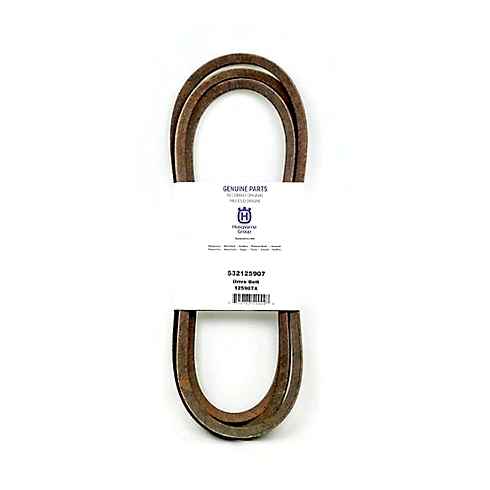

Husqvarna mower drive belt. Craftsman Parts for Outdoor Power Equipment

CRAFTSMAN

Find the CRAFTSMAN original equipment parts and accessories you need to keep your lawn mower, snow blower and other outdoor power equipment performing strong. These parts and accessories are designed and engineered to exact standards to provide reliability and optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment parts and accessories.

Can’t find your part? Customer Service can help. 1-855-971-2271 Monday. Friday, 8:30 am. 5:00 pm EST CHAT WITH US

FIND PARTS BY DIAGRAM

Find the original equipment parts and accessories for your CRAFTSMAN outdoor power equipment on our Parts Diagrams. The Parts Diagram helps visualize components found on your equipment. If you can’t find what you’re looking for or need assistance installing the new part, call 1-855-971-2271.

FIND PARTS BY MACHINE TYPE

CRAFTSMAN original equipment parts can help you maintain your CRAFTSMAN outdoor power equipment long-term. Find parts by machine type: Riding Lawn Mower, Walk Behind Lawn Mower, Garden Tiller and Snow Blower to repair your machine.

Help keep your CRAFTSMAN riding lawn mower running strong year after year with original equipment parts. SHOP PARTS

Find the parts you need to keep your CRAFTSMAN push mower operating in peak condition. SHOP PARTS

Whether you’re cultivating your entire lawn or just a small garden, find the CRAFTSMAN garden tiller parts you’ll need to get the job done. SHOP PARTS

Avoid waking up to that fresh snowfall with a snow blower that doesn’t work! Regular maintenance and replacement of your CRAFTSMAN snow blower parts will keep you ready all winter long. SHOP PARTS

FIND PARTS BY PART TYPE

Find parts by part type: Blades, Belts, Tires and Wheels, Engine Parts, Cables, Attachments and Accessories, Pulleys and Spindles.

When you need blades to deliver a clean cut and a healthier-looking lawn, look no further than CRAFTSMAN original equipment blades. CRAFTSMAN blades are designed to provide a precise fit with every blade change. Heat dipped for durability and flexibility, these blades have been tested for thousands of hours to meet equipment standards. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment blades. SHOP PARTS

CRAFTSMAN original equipment belts are manufactured to equipment specifications so you can attain a precise fit with every belt change. These belts have been designed to combat conditions. Made with durable, high strength materials, they’re designed to be flexible enough to withstand continuous bending around pulleys. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment belts. SHOP PARTS

CRAFTSMAN original equipment engine parts are specifically designed for your outdoor power equipment’s engine. Shop air filters, oil filters, fuel filters, spark plugs and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment engine parts. SHOP PARTS

How to Replace the Ground Drive / Transaxle Belt on a Craftsman YT4500 Lawn Tractor

When it’s time to replace the cable in your CRAFTSMAN outdoor power equipment, you’ll find the exact part you need. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment cables. SHOP PARTS

A properly working pulley helps your machine perform with maximum power. You can find the exact part you need when it’s time to replace a pulley on your CRAFTSMAN riding lawn mower or snow blower. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment pulleys. SHOP PARTS

A proper-fitting tire will help your CRAFTSMAN riding mower, walk-behind mower and snow blower to have a smooth and sturdy ride. Replace tires and wheels as they wear to help make sure your CRAFTSMAN outdoor power equipment runs at optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment tires and wheels. SHOP PARTS

Find the spindle assembly parts you need to help maintain your CRAFTSMAN lawn mower’s performance so your lawn looks pristine. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment spindles. SHOP PARTS

Do more with your CRAFTSMAN outdoor power equipment with a wide variety of attachments and accessories including baggers, mulch kits, sun shades and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment attachments and accessories. SHOP PARTS

SUPPORT RESOURCES

Enter the product code shown on the product serial number. Then select your language, click “Search,” and download your manual. FIND OPERATOR’S MANUALS

With our easy-to-use online Service Locator, you will get information on your current location and closest service locations, as well as their contact information and driving directions. You can choose to view the service points either conveniently on a map, or a list. FIND SERVICE LOCATIONS

Replace Drive Belt Husqvarna Yard Tractor

Have your CRAFTSMAN equipment registered Online now. If you don’t know your model and product serial number, call 1-855-971-2271 and we will be glad to assist you. REGISTER YOUR PRODUCT

How to adjust belt tension on a Husqvarna riding lawnmower, step by step

One of the core components of a Husqvarna riding lawnmower is the drive belt. The mower blades are driven by a drive belt that connects them with the engine crankshaft pulley. This belt is also called a blade belt. If the belt malfunctions, the lawnmower won’t move. If the belt is worn out, the lawnmower moves slowly because the belt slips on the pulley. If the belt is loose, it will keep your blades from rotating. All these issues require knowing how to adjust the belt. This article will help to adjust the belt tension with a step-by-step approach.

How to adjust belt tension on a Husqvarna lawnmower, step by step:

- Step 1. Park your lawnmower in a flat location

- Step 2. Disconnect the spark plug

- Step 3. Turn the log lever

- Step 4. Inspection of blade belt

- Step 5. Adjustment of the drive belt

- Step 6. Check the blades

How would you know that your belt needs adjustment or not? There’s a long belt that goes from your blading engagement by your steering wheel down to your mowing deck. That belt stretches over time. This causes the belt to slip. If you feel this, then the belt needs adjustment. If you have a Husqvarna riding mower and don’t know how to tighten the drive belt, don’t panic. This blog explains how to adjust the belt tension on a Husqvarna riding lawnmower. IT will give you an insight into the tools you need, the technicalities you should know, and the precautions you should take.

Step-by-step Guide:

Adjusting the belt tension itself is a relatively simple process. However, opening the mower base and exposing the system can be technical and somewhat complex for newbies. Here the easy-to-follow steps will help you with performing the job at home.

Step 1: Park your mower in a flat location

Place the lawnmower on an even, smooth, and plane location. This helps to get easy access to the underside of your mower. Please do not tilt the Husqvarna lawnmower on its side, as oil can run from the reservoir to the engine’s wrong parts. Use the parking brake to keep it from moving. If you have a lawnmower lift, you can use it to raise the mower so that approaching the base becomes easier.

Tip: Let your Husqvarna mower run in a well-ventilated area for a few minutes before starting. This will warm up the engine and oil. If the belt and pulleys run for a while, they will become easier to move by hand. This will make the task somewhat easier.

Step 2: Disconnect the spark plug

As a safety step, it is good to disconnect the spark plug. That will ensure that the engine does not unintentionally start. You will find the spark plug on one side of the combustion chamber; unplug it. Some people ask if there’s a need to remove the Husqvarna mower’s cutting deck while adjusting your mower or blade belt. It both has advantages and disadvantages. In some types, removing it will make your approach to the belt components easier. For other types, just lowering the mower deck to its lowest position will give you enough room.

Step 3: Turn the log lever.

The log lever serves a single purpose of engaging or disengaging the Husqvarna mower blades. Locate the log lever that is extending from the top of the control panel nearby the steering wheel. It turns at a 90-degree angle as it comes out of the control panel and extends to the right. On the end of the lever, there is a paddle handle. Rotate the log lever by holding the paddle handle away from forward away from you to engage the blades. While operating, if you notice a 2-3 seconds delay instead of a 0.5 seconds delay, the belt is loose. Now, pull the lever back to engage the blades.

Step 4: Inspection of blade belt.

Next, you need to locate the Husqvarna blade belt. You can find it across the belt and pulley system underneath the deck. You can approach it from the mower’s base along with the blades, so you must have your mower on a raised platform. Before adjusting, you must look at your belt and make sure that there are no cracks. Suppose you see some cracks and chunks at this time. It would become critical to replace the belt. Next, you must inspect that your spring arm is working correctly. Make sure that it moves back and forth correctly.

Underneath the deck, check by hand that the spring attached to that spring arm is a bit slack, and the belt is easily stretched by hand. Also, check the sag of the belt as it passes over pulleys. If it is sagging below, it needs tightening. If it feels too tight, you need to loosen it. This will give you a complete analysis that which components must be tightened. over, there is a cable that originates from the blade engagement level all the way down to the mower deck connecting the spring arm. It gets extended over time, so the belt gets loose.

Step 5: Adjustment of mower or blade belt.

Now we can start with the adjustment. At the point where the cables come down and attach to the pulleys, there’s a small bracket from where the cable is adjusted. This is the same point where the cable from the blade engagement lever is connected to the spring arm. As the deck and blades are disengaged, everything beneath the deck is in a slack position. The same screws you need to tighten are the screws over the spring arms. Now take an adjustable wrench and unbolt the screws and washers, push the bracket away from the spring, put the bolts back in position, and tighten them up by wrench. You need to set a proper distance between the bracket and spring to tighten or loosen it.

In the case of Husqvarna, you need a 10 mm wrench for the bracket bolting and unbolting. When you are done with adjusting the belt, push the log lever away from the steering wheel to engage the mower deck and blades and check whether the spring is further stretched by hand or not. In an ideal position, it should be tight without any stretching caused by the hand. The belt has been adjusted. Also, you can always grease the belt while operating. Run it by hand to give it a few cycles. This will help lubricate the pulleys too. In the end, tighten any loose connections the pulley might have. Check all springs if they are free to move.

Step 6: Double-check the Blades.

You need to check if the belt and pulley system is working. Use a pair of heavy safety gloves, twist the mower blades and check if the belt moves over pulleys without lagging or sagging. Reconnect the spark plug, and start the Husqvarna engine. Now you can see if the belt and pulleys are driven correctly. If they are, your blades should be continually moving and instantly startup without any delay.

Note: If you want to loosen the drive belt, you need to push the log lever away from the steering wheel, and you have to pull in the spring arms. You’ll be doing the opposite of what you did for tightening the belt.

Additional safety concerns:

We all are aware that blades can be very unsafe to operate without taking preventive measures. Also, when you are adjusting your drive belt, there are some safety tips that you should take into account.

Always Check the Manual

Always read the Husqvarna manual! Ensure that you know every detail about the drive belt. The manual will give you all the basic details you need. Ensure that the belt you use is specifically made for your model. over, match the numbers on the blade belt with the mower manual. Even a slightly higher or lower number can cause the belt to be too tight or loose. This also reduces the mower’s life.

Double Check the Blades

You should always double-check the blades to see if they’re moving correctly without whirring when you move the lever. This is to make sure that the blades will not start cutting up everything. So, when you move the lever, check the blades’ movement. Also, check them when closing the compartments. If the blades are suck, your belt will immediately break up as you try to start up the mower.

Frequently asked questions:

Why does my belt keep slipping off my lawnmower?

The drive belt may come over a riding mower pulley if it is too loose. This is the reason for its slipping too. As the belt is made from fairly flexible rubber to add heat resistance and flexibility. Over time, the belt gets worn out that elongates the belt. Also, the pulleys are supposed to be adjusted at a fixed distance. Over long-term operation, the distance between them may reduce due to the belt stretch and bolts’ loosening. Both these are the causes of a loose belt.

When should I replace my mower belt?

At first, there is no definite amount of time that a mower belt is supposed to last, but most of the mowers have short intervals, after which a belt requires adjustment. Typically, you should adjust the belt once in a while and replace it every two seasons. If you do hectic mowing in one season, you should replace it. This will help protect other critical internal components.

Does a lawnmower drive belt stretch?

Yes, a Lawnmower belt will stretch because of wear and tear after longer use. The mower blades rotate with high RPMs, so the belt itself rotates very quickly as well. Unlike the drive belt of cars, mower drive belts are less sturdy. It means that over time the belt gets loosened over repeated cycles of heating, cooling, and fast turning.

Final remarks:

A loose drive belt can be the reason for your Husqvarna lawnmower to slow down unexpectedly. Over time the belt will stretch. This will reduce the belt tension and can cause several problems. To keep your Husqvarna lawnmower operating properly, the belt adjustment is something you will come across from time to time. This article gives you an easy to follow guideline to adjust the drive belt on your Husqvarna lawnmower.

How to Change Drive Belt on a Husqvarna Lawnmower, step by step

Husqvarna lawnmowers have been around for quite some time and are one of the more popular brands. If you find that your Husqvarna lawnmower is running sluggish and does not cut the grass like it used to do, there may be a problem with the belt. It may also mean that the mower belt is an issue if your Husqvarna Lawnmower engine is running, but the mower blades are not turning at all. With a step-by-step solution, this blog helps troubleshoot your problem and fix the Husqvarna belt.

How to Change Drive Belt on a Husqvarna Lawnmower, step by step:

- Step 1: Determine whether you have a rear-wheel drive or front-wheel drive mower.

- Step 2: Before you tip the mower to its side, empty the gas tank and remove the spark plug cable.

- Step 3: Place the mower upside down. Now, the components are unscrewed to make the belt accessible, such as the baffles, brackets, and mower blade.

- Step 4: Remove the pulley’s belt and replace it with a new, identical belt of the same model.

- Step 5: Connect the removed components back onto the mower, and test it with the new drive belt.

Drive belts are situated underneath the mower. Their job is to pass power out of the engine-transmission to the lawnmower blades. Attached to the blades is an axle that also includes a pulley. The drive belt passes above the pulley. In lawnmowers, Drive belts are commonly composed of Fiberglass and steel-reinforced rubber. They get worn out quite rapidly due to continued rough operation.

Please stay tuned to this post as we explain all the above steps and videos showing a hands-on demonstration of the processes.

- 1 Steps by step procedure for changing Husqvarna mower drive belt:

- 1.1 Rear-wheel drive lawnmower:

- 1.1.1 – Step 1: Make preparations for belt change:

- 1.1.2 – Step 2: Detach the following parts:

- 1.1.3.Step 3: Removal of the old belt:

- 1.1.4 – Step 4: Assembly of removed parts:

- 1.2.1 – Step 1: Setting up the mower:

- 1.2.2 – Step 2: Remove the components

- 1.2.3 – Step 3: Replacing the damaged belt

- 1.2.4 – Step 4: Reassembly

- 2.1 1. Why does my drive belt keep slipping off from the lawnmower?

- 2.1.1 – Defective Components:

- 2.1.2.Debris Buildup:

Steps by step procedure for changing Husqvarna mower drive belt:

Husqvarna lawnmowers have two key categories when it comes to driving belts. That is front-wheel drive mowers where a belt powers the drive of the front wheels alongside the blades and rear-wheel-drive lawnmowers in which the belt drives the rear wheels of the lawnmower. We have listed the method for each of these categories below:

Rear-wheel drive lawnmower:

Here are the steps for the rear wheel belt drive change:

– Step 1: Make preparations for belt change:

Before you change the drive belt, prepare the surface by placing some plastic sheets or cardboard. The lawnmower has to be positioned upside down on that surface. This step is done to prevent oil spills from spoiling the floor. It is often easier to empty the fuel tank before tilting the mower. Now, incline the lawnmower so that the air filter points upward. This position stops gasoline from pouring into the oil. To prevent the engine from starting accidentally, ensure that the spark plug wire is disengaged.

– Step 2: Detach the following parts:

Belt cover and baffle: You should remove the belt’s cover and baffle for most mower models. When tilting the lawnmowers, turn the screws that support the baffle and belt cover using a socket wrench.

Mower Blades: The belt is placed under the blades on the same shaft. Hence, if you unscrewed the nut that secures the engine blades to meet the belt pulley, it would help. Now, gently dislodge the blades while ensuring that you use gloves while handling them.

Traction spring: Afterwards, you have to detach the traction cable spring with a pair of nose pliers on the rear axle. Now, the transmission bracket can rotate freely.

Belt Guide: There is a belt guide that protects the pulley, and it is mounted on the transmission. You should turn the bolts and dislodge the guide so that the pulley is visible.

-Step 3: Removal of the old belt:

Next, detach the belt from the pulley when it is visible. You should make sure that you have purchased the right kind of belt for your model by going through the owner’s manual.

– Step 4: Assembly of removed parts:

Fix the new belt to the transmission’s pulley. At the same time, wind the other end of the belt onto the pulley below the blade. Place the belt guide back on the transmission bracket and secure the screws. Then, attach the traction cable’s spring back to its original position. Ensure the replacement and assembly of everything you have removed, such as the mower blades, belt cover, and baffle. With the latest belt-mounted now, it might be a good idea to take your mower for a test drive.

Front-wheel drive lawnmower:

The procedure for changing the front-wheel of the belt is much the same as above. Below, for the sake of detail, we shall build on it.

– Step 1: Setting up the mower:

This stage, as mentioned above, is quite the same. Just ensure that the lawnmower is oriented with the air filter pointing up and the spark plug wire disengaged. If you are using an electric lawnmower, you should remove the key from the switch.

– Step 2: Remove the components

Next, parts need to be removed, such as the belt cover and baffle, mower blades, traction spring, and belt guide. You should know that different models have different components, so you should detach them one by one to access the belt drive.

It is also better to take photos of the parts before removal and replacement so that it is easy to know which portion goes where before reassembling them.

– Step 3: Replacing the damaged belt

Replace the old belt with a newly acquired drive belt for your Husqvarna lawnmower model.

– Step 4: Reassembly

Fit all of the removed pieces back into their original places and fix the bolts tightly. Now, turn the lawnmower upside down and take it out for a run. It is appropriate to analyze a renewed belt drive’s performance on the mower’s speed and the cutting quality.

Related Questions:

Why does my drive belt keep slipping off from the lawnmower?

The drive belt may come off your riding lawnmower for various reasons. The necessary interpretation can depend on the make and model of the mower. Before you decide what went wrong, and attempt to fix the problem, perform a safety inspection. Wear gloves and goggles after the engine cools, separate the wire or cables from the spark plug, and ground the wire or cables against the engine. When you are operating, the engine does not operate by accident.

– Defective Components:

Many other mower components repeatedly allow the drive belt to come off. If they are not in working order, drive pulleys and idler pulleys hamper regular belt operation. Without restriction, the movable arm should swing freely, and the blade spindles should also freely move. Test the rake or pitch of the mower. Slightly forward, a correctly adjusted mower deck tilts, making it 1/8 to 1/4 inch lower in front than in the back. And the belt comes off if the angle is too high.

-Debris Buildup:

In a riding mower, an accumulation of debris may interfere with normal belt function. Ensure that no grass, dirt, sticks, saplings, or other sludge is found along the drive belt anywhere. Not only can debris cause the belt to slip or work poorly, but it can also present a fire danger. Clean all of the debris thoroughly, using a firm brush to rub the belt.

What is a belt-drive in a lawnmower?

A drive belt is a mechanical instrument that links the engine and the transmission shaft and transfers power from the lawnmower’s engine. Thus, the mower functions are carried out, including advancing the unit forward and spinning its blades.

In lawnmowers, the drive belt primarily links the transmission shaft to the engine shaft. The transmission shaft is then used to drive the lawnmower’s wheels either forward or backward. In most situations, the blades are also connected to the transmission shaft. The drive belt then performs its functions in such a way by both rotating the blades and propelling the mower forward.

What are the main types of drive belts based on design?

V-belts and synchronous belts are the two commonly used design types in transmission applications. The two belts are different from one another depending on the tooth shape and application.

In V-belts, to create the cross-section, a wedge-shaped profile is used. They use friction to create a tight grip on the pulley. Synchronous belts give a toothed or notched profile on the belt. Sometimes referred to as timely belts, they are typically mounted on a pinion or toothed gear.

All kinds of belts are lined with a tensile cord material that carries the load or is identified as the belt’s muscle. Materials including polyester, polyurethane, Fiberglass, steel, or Kevlar are widely used as tensile cord materials in drive belts because of their high stiffness.

Is Kevlar useful for drive belt applications?

Kevlar-reinforced belts have better shock and impact resistance as opposed to steel. Furthermore, Kevlar has a high elastic modulus, suggesting that its percentage of elongation is lower than that of other materials at a given load. However, belts with Kevlar tensile belts are usually expensive.

Final Remarks:

The belt drive is among the essential transmission mechanisms. Therefore, one must know the setup to carry out the belt’s ultimate replacement without further issues. The lawnmower is subjected to dusty environments, and constant usage deteriorates the belt’s output overtime in harsh circumstances. If you have all the mechanical instruments and expertise at your disposal, removing the belt is not challenging. Before the belt is visible, the screws and brackets under your mower need to be dismantled. Also, make sure you follow the safety procedures and don’t start your machine accidentally.

The Best Self-Propelled Lawn Mowers in 2023 for Making Your Yard Work Easier

These lawn mowers drive themselves, taking the load off you in the process.

By Roy Berendsohn Published: Mar 21, 2023

One of the perks of the warm-weather season is getting to spend time outside. If you own your own home and have a yard, it’s very likely that in order to enjoy your outdoor space, you need to mow the lawn. The larger the yard, the more work it will be to maintain. If you have a lot of grass to cut, you’d be wise to consider a self-propelled lawn mower especially now that there are a ton of sales just in time for Memorial Day.

The primary difference between a standard push mower and a self-propelled mower is that the former moves when you push it, and the latter essentially moves itself with only your guidance. Once the engine is running, all you have to do is squeeze a handle or push a lever and the mower will start moving forward with you as you walk.

Turning the mower around is your job, but once you have your heading, just keep the drive handle squeezed and escort the mower down the path, no pushing necessary.

Self-propelled law mowers take power off the engine and route it via a belt to a pulley on the transmission and axle. When you move the drive control lever on the mower handle, you tension the belt, causing the pulley to turn, and this drives the transmission, moving the mower forward.

Move the drive control lever back and the tension is released, the pulley stops turning, and the mower stops moving forward. The belt-driven transmission is a time-tested design to power the mower and take the load off you in the process.

What to Consider

A mower is like many consumer products in that the more features a manufacturer adds, the more expensive it becomes. But a longer or more eye-catching list of features isn’t necessarily better. Sometimes less is more. Here are the most important to keep in mind.

Front-wheel drive mowers tend to be less expensive than rear-wheel drive units. They can be easier to turn because you don’t have to disengage the drive wheels to do so. Simply push down on the handlebar to raise the front wheels off the ground. However, their traction isn’t as strong on hills or when the bag is full, as there isn’t as much weight over the drive wheels.

Rear-wheel drive mowers do cost more and aren’t as easy to turn, as you do need to disengage the drive—but this isn’t too much of a hassle. Rear-wheel drive mowers shine on hills and inclines, and when the grass bag is full. In either scenario, weight is shifted rearward and over the drive wheels, which enables superior traction, thus making the self-propel more effective.

An engine as small as 125 cc can power a mower, but most are somewhere in the 140 cc to 190 cc range. A large engine helps when powering through tall, lush grass or in extreme conditions, such as with a side discharge chute in place and mowing tall weeds in a border area. Also, the extra torque provided by a larger engine can improve bagging when the going gets tough (tall, leaf-covered grass in the fall). But if you mow sensibly and pay attention to deck height—and especially if you don’t let your lawn get out of control—an engine between 140 and 160 cc has more than enough power to get the job done.

A mower can have all four wheels the same diameter (7 to 8 inches), or it may have rear wheels that range from 9.5 inches to 12 inches in diameter. Larger rear wheels help the mower roll more easily over bumpy ground.

With some mowers you can start the engine with the twist of a key or the press of a button. It’s a great option, but a luxury. Keep the mower engine tuned and use fresh fuel with stabilizer added to it, and you’ll never have trouble starting.

Any number of mechanisms can control a mower’s ground speed—a squeeze handle, a drive bar that you press forward, even a dial. There’s no single right answer here. Look at the design and think about how you like to work. For example, if more than one person will be using the mower (and not all of them are right-handed), a drive control like that on a Toro Personal Pace mower might be the answer. Just push down on the bar to make it go faster. Let up on the bar to slow down.

A mower that can bag, mulch, and side discharge is known as a three-function mower, the most versatile kind. Two-function mowers bag and mulch or mulch and side discharge.

Mowers will typically have one, two, or four levers to control the deck height. Single-lever adjustment is the easiest to use, but it requires more linkage, which adds weight and complexity. If, for some reason, you find yourself varying deck height frequently, it’s a good option. Otherwise, two or four levers work just fine.

Only Honda makes a gas-engine mower with a high-impact plastic deck (there are battery mowers that have plastic decks). Otherwise, mowers generally have a steel deck, and a few manufacturers—Toro, for one—offer a corrosion-resistant aluminum deck. An aluminum deck won’t rot the way a steel deck will, but you still need to keep it clean.

This is a hose fitting mounted on top of the mower’s deck. When you’re done mowing, hook up a hose and run the mower to power wash the underside of the deck. We’ve had mixed results with these, but they’re better than just letting a mass of dried grass clippings accumulate.

expensive mowers come with a more durable bag with more dust-blocking capability. If you bag a lot, especially leaves or other lawn debris in the fall, then you need a mower with a higher quality dust-blocking bag. Having said that, if you rarely bag, the standard one that comes with a mower will last you the life of the mower.

Also called wide-area mowers, machines in this subgroup help homeowners better reconcile their need for more power and speed with the fact that they may not have enough storage for a tractor or zero-turn mower. A typical residential walk mower has a single-blade deck that cuts a swath from 20 to 22 inches wide. Wide-cut mowers (built for homeowner use) have either a single blade or, more typically, a pair of blades, cutting from 26 to 30 inches with each pass. Some of these are rated for light commercial use and have larger decks, in the 32-inch range, and engines that start at 223 cc and go up to about 337 cc.

Wide-cut mowers typically employ gear or hydrostatic drive transmissions, and they have top speeds of about 4 to 6 miles per hour. At their fastest, they move so quickly you have to trot to keep up with them. Needless to say, they’re overkill for small yards; only opt for one of these if you’ve got a significant plot of land that you need to keep tidy, but not one so large that you’d be better off going with a full-on riding mower.

How We Tested and Selected

We compiled this list based on Popular Mechanics mower testing and our knowledge of the lawn mower market at large. For our testing, we put mowers through the paces using our standard Popular Mechanics methodology: We cut turf grasses such as fescues and blue grass and rougher non-turf grasses like Timothy, clover, orchard grass, and wild oats, all in both normal and shin-deep heights. We mow uphill, downhill, and across the faces of hills. The maximum slope we cut is about 30 degrees.

That may not sound like much, but it’s about all you can do to stand on it, let alone push a mower up it or across it. We mow damp and wet grass to test general cutting performance and whether clippings accumulate on the tires. And we cut dry and dusty surfaces to see how well the bag filters under less-than-optimal conditions.

Honda HRN 216VKA

Key Specs

Honda mowers enjoy a sterling reputation. Having tested their walk and self-propelled mowers for the last 30 years, we feel confident that Honda’s entry level mower is a great choice for homeowners looking for power and durability. The HRN features a GCV 170 gas engine that’s built to withstand long hours of operation.

If you do your own maintenance (and most owners who buy this class of product do), you’ll appreciate the easily accessible spark plug and the fuel shutoff valve that enables better winter storage. Close the fuel shutoff and run the mower until it sputters to a halt. This will clear the carburetor of any gasoline, which will prevent the ethanol in it from disintegrating and causing running issues later on. Open the shutoff valve in the spring, add some fresh gasoline, and the mower should start easily.

All this maintenance stuff is great, but we can also tell you that our past test findings on other Hondas prove that their cut quality is outstanding for cleanliness. Sharp blades deliver a velvet-like finish. And their bagging ability is also quite good, in the same league with other well-bagging mowers from Toro.

In all, if you take mowing seriously, you should enjoy this Honda. If you have a little wiggle room in your budget, consider the Honda HRX, which features a mower powerful engine and a composite deck that won’t rust and is renowned for its durability.

One note is that Honda has announced that it will cease selling lawn mowers in the United States after this year—so if you’re considering buying one, best do it sooner rather than later.

Toro Recycler 60-Volt Max Lithium-Ion

Key Specs

Toro mowers have garnered more recommendations from us than any other brand for two reasons: build quality and cut quality. These were amply demonstrated in our testing as the Recycler turned in the best ratio of cut area per amp-hour of battery in the self-propelled category, while at the same time not skimping on cutting, mulching, or bagging quality.

We attribute this outstanding mower performance to three features, all upgrades to the previous version of this machine. First, the air vent at the front of the mower deck seems to improve mulching and bagging performance. Toro calls it Vortex technology, a design that increases air flow under the deck. This helps to stand the grass for a cleaner cut, which improves mulching performance, and also allows better airflow into the bag when collecting the clippings.

Next, the company’s redesigned “Atomic” blade configuration appears to assist the air flow and clipping movement. Finally, the three-phase, 60-volt motor is exceptionally efficient, resulting in a large cut area for a single battery.

Toro has maintained features that make this mower work: rear wheel drive, a one-piece deck that’s all steel (no plastic nose), 11-inch wheels to help it roll over roots and crevices, and the same fold-forward handle that was an industry breakthrough when it was introduced some years ago.

Ryobi 40-Volt Brushless Self-Propelled Mower

Key Specs

This is one of Ryobi’s top-of-the-line mowers, and it’s American-made construction is something we wish we saw more of. It delivers a tremendous cut area with its two 6-Ah batteries providing a total of 12-Ah of capacity, and its X-shaped blade leaves a pristine surface in its wake.

Ryobi estimates the design should provide 70 minutes of run time; we didn’t time our cut, but it strikes as plausible. Its rear-wheel drive and reasonably aggressive tire tread pattern provide good hill climbing and sidehill cutting performance, and its bagging on all surfaces (level, sidehill, and uphill) is also commendable.

Other ease-of-use features include an easily installed or removed bag that mounts and dismounts straight up and down through the handle; deck adjustment is quick and easy thanks to a single-level deck height adjustment. The straight edge deck is polypropylene; it will never rust and needs very little care other than basic cleaning.

Toro TimeMaster 30 in. Briggs Stratton Personal Pace

The Toro Timemaster 30-in. mower has been around for several years and has earned a reputation as a sturdy workhorse for homeowners who want to cut down on their mowing time. It’s also used by some professionals as well. A few years ago the Timemaster got a slightly more powerful Briggs and Stratton gas engine, so it should have no issues powering through most demanding mowing jobs.

The Timemaster is rear-wheel drive and features Toro’s Personal Pace drive system that’s used on many of its self-propelled mowers. This allows the mower to move at your speed by simply pushing down or releasing the handle, which is spring-tensioned.

With a 30-in. deck, Toro claims the Timemaster will help you reduce your mowing time by about 40% compared to using a standard-sized mower. You can mulch, back, or side discharge with the Timemaster, and the handlebar can be locked in a fully vertical position to reduce space consumption in storage.

If you have half an acre to a full acre of lawn to mow and prefer the experience of a walk-behind mower versus a tractor or zero-turn, the Timemaster is worth a look.

Craftsman M220

Key Specs

Craftsman mowers have been doing very well in our tests, so we can recommend this one because it’s so much like the many other of the brand’s models that we’ve tested. If you’re looking for a good blend of maneuverability and power, you’ll get it with this mower. Its front drive helps move it along and makes it easy to turn.

It’s important to note that front-drive mowers do lose some traction when running uphill, particularly with a full grass bag. But if your slope is less than 20 degrees, and you’re not bagging uphill, you’ll be fine. The side discharge will also help you handle tall grass. Adjust the two deck levers to bring the mower up to full height and have at the rough stuff.

The fact that this mower bags, mulches, and side discharges is a plus, enabling you to handle a wide range of mowing conditions, from early spring and late into the fall. Three-function mowers like this are our preference for that versatility.

Toro Super Recycler Self-Propelled Lawn Mower

Key Specs

This is a beauty of a mower, with a cast-aluminum deck and a smooth-running Briggs Stratton 163-cc engine. We tested the Honda engine-equipped version, and it was effective at both bagging and mulching, even in moist grass.

Equipped with rear-wheel drive and the Personal Pace system (the farther you push the drive bar, the faster the mower goes), it’s an effective hill climber and moderately effective on sidehill cutting. It has relatively small 7.5-inch tires on all four corners, which causes this Toro to bump up and down a bit on washboard surfaces. But the good news is that it’s equipped with a far higher quality tire than we’re used to seeing these days. We didn’t notice them pick up any grass on moist surfaces.

Other features we like include its forward-fold handle that has a built-in shock absorber that Toro calls a Flex Handle Suspension, and a high-quality grass bag that loads through the handle, from the top.

QA

Are there special maintenance considerations with self-propelled mowers?

Yes. Both front- and rear-wheel drive mowers typically feature a drive belt, which can crack or wear out over time. Fortunately these belts are not difficult or particularly expensive to replace.

Secondly, you may have to replace the drive wheels occasionally. These wheels are driven with gears. there are typically teeth on the inside diameter of the drive wheel that line up with a gear on the axle. These teeth can wear out, especially if they are made of plastic. Higher-end mowers may feature drive wheels with a metal gear that meets the metal axle gear, which improves longevity of these components.

My lawnmower says I don’t ever have to change the oil, but just add oil when needed. Is this OK?

It’s not a good idea to never change the oil in your lawn mower. In a lawn mower, same as a car, oil degrades over time and is less effective at reducing heat and friction in metal components. Changing the oil in your lawn mower is easy to do and will significantly increase its service life. For most homeowners, changing the oil at the beginning or end of each mowing season should be sufficient, though there is certainly no harm in doing it more often.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.