How to install a circular saw on a table

Manufacturing process

It is quite simple to create with your own hands a multifunctional design for an electric circular saw, however, it is necessary that the manufacturing process goes strictly according to certain stages. Strict adherence to the advice is necessary so that there are no problems or difficulties.

- First of all, each master must create a drawing and a plan for the future product. According to the drawings, the work is much easier to perform, the risks of making something wrong or of poor quality are reduced. At the planning stage, you need to take into account the dimensions of the future structure as clearly as possible.

- After creating a plan and a rough sketch of the product, as well as preparing all the necessary materials and a set of tools, we begin to manufacture the table body. We align all the edges of the bar with a plane. Then, from sheet material and aligned bars, we assemble the base, the dimensions of which were determined at the planning stage. The working surface area is usually about 1-1.5 square meters. All parts are attached to each other with bolts and screws. At the end of the work, we get a box without the upper and lower parts.

- Next comes the manufacture of a tabletop for a sawing machine, it is cut out of plywood or chipboard sheet based on the size of the frame. The table top should be the same area or slightly larger. The main thing is that it does not outweigh the body to one side. If the table top is made of non-laminated material, then it should be sanded and trimmed. Further, using a ruler and a pencil on the table top, the marking of the attachment points of the saw to it, as well as the upper part of the table to the main body is performed.

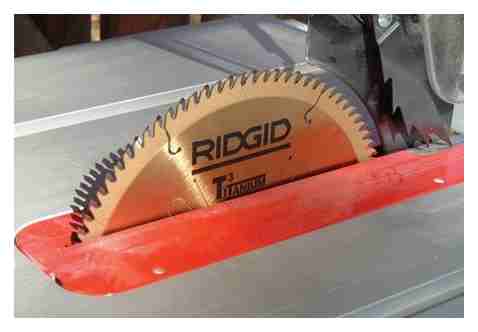

- The next step is to cut a hole for the saw itself. For this, measurements are taken of the support shoe of the sawing machine, which will later be used on this structure. On the reverse side of the tabletop, the corresponding markings are made, which will accurately determine the attachment point and the area along which it is necessary to cut the circular disc. For accurate marking, it is better to draw axes that connect exactly in the center of the plywood sheet. After determining the axes and making accurate markings, you need to cut a hole for the disc, as well as drill holes for attaching the saw shoe.

- The circular saw is attached to the plywood tabletop from the back (inside). To do this, you need to make 4 holes in the shoe of the saw itself, their diameter should be about 1 centimeter. Then you should completely align the saw and match all the markings so that the tool is level, all the marks and holes correspond to each other, the disc fits freely into the central hole of the tabletop. In order for the saw to be securely attached to the table, it is necessary to use special countersunk head plowshares, the head of such bolts must be deeply immersed in the sole of the tool and not stick out.

- Then the saw is set aside and the assembly of the table continues. In order for the structure to be stable. special attention should be paid to her legs. The legs that diverge downward will provide the best stability of the structure. They are fixed with large bolts and nuts.

The length of the legs is determined individually, in accordance with the height of the person who will work at the table. Ideally, the tabletop, and, accordingly, the saw itself should be located just above the master’s belt.

- The next step is to attach the tabletop to the cabinet. At a distance of about 3 centimeters from the edge, you need to make holes in the corners of the plywood, then holes are drilled in the corner bars for further fastening the bolts in them. Further, the parts are connected using steel fittings M8.

- After the structure is assembled, it is necessary to fix a special switch on the table, which will regulate the turning on and off of the saw with an electric motor. To do this, cut a hole in the housing for the switch and fix it with bolts, special glue or a construction screed. There must be electrical power from the switch to the saw itself, which means it must be connected to any electrical source in your workshop using a cable. It attaches from the side of the bottom of the countertop using construction fasteners.

- Then you can make special stops. First, a cross beam is made, it greatly simplifies the work with the structure. It is carried out mainly from plywood or chipboard. First, you need to cut out 2 strips equal in length to the width of the table, the second side should be about 100 millimeters, the corners of the strips must be rounded.

- Then the workpieces are ground and fastened with self-tapping screws at a slight angle, a metal corner is screwed inside. After that, the strips are attached to the table on movable furniture rails, which will allow these stops to move along the entire table.

- If you wish, you can make various additions to this design, it all depends on your skills. Some craftsmen remove the safety guard and all the devices for adjusting the tilt of the blade, this allows you to get an additional few millimeters of cut. Some replace the factory platform with a turntable of their own manufacture, with a professional approach this also gives a number of advantages in work.

- The construction is completed with the stage of processing and preparation for operation. The entire table should once again be sanded, wiped and varnished or with special agents that ensure durability of use and repell moisture and rust.

Installing a circular saw in a homemade table

After making the main body, the saw is installed in a homemade table.

- At the stages of manufacturing the table structure, all the necessary holes were cut in the tabletop.

- During the installation of a stationary saw, it is necessary to perfectly adjust the inclination of the tool, otherwise the sawing of wooden parts will be of poor quality. The first step is to install the tool on the finished tabletop in all grooves and determine whether you need to change the slope. If the angle does not correspond to the desired one, then you will have to adjust it using special bolts, this is the easiest option. Or you can cut out special pieces that will be attached to the tabletop, and already on top of them, at the right angle, the saw will be attached.

- If the tool is in place correctly, all the holes converge, you need to position and fasten the sole to the table with bolts and tighten them from the inside using nuts with lock washers.

- After the hand-held circular saw is installed, you need to take a block slightly larger than those with which the tilt angle was adjusted and fix it on the tabletop in the place where the saw platform was marked.

This block is needed so that after dismantling the circular saw from the table, you can build it in exactly the same place without using any additional markings.

Selection of tools and materials

At the beginning of work, you need to make sure that all the necessary raw materials are always at hand, as well as a set of tools that would be useful throughout all actions. To create a table, you need the following materials:

- plywood about 2-3 centimeters thick or an identical piece of chipboard;

- wooden bars measuring 40×40 millimeters;

- metal building corners. 12-15 pieces;

- self-tapping screws of different lengths and bolts of different classifications;

- glue used in carpentry;

- means for treating the product against moisture and rust;

- external socket;

- cable;

- switch.

This set of materials is required for a standard construction of ordinary dimensions with an area of just over one square meter. Almost any hand-held circular saw can work on such a table, except for tools with small discs, since the cutting depth sags during attachment to the tabletop, on average by 1-2 centimeters.

The following tools will come in handy for your work:

- marker or thick pencil;

- tape measure, metal ruler, angle;

- jigsaw;

- screwdriver;

- Grinder;

- drill;

- sandpaper.

How to make a table for a circular saw with your own hands?

The circular saw is an excellent maneuverable tool with high productivity. However, like all tools, the saw has some disadvantages. For example, you may have trouble cutting large pieces of wood. In such a situation, a special table made by hand will help you. This design will allow you to easily and quickly cut large parts without unnecessary problems.

Advice

- Before using the saw on the table, you should check the saw blade itself using a square, since some unscrupulous manufacturers do not set the blade exactly at an angle of 90 degrees, as a result, the cuts turn out to be beveled.

- If during work you plan to use the table also for storing tools on it, then the dimensions of the tabletop should be more than a square meter in area.

- For manufacturing, it is better to use high-quality and durable materials, otherwise the table will not last long.

- The table can be supplemented with anything you like, for example, some manage to attach a special vacuum cleaner or a riving knife with a disc protection to it, so that chips and residues from cutting wood do not fly around.

- Choose a place for the table in advance, and also make sure that the floor where the table will be installed is level.

- If you have the desire and certain skills, you can make a folding tabletop or a lifting table, but this will take more time and materials.

- If the table shakes or vibrates during operation, adjust the feet with suitable pieces of rubber.

Since a circular saw is an electrical device, it is better to work with it by a specialist who understands electricity. It is also better to entrust the transfer of the switch to another place to a specialist.

Safety engineering

- it is preferable to work with wood, metal and chemicals outdoors or in a well-ventilated area;

- the workplace must be kept clean and tidy;

- periodically it is necessary to check the stability of the structure, as well as the serviceability of equipment and electrical appliances;

- before turning on the saw, you need to make sure that it is well fixed;

- when working, you need to use special glasses and gloves;

- you need to keep a first aid kit at hand.

Making a table for a circular saw is not so difficult, but it does require some skill in joinery. Having at hand the necessary tools and materials and clearly following the step-by-step instructions, you can make a table of the required dimensions, as well as equip it with all the necessary additions.

For how to make a table for a circular saw with your own hands, see the next video.

DIY circular saw table, installation, fastening

Table circular saw

When choosing a circular saw, you need to be guided by the following characteristics:

- Saw power. If the volume of work is quite large, it is advisable to take a tool with a power of at least 1.2 kW.

- Cutting depth. The thickness of the material to be processed depends on this parameter. For hand saws it is 40–70 mm. But when it is installed in the table, there will be a decrease in the region of 10 mm.

- Placement of buttons. The design of the sawing table must provide free and safe access to all control buttons, otherwise it will be necessary to modify the control system yourself.

- Rotational speed. For cutting wood, high rotation speed is priority. This affects the quality of the cut. For plastic, for example, this is not very good. The plastic heats up from the high speed of the wheel. You need to choose average characteristics. 3-4 thousand rpm will be enough.

Circular saw table

The fact that a table is needed for a hand-held circular saw, I realized as soon as I bought this very saw. Of course, sometimes it is better to use the circular saw in “normal mode”. In most cases, it will be more convenient to work if you fix it permanently.

In addition, making a table for a circular hand saw was not very difficult.

I decided to make the saw table in the form of an attachment to the carpentry workbench. This workbench is large enough and not light at all, which is important in terms of overall rigidity and stability.

Of course, the design turned out to be quite primitive, but very simple and quite workable.

How to Make a Powerful Table Saw at Home

Switching the saw on and off

When someone is ready, you can decide how the equipment will turn on and off. If you have relevant knowledge in the field of electrical engineering, then the power key can be bypassed by you. In this case, the control button is brought to the outer surface of the rib.

If you have made a table for a hand-held circular saw with your own hands, but automating the operation of electrical equipment is too difficult for you, then the key can be pulled off with a wire, and the device itself can be turned on and off with a power cord. The above table design is pretty simple. Any home craftsman can handle the task of making. If you want to expand the functionality, you can take care of security by making the design more complex.

Circular saw table with lifting mechanism

To change the depth of the cut, you can additionally install a lifting mechanism (lift).

The lifting mechanism itself is mounted from a metal sheet, which is attached to the frame on the machine. Lifting will take place along the guides by tightening the bolts.

One way is to install the adjusting bar with the locking nuts. Instead of rods, we use studs. We make the adjustment handle from a plate welded to the end of the stud. At a distance of 4–5 mm from the center we make holes for self-tapping screws. We weld a rod to the edge of the plate, with which we will rotate the structure.

DIY circular saw table: drawing and features

A circular saw, which in the common people is called a circular saw, is a productive and convenient tool. It can be used for a wide variety of tasks. Perhaps you also own it or are just planning to purchase it. However, when cutting large batches of material, it is rather difficult to work with such a device. To facilitate this process, you can use a table, which you can make yourself. This idea is easy to implement, and you need to prepare boards and plywood before starting work.

At the same time, the hand saw is located at the bottom of the working surface, but its working disk is in the slot. After turning on the equipment, the disc rotates, and when the lumber is fed, the cutting process begins. The maximum workpiece thickness to be cut will depend on the saw power and blade size. When choosing a tool, you should take into account the thickness of the tabletop on which it will be reinforced.

Circular saw table drawings

There are other ways to make a do-it-yourself circular saw frame. Here are two more examples.

Deciding on the design and construction

The simplest version of a circular table is a structure made of fairly thick plywood and boards

The base can be made of wood or metal. For the countertop, leafy tree species are chosen. A special hole for the disc should be made in it. The key property of the created table should be convenience.

Circular machine bed

Care should be taken to ensure its stability. Any loosening is unacceptable, otherwise it will negatively affect safety. The countertop should have the most flat surface. Then the likelihood of injury during work will be reduced.

A circular saw table requires the presence of guides

The structure can be supplemented with a special riving knife. He can be filmed. It is equipped with a special disc protection that allows it to get rid of the chips flying into the working.

Circular table guide carriage

Some remove the factory cover and change the factory platform to a homemade one. If you are not going to cut at an angle, you can remove the parts that adjust the inclination of the blade.

Benefits of DIY

The table is made taking into account the fact that the hand tool will be installed and fixed on the table, thus turning into stationary equipment

The construction of an element with your own hands allows you to make the saw as suitable as possible for individual conditions. Difficulties in the process will not arise if you carefully study the issue. You can adjust the product to the desired size, distribute everything so that it is convenient for you.

It is quite within the power of every master to make a table for a circular saw.

The handcrafted model will be one of a kind, which makes it unique.

Small tabletop circular stand

Necessary materials

Homemade table can be made of wood

For such a table, wood, plywood or chipboard can be used. MDF and chipboard are also suitable. Some people prefer to choose steel or aluminum.

Steel plate circular machine table

It is not recommended to use plastic, it is completely unsuitable for a table of this purpose. If wood is chosen, then after the assembly is completed, the product should be treated with a special antiseptic composition. This will provide reliable protection from moisture and help prevent rotting.

To make a saw table yourself, you need to prepare materials.

- Selected raw materials for the base. The thickness should be 21 mm.

- The beam required for the frame. An edged board with a length of 3 meters with dimensions of 50 to 150 mm is suitable. You need 5 pieces in total.

- Dowels made of wood with dimensions of 10 cm.Not less than 12 pieces.

- Wood glue.

- Metal fasteners in the amount of 4 pieces.

- Metal corners. Enough 10 pieces.

- Self-tapping screws.

These elements must be prepared in advance and placed near the workplace.

Blueprints

Scheme for making a table for a circular saw

Before starting work, it is recommended to go through the preparatory stage. Be sure to make a drawing. This will facilitate the process of creating the structure. First calculate the dimensions of the table, then transfer the obtained data to paper. The hole to be made in the structure must fit exactly the size of the saw. It all depends on the brand of equipment. Therefore, it is impossible to make a universal hole. The base must be stable and withstand well mechanical loads.

DIY circular table drawing

It is inadmissible to outweigh the structure to one side. The dimensions of the table top should be suitable for the cutting flow. The final version is determined based on individual desires. Some people work comfortably with a folding table or a product with small dimensions.

Drawing of a universal bench machine

An important point should be taken into account in the drawings. If you plan to leave tools or materials on the table during work, then the dimensions of the countertop need to be increased to a square meter in area. A suitable size would be 120 by 120 cm.A drawing should be done carefully and slowly in order to do everything correctly.

Circular table layout with detailed description

Table for a circular saw with your own hands. Drawings, photos, tips.

A circular saw is used to cut wood.

Using a hand saw is not always comfortable, using a table allows you to make the sawing process smoother and more accurate

The cutting base has a disc-like plane with a serrated outer edge. There are models not only of the manual type, but also with the possibility of fixing on the table.

It is difficult to work with large volumes of wood with a regular circular, so it is better to place it on a table.

There are several ways to acquire the latter for the convenience of performing manipulations. The table for a circular saw can be built independently, precisely following a certain pattern.

Circular saw table device

Required tools

- pencil and marker;

- measuring instruments including meter and tape measure;

- jigsaw;

- manual frezer;

- grinding machine;

- sandpaper (should have medium or fine grain);

- plane and drill;

- screwdriver.

You need to prepare everything in advance and keep it at hand throughout the entire process.

Manufacturing process: step by step instructions

Marking the attachment point of the saw to the table

Marking and fastening stiffeners

Tabletop for circular saw, ready-made

To make a quality structure, you must follow some tips. The process consists of several steps, presented in the table.

| Steps | Description |

| one | The block should be trimmed on all sides using a planer. Then the frame of the future table is assembled from it. Several 5 mm holes must be drilled on each side of the countertop. Additionally, one pass-through is performed for the legs of the product. |

| 2 | Several holes of the same diameter are made in the drawers. In the legs, one through is performed. The diameter remains the same, 5 mm. |

| 3 | Proceed with installing the dowels in the table top. Before that, they are covered with wood glue. Legs and tsars are placed on top. If there are clamps with screeds, the product should be fixed with them. When the glue is completely dry, you need to fasten the drawers and legs using special metal fasteners. Additionally, it should be tightened with self-tapping screws. You can add reliability and strength to the structure by using the corners. They will become an element of additional fastening, give stability to the product. For the short side, 2 pieces are enough, and for the long side, 3. |

| four | The next step involves securing the saw to the workpiece from the inside. There are several methods to accomplish the task. For fastening, M4 bolts or bars with self-tapping screws are suitable. The first case is fast and reliable. The second method does not involve additional holes, which eliminates the need for drilling. It is necessary to do a drank in bars, the width of which is equal to the dimensions of the saw platform. Further, self-tapping screws and bars on both sides fasten the equipment and the countertop |

| five | After installing the saw, you will need another larger block. It, using self-tapping screws, is fixed on the basis of the structure. Fastening is carried out at the marks made when the platform was set in a level position. These manipulations will help, when removing the saw, return it usually quickly without looking for markings. |

| 6 | The saw blade is set in place. The base is sawn to obtain a longitudinal hole. Then the product needs to be turned over |

| 7 | Then the production of the parallel stop is started. Two strips are sawn off from the plywood. Their length should be the same as the width of the table. On average, these dimensions are 10 cm.The corners should be rounded |

| 8 | The resulting strips are sanded. They need to be fastened at an angle with self-tapping screws. A metal corner should be screwed inside |

| 9 | If you need to fix the stop on the base and the structure will be used often, you should attach the guide so that it is perpendicular to the disk. Attach the roller on the bottom. This will allow him to move. |

The structure is completed and ready to use. When performing the described manipulations, it is important to remember the observance of safety measures. Also applies to any manipulation of the circular saw.

Check the position of the table and its firmness on a regular basis. The structure must be stable, without loosening.

Example of a manufactured table for a circular saw

Table option for hand-held circular saw with lifting mechanism

Make sure the saw is securely fastened first, then turn it on. Do not hold the cut material with your hands. This will help prevent the wood from getting in your face as the knots begin to bounce. Additionally, it is recommended to use special safety glasses when working.

Be sure to wear safety glasses for safety.

These simple tips will help you avoid injury in the workplace.