How to increase circulation circuits. Adjustment of the electric motor revolutions…

Engine power from the diameter of the circular disk

The three phase engine on one phase produces less than half of the rated power. That is, the 3KW engine will issue 1-1.5 kW. I think 3kW will be not enough. At 380 volts it would be just right and 220 it is better to take more.

Yeah, for the fiftieth, you would need a more powerful engine. I have a circular with a engine 900W, well, very weak. You even plow to drink a magpie, especially if the tree is raw.

I have been working for a long time: email. 4 kW engine for a board 50 mm is normal. But less than a mute. (380 V and 3000 revolutions. saw with a diameter of not more than 250 mm).

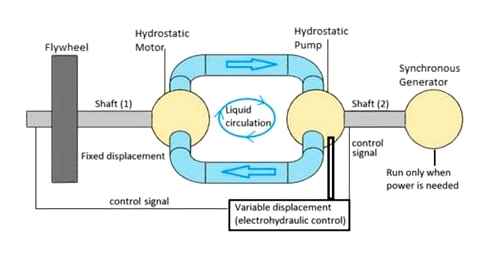

Proportional hydraulics, proportional valve, servo valve. how it works. Technical animation

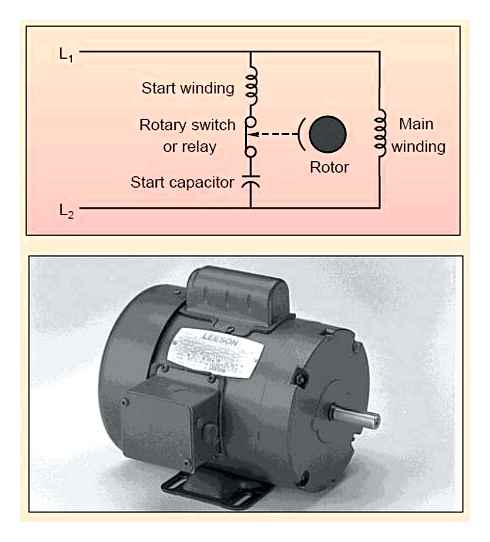

3000 revolutions, 3 kW are enough to dissolve the board 50mm. subject to 380 volts without problems. 220 volt through the start.up capacitor is an electrolytic or working capacitor at the rate of 70 μF per 1 kW. The main condition, a good disc shirrcular and pulley on zl. engine with the same diameter as on the shaft or a little more. https: // fazadom.com

-I would like to know the power of power on the engine shaft T. e. the force required for rotation without overheating of the engine just do not guess but count. I have long been designing the programs of the parts of mechanisms and machines. I would like to refresh Ane by trial and error. Corrected e.D 2.2 kW heats up after a short time of work. Universal shaft with interchangeable knives for stricting the surface of the boards and cutting edges. How to determine power on the engine shaft, mystery.

How to choose the right electric motor, taking into account the mode of its work?

There are two electric motors for sale on the shop window. Both are 2.2 kW, 3000 revolutions per minute, supplying voltage. 220V (single.phase), on paws, 80 dimensions (shaft diameter 22mm), the price is approximately the same (the difference in price is 10%), the production of different factories. Which is better to choose an electric motor ?

And here we recommend paying attention to such an electric motor parameter as its operation mode. See photos of electric motors: one electric motor operating mode: S1; The other has: S6-40%:

Large homemade circular saw

In the manufacture of a frame for the top of the saw, it is best to use a metal corner with a width of 25 mm. In this case, the rectangle, which will be the frame of the upper part of the home.made circular, must have dimensions 600×400 mm. Further in the corners of this quadrangle four pipes are welded, the diameter of which should be 17 mm, and the height is about 2.2 m.

After that, it is necessary to strengthen two corners on the frame, on which bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix bearings, as a rule, clamps are used. It is best if the bearings installed on a home.made circular will be closed. So you can not be afraid that wood chips will fall into the space between balls, rings and a separator. Do not forget to cut the thread at the very end of the shaft, so that in the future you can install a cutting disk on it.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, in the manufacture of the lower frame, you need to take a corner with a width of at least 40 mm. Next, two more additional corners should be fixed across the frame, on which a homemade circular engine will stay in the future. The most appropriate engine for a Circular saw made by yourself is an asynchronous three.phase motor, with a power of at least 1.5 kW and with 1,500 revolutions per minute. The pulley stream should have a fairly large size, about 80 mm, and it should be planted directly on the shaft itself. In addition, you will need to weld a rather small metal site to the frame, on which the starting device will be placed. Large pipes 2.2 m long, which were previously welded by you in the corners of the frame, are necessary for high.quality stretching the belt so that metal lambs clench thin pipes.

Electric motor for circular 220V 4kW 3000ob.

Measurement using a mechanical tachometer requires direct contact with the surface of the object.

Now, in finished supports made of pipes, it is necessary to fit both the lower and upper parts of the home.made saw, and then tighten and squeeze the belt with metal lambs. The launch of the motor in this model of the circular with your own hands is carried out using start.up capacitors. In order to load the motor and increase its torque, you can apply 220/36 400 W transformer.

What turns should be on the circular

The circular saw made at home is a good method to save a lot of money and at the same time get quite high.quality and reliable equipment. The assembled homemade circular is true in no way inferior to the factory saw and is also capable of sawing the logs of even a very huge diameter.

The circular saw is used for a flat sawing of lumber.

So that the circular can easily saw logs of a huge size, you need to equip it with a truly massive electric drive. For this purpose, belt gear, shaft and engine with the highest strength of traction are installed on its surface. Our client remains circular saws made independently, consist of 2 parts: the upper and one of.

Various electrical equipment is always placed in the bottom, and specifically:

At the top of the circular saw, they install:

In the process of making a frame for the top of a saw, it is better to use an iron corner with a width of 25 mm. At the same time, the rectangle, which will be the frame of the highest part of a home.made circular, is obliged to have sizes of 600×400 mm. Further in the corners of this quadrangle four pipes are welded, the diameter of which should equate 17 mm, and the height is approximately 2.5 m.

After a while on the frame you need to strengthen two corners, where bearings will be fixed later. The distance between these corners is directly dependent on the length of the shaft. To fix bearings, you use clamps. The most ideal if the bearings installed on a home.made circular will be closed. So you may not be afraid that wood chips will fall into the place between balls, rings and a separator. Do not forget to cut the thread at the end of the shaft, so that in the near future there is an opportunity to install a cutting disc with him.

The lower part of the circular saw should be made significantly more bulky, which will provide it with the necessary stability and reliability. Therefore, at the stage of production or the upper frame, it is necessary to take the corner with a width than two 40 mm. Then two more additional corners should be fixed across the frame, on which, if necessary, the engine of a homemade circular will hold. A more suitable engine for a circular saw at home is an asynchronous three.phase motor, with a capacity of about 1.5 kW and with 1,500 revolutions per minute. The pulley of the pulley is obliged to have an unusually screaming size, approximately 80 mm, and it should be planted specifically on the shaft itself. In addition, for you it will be necessary to weld a fairly small iron venue to the frame, on which the starting device will be required to be located. Huge pipes 2.length 2.4.4.5 m, which were previously welded by you in the corners of the frame, are needed for high.quality stretching the belt so that iron lambs clench thin pipes.

Now in the finished supports made of pipes, you need to end in both the lower and upper parts of a home.made saw, and then tighten and squeeze the belt with metal lambs. The motor launch in this model of the circular is independently carried out using start.up capacitors. To load the motor and increase its rotating moment, you can apply 220/36 400 W transformer.

Circular saw test scheme.

You can simply make a homemade circular to cut logs and bars of wood, the thickness of which corresponds to the power of the electric drive installed here. If you want to work with large and very thick bars of a tree, then you should equip your home-made saw for a truly massive electronic engine, and of course install the shaft and belt transmission here. The best solution in this case will be the installation of a special pendulum village.

Circular with a 1.5 kW engine for 1500 rpm 220 volts

At the stage of production of a pendulum circular in artisanal conditions, only very strong iron corners should be used in the role of material for the frame. Further on the finished metal frame it will be necessary to arrange what remains our client with the mechanisms necessary for the usual operation of a home.made circular saw. In the presence of such a design, you can without any problems personally without any special efforts to establish the height of the cutting disk, avoiding unnecessary design difficulties with all this.

Read on what gasoline Partner chainsaw works

For the production of similar homesproofs, they will come in handy:

Circular saw device with a separate engine.

A mini-cycle should stand on a strong and stable table, since at least what kind of rocking can pose a danger to human health and also interfere with ordinary work with a saw. While starting the manufacture of a machine from a manual circular saw, you need to make a special table. Since the beds use iron goats and an ordinary old kitchen table. In the beginning, for you it will be necessary to connect the goats with each other with a wide wooden board than two 50 mm, and then fix the kitchen table in this case.

You can easily make the countertop from 2 iron (ideal) plates with a cross section of about 4 mm. Already today, for this purpose, it is possible to use thick wooden bars.

It is fundamentally not to blink to throw a small clearance between metal sheets, the size of which is usually 10-12 mm.

Here it is necessary to ensure that the edges of the iron plates are completely parallel in relation to each other. Now, when the table is quite ready, we proceed to the attachment to it the most circular saw. It is fundamentally noted that it should be fixed from below, while such a macar that its cutting disk is specifically in the gap between 2 sheets of the countertop.

Read adjusting the carburetor of the chainsaw STIHL MS 180

To make a home.made circular, you need to think in advance with which device the force from the motor will be transmitted to the cutting disk. Small equipment in size is an option to place specifically on the engine axis. But this will not in the best way affect the power of the circular made in artisanal conditions.

As such, the transmitting mechanism, without which the work of at least some circular saw is impossible, can be ordinary bicycle spindle. So often refers to the case, in which the shaft with bearings is located. To cut it from great, you need to use a hacksaw. With all this, an asterisk will not be needed for you, because even then it is most perfect to take from the D6 motor in other words D8. So that this asterisk has firmly sat on a new shaft, for you it will need to make a transition sleeve for you. While installing a disk saw on a bicycle spindle, you need to make sure that it has a suitable size of the landing hole for you. Now, given this information, it is necessary to set the size of the external diameter of the sleeve created for the transition mechanism. The sleeve should be attached to the spindle in several places. Further on the hull of the spindle assembly, the plate should be fixed with a width of more than 5 mm.

The main diameters

To calculate the parameters of the pulleys, as well as the drive as a whole, various diameters values are used, so, for the pulmonary gear pulley, they are used:

To calculate the gear ratio, the calculated diameter is used, and the external, to calculate the dimensions of the drive when laying the mechanism.

For gear, dedication differs from DNAR to the height of the teeth.The transfer number is also calculated based on the value of D.

For calculating a flat.time drive, especially with a large size of the rim relative to the thickness of the profile, they often take dedication equal to the outer.

The calculation of the diameter of the pulley

First, the gear ratio should be determined, based on the inherent speed of rotation of the leading shaft N1 and the required speed of rotation of the drive shaft N2/ it will be equal to:

If there is already a finished engine with a drive wheel, the calculation of the diameter of the pulley according to the transmission attitude I is carried out according to the formula:

If the mechanism is designed from scratch, then any pair of drive wheels that satisfy the condition is theoretically suitable:

In practice, the calculation of the drive wheel is carried out based on:

The final calculation of the diameter is finally clarified by the result of overall and powerful assessments.

If you find an error, please select a fragment of the text and click Ctrlenter.

The belt transmission transmits torque from the leading shaft to the driven. Depending on it, it can increase or lower the speed. The gear ratio depends on the ratio of the diameters of the pulleys. drive wheels connected by the belt. When calculating the drive parameters, you must also take into account the power on the leading shaft, the speed of its rotation and the general dimensions of the device.

Belt transmission is a pair of pulleys connected by an endless, looped belt. These drive wheels, as a rule, are located in one plane, and the axes are made parallel, while the drive wheels rotate in one direction. Flat (or round) belts allow you to change the direction of rotation due to intersection, and the mutual arrangement of the axes- through the use of additional passive rollers. In this case, part of the power is lost.

Cuneacomic drives due to the wedge.shaped cross.sectional form of the belt allow you to increase the area of engaging it with a pulley of belt transmission. It is made in the form of a wedge.

Gague.free drives have teeth of an equal step and profile on the inside of the belt and on the surface of the rim. They do not slip, allowing to transmit greater power.

The following main parameters are important to calculate the drive:

- the number of revolutions of the leading shaft;

- power transmitted by the drive;

- the required number of revolutions of the driven shaft;

- belt profile, its thickness and length;

- calculated, external, internal diameter of the wheel;

- groove profile (for cuneiform);

- Transfer step (for gear)

- Interssection distance;

Calculations are usually carried out in several stages.

The main diameters

To calculate the parameters of the pulleys, as well as the drive as a whole, various diameters values are used, so, for the pulmonary gear pulley, they are used:

To calculate the gear ratio, the calculated diameter is used, and the external, to calculate the dimensions of the drive when laying the mechanism.

For gear transmission, D Simch differs from DR to the height of the teeth. The transfer number is also calculated based on the value D of the.

For calculating a flat.frequency drive, especially with a large size of the rim relative to the thickness of the profile, they often take D of the CISS equal to the outer.

Belt gear device, its characteristics

Belt transmission is a pair of pulleys connected by an endless, looped belt. These drive wheels, as a rule, are located in one plane, and the axes are made parallel, while the drive wheels rotate in one direction. Flat (or round) belts allow you to change the direction of rotation due to intersection, and the mutual arrangement of the axes- through the use of additional passive rollers. In this case, part of the power is lost.

Cuneacle drives due to the wedge.shaped cross.sectional shape of the belt allow you to increase the area of its hook with a pulley of belt transmission. It is made in the form of a wedge.

Gague.free drives have teeth of an equal step and profile on the inside of the belt and on the surface of the rim. They do not slip, allowing to transmit greater power.

The following main parameters are important to calculate the drive:

- the number of revolutions of the leading shaft;

- power transmitted by the drive;

- the required number of revolutions of the driven shaft;

- belt profile, its thickness and length;

- calculated, external, internal diameter of the wheel;

- groove profile (for cuneiform);

- Transfer step (for gear)

- Interssection distance;

Calculations are usually carried out in several stages.

The main diameters

To calculate the parameters of the pulleys, as well as the drive as a whole, various diameters values are used, so, for the pulmonary gear pulley, they are used:

To calculate the gear ratio, the calculated diameter is used, and the external, to calculate the dimensions of the drive when laying the mechanism.

For gear, dedication differs from DNAR to the height of the teeth.The transfer number is also calculated based on the value of D.

For calculating a flat.time drive, especially with a large size of the rim relative to the thickness of the profile, they often take dedication equal to the outer.

We determine the speed

There are several ways to measure the engine speed. The most reliable is the use of a tachometer. a device intended specifically for these purposes. However, not every person has such a device, especially if he does not engage in electric motors professionally. Therefore, there are several other options that allow you to cope with the task “by eye”.

The first implies the removal of one of the engine covers in order to detect the winding coil. The latter can be several. Chosen one that is more accessible and located in the visibility zone. The main thing is to prevent a violation of the integrity of the device during work.

When the coil was opened, it is necessary to carefully examine it and try to compare the size with the stator ring. The latter is a motionless element of the electric motor, and the rotor, being inside it, rotates.

When the ring is half closed with a coil, the number of revolutions over a minute reaches 3000. If the third part of the ring is closed, the number of revolutions is approximately 1500. With a quarter. the number of revolutions is 1000.

The second method is associated with windings inside the stator. The number of grooves that one section of any coil is considered to be considered. The grooves are located on the core, their number indicates the number of poles pairs. 3000 revolutions per minute will be with two pairs of poles, at four. 1500 rpm, with six. 1000.

Motor speed controller tutorial. PWM how to build

The answer to the question of what depends on the number of revolutions of the electric motor, there will be a statement: on the number of pairs of poles, and this is an inversely proportional dependence.

On the case of any factory engine there is a metal tag on which all the characteristics are indicated. In practice, such a tag may be absent or erased, which a little complicates the task of determining the number of revolutions.

Increase. diameter. pulley

A study of transmission with pulleys without ring grooves: at a speed of above 50 m / s showed that its traction ability is reduced, despite an increase in the diameter of the pulleys. The latter is explained by the appearance of air pillows in the places where the belt is running into the pulleys, which cause a decrease in the angles of the belt and the more, the higher its speed. This is most manifested on the driven pulley, since the driven belt branch is weakened, which helps to penetrate the air cushion into the belt contact zone and causes its slip. [17]

Calculation of pulley for a gear belt. Calculation of the turnover of pulleys, a change in the transfer of belt transmission.

Increase or decrease in revolutions using pulleys.

Dimensions of pulleys and belts.

Protective selection and calculation of loads. pump, install and consider the belts and pulleys ourselves.

Increase. diameter. pulley

A study of transmission with pulleys without ring grooves: at a speed of above 50 m / s showed that its traction ability is reduced, despite an increase in the diameter of the pulleys. The latter is explained by the appearance of air pillows in the places where the belt is running into the pulleys, which cause a decrease in the angles of the belt and the more, the higher its speed. This is most manifested on the driven pulley, since the driven belt branch is weakened, which helps to penetrate the air cushion into the belt contact zone and causes its slip. [17]

Calculation of pulley for a gear belt. Calculation of the turnover of pulleys, a change in the transfer of belt transmission.

Increase or decrease in revolutions using pulleys.

Dimensions of pulleys and belts.

Protective selection and calculation of loads. pump, install and consider the belts and pulleys ourselves.

Belt gear device, its characteristics

Belt transmission is a pair of pulleys connected by an endless, looped belt. These drive wheels, as a rule, are located in one plane, and the axes are made parallel, while the drive wheels rotate in one direction. Flat (or round) belts allow you to change the direction of rotation due to intersection, and the mutual arrangement of the axes- through the use of additional passive rollers. In this case, part of the power is lost.

Cuneacomic drives due to the wedge.shaped cross.sectional form of the belt allow you to increase the area of engaging it with a pulley of belt transmission. It is made in the form of a wedge.

Gague.free drives have teeth of an equal step and profile on the inside of the belt and on the surface of the rim. They do not slip, allowing to transmit greater power.

The following main parameters are important to calculate the drive:

- the number of revolutions of the leading shaft;

- power transmitted by the drive;

- the required number of revolutions of the driven shaft;

- belt profile, its thickness and length;

- calculated, external, internal diameter of the wheel;

- groove profile (for cuneiform);

- Transfer step (for gear)

- Interssection distance;

Calculations are usually carried out in several stages.

Calculation of gears.

Calculation of pulley for a gear belt. Calculation of the turnover of pulleys, a change in the transfer of belt transmission.

Increase or decrease in revolutions using pulleys.

Dimensions of pulleys and belts.

Protective selection and calculation of loads. pump, install and consider the belts and pulleys ourselves.

From the network

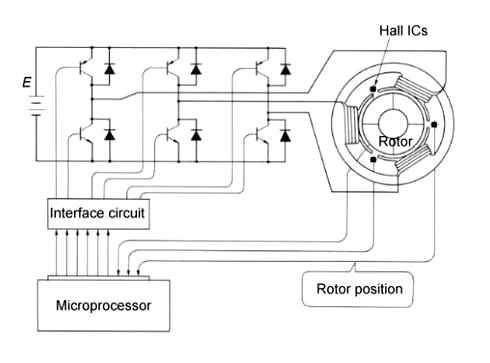

Single.phase alternating current electric motors also allow you to adjust the rotation rotation.

Collector machines

Such motors are on the electric drifts, electrolobsics and other tools. To reduce or increase speed, it is enough, as in previous cases, to change the voltage of the supply. For this purpose, there are also decisions. The design is connected directly to the network. The adjusting element is the systemist, the control of which is carried out by the dinistor. The simistor is placed on the heat sink, the maximum load power is 600 W.

If there is a suitable land, you can do all this with it.

A two.phase engine

The device, which has two windings. launch and working, is by the principle of a two.phase. Unlike three.phase, it has the ability to change the speed of the rotor. The characteristic of the spinning magnetic field is not circular, but elliptical, due to its device. There are two possibilities to control the number of revolutions:

Such units are widespread in everyday life and production.

Ordinary asynchronics

Three.phase current electric machines, despite ease of operation, have a number of characteristics that need to be taken into account. If you just change the supply voltage, the moment will change within a small limits, but no more. In order to adjust the revolutions widely, it is necessary to quite complex equipment, which is simply difficult to assemble and set up and expensive.

For this purpose, the industry has established the production of frequency converters that help to change the power of the electric motor in the desired range.

Asynchronik is gaining momentum in accordance with the parameters set on a frequency, which can be changed in a wide range. The converter is the best solution for such engines.

Alem 30.09.2018

Everything is much simpler. we take a rope and use it instead of a belt, then measure it with a roulette. profit)

Here the problem is not to measure the belt on the finished pulleys, but to calculate the diameters of the pulleys for the existing size of the belt.

T.e. You need to dance from the belt that you can buy, you can make any pulleys, and it will be a belt from a fixed set according to GOST.

SIA.ori 30.09.2018

Here the problem is not to measure the belt on the finished pulleys, but to calculate the diameters of the pulleys for the existing size of the belt.

T.e. You need to dance from the belt that you can buy, you can make any pulleys, and it will be a belt from a fixed set according to GOST.

Tolerances, that is, there is no much difference whether it will be slower at 1.85 or 1.93 times. Formula in the exel and forward, calculate the cuneiform transmission.