How to sharpen a chain of chainsaws with a device.

How to use a device for sharpening a chain of a chain

The most fundamental when sharpening the chainsaw is to achieve the right angle of the upper blade, which should be within the boundaries of 60-50 degrees. The angle of the end blade is observed within the boundaries of 85-60 degrees. It is also worthwhile to adhere to the angle in plan (sharpening angle), and specifically what is perfectly visible when you look at the chain link from above. It moves away from the side edge along the mowing trimmer line of the front and should be 10-15 degrees.

The productivity of operations of the cut of wood in the transverse direction is growing if an increase in the angle of sharpening of the chain of the chainsaw is to a very probable and opposite. The chains created for longitudinal cutting of the wood trunk should be hidden with an angle of approximately 10 degrees.

Under no circumstances, a limiter of depth can be touched again: incorrect grinding can lead to vibration when working as a tool. His refinement is done according to a special template.

Video

In this video, you can familiarize yourself with the trim process, the most popular ways and tools used for this.

A person who has a chainsaw in his household should know how to sharpen a chain of chainships with your own hands. There are several ways:

- Sharpen with the use of a file (the most common method of sharpening, t.To. Allows you to tighten the tool directly at the place of work on sawing.)

- Silence using a special machine (this method is used in service centers, but can also be used in the personal economy)

- Be sharpened with a grinder. To sharpen this method, it requires certain skills. A little.Won method, t.To. It is difficult enough to sharpen with Ushm correctly.

1 method. File

The first thing you need in order to sharpen the chain, or correct it a little, these are special files.

File

For sharpening and editing chains for saws, two types of files are used. The first, this is a gun file with a diameter of the corresponding diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of a household tool, round Files with a diameter of 4, 4.8 mm, This is due to the fact that they have a small tooth. For professional models, more powerful chains with a large tooth are used, and accordingly, files with a diameter of 5.2, 5.5 mm are needed.

In order to properly sharpen, it is not enough to sharpen only the cutting edges of the tooth, you still need to adjust the restriction of the cut depth of the cut. If this is not done, the chain will not crash into the sawing material to the required depth, which will noticeably reduce the speed of work and in the same way as in the situation with a dumb chain can lead to a saw engine overheating due to a not enough load on the engine. This work is done using a flat file.

Process description

The first where the editing of the saw chain begins on the saw is the installation of the tool on an even platform or table. In forest conditions, for this, a large.Diameter chock is well suited. Next, you need to examine the saw chain for any defects, it can be cracks, completely fragmented teeth. After inspection, you need to install the brake in working condition, thereby blocking its movement along the bus.

It is advisable to lay a stand under the tire, you can use logs as it, a piece of a branch of suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the tire during the sharpening of the circuit.

STIHL clamp

The circuit is sharpening is carried out by the movements of the file from the inside of the tooth outside. In this case, the file should be located parallel to a special mark on the chain. This label is applied by the manufacturer of circuits to specify the standard angle of sharpening.

The hidden tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process you need to advance the chain along the tire, without forgetting to install the brake in the working position each time.

Ideally, manufacturers advise to conduct the same number of movements with a file for each tooth, but in practice this is not always possible, t.To. Teeth have a different degree of damage to the working edge.

To facilitate the sharpening of a saw chain using a file, special holders can be used, with the markings of the angles applied to them. Markings are made not only for standard transverse cut, but also for longitudinal.

The holders are also convenient to use if you do not have sufficient sharpening experience. Experienced masters for sharpening do not use holders, but can only use special devices that support the file.

Another device designed for sharpening is a manual machine for editing saw chains. As a sharpening tool, it uses a regular file that can independently replace. The machine is mounted directly onto the tire, it also has the ability to adjust the angle of tooth sharpening and a special emphasis that holds the pulled tooth.

Hand machine for sharpening, perfect for beginners. Along with electric models for sharpening, manual has its own undeniable plus in the form of a low price. Depending on the manufacturer of a manual machine, their appearance may vary, but everyone has one principle.

The cut depth adjustment is carried out using a flat file, so that there is a difference between the upper cutting edge of the tooth and a height limiter.

As can be seen from the figure, the depth limiter is flowed in such a way as to bring the clearance indicator to the factory value. Below is a table, which contains the main values of the angles, as well as the clearance for the most common types of circuits.

As a rule, the size of the gap is adjusted using a special dick. It is installed on the circuit during sharpening, after which the depth limiter grows.

The simplest electrical devices for sharpening

The use of a special electrical device for tightening the chain of the chainsaw allows you to perform work not only more comfortable, but also as accurately as possible. If you have to sharpen a large number of chains of chainsaws with your own hands, then it is advisable to replace the file with a grinder, which will increase the speed of work several times. Such a device for a chainsaw as a Bulgarian requires skill from a person who performs the tool.

It is very difficult to grind cutting products with a grinder, therefore, in the absence of proper experience, it is still not recommended to resort to such procedures. Experts claim that in this way it is possible to harm the tool more than help.

The principle of tightening with the help of a grinder is to perform the following actions:

The disadvantage of this method is the need to have a high degree of skill when working with a grinder, as well as time. If everything is done correctly, then the tool will function for at least 5-7 sharpening.

The best option for sharpening the chain of the chainsaw is the use of an electric motor of small power. As a sharpening product, an abrasive disk is used. It will be necessary to install the disk on the electric motor, and then make a special rack or template out of the metal. It will not be difficult to make such a device, but in the end you can get a highly effective tool for hidden chainships.

Sharpening on special manual and automated machines

If the tooth has significant wear, then restoring their acuity will be problematic. For such purposes, special manual machines are used, the functioning of which is carried out in this way:

- The screw for adjusting the clip is weakened

- The direction of the links is aligned on the saw, which should look towards the sharpening stone

- The necessary angle is set

Deep sharpening will negatively affect the strength of the teeth, so soon you may need to replace the chain. After work, you can proceed to the removal of the metal edge using a compressor. The placement of the entire device in oil for several hours will not hurt.

Automated machines are used for sharpening, on which the chain is placed and fixed. The device is fixed in the tool, after which the engine starts. Such sharpening needs a chain at which it is impossible to FOCUS the teeth with a file.

Consequences of operation, not sharpened circuit

The operator must take care of sharpening in a timely manner, focusing on the main signs indicating a decrease in the severity of the teeth. If this is neglected, then he will face a heap of problems, expressed as follows:

- Curved saws;

- High load;

- Inaccurate saws and fuzzy contours;

- Increased fuel consumption;

- Reducing the operational period of saw.

Comparison of the advantages of mechanized and manual sharpening

Mechanized sharpening on special machines with an electric drive is carried out without taking into account the individual characteristics of the chain, in particular, the degree of wear. All cutting links are hidden under a standard template, which inevitably affects a decrease in its working resource.

In the second case, the loss of working time is compensated by the extension of the service life of the circuit, since each of its links is corrected individually. Additional advantages of manual sharpening in saving material resources, the ability to perform work in the field.

Subject to certain requirements and the availability of the necessary equipment, the quality of manual sharpening of the circuits is not inferior to the machine level.

Homemades for sharpening the chain

Before starting work, the gas tools need to tackle the cutting elements. Before proceeding with the sharpening of the chainsaws with your own hands, you need to determine the design of the cutting edges. The cutting edges of the chains have a side and beveled shape (cheese or chipper). The angle of the file of the file during sharpening depends on this.

The easiest way to sharpen teeth on an electric or chainsaw is the use of files that are equipped with tools. Such files can also be bought in a specialized store for the sale of benzo.Tool. If it is necessary to drag several chains daily, then it is advisable to use a grinder or a special machine.

It is interesting! When operating a grinder for sharpening, it is important to use the voltage regulator, with which you can reduce the number of revolutions.

How to sharpen a chain of chainsaws with your own hands. Step-by-step instruction

In order to properly sharpen a chainsaw, you need to follow some rules. The ability to correctly remove and fix the chain is one of the important factors of successful sharpening.

What will be needed to sharpen saw at home

You can sharpen the saw chain manually and on a special machine. Most people perform this procedure manually.

However, professionals advise not to do this very often, as this can lead to Rapid wear. But there are still cases when it is necessary to sharpen the saw manually.

For this, special devices for sharpening chains of chainsaws are sold, which include:

A template is needed to adjust the sharpened depth limiter. And the hook is designed to remove dust and sawdust from the chain. Such a set of sharpening the chain of the chainsaw will be needed by all gardeners.

During operation, the holding is installed on the tooth that you drag. Flat file is used to work with a depth limiter.

- With manual sharpening, teeth are stuck unevenly, which leads to an imbalance in the work;

- The old chains wear out over time, and the sharpening manually becomes almost impossible;

- The cutting edge may lose its normal shape;

- There is a risk of chain break over time.

There is also a third way to sharpen the chain chain. This method is quite new and probably the easiest. It is enough just to buy a special circle to sharpen chains of chainsaw along with a special chain. This is a small device, which is put on the end of the tire and fixed in a stationary position. In the middle of it there is an emery stone, which will sharpen your chain while you just press the button.

This stone is placed in the concave side to the bus. There are links on the clip that rub the stone and do not allow the oil to get on the saw. How to sharpen a chain with your own hands by this method, you can watch on the video.

Removing the chain from the chainsaw

To remove the chain from the chainsaw, first you need to pull the protective shield on yourself. As soon as you heard a clicking sound, take a screwdriver and loosen the chain. After that, unscrew the nut with the key and remove the tire along with the tenacious. There is nothing complicated in this procedure, except that you need to correctly pull the chain when you put it back. If you pull it, that is, the chance of gap. Well, if you do not tighten it properly, then the chain can generally fly off the tire.

But also you need to be able to pull it correctly. After you put the chain on the tire and collected everything, make sure that it adjacent tires tightly below. A normally stretched chain should move away from the bottom of the tire when pulled by a hand by 3-5 mm.

How to fix and sharpen a chain at home

To understand how to properly sharpen a chain of chainsaws with a file, and learn to do this at home, you need to adhere to the next step.By.Step instructions. First you need to correctly fix the chain. Fixation methods are several. The first method consists in fixing the tire in a vice. This is the most correct method.

So you can definitely be sure that the chain will remain motionless. However, there is and The second method. You can just sit comfortably, fix the saw between the legs at the knee level and start sharpening. The most important thing is that the lower part of the tire is not lower than the level of your knees.

Here is a step.By.Step instruction on how to sharpen a chain of a chainsaw with a file:

- Fix the chainsaw tire so that it is in a stationary position.

- Choose the right round file and hold, so that when sharpening the cutting edge of the stall of the file, it protrudes no more than 20 %.

- Place a tooth from which you start sharpening, so as not to go in the second round.

- Hurring, stretch the file only in one direction and regularly scroll it around your axis so that there is uniform wear.

- If necessary, sharpen the depth limiter with a flat file.

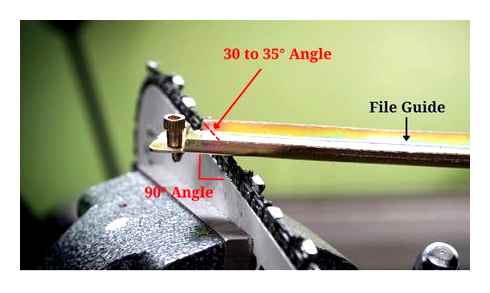

And it is important to remember the angle of sharpening the chain of the chain. The angle in the vertical plane of the file in relation to the circuit should be 90º, And in the horizontal.30º or 10º, Depending on the parameters of the saw (at an angle of 10º, the saws that are designed for longitudinal cutting logs are sharpened). The correct angle and position of the file will help you hold the holder.

Important! If you see that the depth of sharpening of the teeth is already quite large, it is better to change the chain to a new one in order to avoid its gap during operation.

If you or your neighbor have a machine for sharpening chains, then you are lucky. With this equipment you can quickly, efficiently and without much effort to sharpen your saw. Here is the approximate procedure for sharpening on the machine:

- Loosen the chain on the chainsaw a little, scrolling the side screw with a screwdriver.

- After that, you must place the chainsaw in the machine so that the teeth are directed to the sharpener stone.

- Next, you must choose an angle of sharpening (it depends on the type of chainsaw).

- Set polarity.

- Select the sharpening method: consistent or through a tooth.

Now you can start the procedure itself.

To worry about how to sharpen a chain of chainsaw on the machine as accurately as possible, not worth. All modern automatic sharpeners are brought to the ideal. Therefore, you just need to follow the instructions prescribed above.

Basic rules and sharpening procedure

Device and shape of the teeth

First of all, you should understand the device of the tooth of the chain, which is subject to sharpening. The tooth cuts the wood like a roof. It has a complex configuration and an unusual cutting surface. Two edges: one of them is lateral, and the second is the upper, slightly mowed. Tooth limiter, the height of which changes, regulates the thickness of the shavings. Of course, to sharpen such teeth is much more difficult than, for example, a kitchen knife.

The tooth of the chainsaw is more complex than other sharp objects to be sharpened

In this case, the right angle of sharpening of the chain of the chain of the chain should be set. It is clear that it is difficult to act with one file, so there are different auxiliary devices that help adhere to the exact sharpening parameters. Such sets are sold complete with chainsaws, as well as separately.

The diagram shows the angles of inclination, which must be observed during sharpening

When sharpening, you should choose the right tool location. A round file is chosen not in vain-due to the rounded shape of the inner contour of the tooth. The edge of the file should be higher than the cutting surface by 20% of its diameter, and the length of the chain step lasts the choice of the diameter (usually from 4 mm to 5.5 mm). The procedure should be observed: first process the cutting teeth, then-the tooth restraint.

Sharpening of cutting teeth

The question arises: how to sharpen the chain so that all the teeth are evenly even and sharp? Work facilitates the use of a metal template, which is superimposed on the chain. It is installed in a strict position. Along the arrows, the ends of which are directed at the movement of the chain. The main pressure falls on the front edge, in compliance with the angle of inclination, which correlates with the length of the chain step.

It is necessary to try to make an equal number of movements for each tooth. The teeth are hidden in turn: one. On the left side, the following. From the right and so on. For the convenience of performing actions, the tire is clamped in a vice, and then processed through a tooth on one side, then also on the other.

During sharpening, the device must be kept at a certain angle

Suffering the limiter

The work regulates the template, to the level of which it is necessary to grind the tooth-border guard no longer round, but with a flat file. The position of the template “S” is intended for soft wood, “h”. For solid. If you do not use the template, you can get the wrong, low sawing, from which the efficiency of the saw will decrease sharply.

When processing the limiter, the protruding part indicated in the photo

Something useful for yourself can be gleaned on this video:

Proper care for the saw. Timely sharpening of teeth, cleaning, lubrication. Extend the life of the tool and increases labor productivity.

How to choose the right angle of sharpening of the chain of the chainship for longitudinal and transverse saws in dependence on the material

The need to sharpen the chain of the chainsaw is a prerequisite that is relevant for chainsaws with daily use, for example, on logging, and during periodic use in garden plots and households. Like any process associated with the technique, the sharpening of the chain has a number of nuances, for example, the angle of sharpening, it must be taken into account and selected a certain value for a specific work.

The angle of sharpening the chain is an important characteristic, the performance of the chainsaw mainly depends on the value of which. It also affects the following parameters:

- The intensity of pressing increases, as the ability of the chain to “enter” the tree without pressing is reduced. This leads to an increase in tension in the human body.

- Fuel consumption increases.

- The load on the links of the saw chain increases.

- Significantly reduced the service life of the chainsaw due to additional efforts to the gearbox and motor.

There are two important rules that relate to the sharpening of chain saws:

- The higher the performance, the greater the angle.

- A decrease in the angle of sharpening during the cut of solid wood can be significantly reduced by vibration.

Description of the sharpening process

Consider in more detail how to sharpen a chain of chainsaw. The first thing to do is to prepare a place for installing a clamp, or if the process goes without it, it is convenient to use a regular log as an stop for fixing the tire in a horizontal plane. The chainsaws are installed on a flat surface, the log is placed under the tire, the brake is turned on.

The next stage is direct sharpening of the tooth. To do this, with a round file, movements are made from the inside of the tooth to the external.

It is very important at this moment to maintain the right angle of sharpening. The standard angle is thirty degrees from the perpendicular location of the file to the tire plane. How to arrange it correctly shown in the photo below.

In the process of sharpening a chainsaw for non.Standard cut, for example, longitudinal. The sharpened angle changes to a less acute. As a rule, it is no more than 10 °. It is in such cases that a holder, manual machines or sawing calibers are used to control the angle of sharpening.

Some manufacturers of chain chains, to facilitate sharpening, as well as to indicate the maximum possible sharpening, make a special label on the upper surface of the tooth.

Holding the file parallel to the mark, you can be sure that the correct angle is observed.

In the process of editing the chain, it is customary to sharpen the teeth on one side first, and then on the other, it is convenient. To. There is no need to constantly change your location in relation to the chainsaw.

After the working teeth are sharpened, it is necessary to adjust the height of the restrictive tooth a flat file. To do this, the supporting caliber is laid on the chain so that the restrictive tooth coincides with its slot, after which the protruding part is grown by a file. This procedure is performed for all restrictive teeth.

The use of roller devices

Sharpet device, with which you can quickly and efficiently correct the teeth consists of a small guide template, on which two videos are installed.

By installing the adaptation on the tire, you can sharpen the teeth of the chainsaw, without even the experience of conducting such operations.

General rules for sharpening circuits

The general rule of this manipulation is the exact location of the tool used relative to cutting teeth. The configuration of their inner part is a circle, so the sharpening is performed by a round file. The section of the tool is determined by the dimensional characteristics of the chain. The size of its pitch usually varies from four to five and a half millimeters, based on this, the desired section of the file is selected.

Sharpet rules provide for the location of the tool at right angles to the vertical plane of the processed surface, the angle of the horizontal direction can be ten or thirty degrees, depending on the configuration of the cutting tooth. The file of the chain should protrude twenty percent of its diameter.

Sharpet set will help to sharpen the chain of the chainsaw manually

These conditions are quite difficult to provide when using only one file, therefore, special sets are often used to perform this operation. They are most often included in the combination of the mechanism or are purchased in specialized stores.

How to sharpen a chain of chainsaw

Sharpening of the chain for the chainsaw is no less important than lubrication and other care. Never work with stupid chains, because only with a sharpened chain of cut will be effective, accurate and safe. We strongly recommend that you learn sharpening, and you will know how to sharpen a chainsaw yourself, so as not to contact specialists on these issues and save some money. Of course, those who are repairing chainsaws have a special device for sharpening chainsaws, but you can do without it, if you know what to use. The sharpened chain is often more important than a strong engine if it comes to high.Quality sawing.

So, how often should the chain for the chainship be sharpened? There are no specific standards for terms; It all depends on how often you use the saw. When you begin to understand that the sawing becomes slow, or the saw “takes” to the side, and the sawdust in shape resembles needles and there is a lot of dust in the chips (with the sharpened saw, this does not happen). That means that the time of sharpening has come.

What is the device for sharpening the chainsaws at home? This can be done with a cylindrical file. The size must correspond to the circuit: for example, for a chain with parameters of 1.3 mm; 3/8 “You should use a file with a diameter of 4 mm; for a chain of 1.6 mm; 3/8” it will be better to be a file of 5.2 mm. Chains with a step of 0.325 mm and with a tooth height 1.3; 1.5 or 1.6 mm are recommended round files with diameters, respectively 3.8; 4.2 and 4.8 mm.

But how, in fact, to sharpen a chainsaw (more precisely, a chain of a chainsaw)? If the question is what to sharpen, then the machine for sharpening the chains of the Oregon chainships or another device for sharpening chainsaws will help. But you can use the file. Take a round file of a corresponding size (or bar with a file), a flat file (which you will need to grind tooth-border guards). It is better to use a sharpening set suitable for your saw (it is better to purchase with a saw); It includes: a bar with a round file, on which the desired angle of sharpening of the chain of the chain of the chain is already applied; Template and file for tooth restraint. Your work will greatly facilitate the vice in which the saw tire should be squeezed.

So, first, we are dragging cutting teeth. We put a sharpening template on the circuit and we tighten with light measured movements, led forward at some angle to the saw bus. Take one tooth on the right, one on the left; the same number of movements and only forward. As for the sharpening of the tooth of the limiter-we lay the template (sawing caliber) on the tooth restraint, observing the angle of sharpening of the chain of the chainsaw, and with a flat file we grind the protruding part of the tooth-restraint. The main thing is not to cut too low. Sharpening of the chains of the Oregon chainsaws will help with professional accuracy to sharpen, because a high.Quality device for sharpening chainsaws is the key to a long and efficient operation of your saw.

Types of sharpening chains of chainsaws and proper work with them

Next, we will talk about several popular ways of sharpening a chain that can be performed both at home and in production.

Manual sharpening with a file at home

Manual sharpening is considered the most economical, budgetary, this will require only a file that is in every house with the owner, if it is not. It is inexpensive and is sold in any construction market or in a building store and tools. For the size of the chain of 1.3 mm, you need a file with a diameter of 4 mm, for the size of the chain 1.6 mm. You need a file with a diameter of 5.2 mm.

Stages of manual sharpening of the chain of the chain at home:

- Fasten the chain (tire) so that it is completely motionless;

- Do not change the angle of sharpening during the entire drag;

- Perform 2-3 forward movements with a file with a slight press;

- Turn the file with different sides;

- Perform sharpening in size of the smallest tooth.

How to sharpen a chain of a chainsaw with a file with your own hands. About this video below:

Professional sharpening on the machine

Sharpowing on the machine can be performed with a hand.Made or professional machine.

Professional machines work from the network. The principle of sharpening is almost the same as with manual drag:

- The chain of the chainsaw is fixed in the guides;

- Next, set the width of the grooves and choose an angle;

- Lower the dragging disk;

- The chain is moved along the holder, clamped, each tooth is processed.

The toochial element in professional machines is an sandpaper. A good automatic machine is expensive, because professional equipment for sharpening is mainly in services and workshops. Buying this for home use is not rational.

Video on how to sharpen a chain of chainsaw on the machine

Sharpening with a grinding machine or grinder

The process of sharpening the chain of the chain of the chain with a grinding machine or grinder is carried out using a special nozzle, the same grinder, which is used as a nozzle in professional machines. Of all the methods of turning, the method with the grinder is the simplest, however, requiring some skills.

For sharpening, you will need a grinder and a disk for metal 2.5 mm thick. You need to sharpen the chain at minimum speed, alternately processing each tooth on the chain. When using a grinder, put on a protective plastic mask or glasses, as well as gloves.

Video on how to sharpen a chain of chainsaws with a grinder

Possible methods and methods of sharpening a circuit

We work as a file

The best solution is simple “bells and bellsways” for sharpeners. This set includes a round and flat file, special holders, a caliber template, a hook for removing chips, etc. Structurally, “devices” may differ, but the functionality has a general logic.

The diameter of the round file directly depends on the size of the chain:

- – chains with Ø 1.3. Require a file of Ø 4 mm (used much more often);

- – chains with Ø 1.6. Require a file of Ø 5.2 mm;

- – to sharpen a depth limiter, use a flat file.

- Previously “turning on” the chain brake, tightly click the tire of the chainsaw in the vice (tightly clamped saw. The key to successful sharpening)

- Set the template so that the Strelka is directed to the “nose” of the tire. Be sure to mark (you can chalk) the tooth from which they started sharpening, otherwise you can go in the second circle;

- Sharpage to the side indicated by the arrows. Remember, on each tooth of the chain there is a special factory notch. It indicates the maximum angle of sharpening.

- In addition to the cutting tooth, there are limiters at each link. Their sharpening is carried out as needed. This is necessary when the height of the tooth decreases as a result of sharpening, and problems in the chainsaws appear. As a rule, the limiter is undermined after 2-3 sharpening of teeth;

“If there is no skills in sharpening, it is better to start with inexpensive chains.”.

- The file should not go beyond the upper part of the cutting edge, more than 1/5 of the working part of the file. Pressure is carried out with the same effort;

- The movement of the grinding instrument is performed in one direction “from yourself”, and the number of movements for each tooth should be equal;

- For sharpening a vertical plane, the position of the file should be at a right angle;

- For sharpening the horizontal plane, the position of the file, at an angle of 20-30 °

- If there are teeth of different heights, the guideline is the smallest.

Advantages: The ability to “charge the saw” in the field. At the same time cheap.

Disadvantages: Takes time and strength. At the same time quickly “kills” the file. By the way, about files: it is better to pay a little more and take a quality product than purchase for 40-50 rubles and throw it away after the first sharpening (verified in practice). And yet, if the chain “plowed” the soil so well that its cutting edge changed its original shape, sharpening with a file is difficult and not at all fast.

Which Chainsaw Sharpener is Best? Let’s find out! Stihl, Granberg, Chicago Electric, Oregon

Smooting a grinder

Professionals consider this work, primitive. There is a risk of tire damage, and not only.

Process (it looks easy, but in fact. It is difficult)

- The chain also remains on the tire;

- We fasten the cutting disk for a metal with a thickness of 1.5-2 mm on a grinder. It is advisable to take not a new one, that is, with a part.Time edge;

- In front of the chain and tire, put an obstacle (the sliver will come);

- We sharpen at the right angle;

- Upon completion of work, the chain must, properly, pull up.

With a professional approach and a “stuffed hand”, the number of sharpening can be more than 7 in this case.

“To a beginner, it’s better not to“ experiment ”with a saw, chain and. Their parts of the body!””

Advantages of the method: Quickly, cheap and does not take away strength;

Disadvantages: We need special skills, a firm arm and the ability to observe safety precautions.

Electric grinding machines

They are equipped with special settings that help arrange a chain at a certain angle. At the same time, it is possible to accurately and carefully bring the disc to the teeth of the chain. There are machines equipped. They are turned on when the disk is filled to the lined edge. Convenience and functionality, of course high. You can find models at the “lifting” prices.

Manual drive machines

The design of such a machine is similar to a beam saw. Only where the saw canvas is located, there is a round file. With such a machine, you can sharpen and rule the teeth, adjusting the proportionality of the upper edges to the smallest (control) size. The mechanism allows you to accurately set parameters. After setting up the “control” tooth, sharpening is carried out in two or three movements. And then the transition. To the next tooth.

When it is necessary to relate the limiter, we change a round file to a flat.

Advantages of the method: Allows you to sharpen the teeth, including those who have lost their original form.

Disadvantages: The price of the tool and remoteness from the possible area of operation of the saw.

What to choose for sharpening, you decide. This is due to how often you work a chainsaw. From the accuracy of handling her. From the quality of the purchased chain. And, of course, from the ability to spend an ennary amount. It is impossible to compare the methods, because as the German proverb says. “apples must be compared with apples”.

How to sharpen

Sharpening of the chain of the chain. The process of difficult. There are three options that use today:

Similar ways are used to sharpen knives, scissors and other cutting tools, so nothing superintendent has been invented here. However, there are special devices for sharpening the PowerSharp system. They allow at home to quickly sharpen saws on which there is a special mark indicating the design features.

File

The use of a set of files is the most common way that can be carried out at home. But he is not as simple as it might seem at first glance. For sharpening, two types of files will be required: round and flat. Each of them has its own purpose.

Using a round tool, you need to sharpen the working edge of the saw tooth, because its configuration is rounded. For household chainsaws, a file of 4-5 mm with a diameter is used, because the drains of saws are small in size. Professional saws are sharpened with files with a diameter of 5.2-5.5 mm.

A flat file sharpen the cutting limiter. If the adjustment of this edge is not made, then the chain will not crash into the wood into the required depth, which will reduce the speed of sawing. And this will directly affect both the overspending of the fuel and on the overheating of the saw engine.

How to properly sharpen with files

First of all, the power tool must be prepared. It is installed on a flat surface, it can be a table or a workbench. The chain is pulled to the maximum, set to the brake mode, for which the lock lever rotates. Examine saw teeth for their defects: chips, cracks, full of fracture and so on.

As for the process of sharpening chains for chainsaws with your own hands, there are several recommendations here:

- The teeth should be sharpened with a file from the inside;

- There is a label on the chain that the manufacturer applies specifically to indicate a degree of sharpening;

- The sharpened tooth should be located in the middle of the chain for the convenience of work;

- They sharpened, removed the chain from the lock, advanced the next tooth to the middle, put it on the brake.

You need to work with a saw carefully, putting on protective gloves in your hands, because the teeth of the chain are quite sharp. The number of movements on the edge of the edge is different, depending on damage to the teeth.

Auxiliary devices

In construction stores, special holders are sold, with which it is easy to sharpen the electric or chainsaw chain, because they clearly indicate the angle of sharpening and the depth of the limiter. Having installed the device on the chain, you just need to adhere to the configuration of the holder without going beyond the borders. In principle, this will not work, so the teeth sharpening in the holder have the required parameters of the angle and depth.

Another device with which sharpening is facilitated is the so.Called machine for editing saws of saw chains. The device is fixed to the chain tire with special clamps included in the design of the device. The guide is exposed at an angle that determines the degree of sharpening. It can be adjusted by changing the parameter.

The sharpened tooth is fixed with a special emphasis on which the file is also laid. The machine of this type produces a large number of different manufacturers. The tools may vary purely externally, but they are all the same constructively.

Please note that at first the working edges of the teeth are sharpened manually, and only after that the depth limiter is trimmed. In this case, it is necessary to strictly lift the difference in height of the edge of the tooth and the upper plane of the limiter.

Powersharp system

It should be noted that this device cannot be sharpened all types of chains. For them, their chains and tires with powerSharp marking are suitable for them. The tire is easily inserted into any saw, and it has one difference from the standard ones. An additional hole in the front.

In the configuration of the sharpening system, there is a block of plastic, in which a stack is installed. That is, a tire is inserted into the block, which is previously worn by the chain. It is fixed there with a pin, which is stuck just through an additional hole in the tire. The block is closed with a lid. In front of the block, a key is installed that performs the functions of the lever. It must bend it, thereby pressing the abrasive stone to the teeth of the chain.

After that, the saw must be rested on the ground with the key and turn it on at maximum speed. A couple of seconds and sawed sharpened.

Sharp machines

In service centers, no one has been using files for a long time. Because the correct sharpening of the chain is precisely the sustainable parameters of the angle of teeth and the height of the limiter.

How to Sharpen a Chainsaw?

It is difficult to achieve this manually, and the service center guarantees the quality of the operation with the long-term operation of the electric or chainsaw.

The variety of sharpening machines is only surprising. Here are ordinary simple mechanical devices and electrical. At the same time, manufacturers offer small machines that are installed directly on the tire, desktop, in them the circuit is installed without a tire.

The simplicity of the production of the sharpening procedure is due to the fact that the hiding machine has a fixer in its design, in which the chain is fixed. It is installed so that the chain is fixed in it vertically.

How to use saw chain Grinder Machine? Chain saw chain sharpener Machine Use.

You can adjust the installation site of the device. To do this is quite simple, because the latch can move in a horizontal plane. The angle of inclination determines the abrasive disk (circle), which is installed on the shaft of the electric motor. Thus, the sharpener is located at the required angle exhibited at the factory. But it can also be changed depending on the required degree of inclination.