How To Use A Miter Saw. Woodworking mitre saw

How To Use A Miter Saw

The miter saw was the first tool I bought when I moved into my own home. I remodeled that entire house using primarily a Ryobi miter saw on the floor of my garage. I cut a mile of baseboard on that garage floor and I supported the long pieces with anything I could find. I didn’t even have a bench or table to set it on.

It’s hard to get much done in the shop or on a job site without a miter saw. You can’t beat it for roughly crosscutting wood to length and, if tuned properly, it can be great for cutting miters for picture frames or boxes. You can get a lot done with a miter saw, a drill, wood glue, and screws.

I recommend the miter saw as an essential tool for the beginning woodworker and DIYer. While it is safer than many other stationary cutting tools such as the table saw, it is still a very sharp blade spinning very fast and you must be careful. Your finger is no match.

What does the miter saw do?

The miter saw is a tool that crosscuts wood to a desired length. Assuming the wood grain is running with the length of the board, the miter saw blade cuts perpendicular to that grain, or across it.

The “miter” in miter saw is the ability to cut angled miters. The saw rotates from side to side and can crosscut wood at different angles. This primary feature is useful for making picture frames and boxes with miter joints. Two 45 degree miter cuts come together to form a 90 degree angle. It’s an easy way to join wood, but it’s not the strongest joint. You wouldn’t want to use this joinery method for any project that will be subject to force unless the miters are reinforced.

Compound miter saws can also tilt to cut a bevel angle. Cutting a bevel in a board laying flat is the same as putting the board on its edge and cutting a miter. A “compound” cut is a bevel and miter cut at the same time.

How does the miter saw work?

The miter saw head has a spring that keeps tension on it. As you lower to make a cut, the spring returns the head to the upright position.

This miter saw is a 10 inch saw. That refers to the size of the blade it uses and there are 12 inch and 7 1/4 inch saws, as well. A 12 inch saw can cut a thicker piece than a 10 inch saw which cuts thicker stock than a 7 1/4 inch saw.

The saw dust that comes off the blade is supposed to be directed to a chute and into a collection bag. Unfortunately, most miter saws are horrible at dust collection. Most of the dust goes under and behind the chute.

Many miter saws have a clamp of some sort that secures the work piece to the table during the cut.

Extensions allow support for longer work pieces and can sometimes have stops that flip up for repeat cuts. The handle is a screw that tightens the table in place. The table swivels back and forth to the desirable angle as indicated on the tape and the handle locks it in place.

Sliding miter saws have some mechanism for extending the cutting head for extra capacity. This saw has rails that allow the saw to cut much wider boards.

Safety

You’ll notice a guard covering the blade. As the saw is lowered the guard lifts to allow for the cut but stays between you and the blade.

Important: Don’t ever remove the blade guard for any reason

The stock fence that comes with most miter saws is inadequate for cutting smaller pieces. Trying to cut a piece like this with no support will end in severe kickback. Do not attempt a cut like this without adding a zero-clearance, sacrificial fence.

My saw has holes on the back side of the aluminum fence to secure a sacrificial fence with screws. Smaller pieces can be more safely cut with this fence and a push stick. Make sure your hand is nowhere near the blade anywhere along its path.

Keep even pressure on the piece so it doesn’t turn after the cut and get caught in the blade and thrown.

Never cross your arms when making a cut, i.e., holding the right side of a workpiece with your left hand. Your hands and arms should never cross the middle of the blade insert.

Place your left hand a good distance away from the blade on the left side of the workpiece with enough pressure to keep it secure against the fence and on the table.

Miter Saw Tips

Make a scoring cut first before plunging the full depth of the workpiece. A scoring cut is a light pass along the full width of the workpiece and will help prevent tear out and keep the cut clean. After making the scoring cut make the full cut.

To make consistent, repeatable cuts, I like to use a stop block. If your saw has extension wings with stops, those can be used. Otherwise, securely clamp a block to the fence, push the board up to the block, and make the cut. Part of the workpiece is trapped between the stop block and the blade and this can be dangerous, so wait for the blade to come to a stop before raising the saw.

After measuring and marking the length to cut on the miter saw, draw an X on the side that is being cut away. The blade teeth should be entirely on this side marked with an X with the outside edge of the teeth right on the edge of the line. The result will be a workpiece that is the length you expect it to be. Putting the blade directly on the line will cut into the side you want to keep.

Sometimes you need to just cut the tiniest sliver from the end of a workpiece to sneak up on a fit or to clean up the end without taking much off. Pull the saw down all the way and hold it. Push the workpiece into the face of the blade and make sure it’s not hitting the teeth (FIG 30). With the workpiece against the face hold it firmly in place, raise the saw, and then make a cut.

Alignment

It’s important to make sure your saw blade is square with the table and fence to make accurate cuts. I use a 4 inch try square that fits perfectly on my saw. Pull the saw down and lock it in place. Slide the square up to the face of the blade, again making sure it’s not touching the teeth, and the square should touch the saw from top to bottom. If it doesn’t, the saw is not square and you should consult your owner’s manual to adjust it.

Place the square flat on the table and slide it up against the fence. Just as before, make sure the square isn’t touching any teeth and slide it against the face of the blade.

A miter saw, drill/driver, and a circular saw should be the first power tools you purchase as a beginner woodworker. You can create so many impressive projects with just these three tools and a few affordable accessories!

Miter Saw Guide

Miter saws are versatile woodworking tools created for cutting a variety of building materials such as lumber, siding, flooring, or even PVC pipes. Used primarily for crosscuts, which are cuts that go across the grain of the wood, miter saws have mounted circular saw blades that you pull down to cut the workpiece. Many miter saws are stationary saws, as you bring the mounted blade downward, rather than running it horizontally along the workpiece. One that slides horizontally across the piece as you cut would be a “sliding” miter saw. Miter saws go by many other names, such as a chop box saws, chop saws, and miter box saws.

A miter saw’s standard cutting angle is 90 degrees. However, both single and dual bevel miter saws allow you to make bevel cuts, which are cuts that are along the material’s thickness at an angle other than 90 degrees. The bevel of a miter saw is useful for intricate work and often a major differentiator for buyers. The saw blade rotates — either to the left or right — allowing you to adjust the saw positioning to different angles, such as a 45-degree angle. Typical miter saw applications include making trim, molding, baseboards and other fine carpentry work. Miter saws allow you to achieve complex angles that are often required with woodworking and carpentry projects.

This guide to miter saws will explain the different ways you can achieve bevels cuts with two different types of circular saws: single and dual bevel miter saws.

Single Bevel Compound Miter Saws

A single bevel miter saw only adjusts its positioning in one direction: to the left or right. Therefore, a single bevel miter saw allows you to make one-directional bevel cuts. Single bevel miter saws can make both bevel cuts and miter cuts independently or together.

Depending on your project, you may need to make bevel cuts on both sides of the workpiece. Because a single bevel miter saw can only make bevel cuts in one direction, you’ll need to turn your workpiece around to achieve an additional bevel cut on its other side.

Even though a single bevel miter saw can only make bevel cuts in one direction, the saw can still accomplish the same thing a dual bevel does, just with a little more brainpower. If you need to make multiple cuts on both sides of your workpiece, it will take longer and require more effort using a single bevel miter saw.

Dual-Bevel Compound Miter Saws

The blade angles of a dual bevel miter saw can adjust to both the left and right, as opposed to just one side, like the single bevel saw. Some people call this type of tool a double bevel miter saw because it can be adjusted to make cuts in any direction.

Because the saw head can rotate on a fulcrum towards both the right and the left, you can make identical bevel cuts in your workpiece without having to turn your material around. Double bevel miter saws allow you to make precise and uniform cuts on both sides of your workpiece. It also makes the job easier and quicker, as you can make faster repetitive cuts even on longer workpieces.

For contractors or highly committed hobbyists, a dual bevel miter saw will improve your workflow and efficiency.

Single vs. Dual Bevel Miter Saws

Both single and dual miter saws can make miter and bevel cuts, and both use circular saw blades for cutting. They are also both referred to as “Compound” miter saws because they can make miter cuts and cuts in 1 or 2 directions. Despite these basic similarities, there are some differences between each.

Pros and Cons of Single Bevel Miter Saws

Single bevel miter saws are more straightforward machines, ideally suited for the beginner craftsman or home improvement hobbyist. If you’re new to woodworking or looking for a lower maintenance saw, consider these pros of single bevel miter saws:

- They’re Cheap: Single bevel compound miter saws are typically a few hundred dollars cheaper than dual bevel saws of the same brand.

- Simplicity: Single bevel miter saws are straightforward and easier to use. If you plan on making most of your cuts at 90-degree angles, then this will do everything you need.

- Versatility: Single bevel miter saws are great for beginners or professionals since you can accomplish what you can with a dual bevel, with a hair more effort.

Despite their advantages, single bevel miter saws do have some drawbacks:

- Fewer capabilities: The main disadvantage of the single bevel miter saw is that it makes one-directional angled cuts, meaning you have to turn your workpiece around to make matching cuts. This matters most when installing crown molding or other types of trim.

- Less uniformity: Because you can’t make double cuts at once with a single bevel miter saw, any matching bevel cuts you make on the other side of your workpiece might not appear as uniform.

- Longer work time: If you’re working on a more intricate project requiring double cuts, it will take you longer with a single bevel cut miter saw.

Pros and Cons of Dual Bevel Miter Saws

Many professional contractors and advanced woodworkers prefer double bevel miter saws. If you’re a more experienced craftsperson, then here are some of the benefits of investing in a dual bevel miter saw:

- Take on more work: With a double bevel miter saw, you can take on more projects because you’ll be able to cut in both directions efficiently. This is very helpful for crown molding projects and other projects with trim.

- Meet tight deadlines: Being able to make bevel cuts in two directions without rotating your workpiece saves time, meaning you can get more done faster if you’re on a tight deadline.

- Make precise cuts: Having the ability to rotate the saw head allows you to make more precise matching cuts on both sides of the workpiece, improving the quality of your work.

It’s essential to choose the right miter saw for you, so first consider some of these possible disadvantages of dual bevel miter saws:

- expensive: Dual bevel miter saws are typically at least 100 more than single bevel miter saws from the same brand, so it’s important to consider the return you’ll get from your investment.

- complicated to use: Dual bevel miter saws have more extensive capabilities, making them more complicated and not as suitable for beginners. Typically the projects where these are most helpful, such as crown molding as mentioned above, are not beginner woodworking projects.

The Miter Saw Says it’s Sliding. What does that mean?

Both single and dual bevel miter saws can be sliding. Sliding miter saws are designed to expand the capabilities of the miter saw. The blade sits on a rail and slides across the board you’re cutting. This will allow you to cut wider boards. Some sliding saws allow you to cut boards that are 12″ or even 16″ in width, which you couldn’t accomplish with a normal miter saw. Instead of “chopping” through the board, you’ll slide the blade across the board since the blade sits on rails. To use a sliding miter saw, you simply pull the blade toward your body and push away as you cut. Typically single and dual bevel miter saws that are sliding cannot be adjusted to angles that are as steep as the non-sliding saws. This is because the rails used for sliding interfere with the side to side motion.

Blades You Can Use With a Miter Saw

Whether you use a single or a dual miter saw, the quality of your work still depends on the right type of blade for the job. Miter saws are versatile woodworking tools that you can use with a variety of circular saw blades. Here are some of your best saw blade options to use with a miter saw:

- Crosscut blade: Miter saws are meant for crosscutting, which is why your miter saw needs a good crosscut blade. For best crosscutting results, choose a blade with a high tooth count, so you can achieve smoother cuts.

- Combination blade: If you use a variety of materials besides lumber, then a combination blade is a good option. Combination blades allow you to achieve smooth cuts in materials other than lumber.

When selecting your saw blade for your miter saw, be sure to choose high-quality blades that are built to last longer and perform better.

Choose Luxite Saw Blades for Superior Woodworking

Whether you’re a professional craftsman or carpenter or you’re new to hobby woodworking, choose Luxite woodworking blades for high-quality woodworking results. We offer superior carbide-tipped circular saw blades that are made to last, giving you a better return on your investment.

For more information on Luxite saws, reach out to our representatives today. Call us at 1-800-654-7297 or contact us online.

The Best Miter Saw – Complete Buyers Guide Reviews

Miter saws are a versatile and exceptionally handy power tool for anyone looking to get serious about project work. For birdhouses and wood crafts, smaller saws are perfectly adequate. However, if you’re ready to tackle more robust lumber and projects requiring more than simple angles, the best miter saw should be there for you to do a great job. Every woodworker needs a tool shop miter saw, that’s where your expertise is shown. A fine woodworking miter saw. Every woodworker’s dream tool.

- Top Rated Miter Saws (Compound, Sliding)

- Top 9 Miter Saws Reviewed

- 1. DeWALT DWS780 12-Inch Double Bevel Sliding Compound Miter Saw

- 2. Makita LS1016L 10-Inch Dual Slide Compound Miter Saw with Laser

- 3. DeWALT 12-Inch Sliding Compound Miter Saw (DWS709) – Best Budget

- 4. Bosch CM10GD 15-amp 10-inch Dual-Bevel Glide Miter Saw

- 5. Ryobi TSS102L 15-amp 10-inch Sliding Miter Saw with Laser

- 6. Craftsman 21237 15-amp 10-inch Single-Bevel Sliding Compound Miter Saw

- 7. Hitachi C10FCG 15-amp 10-inch Single Bevel Compound Miter Saw

- 8. DeltaS26-262L Shopmaster 10 In. Miter Saw with Laser

- 9. Makita XSL06PT Cordless 10″ Dual-Bevel Sliding Compound Miter Saw with Laser Kit

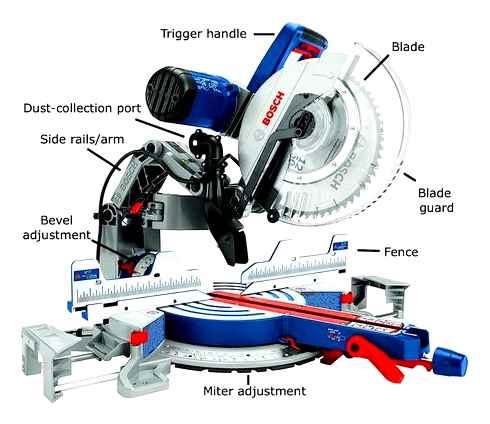

- Fence

- Miter Adjustment

- Bevel Adjustment

- Handle/Trigger

- Sliding Rails

- Cross Cuts

- Rip Cuts

- Compound Versus Sliding Compound Miter Saw

- Compound Saw

- Sliding Compound Saw

- Miter Saw Safety Focus

Top Rated Miter Saws (Compound, Sliding)

I believe the natural progression for any professional and DIY’er as they increase their power tool inventory is as follows:

Cordless Drill – I’m not really sure what kind of project you can take on without one. Don’t cheap out, you will use this tool far more than anything else.

Circular Saw – Definitely the first saw everyone should purchase. It’s fairly inexpensive and can basically do it all.

Sawzall – Also called a reciprocating saw, this tool is versatile, and the best tool for disassembling pallets.

Miter Saw – Functions like a table saw, circular saw, and more. The best miter saws combine portability with high-functionality, letting you make that perfect angled cut (miter cut). (Also See: Miter Saw vs. Chop Saw – which one should you buy?)

Top 9 Miter Saws Reviewed

DeWALT DWS780 12-Inch Double Bevel Sliding Compound Miter Saw

I’m positive after you read what we have to say and the reviews we will feature, you will agree with why we chose the DeWALT DWS780 Compound Miter Saw for our best miter saw overall.

I’ll confess, I didn’t want to give the best miter saw overall ranking to a DeWALT miter saw.

My father owns (and only recently purchased) a Bosch miter saw, and in the spirit of loyalty, I wanted to help justify his decision. Not to mention, I have been digging Bosch tools lately.

They really are an amazing product and I wouldn’t discourage anyone from buying even a Bosch miter saw.

Yet, it simply wasn’t the best miter saw, and I have to be objective. After reading a ton of reviews, and coming across a few too many referencing some design flaws, I couldn’t objectively add it to my list.

The DeWALT DWS780 however, I had a very hard time even finding a bad review. Which for anyone who reads a lot of reviews, is quite an amazing testament to this saw as one of the best miter saws overall.

Key Features

- Integrated XPS cross cut positioning system provides adjustment-free cut line indication

- Powerful 15 amp, 3,800 rpm motor delivers extended power and durability

- Exclusive Back Fence design cuts up to 2 by 16-dimensional lumber at 90-degrees, 2 by 12 at 45 degrees

- Adjustable stainless steel miter detent plate with 10 positive stops improves productivity, ensures accuracy

- Super efficient dust collection system captures over 75-percent of dust generated

- This product does not come with a stand

What’s in the box?

One DeWALT DWS780 12-inch double bevel sliding compound miter saw, one carbide blade, one blade wrench, one dust bag, and one vertical material clamp.

Customer Reviews

Like I mentioned before, I had a difficult time finding bad reviews for the DeWALT DWS780 Miter Saw. If you don’t know already, this is a very good sign.

I know it’s hard to ignore negative reviews, but the fact is, with as many saws as DeWALT manufacturers, there are bound to be some occasional defects. The same goes for every brand. Sometimes we just need a little perspective. The few negative reviews I read referenced an issue with the bearings in the slide.

However, DeWALT has since corrected the issue. If you’ve come to the conclusion that the 12-inch blade is just unnecessary for you, the smaller DeWALT DW717 may suffice.

Makita LS1016L 10-Inch Dual Slide Compound Miter Saw with Laser

I have many friends and coworkers who prefer Makita power tools. It’s kind of hard to understand.

I guess it’s kind of like those who prefer Ford’s over Chevy’s…it’s really down to a matter of opinion.

Yet, I have to say, Makita has been making great tools for a very long time. And if you can trust anyone, trust the contractors and professionals who use them. Makita is a well-trusted company founded in Japan in 1915.

Much like Hitachi Power Tools, Makita tools have fast become a household name in the industry. Makita’s commitment to excellence is why the Makita LS1016 Compound Miter Saw has voted our best miter saw runner-up.

Key Features

- Powerful 15.0 AMP direct drive motor requires less maintenance and delivers 3,200 RPM

- Compact design with a patented 4-Steel Rail Sliding System further increases rigidity to produce superior cuts

- Exclusive 6 linear ball bearings engineered to deliver “”dead-on”” accurate cuts

- Increased capacity for up to 6-5/8″” crown molding (vertically nested), 4-3/4″” baseboard (vertical), and 12″” crosscuts at 90°

- Largest crown molding cutting capacity in its class

- Innovative direct drive gearbox and guard system is engineered for increased vertical cutting capacity

- Miters 0°-52° left and 0°-60° right, with positive stops at 0°, 15°, 22.5°, 31.6°, and 45° (left and right)

- Dust bag to minimize your mess

What’s in the box?

Makita LS1016L 10-inch Dual Slide Compound Miter Saw, 60 Teeth TCT Saw Blade, Vertical Vise, Dust Bag, Triangular Ruler, Socket Wrench, and Hex Wrench.

Customer Reviews

We couldn’t determine what the best miter saws are without testing many of the saws ourselves or without the help of thousands of reviews from verified owners.

We exist to help you sift through some of the best reviews (not just good ones) that help you make an informed decision. Besides, a miter saw isn’t a small investment…unless you’re Bill Gates.

In which case, I desperately need a new truck…hook a brother up. The chief complaint about the Makita LS1016L is that the slides have a tendency to become stiff and difficult to move. This can affect both the accuracy and quality of your cut.

Fortunately, the laser guide on this particular saw takes some of the guesswork out of the equation. I’ve also recently read that this issue has been resolved and or greatly improved.

However, the slides on all saws are going to be a bit rough at times. It’s kind of the difficult nature of any element involving bearings.

One thing you can always count on with Makita, you’re getting a reliable saw matched with durability. Easy to read manual…not so much.

Key Features

- 15 Amp motor, 4,000 rpm delivers extended power and durability

- Adjustable stainless steel miter detent plate with 11 positive stops improves productivity and ensures cutting

- Precise miter system and machined base fence support optimize cutting accuracy

- Tall sliding fence supports crown molding up to 5-1/4-inch nested and base molding up to 6-1/2-inch vertically against the fence while easily sliding out of the way for bevel cuts

- Bevels 0 degree-48 degree to the left and 0 degree-3 degree to the right for increased capacity; 0 degree-50 degree left and right miter capacity for greater versatility

What do the reviews say?

A miter saw on a budget? Does that really exist? It does, and it’s another great saw from DeWALT called the DeWALT DWS709 Compound Miter Saw.

Naturally, you can’t expect to get all the same features and power from a budget saw as you would a top-of-the-line saw. The price difference can be as much as a few hundred dollars and that kind of cost difference goes a long way toward upgrades and features.

You’re going to sacrifice certain features such as the double-bevel and sliding arm, which are features that do drive the price up. But, you’re still getting a 15-amp motor and a 12-inch blade capacity.

The simple design of this saw will definitely get the job done. What you should expect from a budget saw is quality and durability. The DeWALT DW715 provides both of the aforementioned attributes, and will certainly satisfy the amateur DIYer or beginner handyman’s needs.

Talk to a tool expert in minutes, 24/7

Fence

This is the wall that your material is pressed against to allow a flush and level cut. A straight fence ensures the angle you set your miter saw to is the angle you will end up with. A nice tall fence is what you want to look for as it provides the most stability for taller material.

Especially when cutting large crown molding or baseboards. Also, a sliding fence that extends away from where you are cutting is handy.

Miter Adjustment

This is where a miter saw gets its name, the bread, and the butter of the tool. This adjustment will turn the motor housing and blade to different angles, sometimes up to 60° in either direction.

A quick and easy-to-use adjustment system will save you time and frustration and multiple positive stops (preset locking points) are a must.

Bevel Adjustment

If the miter adjustment is what makes a miter saw, the bevel adjustment is what makes it a compound miter saw. The bevel adjustment is typically (but not always) located toward the back of the saw and allows you to change the vertical angle of the blade.

A single bevel will only allow the blade to tilt to either the left or the right, while a dual bevel will allow the blade to tilt both left and right. A nice large and easy-to-read scale makes adjusting the bevel much easier.

Handle/Trigger

As straightforward and simple as this one seems, there are a few things to pay attention to here. The handle is obviously the handle and it contains the trigger to activate the saw and allows you to pull the blade down and into your material.

Some saws will favor a right or left-handed person (almost always right-handed) with the placement of the handle. Others place the handle in the middle and allow for equal left or right-hand use. Also, some saws have a horizontal grip and others have a vertical (pistol) grip on them.

Sliding Rails

These will only be found on a sliding miter saw and their purpose is pretty straightforward. They allow the motor housing, handle, and blade to extend out and away from their set position.

The length of the rails will help define the maximum width of material that can be cut, as well as the amount of space required behind the saw to allow the rails to retract.

What Kinds Of Cuts Can Miter Saws Do?

Cross Cuts

Miter saws are a great tool that excels at performing many different types of cuts. Among those are cross cuts (perpendicular to the grain), miter cuts (angled across the face of the wood), and bevel cuts (angled across the edge of the wood).

With a depth control on a sliding miter saw you can even cut away material for dadoes, rabbets, and lap joints with multiple passes. It’s safe to say there’s a lot they can manage.

Rip Cuts

But they are not without their limitations. For instance, you’re not going to be making rip cuts (parallel to the grain) or curved cuts.

Miter saws are also limited in the width of material they can cut. This is especially true for non-sliding miter saws (which is why it’s such an important feature) where the size of the blade is the most significant factor in determining material width.

Overall, what miter saws can do, they do better and faster than any other tool.

Which Type of Miter Saw?

Basically, we will FOCUS on 2 types of miter saws: Compound and Sliding Compound. Over the last ten years, the compound and sliding compound has emerged as the standard for the best miter saws.

Not only are chop saws and plain miter saws difficult to find, the cost savings just aren’t there to justify purchasing one. The term compound means the saw is capable of cutting miters, bevels, and even miters and bevels at the same time.

Compound Versus Sliding Compound Miter Saw

You’re probably wondering, “what’s the difference between a compound miter saw and a sliding compound miter saw”?

Compound Saw

A compound miter saw’s blade can only be moved up and down but a sliding compound miter saw has a sliding arm that allows the blade to move out away from the fence. This allows a sliding miter saw to cut through wider and thicker material than a compound miter saw can manage. (Here’s our full guide to sliding vs. non)

The more apt question is, “why would I need a sliding compound over a regular compound”? That question isn’t quite as simple…

Tim Carter of askthebuilder.com had this to say on the subject:

“A sliding compound miter saw is a wonderful tool to have around the shop or for a serious do-it-yourselfer. You will use it for many purposes, but don’t buy it just to cut crown molding.

There are many finish carpenters who love their compound miter saws and use them regularly to cut crown molding. But realize that the master carpenters of yesteryear installed crown molding without this fancy tool, much less a saw powered by electricity!”

For instance, don’t invest in a fairly expensive tool for one purpose unless it’s something you’ll be doing often.

For example, a finish carpenter would need the features a sliding compound miter saw provides, while a DIYer would need to assess how far they intend to take their woodworking. You’ll get more mileage out of a sliding miter saw as they are also capable of cutting out dadoes, rabbets, and lap joints with multiple passes and can handle material a regular compound just can’t. But they are more expensive, they are heavier, require more space to operate, and add another piece that can potentially break or wear out.

Sliding Compound Saw

A sliding compound miter saw is the best compound miter saw you can buy without a doubt. Yet, the best miter saw doesn’t mean it’s the best miter saw for you. Can you afford the upgrade to a sliding? How often do you think you will “need” the sliding feature?

These are important questions you must answer before making the investment in a sliding miter saw, or even just a regular compound miter saw. I use the analogy all the time, “why opt for the 4×4 version of a truck if you’ll never use it”?

Sure it’s nice to have 4×4 for the occasional off-roading or Winter snowstorm, but is it worth the additional investment? It wasn’t to me (still talking about trucks).

Now just apply the same logic to miter saws. We’ll be primarily discussing sliding miter saws. Because when we are talking about the “best,” we believe you need to be able to get the most out of that tool for it to be the “best.” Leaving out a major feature like the sliding capability is a major loss in usability.

10″ vs. 12″ Miter Saw

When it comes to what size of miter saw to select, you are essentially in the same boat with evaluating whether or not to purchase a sliding miter saw or regular miter saw. While a 10-inch will make the cuts for nearly any project the average homeowner will take on, a 12-inch will simply expand your capabilities. Tim Carter of askthebuilder.com loves his 12-inch compound miter saw, and explains why here:

“I own a sliding compound miter saw and must tell you it is a fantastic tool. But the reason I love it is that the combination of the 12-inch blade and the sliding function allows me to make precision crosscuts on material as wide as 14 inches.

I liken sliding compound miter saws to small portable radial arm saws. It can’t do everything a radial arm saw can do, but it sure comes in handy most of the time.”

A 12-inch sliding miter saw will be more expensive, to begin with, and 12-inch blades are harder to find and more expensive to replace when you inevitably need to.

They are also heavier and the blades often spin slower due to their increased circumference. A 10-inch sliding miter saw can crosscut material roughly 12 inches wide, while a 12-inch one can reach 14 (and in some cases 16) inches.

Additionally, some 12-inch miter saws will accept a 10-inch blade so you have the capability of getting the full 12-inches of cut capacity as needed. You won’t find a 10-inch saw that can accept a 12-inch blade.I personally prefer a 10-inch because of the price difference and based on my needs.

Purchasing a 10-inch miter saw with the sliding feature will cost you approximately the same as a 12-inch without the sliding feature. Anything beyond my saws capabilities I can make do with another saw like a circular saw or jigsaw.

Miter Saw Safety Focus

I know, most of you might gloss right over this part. Safety isn’t as fun and sexy as getting down to features and models, but it will only take one accident for you to become a safety fanatic.

A lot of this stuff is repetitive but the more you hear it the more these things become instinctive. The most important safety device on any saw is you, the operator, and the decisions you make. If you make safety a low priority, all the gadgets in the world won’t save you. As with any power tool, the safe operation needs to be priority #1.

Wear protective eyewear, make sure you have no loose articles of clothing or jewelry, and always inspect the material you intend to cut first for things such as nails, screws, staples, or anything else that might interfere. Hearing protection is also advised.

Any miter saw you seriously consider should include a blade guard and the blade guard needs to be transparent and easy to see through. If you can’t see through it easily, you just might decide to lift it out of the way to get a better look. At that point, the blade guard isn’t doing its job. It also goes without saying you should not remove this guard. It was put there for a reason.

An electric brake is a pretty standard safety feature on newer saws as well. This electric brake’s job is to bring the spinning blade to a stop as quickly as possible. Leaving the blade in the material after you’ve made your cut will not only help slow down the blade even faster, it’s safer and gives the best finish for a cut.

The Saw Guy – Saw Reviews and DIY Projects Copyright © 2020. Copyright © 2019 by The Saw Guy – Saw Reviews and DIY Projects. TheSawGuy.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Full affiliate disclaimer here

What Size Miter Saw Do I Need?

Does size matter? It’s a question often asked, and in woodworking, size does matter when it comes to your power tools. In particular, when it comes to miter saws, it’s the blade size that is the first consideration.

The right tool for the right job is one of our mottos at Obsessed Woodworking, as you know. In choosing a miter saw for your shop, the first consideration is the need: what kind of projects will you be pursuing? As Goldilocks learned, you want to make sure the miter saw you choose will be a good size for those projects:

- Too small, and the job doesn’t go well, like having to flip material or making more than one cut.

- Too large, and the cut capacity is wasted, along with some of the money you spent.

- Just right, and the job goes well, no cut capacity is wasted, no money spent poorly.

Types of Miter Saws

We’ve written in the past about miter saws, including this piece on single and dual bevel miter saws. We like miter saws here at Obsessed Woodworking and think every woodworking hobbyist should have one in their shop.

There are 3 main types of miter saws to choose from: standard, compound, and sliding. Each has its own qualities and strengths and brings something worthwhile to your shop.

Standard. A standard miter saw rotates to the side, allowing you to cut at your desired angle from top down. This makes it easy to cut corner pieces accurately – door frames, window frames, picture frames, for instance. The standard miter saw is sometimes referred to as a chop saw – – the cutting motion is down and through the workpiece, thus similar to “chopping” through.

Compound. A compound miter saw also bevels (tilts). This allows you to cut at angles both horizontally and vertically, something that comes in handy when cutting crown molding, for instance.

Compound saws come in single and double bevel models. Each works well, but with the dual bevel models, the workpiece does not need to be flipped. This makes cutting easier, more convenient, and less involved.

Sliding. A sliding miter saw does just that – the blade can be drawn toward you through the workpiece, not simply down through it. This extends the cutting width, allowing you to cut wider lumber.

Is a Sliding Miter Saw Better?

It depends on what projects you will likely be working on, as well as the size of your shop. Each plays a part in your choice.

Sliding miter saws allow you to make those wider cuts, but it does not increase the cutting depth. Their compact size, though, fits well in shops with limited space that otherwise could not accommodate a larger saw. The sliding depth, how far forward the blade can be drawn, determines the total width of the material you can cut.

If space is at a premium but you need the ability to cut wider materials, a sliding miter saw is a good choice. The blade size you choose will determine the depth of the cuts you will be able to make. So, type (standard, compound, sliding) and blade size are related, and the best choice will then be determined by the projects you will tackle.

Miter Saw Blade Sizes

Within these three types of miter saws, there are different blade sizes, too. Blade size refers to a blade’s diameter. The 3 most common sizes are 8-inch, 10-inch, and 12-inch, although there are some monster 15-inch blades for those who need the power and cutting capacity.

In addition to the blade’s diameter to consider, there is also the tooth count. The lower the tooth count, the coarser the cut will be, cutting a 2 x 4 or 1 x 6 deck lumber, for instance, where the cut does not need to be fine. The higher the tooth count, the finer the cut, something you would want for interior trim like baseboard, crown molding, window and door frames, picture frames, etc.

Miter Saw Motors

Most miter saws are corded. While a standard miter saw (sometimes called a chop saw, although a true chop saw blade is sealed to protect it from heat generated by cutting metals) might be a job site power tool, that job site most likely has a power source to plug in to. Even trim work in new construction takes place in a house that already has a power supply to plug into, so corded saws are common.

There are cordless miter saws, though, too. They will likely be more costly – yes, you pay for the convenience – but they often come with neat features like brushless direct drive motors and automatic speed controls. Again, though, you pay for the innovation.

Miter saws come with 10-, 12-, or 15-amp motors. If your projects will include the making of wide crosscuts or your materials will be hardwoods, you will want to consider a more powerful motor. If your projects will use your miter saw to cut thinner trim or composite materials, a less powerful motor will suit you well. Again, there is a cost difference, and you’ll pay more for a more powerful motor model.

All of the major power tool manufacturers offer all three types of miter saws – standard, compound, and sliding. They also offer different size models: 8-inch, 10-inch, and 12-inch, and all of them offer different motor sizes, too. These manufacturers include DeWALT, Milwaukee, and Festool. Hitachi even offers a 15-inch miter saw, a beast that comes with a 15-amp motor.

Miter Saw Tables

While you don’t necessarily need a miter saw table for your work, they do come in handy. You can use your miter saw on any table or flat surface and even build your own workstation for your miter saw.

A standard countertop is 36 inches, and if you’re comfortable in your kitchen with a 36-inch countertop, that’s a good height for your miter saw. You will want to be able to reach the saw handle, and line up the miter saw blade with the cut line you’ve marked without having to bend over or reach up.

Miter saw stands are commercially available at any of the big DIY stores. They are made for the purpose, often have wheels on one side of the stand for easy moving, and are both retractable, foldable, and adjustable for height.

If you want to really spend up, you can purchase a miter saw bench. But, if you are a creative and ambitious woodworker, you can also make your own. Here are a couple of videos to show you how:

mobile model

Each of them is pretty cool, and the videos are worth watching, as they look like fun projects. All you need for them is a miter saw (joke intended) and the usual project accompaniments of a drill, measuring tape, marking pencil, and such.

Best Miter Saw Size For Particular Tasks

We’ve already mentioned the right tool for the right job rule early in this piece. But, now that we’ve discussed miter saws a bit, you can see that miter saw decisions have several components to them: the type of saw, the size of the blade, the power of the motor, and the blade’s tooth count.

There is no single general rule to guide you in your miter saw choice. It depends. To illustrate this point, we’ll mention a couple of projects, and the right miter saw considerations for them.

Can The Miter Saw Cut a 4 x 4?

If you are going to be working with 4 x 4 stock, the choice of miter saw is important. While you can cut a 4 x 4 with a 10” miter saw (blade diameter), you will either have to adjust the blade guard (not recommended – it’s a guard, for your safety, and you shouldn’t mess with safety) or make two cuts by flipping the stock.

For a few cuts of 4 x 4 stock, the minor inconvenience of making two cuts by flipping the stock is nothing. Your 10” miter saw will be up to the task, as will you, as long as you line the blade accurately. Maybe it’s for planting in the ground to hang a bird feeder from in your garden or simply for guide posts. The 10” saw will serve you well.

A 12” miter saw (blade diameter), though, can make that cut at 90 degrees in a single pass. If you are going to be cutting a lot of 4 x 4 stock in your projects or your work, perhaps the 12” size is a better choice.

What Can You Do With a Miter Saw? Should You Get One? | WOODWORKING BASICS

Your budget and your likely projects will determine which to choose. But the short answer to the question is that yes, a miter saw can cut a 4 x 4, whether it’s a 10” or a 12” saw.

Can a Miter Saw Cut a 6 x 6?

The answer to this question is basically the same as the answer to the 4 x 4 question. A 10” miter saw can cut a 6 x 6 at 90-degrees, but not in a single pass. The piece will need to be rotated several times to cut from multiple sides in order to cut through a 6 x 6 completely. A sliding miter saw is the recommended type for this cutting to ensure each cut is lined up properly on the piece.

A 12” miter saw can cut your 6 x 6 at 90-degrees, also, but again not in a single pass. The same process of rotating the piece several times to cut from multiple sites will be necessary. Again, a sliding miter saw is the type to use so that you can line up each of the multiple cuts properly for a straight cut.

Here’s a video to show you what we mean about cutting a 6 x 6 with your miter saw. It’s short and to the point.

Can You Cut 5 ¼ Baseboard With Your Miter Saw

Tall baseboard material presents a unique problem when cutting for corner pieces because the miter saw motor can hit the top of the baseboard as the blade is drawn down to cut, or at least on one of the cuts. Let us explain.

As we have explained earlier, a compound miter saw can make bevel cuts. This tilts the blade to the desired angle. This becomes important for the second corner baseboard cuts and makes a compound miter saw the saw of choice for tall baseboard.

On the first cut for the corner pieces, you are making a 45-degree angle cut on one end of the workpiece, and the baseboard piece is upright. The motor does not interfere with the cut.

But for the second cut, another 45-degree cut but at the opposite angle, the motor will hit the tall baseboard and prevent the cut. The compound miter saw can make bevel cuts, though, and this is how the second cut will be made. This is so because the workpiece can be laid flat, and a 45-degree bevel cut on it will match with the first workpiece to complete the 90-degree angle of the corner.

Here’s a video that demonstrates this process.

Although the workpiece is only a 3 ½” colonial baseboard, the principal is the same as it would be for a 5 ¼” piece.

Is a 10” Miter Saw Big Enough?

For the woodworking hobbyist and the home DIY woodworker, a 10” miter saw is likely going to serve all of your needs. If your projects are simple framing jobs (doors, Windows, picture frames, boxes, and such), you will likely be working with smaller stock for which a 10” saw is well suited.

If your projects will stretch to include baseboard or crown molding, you’ll want to choose a compound miter saw. If your budget will stretch enough, make it a dual bevel compound saw.

And if you will occasionally be working with larger stock and need a wider cutting capability, and the budget allows, spend up for a sliding saw.

A 10” miter saw of any type will turn its blade faster than a 12” saw, and make a cleaner cut. A 10” saw will cost less, be lighter, and more easily moved when necessary. They are intended to be portable, after all.

How Much Does A Miter Saw Cost?

Woodworking 101: Mitre Saw For Beginners

A standard miter saw will start at around 100; a sliding miter saw will start at around 150, and a compound dual bevel miter saw will start at around 200. Higher level (for the pros) miter saws with lots of bells and whistles can run upwards of 800.

Brand, as well as sourcing (the large DIY stores, for example), come into play with miter saw prices, too. Single bevel vs. dual bevel will impact the cost, as well.

If you have decided to purchase a miter saw, shop wisely. Look for sales, check warranties, and read user reviews. Don’t be afraid to ask sales associates questions about a saw’s capabilities; we’ve given you a lot of information about the different types of miter saws, their sizes, and what each is well-suited for.

On a final note, here’s a video for the miter saw beginner, a Miter Saw 101 Basics.

We think, though, that once you have a miter saw in your woodworking shop, you’ll wonder how you ever got by without it.

Last update on 2023-05-25 / Affiliate links / Images from Amazon Product Advertising API

Matt Hagens

Matt is an experienced woodworker and a devoted family man. Matt’s passion for woodworking began at a young age when he would watch his grandfather in his woodworking shop. He has spent over 20 years honing his skills, learning new techniques, and perfecting his designs. When he’s not in his workshop, Matt loves spending time with his family.