How to tighten the clutch on a chainsaw.

How to remove clutch from a Chinese chainsaw

One of the most important nodes of the chainsaw is a clutch or adhesion mechanism. When operating the tool, this part may fail, which will entail the impossibility of carrying out work on sawing wood. If the clutch mechanism has come out of the system, then the question immediately arises of how to remove the coupling on a chainsaw. Such a need arises when it is necessary to repair or replace the device. How to do this is described in the material.

Most sawmills do not understand the principle of operation of the mechanism of clutch chainsaw. When working, knowing the principle of functioning is not necessary, but when the malfunctions arise, then in order to eliminate them, you will need to find out the design and features of the work of the chainsaws.

Modern chainsaws are equipped with centrifugal type adhesion mechanisms. Centrifugal clutch. This means that its performance depends on the rotating moment of the engine. The main purpose of the coupling on the chainsaw is to ensure the transmission of torque from the crankshaft of the engine to the saw set (chain). The device works in automatic mode, and how it happens, we will find out in detail.

The clutch mechanism consists of the following structural elements:

- A drum with a removable or non.Removable asterisk. Is a transmitted mechanism

- Friction linings. Under the influence of centrifugal force move, entering into the engagement with the drum

- Spring. Ensures the pressing of the linings to the crankshaft

Now about the principle of action. When a two.Stroke engine engine starts, the crankshaft begins to rotate. The coupling is attached to the shaft, with which the chain is connected with a sprocket. When the chainsaw works at idle (the speed of rotation of the shaft up to 2700 revolutions per minute), that is, the accelerator trigger is not pressed, the spring presses the friction pads, as a result of which the torque is not transmitted to the drum.

As soon as the saw picks up the tool and begins to increase speeds (maximum to 14000 rpm), the chain begins to move along the bus. This is due to the fact that the speed of rotation of the crankshaft increases. Due to the force of inertia, friction linings (they are also called counterweights) move, and enter into a cloth with the internal walls of the drum. As a result, the drum is moved, which is connected to the asterisk. The rotating star drives the chain.

The principle of operation of the mechanism is simple, which is due to it is not a complex design. If this part comes out of the system, then there will be no chainsaw accordingly. A detailed description of the principle of operation of the clutch mechanism of the chainsaw is described in this material.

Device and principle of operation of the clutch clutch of chainsaws

Modern chainsaws are equipped with centrifugal clutch couplings. This means that their work entirely depends on the torque of the motor, which at a particular moment in time gives out a saw.

Its main constructive elements are:

The principle of operation is as follows. When the saw is launched, the elements that are freely move in the radial direction, with the springs are tightened to the axis of the shaft. In this case, the torque does not enter the drum, which means to the asterisk and the guide. At the moment when the centrifugal force prevails over the power potential of the springs, the adhesion elements are weakened and compressed at the inside of the drum, initiating it. Together with him, the rotational cycle passes to the asterisk and the tire-like headset itself.

The main advantage of the clutch of this type is its slippage when the cutting part is suddenly inhibition, which does not stop the engine. As a result, the “heart” drank. The engines remain intact and preservation.

Recommendations when replacing clutch on a chainsaw

In addition to the basic rules of work told in the previous section, it is worth remembering some nuances when replacing clutch. Use only original manufacturer details. This is the key to a long and productive work of the tool. Clutch thread on all chainsaws of any manufacturer is always the left. Before removing the coupling, carefully remove all dirt and dust from the tool so that it does not get inside.

With independent maintenance of clutch couplings, you need to know that:

- Several saws have a puck that is located between an asterisk and a clutch, and an asterisk and a motor. Consider this when repairing;

- The special firing of the oil pump drive should not be damaged during disassembly, and is also subject to return to the original position. Otherwise, the chain will not receive a lubricant or even cease to be lubricated.

The tool that has visited the repair must undergo a check for the reliability of bolted screeds, the supply of lubrication to the circuit and the serviceability of the motor (it should smoothly turn on and work smoothly). Only after that can it be operated.

Algorithm for independent replacement of the clutch drum with an asterisk

The technology for replacing the leading star provides for the implementation of the entire amount of work in a given sequence:

- Dismantling the headset and air filter;

- Installation in the candle hole of the piston lock;

- Clutch clutch and at the same time with a dentate drum are removed by means of a puller, you can unscrew the asterisk only clockwise.

If the separator is detected, the breakdowns of springs of the centrifugal mechanism and fists are recommended to replace the entire kit.

If the condition of the removed parts is not in doubt, the entire mechanism is collected in the reverse sequence. To reliable fixation of the clutch on the crankshaft, it is enough to turn the piston stopper, pull the standard starter and return it to its original position.

Amateur masters should be warned against simplifying the requirements of repair technology and saving funds on the installation of relatively cheap Chinese components.

The quality of the work done is guaranteed by attention, accuracy, compliance with the sequence of all dismantling and assembly operations. Clutch of a chainsaw. A part that is very often susceptible to various breakdowns

Refers to the number of consumables. It consists of a flywheel, coupling, ignition module, muffler and mounting sleeve. The most common reasons for breakdown include a burst or displaced spring, a chip on the clutch drum for a chainsaw. The clutch of the chainsaw performs the function of braking with a decrease in speed, therefore it is subject to huge loads, which is also fraught with breakdowns

Clutch of a chainsaw. A part that is very often susceptible to various breakdowns. Refers to the number of consumables. It consists of a flywheel, coupling, ignition module, muffler and mounting sleeve. The most common reasons for breakdown include a burst or displaced spring, a chip on the clutch drum for a chainsaw. The clutch of the chainsaw performs the function of braking with a decrease in speed, therefore it is subject to huge loads, which is also fraught with breakdowns.

Replacing this mechanism has some differences, depending on the brand. In general, the algorithm of independent replacement is the same. Of course, if possible, it is better to contact a specialized service center. We will tell you about the nuances of the correct removal of the mechanism and replacing the clutch spring of the chainsaw with your own hands in this article.

Removing and replacing the coupling with your own hands according to the instructions

Far from how to remove the clutch on a chainsaw is known. The constructive performance of mechanisms on different models of chainsaws differs, but the principle of operation is the same everywhere. The dismantling procedure is also practically identical, so then we will consider how to unscrew the coupling on a chainsaw with an internal location.

Initially, you will need to prepare the necessary tools:

- A special key called a puller. He often comes with a chainsaw

- Screwdriver screwdriver with which the protective casing is attached

- Candle key. Used to unscrew the fastening of the casing and tire (it comes with the tool)

- Rope. In order to lock the crankshaft. It is better to use asbestos, but for this purpose any. The rope is used in case a special stopping key for the piston is not attached to the tool

If dismantling is performed for the purpose of replacement, then accordingly you will need to prepare a new mechanism in advance. When buying a new coupling, you only need to know the exact brand of the chainsaw, since the devices differ in the outer diameter, thread and design of the working mechanism. Instructions on how to remove a clutch clutch on a chainsaw has the following view:

-

Initially, it is necessary to unscrew the fasteners of the casing and tires

The procedure is not at all difficult, and does not take much time. The assembly is performed in the reverse order of removal. In order to avoid any malfunctions, it is recommended to set a fully identical adhesion on the corresponding model of the tool.

It is interesting!Similarly, the procedure for removing and replacing the clutch for all brands of chainsaws of Khuskvarna, partner and others is performed.

Ural chainsaw: features, characteristics, adjustment

Babble “Ural” appeared in 1935. Since then, it has become wide distribution in the USSR, and after its collapse. In the CIS countries. In the future, the manufacturer made a number of improvements to the design of this tool. The new model made of high.Strength materials is called Ural-2T-Electron chainsaw. It is designed for use in difficult conditions in any season of the year at extremely low and high temperatures. Via Ural chainsaws produce a roll and sawing large trees. It consists of the following main nodes:

The tool is mobile and autonomous. Although it is equipped with a system of extinguishing vibration, nevertheless vibration with the functioning of the motorcycle is great. For this reason, the forest rollers are prescribed to use the Ural chainsaw no longer than an hour and a half a day. This measure allows us to prevent the development of an occupational disease caused by harmful working conditions.

In addition, this device is inferior to imported equipment in the following relations:

- The Ural chainsaw engine operates with enhanced gas formation, so the operator is forced to be in a gasped environment for a long time;

- For servicing the device, experience and dexterity are needed;

- There is no chain brake;

- The device uses twice as much as oil, the mixture enriched with oil compared to foreign gas tools;

- Increased fuel consumption.

At the same time, Ural chainsaw has a number of advantages that allows it to compete with imported models:

- Reliability;

- The ability to easily carry out both longitudinal and transverse cut;

- High handles, allowing to work in full growth, do not bend;

- Low cost.

Specifications

Ural-2T-Electron chainsaw It has the following technical parameters:

- The motor is two.Stroke, one.Cylinder, works on gasoline;

- Vibration-resistance on control handles is 7.9×10-2 meters per second;

- The power of the device is 3.68 kilowatts;

- The weight of the device is 11.7 kilograms;

- The fuel mixture consumption is 632 grams per kilowatt hour;

- Dimensions. 46x88x46 centimeters;

- The working length of the saw mechanism is 46 centimeters;

- The diameter of the cylinder is 55 millimeters;

- The fuel mixture at maximum power does not exceed 632 grams per kilowatt hour;

- The volume of the fuel tank is 1.6 liters;

- The power of the motor after earnings in operation for twenty.Five hours is at least 3.68 kilowatts (five horsepower);

- The volume of the container for the lubricant is 0.24 liters;

- The speed of the crankshaft of the motor at maximum power is 6200 ± 200 per minute.

Ural-2T-Electron chain chain

The saw apparatus of the Ural chainsaw is based on a 46 centimeter tire equipped with a removable saw chain, which is removed from the tool during periods of prolonged non.Use. During operation, the chain is stretched, so it has to be regulated from time to time. A new chain is most extended stronger, so that its tension must be monitored all the time. After use, the chain requires sharpening. This task is performed using a cylindrical round file with a diameter of five to six millimeters. To achieve the best results, when sharpening, the chain is not removed from the tire, and the tension is enhanced.

How to run up the Ural-2T-Electron chainsaw

Before starting the constant use of the Ural chainsaw, it needs to be running out, that is, let it work out for some time at idle. Typically, for running.In, you need to use approximately four full tank of the fuel mixture. For these purposes, gasoline and oil are mixed at the rate of fifteen to one.

After the Ural chainsaw is idling, the running.In must be continued when using a tool with reduced loads. The term during which the device should not be subjected to full load is twenty.Five hours. During this period, a fuel mixture is used in the same proportions as in the process of running at idle. After the run.In, the fuel mixture is prepared at the rate of twenty liters of gasoline per liter of oil.

One of the main points after running in is the setup of all interconnected systems of the Ural chainsaw. To do this, you should know the principle of functioning and the structure of all its nodes.

The engine operation is largely determined by the correct setting of the carburetor. From the factory, the device usually comes with accurate setting of the most important nodes, but in some cases there is a need to eliminate flaws. When adjusting the carburetor, everything is different. Initially, it is configured to the enriched fuel mixture, which is used during the run.In the new Ural chainsaw.

How to adjust the carburetor

Ural-2T-Electron chainsaw Equipped with the KMP-100U carburetor, which includes:

- Frame;

- Diffuser;

- Inlet, graduation and check valves;

- Fuel channel;

- Small and full gas screws;

- The cavity of the pump and regulator;

- Button;

- Springs;

- Throttle and label.

When switching from the mode of running the tool to a normal fuel mixture, the carburetor must be adjusted by changing the position of the nozzles using three screws:

How to tighten a chainsaw chain

The rotation of these screws changes the speed of rotation of the circuit, and also regulates the throttle flap of the ratio of fuel/air. There is smoke on a rich mixture from the silencer, if the composition is poor. The saw squeals.

Instructions for the Ural-2T-Electron chainsaw

Initially, when creating the Ural chainsaw, it was assumed that its repair would be carried out by non.Specialists in a field atmosphere. For this reason, a detailed step.By.Step instruction was created on how to repair rather complex mechanisms in very primitive conditions on their own. The instructions for the Ural chainsaw are different from the instructions for other motoropeils in that it contains much more information required for work. It provides information on the principles of the functioning of the cooling system, gearbox, magneto and other nodes. The procedure for preparing the device for work, the process of running the motor is described in very detail. In addition, the instructions include recommendations for the preparation of the workplace, the forest roll, and tear off trees.

How the chainsaw engine works

In devices released recently, a single.Cylinder two.Stroke carburetor engine is installed. It includes several mechanisms that work harmoniously. The main components of the engine:

Recommendations when replacing clutch on a chainsaw

In addition to the basic rules of work told in the previous section, it is worth remembering some nuances when replacing clutch. Use only original manufacturer details. This is the key to a long and productive work of the tool. Clutch thread on all chainsaws of any manufacturer is always the left. Before removing the coupling, carefully remove all dirt and dust from the tool so that it does not get inside. During reverse assembly, do not forget to put all small details in place, including pucks and bearings. Follow the installation of a special spring (it is not in all chainsaws). If it is not installed, oil will not be supplied to the saw tire.

Basil for a household man is an indispensable tool that comes to the rescue when performing forestry work of various volumes, the implementation of construction projects from the beam, the improvement of private possessions, the garden, the court, on the farm.

The power unit consists of several important nodes, among which the clutch. Often the tool can fail due to a faulty clutch clutch of chainsaws. This is a typical breakdown that the owners of the chainsaw are faced, regardless of its class, power, model and manufacturer. To fix the coupling or at least accurately diagnose the cause of the breakdown, the operators need to know how to unscrew the clutch on the chainsaw. This knowledge will allow not only forced repair work, but also planned cleaning, inspection for preventive purposes. Do not forget that the clutch and its serviceability affect the long and effective work of the tool.

Types of clutch breakdowns

Types of malfunctions do not depend on the chainsaw model, since the structure and principle of the clutch operation is the same on almost all modern power units. Chainsaw operators know that a slight problem from this node requires immediate active actions. The breakdowns are inevitable, since the clutch collides with not the most intensive operation of the tool with a large load. Often problems are related to:

- The wear of the node as a whole (it may burst the spring or the mechanism will begin to slip);

- Damage to the spring (the chain will rotate, the engine to work, but unstable);

- Sticks formed on the clutch fist due to a large load or overheating (it is enough to listen to the node during its operation, an extraneous noise indicates a malfunction).

Whatever the reason for the poor work of the coupling and related components, you need to dismantle the clutch to carry out its repair. Please note that repair work does not always give the desired result, so sometimes you need a clutch replacement on a chainsaw. All of the listed manipulations can be “crank” yourself, without turning to the specialists of service centers for help.

Be sure to read the article where the correct gap on the candle of the chainsaw and its device are considered.

How to remove clutch on a chainsaw?

It is not necessary to consider instructions for such a type of work for a single model, because for everyone one universal is used, which allows the dismantling of this unit on modern benzo tools.

If there are any distinctive nuances, then they relate to separate traction details. For example, some brands create one spring with two sections in the design of this node, which must be taken into account when the component is completely replaced (it must be replaced when the spring is damaged, due to which the circuit will rotate, and the engine will demonstrate unstable operation).

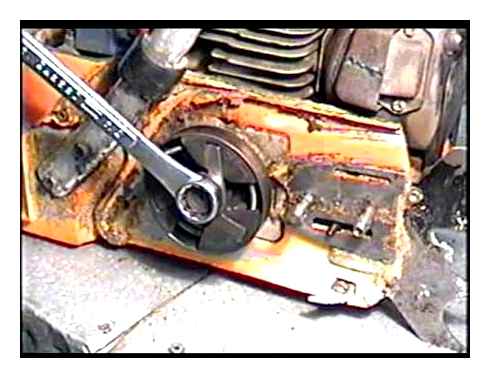

To dismantle the clutch, we adhere to such an algorithm.

- We dismantle the entire headset. Also remove the cap placed on an air filter and clutch.

- Manually stop the crankshaft so that it does not rotate. It is more convenient to do this, using a rope that is threaded through the candle hole, while removing the candle itself. Do not forget that for this you need to reliably fix the piston in one position. Alternatively remove the starter cap and entrust a couple of bolts into the rotary mechanism of the ignition system.

- Using a special key, which is usually included in the tooling of the tool, unscrew the clutch (you need to unscrew with movements against the course of the clockwise). No need to be afraid to make efforts, usually the fasteners of this node on modern chainsaws are strong.

- Remove the drum and the leading star.

After that, you can install new spare parts (which needed to be replaced). Twisting fasteners, we make movements along the time of time. Do not forget about the crankshaft where the starter is placed. It needs to be stopped.

When assembling, we adhere to the same algorithm of actions, but in the reverse sequence.

Barnett Clutch Replacement How To Part 1 Kawasaki 750 H2 Mach Iv H1 Mach III

By screwing the knot manually, use the brake of the SAW ELREANT to fix the handle. Tilt the tool forward, try to start it, remove the unit from the brake.

Speaking about the complete replacement of the clutch, do not forget that experts recommend changing the knot after two replacements for the guide. You need to take into account when servicing couplings and such nuances:

- On some saws there is a washer located in the gap between the clutch and an asterisk (sometimes a motor and asterisk), this must be taken into account during repair work;

- Disassembleing the tool, dismantling the clutch, try not to damage the special spring of the oil pump (the drive of this node), do not try to put it in its original position, otherwise this will cause the causes with the supply of lubricants.

Before operating the saw on which the clutch was repaired, check the unit for the serviceability of the engine, the reliability of fixing the bolts, test the lubricant system.

Device and repair of the chainsaw

Structurally all chainsaws, whether it is household models or powerful professional units, are similar. Tools are collected from several important nodes that guarantee the correct and uninterrupted operation. One of these essential elements is the clutch of the centrifugal type.

The clutch of the chainsaw is on every modern tool. The knot is automatically triggered, depending on the number of engine speeds. The friction elements are attracted by the spring to the drum and begin to rotate it. The rotation of the leading star begins, which sets in motion the saw chain. At low speeds of the engine, the friction elements are pressed by the spring to the center of the shaft and do not transmit rotation to the drum. Which, in turn, leads to the braking of the chain. This principle of operation avoids some breakdowns of benchmate tools.

When you need to remove the clutch

Dismantling of adhesion for the purpose of removal is carried out in such cases:

- When the spring burst (the chain is turning, the engine works with interruptions);

- A spring flew;

- A piece of the drum broke off (in this case, the noise will be heard, the chain of the chainsaw will also spin);

- Temporary wear (it is time to remove and change the clutch due to the development of the resource).

Fixing a Chainsaw Clutch

Modern chainsaws operate on two.Stroke engines, which are connected by a gearbox with a saw chain. The chain moves along the tire, and according to the centrifugal principle, work at idle should remain in immobility, that is, to be safe for the one who holds the chainsaw.

If the load shown on the tool exceeds the recommended, then the clutch will weaken or completely stop transferring the torque to the tire. This will lead to engine stop. In the event of such situations, the clutch wear out, so over time it needs to be replaced. In the operating instructions for the chainsaw, some manufacturers have information that the clutch is a consumable part, that is, it is subject to periodic replacement.

Video. How to remove clutch on a chainsaw:

Repair and replacement of the clutch of the chainsaw

In order to eliminate any of these malfunctions, it is necessary to remove the clutch. This will need to be performed by the following actions.

- Unscrew the nuts and remove the chain star lid.

- Remove the guide tire and chain from the chainsaw.

- Release the brake of the saw chain and remove the chain star. To determine the state of the clutch mechanism on the STIHL chainsaws, it is necessary to remove the sprocket with the clutch drum. On the chainsaw of the Husqvarna brand, it is enough to remove the chain star lid. Before the clutch dismantling, the engine crankshaft should be blocked.

It should also be borne in mind that to remove clutch with most models of chainsaws, you will need a specification. We also recommend that you follow the purity of the clutch mechanism and, if necessary, clean it before further operation.

In most cases, when replacing clutch, it makes sense to update the guide tire and chain of the chainsaw.

If you suspected the tool malfunction, while you do not have sufficient skills and time for your own repair, contact our service center straight hands, service specialists will perform qualified diagnostics and repair of the chainsaws of leading brands.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.

Signs of malfunction of the chainsaw

The centrifugal clutch of the chainsaw works until one of its full.Time elements is out of order. The following signs will be told about the breakdown of the mechanism to the operator:

- The constant rotation of the chain with unstable operation of the power unit is the main reason for this breakdown is a bursting steel spring. To solve the problem, you will need to replace the clutch spring of the chainsaw. At the same time, it is important to consider the design features of the mechanism. For example, 3 springs and the same number of cams are provided in the device of the STIHL brand, and only 1 spring and 2 cams are built in the Husqvarna brand models. If the operator does not succeed in finding a new spring, then it will be necessary to replace the entire mechanism;

- Constant rotation of the chain with the formation of extraneous sounds from the adhesion. This occurs with a flying spring and overheating or damage to the fist. To find the cause of the breakdown, you need to disassemble the clutch. If the fists turned blue, then they overheated. This is due to constant work with a chainsaw with an inertial brake on or as a result of operation of a tool with a dull cutting chain. To eliminate the breakdown, you need to completely replace the clutch;

- Frequent clutch slipping. The cause of the breakdown is the bursting metal spring. To repair a gas tool, you need to replace the entire mechanism.

In each of these cases, it is necessary to disassemble the clutch and inspect all its internal details. In addition to replacing faulty elements, the operator will also need to carefully clean the mechanism of dust and small sawdust. This will extend the life of the remaining elements of the factory coupling.

Clutch device, principle of operation

In order to successfully disassemble this node, you will need a clutch pulp by a chainsaw. But before we consider how to use it, we will study the features of the device of this functional part of the power unit.

Please note that when developing modern chainsaws, manufacturers most often resort to the use of a centrifugal clutch clutch. And this suggests that the tool and its work depend on the stock of the spinning moment that the equipment issues here and now.

The main constructive details of this node include:

- As soon as the chainsaws are transferred to the operating mode, the clutch springs are delayed all freely moving elements (move in the radial direction) towards the axis.

- At this moment, the torque will not be transferred to the guide with an asterisk.

- As soon as the centrifugal force becomes higher than the power potential of the spring, all the freely moving attracted elements are weakened and squeezed inside the drum, which will run it (it will begin to spin).

- Rotation will go to the guide tire and the main star.

It is on this principle that centrifugal clutch works, which has several advantages in comparison with its other varieties. Among them, the lack of engine stop during the sharp braking of the cutting element (that is, the clutch slips). Due to this feature of the mechanism, the main node of the chainsaw remains unharmed.

Pay attention to the fact that this type of clutch coupling will work automatically. Its functioning depends on the number of engine speeds. The movable elements inside the drum will be attracted to the shaft (its center) even at minimal speeds. This plays an important role in preventing serious causing tools. When this mechanism fails, then there is a need to understand how to remove the clutch on a chainsaw.

The device of the chainsaw includes the clutch mechanism, which consists of such elements as:

- Crankshaft;

- Drive.Type disk;

- Pressing disk;

- Protective casing of the mechanism;

- Squeezed lever;

- Bearing;

- Turnpile fork;

- Carter;

- Gears;

- Pipeline;

- Fasteners.

At minimal revolutions of the power unit, the clutch of the chainsaw is attracted to the center of the shaft with a spring device and does not transmit a rotational moment to the drum. At a time when the engine revolutions begin to reach the indicators in which the torn force exceeds the force of the spring device, the frictional segments begin to press against the inner surface of the drum mechanism, which helps to rotate the drum of the Chinese chainsaw.

Reviews of the owners

“After six months of operation, the chain on the chainsaw began to spin constantly. I decided that the problems with idle. No carburetor adjustments helped. They dismantled the workshop. It turned out to be bursting the spring on the clutch. Changed everything in 10 minutes, and I could not find a malfunction for two months. The main thing is the correct diagnosis of a malfunction.””

“I can drink mainly solid wood of wood. Quite often you have to sharpen the chain, and the leading star wears out. The first time I took off the clutch. I had to sweat. The metal tightly seized. Not unscrewed. He sprayed with kerosene. Did not help. Only after use in the kids managed to disrupt. And all because the oil flowed somewhere, so the coupling was welded to the asterisk. I think so.””

Andrey Kosuglazov, 23 years old, Primorsky Territory

“After three months of operation of the chainsaws, a longitudinal groove appeared in the asterisk. Everything works, and the chain does not rotate. Said that the problem is in the clutch. It is not at all difficult to make it out, the main thing is to find a puller and not forget that the nut of the coupling has a left thread. In short, unscrewed and changed everything without problems. It works fine, and there was nothing complicated there, only carefully needed.””