How to lubricate the gearbox of the corner grinder cannon oil. How to lubricate the gearbox

Gear lubricants angular grinding: how to replace, than to lubricate and when to change

Maintenance of corner grinding grinding (angular grinding machine, or corner grinder) includes lubrication updating in the gearbox. Lubrication for corner grinding lifting is one of the necessary consumables. At least once a year it is necessary to update it.

The choice of lubricant for the gearbox should be shown prudence, otherwise the mechanism may fail. The angular grinder gearbox is too important a part to let her work on a gear.

When you need to change the lubricant in the corner grinder

Correctly perform the replacement of lubricants after 12 months after the start of work. If the loading mode and the duration of the work are decent, then the maintenance period should be reduced to six months. Lubrication for angular grinding grinding has the ability to become unusable and even collapse with intensive work.

Determine the time when you should replace the lubricant is quite simple. You need to disassemble the gearbox. the part fixed on the lid is removed. A visual inspection of the gearboxes. gears and their teeth, as well as the internal parts of the walls of the case are performed.

The operating mode of the Bulgarians is extremely irregular to change and off. The temperature can reach such values that the case will be burned. Cutting or grinding is performed in various spatial positions, and the disk stop can be forced. Finally, the errors during assembly or strong dynamic and shock effects can lead to violations of the proper operation of the gearbox.

With the functioning of the corner grinder, the applied lubrication is distributed along the walls. Part remains on teeth or shaft. Gradually, individual clots and Комментарии и мнения владельцев stretch and straighten out when the structure of the corner grinder is heated. Later, the lubricant begins to leave the gearbox. In small volumes, this may remain inconspicuous.

The lubricant for the gearbox angular grinder decreases over time in volume, and a small amount remains inside the gearbox. In this case, it is necessary to add a new lubricant.

The main characteristics of the lubricant for angular grinder

In angle grinding machines, the main node subjected to the greatest loads during operation is a gearbox consisting of scooters.

The rotational moment created by the rotor of the corner grinder is transmitted from the rotor to the working tool through a small, scabbling gear to a large lobby gear. Properly selected lubricant for the gearbox significantly reduces friction and heating temperature.

In the grinder, bearings are used, which also requires periodic lubrication. This is especially true for the spindle support bearing with a large scooter of the gear.

Such lubrication is suitable, which meets not only the listed requirements, but also environmentally friendly.

Lubrices for an angle grinding machine are required to have certain characteristics and must be the required consistency by properties.

The lubricant for the gearbox angular grinder should have:

Lubrication for angular grinder should not have mechanical impurities, it is resistant to corrosion, firmly retained on lubricated details, do not melt at high temperatures, prevent the formation of bully in the places of contact of parts and of course possess water.repellent properties.

In the corner grinding machine of any company, two types of sliding bearings are used: bearings for the electric motor and supporting bearings for the gearbox.

The selection of lubricant for bearings of the electric motor differs from the selection of lubricant for the gearbox bearing. It’s all about different working conditions.

How To Greasing Bevel Gear on Grinder Machine

Lubricants recommended by foreign manufacturers of the tool

Foreign manufacturers of the tool, including angular grinder, recommend specially designed ointments as lubricants for bells.

One of the common foreign lubricants is the lubricant with the marking MOS2 NLGI 2 ISOL-XBCHB 2 DIN 51825-KPF 2 K-20.

- MOS2. indicates the filler material, in this case molybdenum;

- NLGI2. indicates the second class of viscosity;

- ISOL-XBCHB 2-belonging to ISO standards;

- DIN 51825-KPF 2 K-20-the lubricant is made according to German standards DIN;

- Figures 51825 mean that the lubricant belongs to type K.

Lubricants produced with such characteristics are quite expensive. There are imported, less expensive lubricants on the market.

Each tool manufacturer, whether Bosch, Makita, Hitachi, Dewalt, Metabo, Redverg, Interskol, E256, Lepse, recommends its lubricants. This is the manufacturer’s policy. They insist that those lubricants that are indicated in the instructions are used when performing maintenance. over, non.compliance with these recommendations does not allow to carry out warranty repairs.

Lubrication for the gearbox angular grinder Makita is produced in tubes. Its high cost is proportionate to high quality and a long period of work.

It is worth it or not to bother, the pros and cons of

Before you start making home.made lubrication, speculate about whether such a lesson makes sense? What is the extreme need to ignore the recommendations of the manufacturer and fill out the gearbox of the grinder of the “self.packal” mixture of components originally intended for other mechanisms?

The close analogue of the gearbox of the corner grinder is a hinge of equal angular velocities (shock), a responsible node of the front.wheel drive car. Transfers high torque in complex temperature parameters, with a high speed of rotation. The details of the working hinge are in contact with each other in conditions that lead, in the absence of a lubricant film, to local welding. By the way, the same effects arise in the brackets or hypoid gears.

There were times when many set out to replace the factory lubrication of a homemade spum. The most common recipe was simple and affordable. We take Litol-24 and generously add friction modifier, for example, molybdenum disulfide (now sold in the fields of auto chemistry, inexpensive). Of course, mix thoroughly with a wooden stick. Heat the mixture and insert into the hinge with a syringe, piercing the rubber cover with a needle.

Such “useful” tips were very popular in the former USSR in the late 80s, when the first VAZ “eights” and “nine” were faced with the problem of lubrication. Rather, with a lubricant deficiency for them. And there were those who followed such advice, and then shared their experience. Very sad experience.

Let’s get back to our Bulgarians. What extreme, inexorable need requires the use of homemade (surrogate) lubricants? If in the midst of work your angular grinder categorically required grease, apply any plastic lubricant available at hand. Litol-24 and cyatim-221 (preferably 221F) are suitable. The solidel of the USS would also come up, but, fortunately for the corner grinder, it is no longer released. We repeat. any plastic lubricant is suitable, but it must be evaluated not as an analogue, but as a surrogate.

In this case, you will have to perform all procedures to remove the residues of the existing lubricant from the gearbox. Without bothering about the absence of antifriction and outfit additives in surrogate, end the corner grinding of emergency work. Finally cut this corner or sheet of corrugated board. Or a crumpled wing of a car, the steep owner of which demanded: “so that it was ready by morning”. After that, go to look and purchase an original lubricant or a quality analogue from other manufacturers. Remember that the accepted measure is temporary, caused by extreme necessity.

Before laying the original or an analogue of lubrication again in the gear, do not forget to clean and rinse the gearbox from lumps of black sludge, into which the applied surrogate has turned. When you pick a wooden stick with metal dust from the wear of the gears, think about whether it is necessary to invent home.made grease. Not everyone can create a qualitative analogue, and all surrogates have already been invented.

By the way: domestic “lubricant 158”, shus-4, G.energy Grease, designed for hinges of equal angular velocities, work very well in the gearboxes of the Bulgarians. Three shortcomings:

- Low viscosity. Having heated, lubricants flow from the gearbox through the gap between the lid and the spindle.

- Contain additives aggressive to non.ferrous metals. Corps of gearboxes of all aluminum alloys. Some models have spindle bronze-graphic bearings.

- Low moisture resistance, very hygroscopic. Bulgarian gearboxes do not have hermetic seals.

The reasons for overheating of the equipment

During operation, an electric screwdriver may overheat. If you do not stop work in this case, then the tool may fail. There are many reasons for overheating, but there are basic:

- electricity changes or incorrect batteries;

- high load on the tool;

- strong wear of brushes on the engine;

- Fan failure;

- unsatisfactory lubrication of bearings or shaft skew.

Before disassembling an electric screwdriver, you need to start it without load to find out the cause of overheating. If the tool works fine, then there may be a factory marriage. If an electric screwdriver warms up even without load, then one of the reasons specified above is possible.

Varieties of lubricants for angular grind

Before lubricating the corner grinder, you need to familiarize yourself with the main types of lubrication. To process the gearbox, the angular grinder is most often used by the following mixtures:

Important! If there is no way to purchase branded products, it is better to use the mixtures for the CV joints. You can find them in almost every car shop.

The better to lubricate, which one to use for angular grind

Many are interested in what lubricant is needed for the gearbox of the corner grinder and which is better to use. To deal with this, you need to familiarize yourself with the features of choosing lubricants for tools from different brands.

Bosch

Bosch is a fairly popular manufacturer of drums, peorators, bells and other power tools. People who use devices from this brand can use their branded lubricants. They are sold in small tubes with a capacity of 50-100 ml. This is enough to carefully lubricate the gearbox 3-4 times.

If you fail to purchase a lubricant from Bosch, you can look for universal mixtures. Solidol or a mixture for CV joints and the angular grinder of Metabo are also suitable.

Makita

This company, like Bosch, is also engaged in the production of power tools and lubricants for them. Despite the fact that the catalog of lubricant in Makita is small, you can still find a suitable composition for processing the gearbox.

Most often they are sold in large plastic containers of 500 ml. In rare cases, you can find small disposable tubes for 30 ml.

Additional Information! Makita lubricants are many times more expensive than mixtures of other brands.

Interskol

This is a famous Sino-producer, whose popularity is growing rapidly. It is worth noting that Interskol makes not only angular grinding lifting, but also lubricants for them. The brand catalog has at least ten items. They are used to process tail drills, gasoline engines, gearboxes and saw structures.

Dewalt, Dewalt

Dewalt is a popular American brand specializing in the production of high.tech electrical tools. This manufacturer does not create brand lubricants and therefore will have to independently select the appropriate composition. It is allowed to use solidol, lithola and lubricants for cries.

How to lubricate the gearbox of the corner grinder

There are several options for a lubricant-chipper used. A fairly wide list of substances is used in corner grinding machines. Which of them is considered suitable in certain conditions, the user decides. Than to lubricate the gearbox?

- special lubricants for a particular brand or a model of corner grinders;

- ordinary solidol or littes;

- compositions suitable for any electric tool;

- independently made a mixture.

Each manufacturer produces certain consumables for his equipment, including lubrication. It is optimal in that it suits specific materials of the gearbox and body. It is also created taking into account the working conditions of the device. The cost may seem significant, but it is less than the cost of the new angular grinder.

Litol (solidol) available in each garage are not considered the right decision. They are not designed for temperatures to which toothed gears are heated. Therefore, the lubricant does not work, and instead of a positive effect, it creates difficulties. When working, it will be leaning from the body, and the rubbing parts will fail faster.

Universal lubricants may also not take into account certain speeds and temperatures of the gearbox. Also, this option is bad in that such a lubricant may not work for a particular steel used. A certain effect will appear, but not more than the best than from special lubricants for the grinder.

Manually created lubrication will help out with urgent need for lubrication. The basis is advised to take a car lubricant for a shrug. it is a stand to the loads, humidity, heating fluctuations. In order to obtain the desired density, oil is added-for example, MS-20. The mixture is mixed to complete mutual dissolution. Alternative: “TsIATIM” TAD-17. Different masters and thematic forums can offer a lot of compositions, which should be used with caution. Buying a new power tool, especially the professional level, will become a significant investment of funds and time. It will be cheaper to buy the appropriate composition.

What lubricant to use for the gearbox of the corner grinder, solve directly to the user. But you need to remember the main thing: all the requirements are set out in the instructions. Information can be on the site: for example, the RU tool can recommend actions and lubrication for the Makita brand.

Is it possible to lubricate the gearbox of the corner grinding of graphite lubricant

Each tool requires timely maintenance, and first of all, a peorator is needed. After all, the work of this tool is accompanied by a huge number of reciprocating rotations and movements, and the amount of dust allocated by the working object has a high concentration. Under these operating conditions, thorough care for the device and timely oil replacement in the transmission of the peorater are required.

Most users believe that if fat is present, then you can work with it endlessly. Such an idea usually exists among users due to the low level of knowledge of the laws of physics, so we will talk about the lubrication mechanism in more detail.

What is oral oil and why do you need it?

Lubrication is a viscous substance designed to minimize the friction coefficient between parts of the tool. Reduce, not quite neatly. That is, this means friction between parts almost always, and some of the small particles are separated from the tool and in oil itself. After some time, this lubricant saturated with metal dust no longer fulfills its direct function. At first, its viscosity simply changes, and then the oil itself is the cause of the rapid wear of the tool details. Viscosity is considered the main parameter to which you should pay attention to when buying it.

The manufacturer must indicate in the technical documentation all the characteristics of the tool and the lubricant used. Much attention should be paid to the frequency of maintenance, which indicates how long you need to replace the oil.

For a hammer having a quality certificate, you always need to use only branded lubricants, otherwise, after the tool failure, you will lose the right to warranty service. After the warranty period, it is also better to use the oil recommended by the manufacturer, but at this time most often the user uses cheaper domestic analogues. Litol or solidem will not hurt your instrument in any way. But do not forget that Lidol is produced much faster, that is, its replacement must be done much more often.

What you need to lubricate the peorator?

This lubricant is also necessary for operating temperature. But this does not mean that it is impossible to use lip. There are factors when, when using household lubricant fluid, the impact power only increases, and the level of noise created by it decreases. This is even more correct for the Chinese peorator.

Users of Chinese tools do not expect warranty service, so act at your own discretion from the very beginning of the operation of the drill (or electric drill). In the form of a blow of any manufacturer, it has basic design features, then there is simply no single lubrication instructions. The main thing is at hand:

And then, as you already understood, we clearly follow the instructions. And keep this in mind the hammer should be cleaned as much as possible from dust after work. Make sure the oil level is not higher than the control mark. Most often, the peorator has a special container for oil, t.e. to carry out all this procedure will not be difficult.

It is not recommended to lubricate the gearbox in the stamp immediately after use, since hot parts, when they cool, lubricate physical characteristics. Drill shaft should also be lubricated with lithol or solid oil. If the hammer has an open cartridge, it is recommended to process the oil seal. Firstly, it needs to be disassembled and wiped thoroughly. The oil used will allow you to extend the life of the device and protect it from dust entering the device. There are several types of lubricants:

The correct process of replacing the lubrication in the gearbox of the corner grinder

Replacing the lubricant for the gearbox of the corner grinder is performed as follows:

- Disconnect the network cable of corner grinder.

- Dismantle the circle.

- Unscrew the fasteners and remove the gearbox cover.

- Clean the surface of lubrication residues.

- Extract a spindle with a gear and a bearing.

- Rinse the details with gasoline and dry.

- Apply a new layer.

- Collect a gearbox and install it in a corner grinder.

Additional Information! If the remaining lubrication is released through the spindle, they must be removed with a clean cloth.

Signs of obsolescence of lubrication

Gasoline is ideal for removing old lubrication

There are several signs that indicate that it is time to lure grease. These include the deterioration of rotation, tapping the bearing and quick overheating of the angular grinder. In this case, if you do not change the lubricant for a long time, the device will quickly fail. To prevent this from happening, you need to monitor the operation of the gearbox and lubricate it in time.

Replacement periods

Many owners of the corner grinder are interested in how often you need to engage in lubricating the gearbox. It is impossible to determine the exact term, since it all depends on the number of loads. On average, this must be done at least once a year. If the tool is used daily, it is lubricated every six months.

Removing the old lubricant

There are situations when the old lubricant is removed with difficulty. Most often this happens if it has not been changed for a long time. In such cases, getting rid of it with a simple rag will not work. Will have to carefully treat the gearbox with gasoline and kerosene.

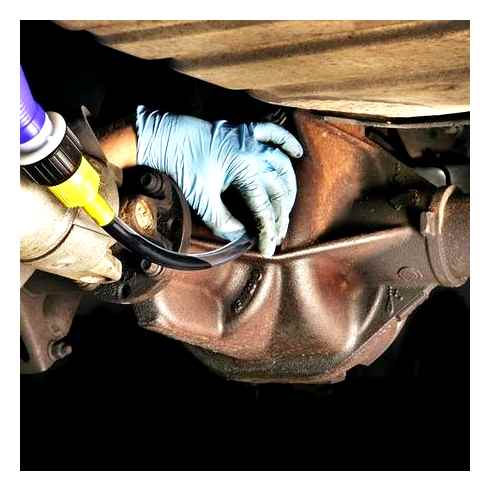

Approaching a new layer

You need to apply a new layer very carefully and carefully. It is necessary to spread it with your hands so that the composition penetrates all free places. It is necessary to squeeze the mixture from the tube until its excess begins to flow from the side of the gearbox.

Required amount

Lubrication should be applied to the entire surface of the gearbox

Some believe that you should not apply too much lubrication, but this is far from the case. The fact is that if it is not enough, it will dry faster and the gearbox starts to work worse. It is necessary to lay so many mixtures that each tooth is covered with it.

Control of the correct process

After lubrication, it is necessary to check that everything was done correctly. To do this, you will have to start the corner grinding for idle.

For reference! If the device works quietly, then the gearbox is well lubricated. The appearance of extraneous noise indicates an insufficient amount of lubrication.

Varieties of lubricants for angular grind

Lubrication can be done in special workshops or independently. When making lubrication on their own, it must be remembered that the lubricant material that does not correspond to the tool can cause a tool breakdown. The course of the processing process with new lubricating materials implies the complete removal of the old lubrication layer. Details and walls of the case should not contain the remains of the old coating.

Stages of lubrication of the gearbox of the corner machine:

- disassemble the corner grinder;

- Wash with a kerosene or solution of kerosene and gasoline of the side and cavity of the gearbox;

- dry the washed parts;

- mix new lubricants;

- apply the coating to the bearings and in the cavity;

- Collect the tool.

When applying, the question arises: how much lubrication is required? Applying a large amount of lubricant will lead to the fact that the excess volume will flow during operation. With a slight content, the functioning of the gearbox will be difficult and will lead to a rapid failure. Therefore, such a volume of material is placed in the case so that the teeth of the gears are hidden under the surface of the applied layer. Estimated coating of gearboxes angular grinder is less than ½ volume of the whole gearbox.

What grease to choose

There are several ways to reduce the friction effect on the interacting elements of the angular grinder gearbox. The choice than to lubricate the friction nodes is made from the following options:

- the use of expensive special lubricants for gearboxes from known brands;

- the use of universal compounds suitable for any power tool;

- lubrication of the gearbox with lithol or solidol;

- Using self.made lubricants.

Application of special materials. the optimal solution. When choosing a lubricant for the gearbox, it is recommended to give preference to the compositions produced under the same brand as the corner grinder itself. For example, if AEG machine machine, then the lubricant must buy the same brand.

When using specialized products, the service life of the angular grinder increases significantly, since the manufacturer takes into account all the features and nuances of the operation of their own equipment. The minus of the use of branded materials is their high cost, which may affect the family budget.

Most masters use budget grinders or a Chinese.made tool. For such machines, specialized lubricants were not developed by the manufacturer and are unlikely to ever appear. However, such a technique requires maintenance. What in this case to do?

Specialists and service masters recommend purchasing any budget non.branded composition designed specifically for gearboxes. You can also use a lubricant used for a CHIR. joint.wheel drive joints operated under significant loads. It can be purchased without problems in any car shop. This option is much worse than using branded materials. This is due to the fact that the specifics of the operation of the friction nodes of two different mechanisms are not taken into account.

The most unfavorable solution is the use of lithola or solidol, since both of these materials are not designed to grease the friction nodes heating to high temperatures. Some owners of the Bulgarians use only these compositions, which is why their cars cannot last during the service life declared by the manufacturer. In an effort to gain profit here and now, they do not take into account future expenses for the acquisition of a new tool or replacing expensive parts.

Lubricant materials for the gearbox angular grinder

An angular grinding machine (corner grinder, or “corner grinder”) is designed for cutting, grinding and cleaning products from stone, metal and other materials.

liquid grease for gear box of grinder

The movable parts of the corner grinder during the operation of the tool are subject to intensive wear. The bearings of the anchor and gears, as well as the gears themselves, located in the gearbox, are covered with grease at the factory, but over time it is aging and losing its properties.

To avoid premature failure of the parts, it is necessary to periodically clean the bearings and gears, as well as update the lubricant.

The fact that it is time to do this is evidenced by increased vibration of the tool and extraneous noise during its operation.

Lubricants for corner grinders should not:

- Contain solid particles that can cause painting mobile parts of the mechanism

- Lose viscosity and become liquid at temperatures less than 120 ° C.

- Absorb moisture

On the details of the lubricants should form a strong film that protects them from corrosion and wear.

The consistency or viscosity of materials according to NLGI (National Lubricating Grease Institute) is selected depending on the speed of the gearbox rotation, the higher it is, the more liquid there should be a lubricant. For angular grinding mash (as well as circular saws and motorcycle), classes of class NLGI-0, half-life consistency are recommended.

Almost all world manufacturers of angle grinders recommend using only materials manufactured under their own brand for their maintenance. In this case, they can guarantee long.term and correct operation of the tool.

However, a significant drawback of branded lubricants is their high price.

Original oils and lubricants may well replace products with similar characteristics, which are represented quite widely in the modern market.

So, the materials of Haskey, Castrol, Liqui Moly and other brands are great as a lubricant for a gearbox of corner grinding.

Good lubricant for electric tool gearboxes is produced by Bosh. It sets in tubes of 65 grams, one is enough for several maintenance corner grinders.

Manufacturers do not lag behind foreign and offer their products. Very popular is the lubricant for the conical gearbox angular grinder “Nanoles Metalplak Electra”.

From domestic lubricants, a shreus or cyatim-201, but they require preliminary preparation and, in fact, are home-made lubricants.

DIY lubrication for gearbox with your own hands

Do.it.yourself lubricant for the gears of the corner grinder consists of the base and diluent.

The basis is usually a russian with disulfide molybdenum or cyatim-201. They belong to the second viscosity class according to NLGI, therefore, for use in the gearbox, they are diluted.

It is best to use simple mineral industrial oil as a diluent-for example, I-20. To obtain viscosity NLGI 0, it will be necessary to mix the composition in the proportion of the base and the diluent of approximately 70 to 30.

There are three disadvantages of such home.made lubricants:

- Low viscosity: heated, they flow from the gearbox through the gap between the lid and the spindle

- Additives aggressive to non-ferrous metals: Bulgarian gearbox houses are made of aluminum alloys, some models have spindle bronze-graphic bearings

- Low moisture resistance, hygroscopicity: gearboxes of Bulgarians do not have hermetic seals

The history of the development of technology

than 150 years have passed that all additional details of the moment are removed from the door, as in the far 1851 the first time began to be used in the works of a manual peorator. It was made for the needs of the mining industry did not have the variety of modes that of course of modern models at the moment. But even then he significantly improved the work of workers. No wonder the presented type of instrument is extensive distribution among masters of various specializations.

Since then, the tool has been subjected to significant design changes. One thing remains constant. The need for proper care. The device of the peorator is quite complicated. Some of its details are variations to wear rapidly.

So that this does not work out, the lubricant for the peorater must own a number of properties. With the development of the submitted power tools, its additional materials were also improved. To realize how to choose a lubricant, you need to see the structural features of the equipment.

Rod and the drive of the working body

The bar has two very important functions: the first. forms a hard frame of the entire structure, the second. a shaft passes inside the metal roller rod, which connects the working organ with the engine. By the appearance of the rod, you can determine the class of the tool, if the bar is curved. this is convenient for work, but in this case the drive is a flexible shaft, which cannot convey a large torque. If the bar is straight, a hard metal rod passes inside, it can transmit more reliably and torque. Therefore, a professional tool always has straight rods.