How To Load The Line Into The Trimmer

A little advice. Try not to let the line come into contact with hard objects when cutting. With this contact, the line will be cut. And since in this trimmer the line is not fed automatically, then every time you have to stop work, remove the reel and release the line again.

Trimming the line into the trimmer.

I want to devote today’s article to the sore subject of summer residents and gardeners of the entire post-Soviet space How to fill the line in the trimmer. Not many trimmer manufacturers answer this question in their instruction manuals. Therefore, it is also difficult for simple gardeners to figure out how to do it correctly.

I want to start with a brief description of the technical characteristics of the trimmers.

So, trimmers are electric and gasoline. The cutting element for trimmers can be a line and a knife. The line is ordinary, four. Pentahedral and intertwined (in the form of a pigtail). Knives come in 2, 3 and 4 bladed knives. Knives also come in plastic and metal.

The line feed system from the trimmer is manual, semi-automatic and automatic.

Development engineers who create new trimmer models clearly calculate the diameter (thickness) of the line and the number of knife blades, according to the power of the trimmers. Otherwise, the motor is overloaded, resulting in damage. And these are additional and significant costs.

Trimmers on the market today:

With one line only.

With two fishing nozzles and three-four-bladed knife.

With one nozzle only three to four blades.

Our Kulibins long ago learned to improve any mechanisms. So, for example, some gardeners make successful, in their opinion, replacement of fishing line with a metal cable, or fishing line. But at the same time, they do not think about the safety of their own and their loved ones, because, like a cable with the power of a working trimmer, it can easily break out and not only injure the mower and others, but leave him crippled for life. Using a fishing line can and gives a better effect, I have never personally tried it than a trimmer line, but such work has a number of inconveniences: when it comes into contact with hard objects, it loosens or can simply be pulled out of the reel without limit.

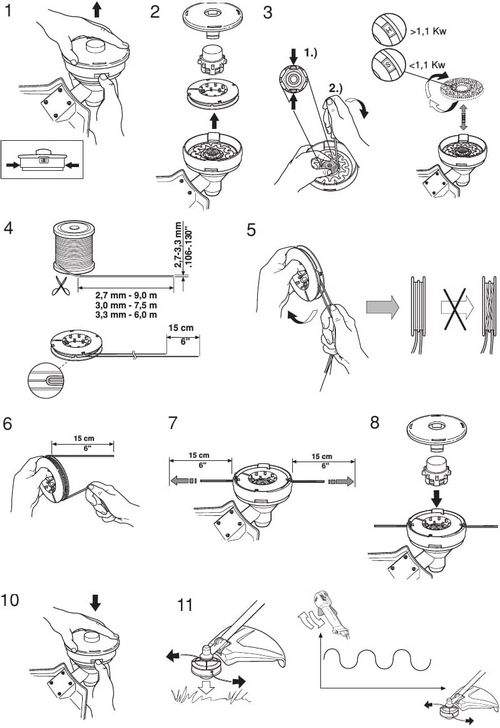

So, what is called closer to the topic. Here is an example of how to thread the line into the trimmer (Trimmer BOSCH Art 30). Everything is very simple. Started.

After you have chosen the line for refueling, you need to cut off the required amount of line, because all the line in a skein will not be wound into a reel.

Cut off and start reeling.

Removing the coil and protective cover from the coil.

They took it off. We fix one end of the line in the gap and carefully and evenly wind the line.

The amount of line should be such that the protective cover of the reel closes and the line on the reel unwinds a little.

We put the other end of the line into the hole on the protective cover.

Next, take the coil and the coil cover. We squirt the end of the line from the reel into the metal hole on the protective cover of the reel. We tighten the line a little.

We put it all on the trimmer. Turn the coil clockwise until it clicks.

They fixed it. Now we connect the trimmer to the network. We put the trimmer in the starting position for work. We turn on the trimmer. Excess line length will be cut on the trimming blade.

Coil in trimmer

That’s all we start working.

In addition to the standard lawn line, my trimmer has a thick line for cutting rough weeds. It is shaped like a pigtail, i.E. Three lines are tightly intertwined. This line has its own spool.

Spare coil storage space

It is very simple to install such a fishing line into the reel according to the internal scheme inside the reel. We insert the center of the line with a metal mount in the upper part of the reel, and draw the ends of the line along the grooves and bring it out.

Thick line

It is stored at the top of the trimmer body.

Heavy-duty line in a reel

This reel is attached to the trimmer in the same way as a reel with an ordinary line.

We wind the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task of winding the fishing line into the spool. Technological features of the spool design and the number of working antennae determine the sequence of actions.

Preliminary preparation

First of all, to wind the fishing line, you need to remove the spool (bobbin, spool) from the trimmer; specific actions will depend on the complexity of the configuration and the type of the product itself:

- Small electric trimmers with a working engine and bottom coil usually have side buttons on either side of the bobbin. When pressed at the same time, the upper part of the spool together with the inner content for winding the line is detached, while the lower part remains on the trimmer. It is advisable to disassemble the bobbin on a flat, smooth place so that the spring included in the structure does not jump out and get lost;

- Electric and gasoline trimmers with a curved bar without the possibility of installing a knife, as a rule, have spools with a special wing: in such designs, hold the spool in a stationary position with one hand, and rotate the locking reel on the rod with the wing nut counterclockwise with the other. After disconnecting the nut, the entire bobbin is removed.

- Electric and gasoline trimmers with the ability to install the knife on a straight bar (for example, Stihl trimmers) have a hole under the reel. To keep the rod stationary, a screwdriver or other suitable object is inserted into this hole and, with slow rotation, such a mutual arrangement is achieved when the screwdriver enters the hole and the bobbin is fixed. After that, the coil body is scrolled clockwise (with a left-hand thread) and removed from the trimmer.

For the second and third cases, the coils, depending on the design, are disassembled in different ways. In bobbins with a lamb, a lamb is unscrewed, in coils with latches, the latches are pressed and one part of the coil is released from the other. If the halves of the bobbin are connected by thread, then it is enough to turn them by hand in opposite directions until they are completely unscrewed.

Coil with two working antennae

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- One groove both tendrils are wound together along one groove;

- Two grooves, each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the bar, the side inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference in line winding in double-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle fold), and the fold loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The following will clearly show how to thread the line into the trimmer reel and wind it correctly, this operation is not difficult and with some patience it will certainly be crowned with success:

How to insert line into the trimmer spool? Instructions

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple science does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

Coil with one working antenna

The simplest option and uncomplicated sequence of actions:

- The dimensions of the spool and the length of the original factory winding determine the recommended length of the 25 m line for winding.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product, as a rule, on the inner side of the bobbin an arrow indicates in which direction it is wound.

- A small section of the line is left free to bring it out, it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

Automatic line winding to a spool

There is a type of reel in which the automatic mechanism produces winding independently from the user, it is enough just to correctly fill the line. The fishing line is passed through a hole on the inner part of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line inside is wound independently. In such a spool, it is impossible to make the winding wrong: the mechanism itself will determine the correct direction, since it can only turn in one direction.

[xyz-ihs snippet = posledniy]

How to tuck the line into the trimmer?

Any machine for mowing vegetation is necessarily equipped with a spool, which, in turn, may differ in different models with a filament feed system (automatic, semi-automatic and manual). It is from this parameter that it is worth starting from before deciding how to fill the line into the trimmer.

In order to tuck the line into the trimmer, you need to take at least 5 meters of material, which is then folded in half. The center of the cutting element must be inserted into a specially designated place, and then the cutting attachment must be wound using the visual cues on the spool indicating the direction. At the end of all the work, the lid, of course, will need to be tightened.

Types of trimmer line

As a rule, line separation is based on different sample diameters, which can vary from 1.2 to 4 mm. The most commonly used material is a material with a thickness of 2 mm, but in no case should we forget that the choice should depend primarily on the trimmer model.

There is one main rule here: the more power the apparatus has, the thicker the line should be.

This element can also differ in the type of its section. So, it can be round (suitable for cutting plain grass) or square (for mowing soft green cover), sharp edges (tall grass), or be equipped with notches ideal for thin grass in diameter.

Do not forget that with the help of a fishing line it is allowed to mow only grass, and for other, coarser vegetation, it is imperative to use knives.

Next, you should take a closer look at the process of how to insert the line into the trimmer correctly. Indeed, it is with this procedure that many consumers often have difficulties.

What is a trimmer?

This equipment is based on the following elements:

- The motor, the main function of which is the rotation of the cutting head at the end of the rod;

- Directly the head, consisting of a coil on which either a fishing line or a knife can be wound;

- Knives or line rotating at high speed, which are the main cutting part of the device, how to load the line into the trimmer will go a little further.

An electric device is inferior in power to a gasoline one, so it is ideal for working on a standard plot of land that is adjacent to a house with source of electrical energy. The main positive aspects of this technique are the absence of noise during operation, light weight, ease of use and, of course, environmental friendliness.

As for petrol trimmers, such equipment, of course, is more mobile, so it can be safely transported from place to place and get rid of annoying vegetation in any area. Electricity does not need to be used here, which has a positive effect on the functionality of such an apparatus, the cutting attachments can be changed, working with weeds of various types.

One of the most common attachments is the fishing line, so you should dwell on this element in more detail.

How do I fit the line into the trimmer? Operating tips

The trimmer is an excellent modern device designed for mowing unnecessary grass, and its main advantage is that this technique can be used in those places where an ordinary lawn mower will simply not be able to reach due to its massiveness. It is necessary to understand in more detail what trimmers are, and how to choose the best option for a particular suburban area.

Line adjustment

One of the main rules when replacing and adjusting equipment, any manipulations with the mechanism should be carried out exclusively with the engine off and the device plug disconnected from the mains.

Perhaps these tips will tell you how to tuck the line into the trimmer as correctly as possible and, accordingly, give your site a neat and aesthetic appearance. All that is required is to correctly select the cutting material required by the type and, of course, to determine the category of the most used trimmer.

How to tuck the line into the trimmer so that working with it does not get tired

Many summer residents use a scythe trimmer with an electric or gasoline engine to combat weeds. It is convenient when working in hard-to-reach places for a lawn mower: near fences, flower beds, houses, in a garden on narrow aisles, and can cut small branches. The main element of this miracle technique is an ordinary fishing line, wound on a reel. The device is simple, but the cutting part wears out quickly and requires replacement. And the question of how to fill the line in the trimmer worries many owners of summer cottages.

How to quickly remove the coil from the tool

Before the thread is wound on a bobbin, it must be removed. over, the methods of removal depend on the characteristics of the instrument. On trimmers with a motor near the ground, the reel has two side buttons, when pressed, a part of the body is separated together with a device for winding the thread.

On tools with a bent rod, the lamb on the device is moved counterclockwise; having disconnected it, remove both the bobbin and the spring inside it. On trimmers with a straight bar, fix it with a screwdriver, rotate it clockwise and remove it. Then the device is disassembled either with the help of latches or by moving its parts in different directions. Take out the spring from the coil.

Briefly about the line

Taking into account the models of the tool, the thickness of the line is 1.2-4 mm. There are such configurations:

- The round is the most durable;

- Curly for soft grass;

- Twisted or serrated for fine grass;

- Professional, not suitable for all instrument models.

When changing the cutting thread, you need to choose the one that suits your trimmer type. Preference should be given to specialized. Before tucking the line into the trimmer spool, it is best to soak it in water for half an hour. Then it will become more elastic and stronger.

Threading the line into the trimmer

The main question is how to properly wind the line on the trimmer spool, securely fixing it there?

In the case of a device with one antenna, up to four meters of fishing line is unwound, one end is inserted into the hole inside it, which fixes the fishing line, and moved in the direction indicated by the arrow. The end of the thread is fixed in a groove inside the bobbin so that it does not unwind during assembly. If there is no groove, then this free end is fixed with a finger. Then the coil is assembled.

How to thread a trimmer coil if it has two antennae? In this case, check how many grooves there are one or two on it. In the first case, both antennae are directed into a common groove, if there are two of them, then each of them into its own. 2-4 meters of thread is passed through the hole so that the free ends of the thread are of the same length, and twist the bobbin in the direction of the arrow-pointer. The ends of the thread are inserted into the grooves or held with a finger, the device is assembled and attached to the trimmer.

In a spool with two grooves, the same piece of thread is folded in the form of a loop, sent to the groove between them and the ends are wound simultaneously. Then repeat the previous assembly. With semi-automatic winding, the bobbins operate as follows. The fishing line is passed through the hole inside, its ends are fixed in the holes on the body, collect it and press the button. The thread can be easily wound in the correct direction.

It is important to remember that the cutting surface must be protected from hard objects so that it does not wear out. Otherwise, it will be necessary to constantly stop and, having removed the reel, replace the used line. Keep your work fun and enjoyable!

See: How to Insert Line into Trimmer

How to tuck the line into the trimmer?

In order for the area near the house to always look well-groomed and neat, it must be cut regularly. Fortunately, modern technology allows you to solve this problem without excessive physical effort. Electric trimmers are so easy to operate and maintain that even a teenager can use them to mow. The main thing is to figure out in advance how to fill the line in the trimmer.

How to load the line into the trimmer?

So, we are faced with the task of correctly loading the line into the trimmer. Let’s take a closer look at where to start implementing it and what pitfalls can await us in the process.

Step 1 choose the line

Step 2 remove the coil from the trimmer

To perform this operation, the trimmer must be disconnected from the mains and turned over with the working head up. The further course of action depends on the trimmer model and the design of the coil itself:

- For small trimmers with a lower engine position, press the keys located on the sides of the coil and remove its upper part from the head;

- On trimmers with a curved bar, we clamp the coil body with one hand, while simultaneously turning the winglet located on the body counterclockwise;

- For trimmers with a straight bar and a gearbox, insert a screwdriver into the hole located under the coil, and then turn the coil body counterclockwise.

Step 3 disassemble the coil

After the coil is removed from the head, it must be carefully disassembled. It is better to do this on an already mown area, since there may be a spring inside the coil, which will be quite difficult to find in tall grass. After disassembly, we will have three parts on our hands: the body (top cover), the protective casing and the coil itself.

Step 4 measure the required amount of line

Newbie mowers are usually interested in how many meters of line to wind on the trimmer reel? There are two ways to resolve this issue:

- Unwind a skein of line on a flat, dry place and separate half of it.

- Measure 3-4 meters of line from the skein.

In any case, after the end of winding, the turns of the line should be on the body of the reel, without sliding off it. You do not need to try to wind as much as possible, as the line will unwind poorly and often break.

Step 5 winding the line onto the reel

How to attach the line to the trimmer depends on the coil design. Consider the option when the coil body has one outlet for the line. In this case, we clamp the end of the line in the crevice of the coil, and then we wind the line, trying to lay the turns as tightly as possible. The direction of laying the turns should be opposite to the direction of rotation of the coil and is usually indicated on its inner part. After the end of winding on the spool, you must put on a protective cover and bring the end of the line into it

If the reel is designed to work with two tails, then the line must be folded in half and laid in the groove in the center of the reel. Further winding will be carried out along one or two slots, depending on the coil design. The direction of winding must also be opposite to the direction of rotation of the coil. At the end of the ponytail, the line will also need to be led out into the holes on the top of the reel.

Trimmer head with two antennae

Double flute head

After removing the spool from the spool body, we determine the number of strands for winding the line (1 or 2). There is no fundamental difference between bobbins with one and two grooves, but if carelessly threading into the twin groove, there will be operational problems. Due to the likelihood of interweaving adjacent lines of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones.

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction to the rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel. After the fishing line is tucked into the trimmer coil, thread the free ends (15-30 cm) into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability. Do not worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off the excess.

Winding the line to the trimmer

Measured and accurate dismantling of the spool from the spit coil makes it possible to go directly to winding the line. The design features of the head, the number and location of fixing holes dictate the sequence of actions when performing this operation, and also determine the methods used. Today there are several types of reels, depending on the number of line antennae and the methods of threading it:

- Trimmer head with one working mustache;

- A bobbin with two line antennae;

- Auto winding reel.

Preparation for winding the line

Before the winding process, it is necessary to remove the spool with line from the body. Depending on the manufacturer, power and type (electric or gasoline), there are three design types of trimmers:

- Compact Electric Trimmers.

Straight bar trimmer

This model provides the ability to install a knife. Removing the coil in such models is done by means of two keys recessed into the coil body. To mount the trimmer knife, it is necessary to align the hole of the reel and the rod, and then insert the device in the form of a steel pin (screwdriver, iron bar). After fixing the coil, the body can be easily unscrewed by hand in a clockwise direction.

Single-barbed trimmer coil

Single-barb lawn mowers reel

Many owners and experts note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of travel of the trimmer reel.

After winding, you need to leave a free end of 15-30 cm to enhance the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. We pass the left end through the working hole of the coil and assemble the head.

How to wind line on a trimmer reel: key points

A gasoline or electric trimmer is an indispensable tool in the arsenal of a modern summer resident or owner of his own home.

Thanks to these gardening devices, even a large garden plot can be mowed with ease. After purchasing this tool and performing several mows, many people think about how to properly wind the line on the trimmer reel. For an inexperienced user, the first operation to replace it will seem problematic and time-consuming, since the developers often do not fully reflect the instructions for replacing the fishing line in the operating manual.

Trimmer head with automatic line threading

Types of trimmer heads

Some models on the market have a reel with an automatic winding mechanism. It is enough for the owner to properly thread and fix the ends in the head, and the winding operation will be performed by the tool itself when it is turned on. It is almost impossible to wind the line incorrectly into a trimmer with such a head, since the coil independently determines the position of the antennae. The advantages of an automatic trimmer head include ease of threading the line, and the disadvantages of frequent breakdowns of the mechanism due to the complexity of the design and high cost.

Coil with two working antennae

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- One groove both tendrils are wound together along one groove;

- Two grooves, each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the bar, the side inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference in line winding in double-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle fold), and the fold loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The following will clearly show how to thread the line into the trimmer reel and wind it correctly, this operation is not difficult and with some patience it will certainly be crowned with success:

Coil with one working antenna

The simplest option and uncomplicated sequence of actions:

- The dimensions of the spool and the length of the original factory winding determine the recommended length of the 25 m line for winding.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product, as a rule, on the inner side of the bobbin an arrow indicates in which direction it is wound.

- A small section of the line is left free to bring it out, it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

Selection by thickness

In addition, you should pay special attention to the thickness of the consumable. For mowing young grass, a thread with a diameter of one and a half millimeters is suitable. The larger the diameter of the thread, the drier and coarser weeds it is capable of overpowering.

When choosing a fishing line by thickness, there is one thing. It is important not only to assess the capabilities of the material, but also to take into account the features of the trimmer. Be sure to check the user manual that came with your tool for information on cutting element requirements.

Using an unsuitable thread can damage the instrument. Using a thread that is too thick will overload the device motor. And the use of a thread that is too thin will significantly increase the wear of the twisting mechanism.

That is why it is necessary to approach the choice of consumables no less responsibly than to refuel it in the trimmer. When a suitable fishing line is found and purchased, you can start considering ways to wind it on a reel.

How to properly load the line into the trimmer

Trimmer head with automatic line threading

Types of trimmer heads

Some models on the market have a reel with an automatic winding mechanism. It is enough for the owner to properly thread and fix the ends in the head, and the winding operation will be performed by the tool itself when it is turned on. It is almost impossible to wind the line incorrectly into a trimmer with such a head, since the coil independently determines the position of the antennae. The advantages of an automatic trimmer head include ease of threading the line, and the disadvantages of frequent breakdowns of the mechanism due to the complexity of the design and high cost.

Which line to choose

Before you stock up on this material for refueling in the trimmer, you need to decide on the choice. After all, the usual so-called round fishing line is far from the only existing species. How to choose the most suitable one? First you need to determine the working conditions.

Selection by type. Round line is the most common. It will fit any coil with very few exceptions. This type of consumable is suitable for cutting fresh, juicy grass. But with the mowing of the so-called dead wood, this species may no longer cope. It is pointless to mention attempts to mow bushes with this thread.

In addition to the usual type, there are others that have sharp edges. Usually they are made with an asterisk or a square. The presence of sharp edges is the main feature and key difference of these threads.

It is due to this feature that threads of these types are able to mow dry weeds. But sharp-cut threads are not without drawbacks, the main of which can be called rapid wear and strength, which is noticeably inferior to the round type.

In addition to the already mentioned types of woods, there are also interesting and common varieties. Especially among them can be noted fishing lines, inside which a metal wire is stretched. This type of thread is often used in gasoline-powered tools with an engine over 1.5 horsepower.

Metal-cored threads come in both round sections and sharp edges. Regardless of the type of section, such threads are the best suited for overcoming difficult-to-cut plants. Threads of this type can easily mow not only dry grass, but even small bushes.

The wires with a wire inside compare favorably with other types of consumables for their incredible wear resistance. Unfortunately, this feature has a more than noticeable impact on the price of this type. The cost of yarns with a core is significantly higher than the cost of other types of yarns.

How to properly wind the line on the trimmer spool Step by step guide. Preparation, remove and disassemble the spool

On most electric and petrol trims, you will need to remove the spool to replace the line. The FUBAG tool lets you skip this step. To make the instruction universal, we will still consider it in detail:

1. Secure the shaft. Insert the locking element into the corresponding hole. It can be a thin screwdriver or a metal rod.

2. Unscrew the bobbin case. In our example, strictly in a clockwise direction.

3. Unscrew the cover according to the direction indicated on the body.

4. Remove the coil for winding.

The preparatory stage has been passed. You can proceed to winding the fishing line.

How to wind the line onto the trimmer spool

Winding Algorithm

2. Insert the resulting loop into the groove.

3. Lay the line in the direction indicated on the element body.

4. Insert the short end into the slot on the side of the spool.

5. Secure the long end in the opposite groove.

6. Place the spool of wound line into the spool body.

7. Pull the line out of the locking slots.

8. Put on the cover and fix.

9. Cut the ends of the line, leaving 10 to 15 centimeters.

The replacement of the line is completed and now all that remains is to screw the bobbin onto the trimmer and you can work.

How to choose a fishing line, length, diameter, restrictions

As for the length, you should count on the estimated frequency of use of the trimmer. The more often, the more it costs to stock up expenses.

Information on the possible line diameter can be found on the body trimmer spools. Most likely, the range will be indicated there. The thickness varies from 1.2 to 4 mm. Choose the appropriate option, taking into account the characteristics of the cultivated area. The larger the diameter, the easier it is to mow tough grass.

ATTENTION! Typical line problems

No wonder they say: Forewarned is forearmed. Knowing about possible problems and the causes of their occurrence, you can prevent them in time. We recommend to remember or leave a memo.

| Problem | Cause | Decision |

| Line break | Stones, twigs and solid objects in the grass | Avoid collision |

| Poor cord quality | Replace with a quality analog | |

| Wear of outlet holes in the head | Complete replacement of part required | |

| The line is unwound | Loose spring in coil | Check spring and replace if damaged |

| The line is sticking | Poor line quality, due to which it can melt under the influence of temperature from the heating head | Reel in less line or replace with a better line |

For a better understanding of the mechanism of the line replacement process in the spool, we recommend that you familiarize yourself with the manual prepared by FUBAG specialists: