How To Set Up A Segment Mower

Tractor mounted segmental mower: how to do it yourself A segmental mower for a tractor, for a mini-tractor allows you to facilitate the physical work of the farmer. Segment mower device.

Characteristic of KSP-2.1

The production process of this mower is carried out by Bobruiskagromash. This company is located. The segment mower can be used in a wide variety of areas, but there should be no stones or bumps there. Otherwise, the segment mower will stop functioning.

The mowing process can offer the removal of both natural and seeded vegetation. These models can have a thrust of at least 0.6 and no more than 1.4. Thus, the power of the tractor equipment is not serious.

The mower is activated using the tractor PTO shaft. The mower can reach a height of 40-80 mm. This allows it to be used for cutting very tall grass. If we consider the speed of work, then the unit operates for about 12 hours. The product is 0.9 m long, 1.2 m high and 2.3 m wide.

This article shows the price of the Challenger tractor and the features of its work.

Manufacturers and prices

To date, the following manufacturers of segment mowers are in great demand in Russia: Strizh KNS-0.8 and Mobile KM-0.5. The presented models are produced by Moscow Avtomash. Names, the products received by this manufacturer are in the widest demand.

What is the consumption rate of fuels and lubricants for the MTZ 82 tractor, you can find out by reading the article.

This model is characterized by compact size and ease of use. Since the size of the unit is small, it is in great demand among gardeners and summer residents. The weight of the equipment is 25 kg. The segment mower of this model is capable of mowing grass, the height of which is 0.5 cm. If the height of the plants is small, then the mowing process will be ineffective.

The article indicates the price of attachments for MTZ 82.

Segment mounted tractor mower: how to do it yourself

For specific agricultural work, special equipment is required. The reason is that it is simply impossible to carry out all the work manually with a large area. For these purposes, segment mowers have been developed. The presented designs are very convenient in terms of operation and greatly simplify all work.

You can learn what a homemade potato hiller looks like from this article.

European technology

The goods, which are received in European countries, can boast of their quality characteristics. But this statement has not received an accurate statement or refutation to this day. But in practice, the matter will be arranged in such a way that the segment mowers of the European assembly are invented in accordance with all standards.

The most popular is the manufacturer Al-Ko. These products are imported to all European countries. The reason for this demand is due to the fact that mowers have already won the hearts of many consumers. Of course, the cost of European products will be higher than Russian ones. The average price of a segment mower reaches 30,000 40,000 rubles. But today people have begun to stick more to quality characteristics than price.

Tractor t 70s technical characteristics and other technical data are indicated in the article.

Device

The segment mower designed for the tractor is used for mowing vegetation, both in large and small areas. The presented equipment is an indispensable element for rural enterprises.

In addition, even an ordinary gardener can use the device. Most often, cut grass is used for feeding pets. Of course, you can use the traditional method and mow with a scythe. But this process is quite lengthy and dreary.

Mini tractor MTZ model range and other equipment data are indicated in the article.

As you know, the segment mower is attached to the tractor. Today, no alternative options have yet been developed that can replace tractor equipment. Although, on the other hand, with the help of a tractor it is possible to carry out all arable, assembly and cultivated work.

On a segment mower for a tractor:

Likewise, a segment mower is a completely pointless thing without a tractor. For those who are confused by this fact, you can try buying a simpler model, such as a hand-held electric mower.

What is the power of the MTZ 80 tractor, you can find out from the article.

Before purchasing a segment mower, you need to understand what its principle of operation is, and also to determine the difference between this product and a rotary. Its installation is preliminarily carried out on the rear of the tractor. After checking all the clutches and bolts, as well as their secure fixation, you can start the tractor engine.

During the movement, the vegetation will be between the segment mowers, thereby rolling over the cutting blades. As a result, the grass will be cut. The vegetation is then lined with an even layer on the ground, which makes it very quick and easy to further collect the grass.

This article contains the technical characteristics of the New Holland T8040 tractor.

The design of the tractor-mounted segment mower is not very complicated. But this does not mean at all the low performance of this device. As practice shows, this method of mowing grass is considered one of the most profitable. It is advisable to use it when processing a large area. The structure of the carrier mower includes the following elements:

- Bearing beam;

- Cardan transmission;

- Transport traction;

- Cutting mechanism;

- External engine;

- Lifting the apparatus.

Characteristics of KP-F-6

The main advantage of the presented model is that it has a small size, and you can use the mowing on large areas. The KP-F-6 segment mower is a popular machine among farmers.

It can be installed on tractors of 0.9-1.4 class. Device length 6050 mm, width 7620 mm, height 2470 mm. Mowers are capable of mowing plants with a height of 80 mm. Travel speed is 9 km / h.

You can find out how the Terrion 4200 tractor looks and what technical equipment it has from the article.

On segment mower for mini tractor:

The main advantage of the segment mower is the ease of physical work. Since earlier it was necessary to mow the grass manually, the whole process was delayed for a long time. Today, all problems with excess vegetation on your site can be solved with the help of a light and effective device. It does not take up much space and is mounted on a tractor.

About how the Buhler Versatile tractor looks like, it is indicated in the article.

Over, such a device allows you to get a much higher quality grass. After mowing, the grass is not distributed over the entire area of the site, but is laid evenly. Thanks to this, it is possible to easily collect vegetation and use it for needs.

How does the device work? Its advantages

Segment mower operates according to a fairly standard principle. The device is equipped with cutting fingers, which carry out rotating movements of a translational shape. At the same time, they move in different directions in relation to the ground. The mower has its own moving and stationary elements that cut the grass that is between them. After that, all the plants are divided into several parts and then lie on the ground.

Segment mower for mini tractor includes parts of the type of a hinged device (with its help, the equipment is attached to the equipment), cutting segments, a knife drive mechanism, a conical-type unit, a draw rod. In principle, such products are considered not particularly complex equipment. Therefore, it will be possible to replace the damaged parts on your own.

Buy segment mower many farmers really want. This is due to the fact that it has several undeniable advantages. This is about:

· Possibilities of functioning on non-standard earth surfaces. This is due to the fact that the blade is capable of deviating from the path by 20 percent.

· Ability to process a fairly solid area.

· Ease of fastening and operation. At the same time, the installation of the device on walk-behind tractors or tractors must be carried out correctly. Otherwise, there will be practically no effect from it.

· Adequate pricing policy. Of course, for personal use, the mower can be a little pricey. But she certainly won’t make a big blow to the budget.

· Possibility to regulate the device. This is done manually and without additional help.

Segment finger mowers

In the field of agriculture, in order to fully mow the plant mass, it is necessary to use special devices. As practice shows, manually collecting large areas is incredibly difficult. That is why it was invented segment mower, greatly facilitating the work.

Specific use of the device

Segment finger mower The device is not the easiest to use, so you should definitely familiarize yourself with some rules for handling the instrument. For example, only those people who have already had experience in using mowers or who have carefully read the operating instructions can work with it.

Over, when starting the attachment, no person should stand too close to the cutting tools. Otherwise, injury may result. It is also worth making sure that the mower is equipped with special materials during use. If you plan to move the product, it is better to cover your fingers with a shield. Upon completion of work (when mower polish segment is no longer required), you need to put on a special cover or shields on the mower and leave it in a distant place where it will be stored. In order not to overturn the mechanism, you need to set it to the operating mode.

Buy a segment mower at an affordable price Do-it-yourself segment mower for a walk-behind tractor Simple design of a segment mower for a walk-behind tractor

Open graph Simple design of a segment mower for a walk-behind tractor in an enlarged form. If this is a drawing or diagram of a device, you can download it to your computer by opening it in large size and using the “Save picture as.” Function (right mouse button).

Please rate this material by marking the appropriate number of stars.

Construction device of a home-made segment mower: drive the mower from the PTO of the walk-behind tractor

To do do-it-yourself segment mower for walk-behind tractor it is necessary to make the lower (table) and upper (segment) of the homemade mower. To do this, you can use a steel strip to which the triangular teeth of a homemade mower must be riveted. The teeth are cut from strong alloy steel and sharpened, alternatively, the teeth can be cut from ordinary steel (then this can be done directly on the steel strip), but in this case they must be well hardened to increase wear resistance. On the lower part of the segment mower for the walk-behind tractor, the so-called table, guides are installed, which can also be made of steel strip. The upper part is installed in them, which is attached to the drive. The mower is driven by an eccentric shaft attached to the power take-off shaft (PTO) of a walk-behind tractor, which converts the rotary motion into a reciprocating motion of the upper part of the segment mower relative to the table, as a result of which the teeth of the segment mower seem to move relative to each other (something like scissors) and the grass stalks are mowed between the teeth. This is the simplest design of a home-made segment mower for a walk-behind tractor, as it consists of a minimum of constituent parts, which also greatly simplifies the adjustment and adjustment of the knives. In the device of a segment-finger mower, the knives are set in motion by means of a finger bar, which significantly complicates the entire design and the possibility of adjusting the knives of the segment mower. Segment mower drive can be simplified if you spring the upper cutting segment, then it will be enough to install a pusher on the drive pulley, which at each revolution of the drive shaft will move the cutting segment set in segment mower guides to the extreme position, and the spring will return it to its original

Construction device and description of how to do it yourself

You can view all graphs, drawings, pictures and diagrams from the Segment and rotary mowers category by clicking on the link. You will find even more materials with descriptions of how to make a motor cultivator and accessories for it in the section Attachments for walk-behind tractor or by making a selection from all materials of the site motoblok.Populjarno.com according to the following tags:

how to make, details, mower.

Perhaps what you are looking for is in one of the most viewed sections of our site:

Segment mower KSF 2.1

Segment mowers of the KSF-2.1 type are manufactured by the Luberetskiy plant Selkhozmash (Russia, Moscow). This enterprise is the successor of the Ukhtomsky plant and the successor of its long-term business of manufacturing hay harvesting equipment of various types and designs.

Features of operation

The mower is attached to the tractor by fixing the longitudinal rods of the tractor attachment device, setting the distance from the ground to their rear ends of about 40 cm and lifting no more than 65 cm.This is done to prevent lateral displacement of the mower frame relative to the central axis of the traction unit.

When working with the device, you should follow the rules that contribute to its long-term and safe operation:

- The mower cutterbar must be covered with a protective cover.

- The stopping of the tractor must take place with the simultaneous actuation of the power take-off shaft.

- All adjustment and cleaning work with the mower itself and especially with the cutting tool is carried out with a complete stop and a plug of the tractor.

- The device is transported with a protective shield put on its teeth.

Advantages and disadvantages

In addition to the ability to use in any weather conditions, segment mowers KSF-2.1 have a number of other advantages, for which they are appreciated by many business executives:

- High productivity achieved by a relatively high working speed and a large simultaneous capture width of more than 2 meters.

- The light weight of this mounted mowing equipment allows you to work with it even on small types of transport devices.

- Low power consumption of the device will help save money and does not affect the increase in the cost of hay while reducing the volume of the workpiece.

- Simple operation without connecting the hydraulics does not require additional service personnel, except for the tractor operator.

- The cost-effectiveness of purchasing the device itself and spare parts for it, which are available everywhere.

- High-quality work at high speed and long service life By the end of the operating period, it will be enough to change the cutting blade, and the mower will be ready for the mowing season again.

Specifications

Technical characteristics of the segment mower KSF-2.1:

| Specifications | Unit measurements | Indicators |

| Total weight of the device | Kg | 190 |

| Transport dimensions, lengths / widths / heights | mm | 500/1800/2555 |

| Drive power | kWh | 7.5 |

| Work progress speed, up to | km / h | nine |

| Capture of the cut strip | mm | 2100 |

| Cutting height | mm | 40-60 |

| Productivity, max. | Ha / h | 1.7 |

| Tractor required traction | 0.6-1.4 | |

| Required PTO frequency | rpm | 540 |

Segment mower KSF-2.1 with a special type of grass cutting elements

The KSF-2.1 segment mower is designed to be mounted on mini-tractors and walk-behind tractors. This device is intended for the mechanization of hay harvesting processes, getting its name due to the special type of cutting elements in the grass in the form of large sharp triangles. Also called segmental finger.

Device

KSF-2.1 mower consists of the following main structural units and parts:

- A frame on which the rest of the working tools are taken on the base and which is fastened for installation to the tractor hitch.

- A pull rod designed to connect the working cutting tool with the device frame.

- A cutting blade with sharp segments (fingers).

In operation of the mower, the blade with knives is set in a forward-reverse motion parallel to the ground surface. In this case, the stems encountered on its way fall on the fixed segments of the canvas and are immediately firmly pressed against them by the movable blades. The grass is cut in a similar way to the work of conventional shears, leaving behind a strip of already finished mowing.

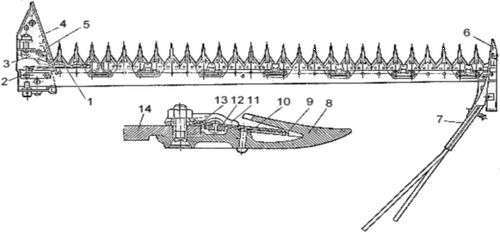

Mower scheme KSF-2.1

1 knife head; 2 guiding knife heads; 3 knife head cover; 4 inner shoe; 5 branch bar; 6 outer shoe; 7 field board; 8 finger; 9 finger liner; 10 segment of a knife; 11 clamping the knife; 12 back of the knife; 13 friction plate.

Features of operation

The mower is attached to the tractor by fixing the longitudinal rods of the tractor attachment device, setting the distance from the ground to their rear ends of about 40 cm and lifting no more than 65 cm.This is done to prevent lateral displacement of the mower frame relative to the central axis of the traction unit.

When working with the device, you should follow the rules that contribute to its long-term and safe operation:

- The mower cutterbar must be covered with a protective cover.

- The stopping of the tractor must take place with the simultaneous actuation of the power take-off shaft.

- All adjustment and cleaning work with the mower itself and especially with the cutting tool is carried out with a complete stop and a plug of the tractor.

- The device is transported with a protective shield put on its teeth.

Advantages and disadvantages

In addition to the ability to use in any weather conditions, segment mowers KSF-2.1 have a number of other advantages, for which they are appreciated by many business executives:

- High productivity achieved by a relatively high working speed and a large simultaneous capture width of more than 2 meters.

- The light weight of this mounted mowing equipment allows you to work with it even on small types of transport devices.

- Low power consumption of the device will help save money and does not affect the increase in the cost of hay while reducing the volume of the workpiece.

- Simple operation without connecting the hydraulics does not require additional service personnel, except for the tractor operator.

- The cost-effectiveness of purchasing the device itself and spare parts for it, which are available everywhere.

- High-quality work at high speed and long service life By the end of the operating period, it will be enough to change the cutting blade, and the mower will be ready for the mowing season again.

Segment mower KSF 2.1

Segment mowers of the KSF-2.1 type are manufactured by the Luberetskiy plant Selkhozmash (Russia, Moscow). This enterprise is the successor of the Ukhtomsky plant and the successor of its long-term business of manufacturing hay harvesting equipment of various types and designs.

Specifications

Technical characteristics of the segment mower KSF-2.1:

| Specifications | Unit measurements | Indicators |

| Total weight of the device | Kg | 190 |

| Transport dimensions, lengths / widths / heights | mm | 500/1800/2555 |

| Drive power | kWh | 7.5 |

| Work progress speed, up to | km / h | nine |

| Capture of the cut strip | mm | 2100 |

| Cutting height | mm | 40-60 |

| Productivity, max. | Ha / h | 1.7 |

| Tractor required traction | 0.6-1.4 | |

| Required PTO frequency | rpm | 540 |

Appointment

KSF-2.1 do an excellent job with mowing work, mainly on flat areas, mowing various types of grass crops with laying the plant mass into mowing:

- Naturally growing herbs.

- Sown grains and other crops.

The mower is applicable for planned mowing in the territories of almost any climatic zone; it ensures trouble-free operation with the exception of only semi-desert and desert areas.

Mowers KSF-2.1

Device

KSF-2.1 mower consists of the following main structural units and parts:

- A frame on which the rest of the working tools are taken on the base and which is fastened for installation to the tractor hitch.

- A pull rod designed to connect the working cutting tool with the device frame.

- A cutting blade with sharp segments (fingers).

In operation of the mower, the blade with knives is set in a forward-reverse motion parallel to the ground surface. In this case, the stems encountered on its way fall on the fixed segments of the canvas and are immediately firmly pressed against them by the movable blades. The grass is cut in a similar way to the work of conventional shears, leaving behind a strip of already finished mowing.

Mower scheme KSF-2.1 1 knife head; 2 guiding knife heads; 3 knife head cover; 4 inner shoe; 5 branch bar; 6 outer shoe; 7 field board; 8 finger; 9 finger liner; 10 segment of a knife; 11 clamping the knife; 12 back of the knife; 13 friction plate.

Features of the rotary model

Rotary mowers have a simple design, which makes them easy to maintain and repair. Working bodies are discs on which knives are mounted. They are attached to the discs with movable hinges. There can be from one to several disks. The more working discs, the wider the area to be treated.

The owner of a rotary mower can easily improve the lawn in front of the house and store grass for the winter for livestock. A small model for a walk-behind tractor is convenient when cleaning areas around fruit trees and beds.

Rotary mowers are produced in our country, as well as abroad. Among the largest and most popular models, mowers for motoblocks Neva, Zarya, Krot, Favorit stand out. The models differ in the number of working bodies and adjustment of the cutting height of the grass. For harvesting grass for animal feed, you can use models with a height of up to 20 cm; mowers with a cutting height of 5 cm have shown themselves well in the local area.

The rotary mower is aggregated with motoblokomi Favorit, Krot, Neva in several ways:

- Front hinged;

- Trailed behind.

According to the method of mowing the grass, rotary mowers are divided into types:

- For mowing grass and laying in an even row. Suitable for mowing grass for hay.

- Mulching grass. Shredded grass quickly decays, suitable for lawns.

When choosing a model for your motoblock Neva, Salyut, Zorya, Favorite, Mole, it is recommended to take into account the following factors:

- Features of the landscape.

- Purpose of acquisition (for mowing grass for hay to livestock or for leveling the lawn in front of the house).

- Mower weight (important when transporting as it is difficult to transport a large model).

- Productivity (for a small lawn, the smallest mower with low power is sufficient).

- Type of grass mowing (models that mulch grass are not suitable for making hay for livestock feed).

AGRON NEWS. Udmurt scientists have developed a new variety of cereals with increased productivity. The 40-year-old head of a farm near Volgograd awarded 4.8 million grants

Mower Zarya-1

A special model from the Kaluga machine-building plant “Kadvi” is designed for the NMB-1 motoblock Ugra, Krot and the like with the same connection. The model has two working bodies with hardened steel knives. Convenient adjustment allows for mowing in fields with any landscape.

Rotary mower Zarya-1

The technical characteristics of the model are presented in the table:

It differs from Zarya in the way of aggregation with a walk-behind tractor and high performance. The design is heavier, so the grass bevel is smoother. Suitable for small agricultural complexes. It is aggregated with MTZ-80 mini tractors. Easily copes with dead bushes, sunflowers and corn.

Of the pros stand out:

- Low price;

- Reliability and durability;

- Easy to maintain;

- Mobility due to low weight.

Among the minuses, there is an insufficient number of service centers in the regions.

Popular Rotary Mower Models

Among the various models of mowers for a walk-behind tractor, Zarya in various configurations and modifications and KM-0.5 Terminator for Caiman Vario, Pubert Quatro Junior, MB-2 and MB-23 Neva, MB-1 Oka, Mole, Luch, Favorite are more popular.