting size in your manual or ask one of the people at your local lawn mower shop. But I’m 99% sure it will be the standard Zerk fitting.

How to Grease Lawn Mower Spindles (Step By Step)

Now that you have your new tube of grease and grease gun, let’s go over how to grease a lawn mower spindle. Here are all the steps you’ll need to follow to keep your spindles running smoothly.

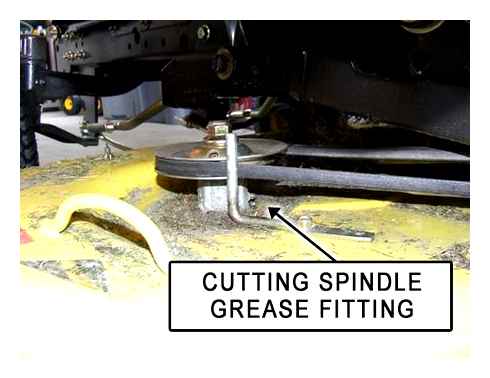

Locate the Hydraulic Grease Fitting

The first step is to locate all the grease fittings on your lawn mower. Usually, a diagram on your lawn mower will show you where all the fittings are. You might find this diagram under the hood of a tractor mower or under the footplate on a zero-turn lawn mower. Failing this, take a look at your owner’s service manual.

Also, you might find a few other spindles or bearings that use the same method, which you can service at the same time. For example, I know the wheels on my lawn mower also have zerk grease fittings, so I do these at the same time as my deck spindle.

Clean the Hydraulic Grease Fitting

Once you have located all the grease fittings, you’ll want to clean them and remove any dirt and grass clippings that might be attached. This is because whatever is attached to the end of the grease fitting will be injected into the spindle. Stuff like dirt and sand definitely won’t help the bearings. So, grab an old rag and give the fittings a good cleaning.

Fill the Grease Gun with Suitable Grease

I had some trouble the first time it tried to fill a grease gun with grease. I thought it would be just the same as a caulking gun from the decorating section at the hardware store. Nope, not quite. Here’s a quick overview of how to load grease into a standard grease gun.

- Pull the Plunger and Twist it to Lock it into Place

- Unscrew the Cylinder

- Remove the Plastic Cap from the New Tube of Grease

- Insert the Tube of Grease into the Grease Gun Cylinder

- Remove the Metal Cap from the Tube of Grease by Pulling the Ring Pull

- Reattach the Head Assembly to the Grease Gun Cylinder

- Release the Plunger and Push it Back into the Cylinder

- Pull the Grease Gun Trigger Repeatedly to Prime the Gun

- Stop Priming when Grease Starts to Come Out of the Nozzle

Connect the Grease Gun to the Hydraulic Grease Fitting/Zerks

With your loaded grease gun, press the end of the grease gun’s hose with the zerk connector onto the fitting attached to the spindle. There is usually a clip inside the nozzle that will snap onto the zerk fitting. So, make sure you give the nozzle a good push so that it firmly clips into place. If you don’t, then you’ll end up with grease squirting everywhere.

Best Grease for Lawn Mower Spindles

Inject the Grease into the Spindle

The next step is to inject the grease into the spindle. Usually, spindles are not 100% sealed, which means that when you overfill the spindle, grease will seep out of the gaps between the bearing housing and the spindle.

So, pull the trigger of the gun until you start to see grease seep out of the gaps in the spindle or back out of the nozzle of the gun. Just be careful that you have the nozzle correctly attached because you might think the spindle is full when it’s actually not.

Disconnect the Grease Gun

You can remove the nozzle when you think you have the lawn mower spindle full of grease. A firm pull should be enough to disconnect your gun from the lawn mower grease fitting.

Clean the Hydraulic Grease Fitting

Finally, use a rag to clean up any excess grease from the spindle and move on to the next spindle.

How Often Should You Grease Your Lawn Mower’s Spindles?

As I mentioned before, John Deere recommends that you grease your lawn mower deck spindles every 25 hours. However, they also say you need to grease a new spindle after 8 hours of use. So if you have a new lawn mower or have just replaced a spindle, make sure you add new grease once the spindle has had a chance to set in.

Now for me, I grease my spindle more often than what my manual states. This is because I know it’s much easier to pull out my grease gun than it is to replace a spindle, and it’s definitely a lot cheaper. So, check in your manual and see what your manufacturer recommends, then knock off a few hours.

For example, my manual states my lawn mower spindle should be greased every 25h, so I do it every 20h. I always think it’s better to be safe than sorry.

Do All Lawn Mower Spindles Need to be Greased?

If you find the phrase “non-serviceable” in your manual, then there is no need to add grease, and you’re not going to find a grease fitting. So it doesn’t matter if you have the best grease for lawn mower spindles since you will not be able to use it.

The best thing to do is check the grease fitting diagram for the location of all the fittings and service all the ones that can be serviced.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the “lawn mower guru” (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Leave a Reply Cancel reply

Copyright © 2010. 2022 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.

How to Lubricate Lawn Mower Wheels in 8 Steps

Whether you own a landscaping company or you have a small patch a grass, your lawn mower needs a bit of maintenance every so often. Lubricating the wheels can make a massive difference to increase speed, prevent smoke, and increase the overall longevity of your mower.

To lubricate lawn mower wheels, start by removing them, using a grease gun, then do the same for the wheel bearings. Next, grease the spindles, then consider using dry graphite spray to remove fine particles. Follow this process twice per year for the best results.

- The step-by-step process to remove and grease your mower’s wheels

- Why it’s crucial that you lubricate a lawn mower regularly

- Additional tips to make your lawn care machines run smoothly

Quick Suggestion: You might not have all of the tools to get the job done, but you can find them in-store or online. If you don’t have the right type of mower wheel lubricant, check out the best lawn mower grease offered by Amazon. You can add it to a grease gun or use it with your hands, it’s up to you.

Remove the Wheels

Did you know that rusted, dull wheels are one of the main causes of smokey engines? Lubricating the wheels of your lawnmower is a crucial and necessary aspect of its maintenance. It ensures your machine keeps performing just like the day you first bought it.

Lubrication reduces friction between the parts facilitating efficient movement by protecting the wheels against corrosion, abrasion, and increasing the waterproofing resistance.

However, you need to consult the operator’s manual for the type of grease recommended for your lawnmower before performing any lubrication tasks.

Manuals contain information concerning mower maintenance, and they also detail the type suitable for your mower. Use your model engine number to access information if you are searching for the user manual online.

The following are guidelines to be followed when removing the wheel of your lawnmower. For specific steps regarding your mower model, refer to the manufacturer’s user manual.

Can You Over Grease Tractor Spindles?

Removing a Push Mower’s Wheels

- Begin by unplugging your power supply.

- Underneath the front edge, gently raise the mower and place a brick or plank of wood. Do the same for the rear wheels if you want to detach them.

- Using a hand or a screwdriver, detach the hubcap. If you miss a screw in the center of the wheel, the hubcap is probably covering it.

- Remove the center screw by rotating it anticlockwise by using a socket wrench.

- Using pliers or hands, remove the washer located under the screw if your mower has it.

Removing a Riding Mower’s Wheels

- Position the mower on a flat surface like the driveway. Carefully disconnect the power cord from the battery.

- Under the wheels you want to change, place the mower lifter. Apply pressure to the mower lifter until it makes a 90-degree angle with the ground, then lock the pins attached to the lifter.

- Using hand gloves, rotate the plastic cap mounted on the center of the wheel anticlockwise. Some mowers lack this cap.

- Remove the cotter pin using pliers or a screwdriver and remove the washer located underneath.

- Pull the washer outwards underneath the pin, and remove it.

Lubricate the Wheel Bearings

If your mower has wheel bearings, make sure to lubricate them after every 25 hours of use to protect them from wear. Always review the safety instruction on your user manual before undertaking any mower maintenance procedure. The zerks make it easy to apply grease to the internal bearings. Use your grease gun and pump in some until you see a little bit of it come out of the fitting, then wipe off the excess.

Use Dry Graphite Spray

Dry graphite is a lubricant to be used where dust and dirt are a problem in mowers. The reason is that it doesn’t leave a sticky residue that may later attract dust particles.

The graphite is combined with fast evaporating solvents for ease of use and packaged into a spray can. This liquid solvent evaporates quickly and leaves a powdery graphite deposit on the lubricated area.

Dry graphite spray also has a high heat and pressure tolerance. Its use is purely a convenience when it comes to lawnmowers.

Investigate Additional Causes

Always clean your mower after use to remove dirt and debris that may collect while mowing. Use a garden hose and spray the mower deck on each side. It will prevent the mower from damage and ensure that it functions properly and lasts longer.

Lubricate the Rest of the Mower

Lubricate the other parts of the mower, such as the deck lift pedal and all the fittings simultaneously. Your mower will last much longer if you keep it greased and ready to go.

Perform the Process Regularly

Performing mower maintenance goes a long way in ensuring the longevity of your equipment. Change your oil and oil filters regularly and grease your mower two times in a mowing season. However, if you are a commercial mower, you should do it more often.

Do you have a riding mower? Consider reviewing the identification and title article.

Conclusion

As you can see, greasing a mower’s wheels is relatively simple. You only need a few tools to get the job started, and it takes less than an hour from start to finish. Make sure you wear protective clothing, and keep your hands away from your face until you’re done.

- Remove your lawn mower’s wheels before you use grease.

- Consider getting a mower lift to elevate it off the ground.

- Grease the wheel bearings, spindles, and other components.

- Follow the steps found on this page one to two times per year.

The Best Grease for Lawn Mower Wheels: A Comprehensive Guide

Do you have a squeaky lawn mower? Are the wheels making strange noises as you push it around your yard? Chances are that the wheels need some grease. In this comprehensive guide, we will discuss what kind of grease is best for lawn mower wheels and how to apply it. We’ll also cover some tips and tricks to keep your lawn mower running smoothly all season long!

What Kind of Grease Can You Use for a Mower Deck?

If you have a mower deck, it is important to know what type of grease to use on it. There are different types of lubricants that can be used on different parts of the deck. For example, you would not want to use the same grease on the drive chain as you would on the steering gears. Each type of metal has its own specific needs when it comes to lubrication. In general, however, there are a few things that you should look for in a good mower deck grease.

First, it should be thick enough to stay in place but not so thick that it will gum up the works. Second, it should be able to withstand high temperatures without breaking down. Finally, it should be resistant to water and other liquids so that it does not wash away easily. There are many different brands of greases on the market, so you should experiment to find one that works well for your particular deck.

What Type of Grease Should I Use on My Mower Deck?

When it comes to greasing a mower deck, there are a few things to keep in mind. First, you’ll need to choose the right type of grease. There are many different types of grease on the market, so it’s important to select one that is specifically designed for use on lawn mowers. You’ll also want to consider the temperature range in your area when selecting a grease. If you live in an area with extreme temperatures, you’ll need a grease that can withstand both high and low temperatures. Finally, be sure to read the instructions on the packaging carefully before applying the grease to your mower deck. By following these simple tips, you can ensure that your mower deck is properly lubricated and protected from wear and tear.

How do you lubricate a lawnmower wheel?

First, check the manual for your specific model of lawnmower to see what kind of lubricant it recommends. Next, locate the spot on the wheel where you will add the lubricant. For most models, this will be a small hole near the axle. If you can’t find the hole, consult the manual or look for an online video tutorial.

Once you’ve found the appropriate spot, add a small amount of lubricant – just enough to coat the surface. Finally, spin the wheel a few times to spread the lubricant evenly and you’re done! Lubricating your lawnmower wheels on a regular basis will help to keep them working smoothly and prevent them from premature wear and tear.

Also Read: How to Make a Lawn Roller: A Fun and Easy Garden Project

Should you grease lawn mower wheels?

The answer might surprise you. According to lawn care experts, you should not grease lawn mower wheels. In fact, doing so can actually damage the wheel and make it more difficult to turn. So, what should you do if your lawn mower wheels are squeaking? The best course of action is to lubricate the wheels with a dry, lightweight oil.

This will help to reduce friction and make it easier for the wheels to turn. Simply apply a small amount of oil to a rag and wipe it along the surface of the wheel. Be sure to check the level of lubrication regularly and reapply as needed. With a little bit of care, you can keep your lawn mower wheels in good condition for years to come.

What grease do you use on lawn mower?

Any good lawn mower maintenance guide will tell you that regular greasing is essential to keeping your mower in top condition. But with all the different types of grease on the market, it can be hard to know which one to use on your lawn mower. The best way to figure out which grease is right for your mower is to consult your owner’s manual. In general, though, most lawn mowers will do fine with a standard all-purpose grease. Just be sure to avoid using any type of grease that is not specifically designed for use on lawn mowers, as this can damage the engine and other parts. With a little bit of care and attention, you can keep your lawn mower running smoothly for years to come.

How do you grease lawn mower deck bearings?

The best way to grease lawn mower deck bearings is to remove the old grease and dirt from the bearings and then apply new grease. You can remove the old grease and dirt by taking a piece of cloth and wiping it on the bearings. Once you have removed the old grease and dirt, you can apply new grease to the bearings by taking a brush or spatula and spreading it over the surface of the bearings.

Make sure that you apply enough new grease so that it covers the entire surface of the bearing. Once you have applied new grease to the bearings, you can reassemble the lawn mower deck and start using it again. Greasing lawn mower deck bearings is an important part of maintaining your lawn mower and keeping it in good working condition.

Zero-Turn Mower Maintenance Best Practices

Here at AMSOIL, we’re always investigating ways to help you get the most out of your vehicles and equipment. One example includes zero-turn mowers used by landscape professionals and homeowners with big yards to maintain. In this post, we’ll review some zero-turn mower maintenance best practices.

How zero-turn mowers work

Zero-turn mowers have been a staple for landscape professionals for several years and are popular among homeowners with large lawns. Their advantage comes from the ability to make sharp turns with swiveling front wheels and independent rear wheels.

The machine is typically controlled by a series of belts, pulleys and hydraulic controls that the user operates with control levers. They cut closely along the edges of shrubs, flowerbeds and other obstacles, decreasing the need for extra trimming.

They’re especially convenient when mowing around trees and making 90-degree turns since you don’t have to engage the clutch several times to go backward and forward, saving time and making the job easier.

Zero-turn mower safety

Zero-turn mowers do have downsides. Steep slopes are a hazard, and many manufacturers warn about potential rollover risk. As a best practice, consult your owner’s manual when dealing with slopes more than 10 degrees, especially if the grass is wet. Many models have roll bars and seat belts to help prevent injury.

Avoid side mowing, especially if there’s standing water or a drop-off at the bottom of the slope. In these cases, a push mower or trimmer is likely the best way to go. As always, it’s best to use proper hearing and eye protection.

Zero-turn mower maintenance

A properly maintained zero-turn mower can deliver years of reliability, even after having logged several hundred hours. Here are a few maintenance tips:

Maintain zero-turn mower belts

Belts are one of the biggest maintenance concerns with zero-turn mowers. To keep the belts working well, keep the outside of the deck clean and periodically clean the underside of the deck of clippings and debris. Keeping the deck clear will help prevent the belts from getting beat up.

Consider coating the deck and blade with AMSOIL Heavy Duty Metal Protector to keep out water and dirt. Be sure to periodically check the pulleys and belts for wear and replace them as needed.