Is It Possible To Cut Tiles With An Angle Grinder

Is it possible to cut tiles with an angle grinder, how safe is it?

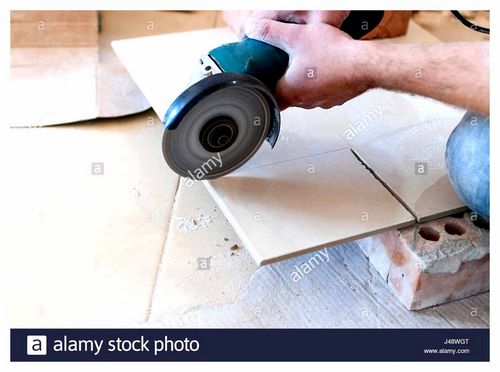

And if you transform the grinder into a tile cutter. But more on that later, but now let’s touch on the safety of working with artificial ceramic cladding. When the question arises whether it is possible to cut tiles with an angle grinder, experienced specialists give an unequivocal answer to it that this process is not much different from the same slitting of concrete walls. Another thing is that the tiles can fly apart at a high rotation speed of the disk. But if you bought not the cheapest power tool, then you may know about such a grinder function as speed adjustment.

By reducing the speed, it is possible to ensure that the tile does not fold back with the cutting wheel. In any case, you should work with a special protective shield on your face, and hold the tool so that the angle grinder is able to cut tiles while rotating the diamond wheel away from you. Never try to cut tile or porcelain stoneware with a metal disc.

How to cut an angle grinder ceramic tiles extremely efficiently?

The area of the surface to be finished can not always be tiled with perfect precision; sometimes you have to think about how to cut a ceramic tile with an angle grinder. Of course, if you have a special electromechanical or manual unit, you can’t imagine better, and a regular glass cutter will take a thin tile, but an angle grinder will help out great.

Finding out how to cut ceramic tiles with an angle grinder

So that there are no areas left uncovered with cladding, sometimes it is necessary to use separate fragments of a tile or porcelain stoneware coating. However, if you chop the tiles at random, the overexpenditure will be significant, and the result will be deplorable. Therefore, if you have a special tile cutter, take an angle grinder and figure out how to cut an angle grinder into ceramic tiles. Definitely, we need the same nozzle as for artificial stone, which means that when purchasing, and if available, we immediately put on a diamond wheel for dry cutting.

One should not expect a high quality of the saw cut, without proper fixation of the tool, the diamond disc for an angle grinder will slide on the tile, taking a high speed of its rotation, count on a large error. However, when the first cut is marked, things will go more fun. Even if you lose a few tiles, then you will definitely start to get tile cutting with an angle grinder, you may not even need training. But, on occasion, still buy a mechanism for cutting tiles, and it is better to consider an angle grinder as a tool for rough cutting.

How to cut tiles correctly angle grinder: mastering the tricks

It is easiest to cut cement paving slabs with an angle grinder, however, any other relatively easily succumb to a diamond wheel, if your hand does NOT accidentally tremble. An angle grinder can tell you a lot about how to cut tiles, but if there is no firmness in your hands, or you may be let down by the eye while cutting, it is better to set the angle grinder on a fixed base and manipulate the tiles. You may have several ways to make a tile cutter from an angle grinder.

Firstly, you can fasten the angle grinder with clamps to the leg of the workbench vertically, with the disc facing up, so that the gearbox of the power tool does NOT reach the edge of the worktop a couple of millimeters. In this case, the entire cutting part of the cutting wheel will be at your disposal, it remains only to attach a metal sheet about 4 millimeters thick to the workbench, with a slot for the disc, an angle grinder (a sort of external tabletop). Another option is to mount the sander to the edge of the workbench horizontally, so that the disc is completely outside the worktop. True, in this case, you will have to work, holding the tile in your hands, a canopy.

We cut the tiles correctly

Using tiles for wall decoration, a situation will surely arise when you need to cut off part of the slab so that it fits into the remaining space. over, a similar procedure will be required regardless of which type of tile you choose. Cutting is most often required when unique patterns on the walls are created or various decorative objects are formed using tiles.

If you have already prepared all the attributes you need for work, you can consider how the tile should be cut correctly. an angle grinder is an excellent assistant in this matter, since with its help you can create not only straight cuts, but also curly cuts. Next, we will look at how to cut tiles in various ways.

A straight cut is as simple as possible:

- First, you need to fix the tile on the plane so that He does not slip and DO NOT ride on it.

- The part of the tile that needs to be cut must remain in weight. The surface line will be a guide for the mowing line to cut;

- It is necessary to take the angle grinder so that you can see the cutting line. If you hide it from yourself, it will not be able to make a straight cut.

- You need to direct and move the blade towards yourself, and not away from yourself. This is the mistake many beginners make. Hold the tool firmly and evenly, so that it does not go in different directions, otherwise the cut will be ugly. Holding the angle grinder crooked can damage the disc as it can fly off.

A round hole is made as follows:

- Initially, you need to use a marker to draw the required hole. Draw on the glossy side of the tile.

- Then you need to determine the center of the circle. This can be done using straight lines drawn crosswise.

- Gently saw the tile from the inside in a circle until we go deep.

- It is necessary to turn the angle grinder so that the blade gradually fits into the outlined circle.

- When the cut is deep enough, you need to cut the drawn cross along the drawn fishing line, after which you carefully take out the resulting 4 sectors of the circle.

You need to cut the tiles only on the front side, since this is the only way to get a cut without various defects. Therefore, all possible damage will be concentrated on the back of the tile, which will be hidden with tile adhesive.

It is best to measure and mark the tiles to be cut from the start.

To cut at a 45 degree angle, follow the instructions below:

- It is important to note that it is more difficult to cut the tiles obliquely than making a straight cut. However, this is much easier than creating curly elements. You need to start by doing.

- the angle grinder must be turned so that the disc is located at the angle you need, while you must carefully drive the blade, absorb the excess, so that at the end an even angular cut is obtained.

- Perfectness can be achieved by using ordinary sandpaper, which is best fixed on a block.

How To Cut Tile Angle Grinder?

When doing renovations, many homeowners find it necessary to cut ceramic tiles, which can be done with an angle grinder. This tool allows you to do this work at a high level, with minimal risk of chips or cracks. In this article we will show you how to cut ceramic tiles using an angle grinder.

Required tools and materials

Cutting ceramic tiles is a laborious process that requires maximum concentration. The difficulty is largely due to the fact that the tiles are made of durable material. Dust-free tiles can be cut and washed down with a tile cutter, but such a tool is not cheap. This is almost impossible with conventional cutters and dust, and the cut will most likely be uneven and unattractive. A regular angle grinder is best suited, the cutting wheel of which allows you to neatly cut tiles even at home.

Despite the fact that this process is relatively difficult, if you get the hang of it, It will not take much time and will NOT require much effort. An ordinary homeowner is able to cope with this task, who have not dealt with such work and will be able to cut off even a “hog” without the help of a tile cutter.

You can cut tiles using the following tools:

- Special tile cutter;

- Diamond tools;

- Angle Grinder.

For cutting ceramic tiles, those that have a diamond coating are suitable. Their use minimizes the formation of cracks and chips. It is forbidden to use discs used for working on metal, as they will only damage the tile. Even if you manage to spray with this circle, it will be uneven and of poor quality. This is due to the sliding of the disc on the tile, due to which the presence of small cracks is inevitable. At the same time, when it comes to home surface finishing, one cannot but pay attention to these damages, since they will surely disappear during subsequent processing.

Be sure to carry the following attributes with you:

- Glasses;

- Mask;

- Heavy gloves.

Please note that the selected angle grinder or grinder must have a speed regulator, since many modern inexpensive tools do not have this function. Such models operate at the highest speed, which is why it is impossible to cut tiles with their help.

Important nuances

The angle grinder must be set at a low speed so that you can control and adjust its actions. When you have the ability to secure the tool, be sure to do so, as this will simplify your work. Once you have secured the angle grinder, you only need to move the tile along the desired path.

If there is no possibility of anchoring, then the floor is the best place to work. Be sure to put bars or lumber under the slab. It is important to note that a low speed should also be set due to the fact that this will exclude the discarding of the blade or disc upon contact with the surface.

By turning on the maximum speed, you will probably simplify the cutting process, but this increases the risk of damage to the tiles, which can simply fly into pieces. The easiest way to cut is the straight mowing line, since even a beginner can handle this job. If the speech is about rounded, then it will take more effort. If you have NOT previously encountered such work, then we recommend that you first try your skills on defective material.

You can protect the tile from chips by using a special grinder or sandpaper. This work is NOT difficult, but it will significantly improve the quality of the cut. Thus, you can get rid of existing defects.

Be sure to observe the following guidelines:

- You need to work in special clothes;

- Safety glasses are required;

- It is recommended to use earplugs when working;

- All used accessories Must be in good condition;

- The work can only be performed by adults who know the safety rules for using cutting tools;

- When wet processing, make sure that the sander does not get into the water, as this can lead to an electric shock;

- You cannot process slices at maximum speed;

- You need to work in a room with good ventilation.

To maintain your health, it is extremely important to follow these recommendations.

Next, see a master class on tile cutting angle grinder.

How To Cut Tile Angle Grinder

No ceramic tile renovation is complete without the need to trim or beautifully work around corners. Using an angle grinder, smooth parts are made in the absence of a tile cutter, holes of various shapes and diameters are milled, two or more fragments are joined.

Main rules of work

In addition to ceramic tiles, there are porcelain stoneware and natural stone. They require careful handling and a reliable diamond-coated bit that can handle hard material.

Cutting rectangular holes

A drill equipped with a drill with a diameter of 5 mm is attracted to help. Marking the tiles with a pencil, lay them out and clamp them so that they do not move during the process. Use a drill to punch four holes in the corners. Next, we get to work with the angle grinder, cutting through the mowing line between the points. It remains only to remove the central part and process with an abrasive nozzle.

Is it possible to cut tiles with an angle grinder

We answer this question in the affirmative. In some difficult cases, an angle grinder cannot be completely dispensed with. It is irreplaceable if you have to divide the tile into thin strips or cut a round, rectangular hole in the tile.

The tile cutter is much more limited in functionality than an angle grinder. He does not have the ability to work on large planes and does NOT know how to cut curly holes. Therefore, experienced craftsmen often prefer an angle grinder when working with ceramics and tiles for finishing walls and floors.

Straight cutting

An angle grinder is indispensable here. This is a complex kind of work. Performed for decorative purposes, to bypass pipes of communications or various elements of the environment.

The scheme of action is as follows:

- Marking the edges of the future hole with a pencil;

- Laying and Fixing the work area;

- How to create short serifs with an angle grinder.

Hole cutting

You will need the help of a compass and a drill. 3-4mm drill diameter will be sufficient. We put a point, outline the contours of the future hole, drill a hole in the middle. Using an angle grinder, cut through cuts from the inside of the circle. Finishing with a sandpaper check.

How to cut tiles with an angle grinder without chips

Only an angle grinder is capable of such work. The main thing is to choose the right disk and follow the basic rules, safety precautions.

The angle grinder has the following advantages:

- Handles surfaces of any size;

- Able to carry out figured cutting with clearly defined parameters;

- Convenient and easy to use.

In addition, different cutting discs are selected for an angle grinder. This allows you to select the appropriate one for a specific type and thickness of material.

45 degree cutting

One of the most difficult operations in the processing of ceramic tiles. Armed with a metal circle, preferably supplemented with diamond dusting, we proceed to action:

- Mark the place of the cut with a marker or pencil;

- We lay out the tiles with the outside side down, Fix;

- We remove the back of the workpiece at an angle using an angle grinder;

- We carry out a repeated pass over the intended field.

If necessary, adjust the cut point and process with an abrasive.

What nozzles to use

There are two main types of discs. solid and segmented in various modifications. For thin ceramic tiles, the first option is more suitable, since it accurately makes a cut, practically NOT creating dust and chips. The second nozzle is less reliable and often leaves defects.

Stone nozzles are practically not used for tiles. They leave a lot of dust, make the cut less accurate and deeper. At the same time, they wear out quickly, which is NOT economical. Metal rims are much more suitable. Diamond plating protects against rapid wear and ensures a thin, clear cut.

Safety engineering

For work such as using an angle grinder for cutting, it is imperative to adhere to a number of rules, and then your actions will NOT end in injury.

Cutting from the wrong side is not recommended, as in this case there is a possibility of damage to the glazed layer

Here’s a list of the highlights:

- Before starting work, check how the disc runs, whether it touches any elements;

- Next. check the sharpness of the disc, since if the tool becomes dull, then there is a possibility that it can simply fly apart, which again will lead to injuries;

- Be sure to wear safety glasses, which will protect your eyes from flying debris;

- When working, it is necessary that no one distracts you;

- You need to start cutting the tile when the disc on the angle grinder is completely unwound.

They work as a tool from themselves so that in the event of a clamping disk, the latter flew in the opposite direction from you, and not at you.

And yet. you need to work an angle grinder at a distance of no more than half a meter (ideal for tiles, isn’t it?), Otherwise, the wire is pulled, you can reflexively raise your hand with a working tool and severely injure both yourself and those around you.

In addition, the principle of cutting with this tool is that it does not put pressure on the angle grinder when working, the tool itself must cut.

In principle, there is nothing complicated, and with a proper attitude to work, you will succeed.

Can tiles be cut by an angle grinder

When laying tiles, the question always arises, is it possible to cut tiles with an angle grinder? So, to begin with. yes, you can, but how exactly. now we’ll tell.

Cutting features

So, for direct cutting you need:

- Marker

- Metal ruler for mowing line

- Protective glasses

- Angle Grinder

So, once again double-check your measurements, they must be correct, as they say, try on seven times, cut one, and now the direct answer to the question of whether it is possible to cut a tile with an angle grinder.

Excellent cutting option

So, here is the algorithm for your actions:

- Apply the line of the cut with a marker with a ruler;

- Lay the tiles on a stable surface (table, workbench) so that the base does not accompany the shaker under the tile;

- Consider, Using safety techniques, where you will lead the angle grinder, what part of it will you return it to yourself;

- Turn on the angle grinder, let the disc spin;

- Guide the line carefully away from you.

If you rarely use porcelain stoneware tiles, then you need to do it on a plane from which one edge of the tile will hang, because the cut should be the full width.

But for ordinary tiles, it is enough NOT to cut through to the end, but only to go half the thickness of the tile. Further. you will proceed as follows:

Put the tiles on the edge of the table so that the line cut coincides with this edge, now hold one edge of the tile with your left hand, and make a slight effort with your right hand, Pressing. The tile will break exactly along the cut line.

So, here is the answer to the question, is it possible to cut tiles with an angle grinder.

Competent work of angle grinder

Here we apply. Where cutting is carried out as competently as possible, note that the master does not put pressure on the tool, he just leads. And the cutting base is directed from the master, and the protective body is turned to him.

Cutting

But the quality one. Which clearly shows:

We hope that the answer to the question of whether it is possible to cut tiles with an angle grinder is now only positive for you, as well as the result!

Like all other tools, the angle grinder is divided into classes, into professional and household tools, as well as by their design features.

It is perhaps the most widely used tool and not counting drills. Many people work with an angle grinder, but not everyone is wondering about the correctness of the manipulations performed, from the point of view of personal safety and quality of work. In this article, we want to devote you to the basic subtleties of working with this tool and consider in detail the following questions:

Let’s go in order.

HOW IT IS CORRECT to cut an angle grinder?

Before getting started, you need to prepare your angle grinder. We mean the choice of rig (disc). The following points should be considered here:

- Disc diameter. Remember, the smaller the disc diameter, the more revolutions (higher rotational speed) it can withstand, and vice versa.

- The choice of the disc depends, first of all, on the material with which you plan to work and the design features of your instrument.

- Pay close attention to the legend and markings on the disc. Carefully studying them, you will understand whether the selected equipment is suitable for the proposed work.

Also, always follow safety precautions and wear special equipment such as gloves, goggles, long sleeved robes and closed shoes.

First of all, clear the workplace of unnecessary items. Securely fix the workpiece to be machined, pre-marking it, if necessary. Getting started.

Always hold the tool firmly and confidently with both hands. Take a steady body position. They need to stand so that sparks, in the process of work, DO NOT fly onto clothes, and even more so in the face.

Always remember about such a thing as kickback. This is the most dangerous thing that can happen when working with a grinder. It can happen if the disc is strongly jammed in the workpiece. In such a situation, the angle grinder will be thrown back sharply. I control the process to avoid this.

Also remember that the power cord of the angle grinder must be isolated from sparks during operation. If you need to move the instrument to a different work surface, be sure to turn it off first and then unplug the power cord. The same should be done in a situation with a power outage. As soon as the power goes off, turn off the instrument and then unplug it. If this is not done, then when the power is restored, the angle grinder will start to work in a chaotic mode again and can cause irreparable harm to your health, others or damage objects around.

The most frequently asked question that arises in novice craftsmen is the following: How to cut an angle grinder correctly: for yourself or away from yourself? Many do not betray this special significance, but in vain.

Manufacturers of an angle grinder advise their consumers the following: The tool should be used in such a way that the course (direction) of the cut coincides with the direction of rotation of the disc.

Experienced craftsmen have a clear answer to this question: You need to cut from yourself. This is for your safety. In case the angle grinder is pulled out of your hands, the tool will be thrown in the opposite direction from you. If you cut towards yourself, when the above situation occurs, the tool will fly to your feet. We will NOT describe the consequences. You can imagine them yourself.

If you are less likely to cut parts or workpieces that have thick metal, cut them in an extremely straight line.

When working with a part such as a corner or we cut a profile or a profile pipe, which are usually quite long, cutting the hanging edge. Otherwise, if you make a cut in the place between the supports, such an outcome as a jam of the disk due to the deflection of the workpiece is possible.

If you are less likely to use a professional sheet (sheet metal sheeting), metal siding (metal siding) or metal tiles, take care of the presence of Special anti-corrosion substances, which need to lubricate the material in order to avoid sudden corrosion.

In case you rarely paving slabs or paving stones, get a special disc with a diamond cut.

Reinforced concrete, concrete and other similar materials must be treated with special discs for stone.

If you need to cut a gas or oxygen cylinder, be very careful as it may explode due to the remaining trace of gas or condensation. It is better not to carry out such work at home.

If you need to cut glass or, for example, a mirror. The most trivial ceramic disc will suit you.

When working with material such as wave slate, do not apply extra effort to avoid chips and irregularities.

It is possible to process rubber with an angle grinder, but not necessary. If you understand what we mean.

Plumbing, springs, fittings or channel can also be cut with an angle grinder.

Need to cut drywall or polycarbonate? Do this very carefully to avoid chipping and breaking the material. You will need neatness if you need to cut glass mosaics. For example, if you are cutting off excess parts from a pasted arch, cover the cut and the part to be cut off with masking tape or construction tape. This minimizes the possibility of cracks and prevents debris from scattering on the floor after cutting.

HOW to cut a TILE angle grinder WITHOUT chips?

As we said above, the range of applications for the angle grinder is incredibly wide. She also acts as an excellent helper when cutting material such as tiles or tiles. But, a logical question arises regarding the equipment: How is it better to work on tiles? To carry out this type of work, you need to get a grinding diamond wheel and a tile holder. It is hardly possible to work without dust with this material, so take care of a protective mask in advance.

Let’s take a closer look at the process itself and methods of cutting tiles or tiles without chips.

- The easiest way is to cut straight. Fix the tile well so that its edge remains suspended along the mowing line of the cut and get to work.

- The next method, which should be noted, is cutting at an angle of 45. This method is more complicated than the first. First, we cut the ceramic tile with a straight cut. Then, when cutting, the angle grinder disc is guided at an angle and removed the unnecessary part. Next, grind the cut with sandpaper.

HOW IT IS CORRECT to cut an angle grinder METAL?

First, let’s talk about the dangers that await the master when cutting metal with an angle grinder, namely:

- Fragments of the disc, in the event of a break;

- Powerful stream of spark and small abrasive particles;

- In some cases, the inability to hold the instrument in the hands.

Now, a few tips for working with metal.

If you have no experience in this type of work, then for a start, it is worth practicing on unnecessary details. If, in the process of work, you decide to change the cutting plane when the disc is inside the workpiece, this will immediately lead to its breakage.

To increase the life of discs, especially expensive ones, they need to be cooled. This is done with water. It is necessary to water the cutting area. It is advisable that you carry out work with a partner, who will carry out all these additional manipulations.

Also, breaks of 5-7 minutes every 20-30 minutes of work will help to increase the service life of the equipment, and the tool itself. This rule is especially important when working with household angle grinders. This way you will save your instrument from overheating.

You should also remember that you should not put pressure on the angle grinder during operation, otherwise it may fail due to overheating, or jam the disc. If you feel that performance is too slow, try changing the drive.

CAN the angle grinder cut WOOD?

Many seasoned craftsmen claim that wood cutting an angle grinder be. Our opinion: it is really possible to cut wood with an angle grinder, but it is extremely unsafe, inconvenient, slow and of poor quality. And that’s why.

Firstly, during operation, the disc of an angle grinder gets very hot and becomes incredibly fragile. The slightest misalignment may result in a ruptured disc. You can recognize the consequences of such a situation by the pictures on the Internet.

Secondly, when working with a disc equipped with victorious solders, these drinks can easily end up under the skin. And this is a direct way to the hospital, because it will not be possible to extract them on your own, plus it is fraught with infection.

Thirdly, when using a disc for wood, the teeth can grab more wood than you expect, and this, in turn, will lead to that. That the angle grinder will simply rip out of your hands. It is very dangerous!

We hope we have explained in an accessible way why you cannot use an angle grinder when working on wood and you will not even try.

But, as practice shows, many craftsmen at home resort to using an angle grinder in the process of processing materials such as chipboard, chipboard, laminate, OSB board or plywood. It should be dusty as carefully as possible and in compliance with all safety measures. Otherwise, you can not only spoil the material, but also be injured.

HOW EXACTLY to cut an angle grinder?

In order not to spoil the workpiece and make a high-quality smooth cut of the angle grinder, you will need to perform a number of preparatory measures, in which we will tell in this part of the article.

- Markup. All ingenious is simple. First we mark it, then we cut it. Take pipe cutting as an example. First, use a chalk or marker to apply the size, then use paper or construction tape. The main thing is that the edge is even. We take the selected auxiliary material and carefully wrap it around the pipe. Its border will be a clear and accurate marking of the cut. When performing work, it is important to remember that under no circumstances should you change the position of the tool stroke. Otherwise, the disc may jam or break. As such, you should not put additional pressure on the tool, as this will immediately be reflected in the curvature of the cut and spoil your workpiece.

- It is very important to choose the right thickness of the circle. There is a simple axiom at work here: the thicker the material you are working with, the thicker the disc should be. When choosing tooling, consult an expert in the field and pay attention to the marking of the grinding wheel applied to his shirt.

HOW to safely cut an angle grinder?

The work of an angle grinder is a matter that requires constant attention and control, because the consequences of accidents are irreversible. Therefore, before starting work, take care of the following:

- Take care of the protection of all parts of the body: face, hands, eyes.

- Clean the workspace from excess, especially the place where the spark is directed, remove further all combustible materials.

- The workpiece to be machined must always be securely fixed.

- Be sure to install the protective cover.

- Hold the tool firmly while working.

- At the end of the work, Wait until the rotation of the disc has stopped completely, place the angle grinder with the disc upward so as NOT to damage it, Unplug the tool from the mains and make sure there is no smoke or signs of fire.

WHAT CANNOT be cut with an angle grinder? BASIC ERRORS

In the list below, the materials with which the angle grinder can work are given. It is prohibited to work with materials on the list.

- The angle grinder is perfect for cutting materials such as cast iron, metal, steel, copper, aluminum, iron, titanium. You can cut stainless steel or galvanized.

- With the appropriate attachments, you can also work with plastic, ceramics, glass, plexiglass and porcelain.

- Stone, granite, marble, asphalt, concrete or wall made of it, brick, porcelain stoneware can also be processed by an angle grinder.

an angle grinder is useful if you need to cut water pipes or old heating.

One of the main factors that guarantee the quality of work is the right tooling. If you have any questions or want to purchase discs, please contact our managers at the specified phones. They will recommend suitable discs and advise you on all questions of interest.

Rules for cutting ceramic tiles on a homemade machine

There are certain strict rules for cutting tiles on a machine from an angle grinder, which mainly ensure the safety of work.

- It is only necessary to cut the tiles “from yourself”. In this case, the pressure on the tile with your hands should be moderate.

- Cutting must be done from the front of the material.

- Clamps are usually used to fix tiles, which should be located in the center of the cut.

- If spraying is done for the first time, then it is worth trying to do it on waste, because there is a high probability that cutting the tile the first time simply will not work.

- It is not necessary to keep the angle grinder plugged in when not in operation.

- Store the machine in a closed room away from children.

- The cutting process must be carried out in goggles or a mask, because in addition to dust from the tool, rather large pieces of material fly.

Tile cutter table

Experts assure that in order to correctly make a tile cutter from an angle grinder with your own hands, you need a good foundation for the future machine. It must be strong and reliable. And, as already mentioned above, it is important that the area of the table is sufficient to fit the tile of the largest size.

In principle, such a table can be made by hand, but today you can find an acceptable sample on sale. It may not seem economical, but practice shows that it is not in vain that such tables are sold today. It can be seen that they have their own consumers. Therefore, when choosing a ready-made table for a tile cutter from an angle grinder, you need to pay attention to the following points.

- Usually, the manufacturer indicates in the accompanying documents how much load his product can withstand. And although cutting ceramic tiles is not a stone to hammer, the table must withstand a certain load.

- Construction reliability. For a machine of this type, this is the most important indicator. The table must be firmly in place because the angle grinder works with vibration. Structural instability is dangerous.

- You need to choose such a product, the tabletop of which will be made of stainless steel or aluminum alloys. Cutting works will be carried out on it using coolant (water). It will immediately rust black steel. In addition, a stainless steel or aluminum table is easy to clean. And this is also an important plus.

Tile cutting methods

There are several options for how to properly cut tiles. That is, it is necessary to get an even cut without chips and defects. There are three directions.

- Tile cutting with an angle grinder along a straight mowing line. This is the easiest option. A cut line is applied to the ceramic surface of the tile. The tile is clamped into clamps so that the cut area is located outside the table surface. That is, he kind of hung. It is necessary to cut in this position “on oneself”. This makes it possible to clearly see the cut line. The angle grinder is switched on and the material is cut exactly along the mowing line with a disc.

- Chamfer cutting. This is when the edge needs to form an angle, usually 45 °. Everything is done in the same way as in the previous case. Only one more stage is added. this is the formation of a chamfer. For this, the disc of the angle grinder is brought to the cut edge at the required angle. There is no need to cut anything, the edge is simply ground at an angle. The angle can be proved to the ideal state by grinding it by hand with sandpaper or a file.

- How to make an angle grinder a hole in a ceramic tile. It is clear that you cannot cut holes of a small diameter of the drive, but you can try more than 100 mm. It should be noted that this is the most difficult option, therefore it is very important to correctly carry out all the stages from the preparatory to the main one. So, a circle is applied to the tile along which the cut will be made. Further, the resulting circle must be divided into four parts, draw two mutually perpendicular mowing lines so that both of them go through the center of the circle. Now you need an angle grinder, holding it at an angle, spray around the circumference. Dust is necessary in small areas. Even if the corners remain, they can be earned. There is no need to saw through, the main thing is to make a small incision. After that, a circle is cut through and through along the applied fishing line (mutually perpendicular). Then you just need to separate the four segments of the sprayed circle one by one. And at the end, the edges of the circle are necessarily worked up to the required accuracy.

Cutting features

To the features of cutting tiles, an angle grinder must include special devices that hold the tile stationary, and the so-called nozzles, with which the cutting itself is performed. In addition, you will have to take into account the features of the technology, because in different circumstances you have to cut different configurations of material at different angles.

As for the nozzles, diamond cutting discs are mainly used for cutting tiles. There are two types of them:

- For dry cutting. This is a fine diamond-coated disc. Its disadvantage is a large amount of dust during the cutting process.

- For wet cutting. This tool is used when a large amount of tile material needs to be cut. To do this, you will have to think about how to supply water to the edges of the tool. The easiest way is to dip the blade in water before each cut. You can spray it with a spray bottle during operation.

As for the device with which it will be necessary to keep the tile motionless, the simplest option is the clamps. They press the tile, for example, to the table surface. To prevent it from breaking under the pressure of a metal element, you can put a wooden gasket between the clamps and the tile.

Homemade tile cutter from angle grinder

It should be noted that cutting tile with an angle grinder is a process primarily inconvenient. Holding the tool in your hands and accurately guiding it along the applied mowing line requires certain skills and experience in carrying out operations of this type. Therefore, you can install an angle grinder on the bed, fix it well on it, that is, build a kind of machine like an electric tile cutter. over, it will be cheaper than the last.

The installation method of the angle grinder can be vertical or horizontal. In principle, there is a special difference in how to install the tool, because the main requirement for a home-made machine is a strong fastening of the angle grinder so that it does not vibrate during the process of cutting ceramics.

Horizontally The installed tool must be fixed in space so that the cutting wheel is positioned exactly vertically. In this case, it must be in the slot of the table. And this slot will serve as a cut-off mowing line, such a kind of landmark. You can do without slots, and install the angle grinder on the bed in such a way that the disc is slightly farther than the edge of the table. This design is considered not the best, because the cut parts of the ceramic tile will have to be held on outstretched hands all the time. And this, with a large volume of cutting operations, is physically difficult. Optimally, if the entire tile will lie on the table, then it is easier to move it along the plane, pushing slightly with your hands.

The vertical installation of the angle grinder is determined by two conditions.

- The tool reducer, or rather its outer part, should be located at the level of the table surface, it can be slightly lower, but not more than 1-2 mm.

- 90 °. this angle should be between the table surface and the diamond cutting disc.

All conditions are defined, you can proceed to the manufacture of the machine. This will require a steel sheet with a thickness of 4-5 mm, metal band clamps, with which you can fix the angle grinder, respectively, the angle grinder itself, plus a few bolts with nuts and washers.

- First, you need to cut out a platform from a steel sheet, the dimensions of which could accommodate the largest ceramic tile. Necessarily a disc and an angle grinder make a slot on the sheet, in which it was mentioned above. Its length must be greater than the diameter of the cutting element.

- Now the tool itself is attached to the table with clamps, on which a steel platform with a slot is preliminarily laid. It is also bolted to the base of the table.

- Craftsmen advise to put the clamps in rubber or plastic tubes. Thus, DO NOT damage the surface of the housing of the angle grinder.

There is one more element that will NOT be superfluous in the design of a homemade electric tile cutter. This is an emphasis on which the tile will abut, thereby creating the size of the required cut-off part. This element must be movable in order to adjust the cut size. Therefore, under it you will have to make a slide with slots for almost the entire length.

On the slide, the stop is fixed tightly, you can use electric welding. The sled itself will move across the cut mowing line on bolts, which, when relaxed, make it possible to move the sled, and when fastened, hold them firmly in one place. Both the stop and the slide can be made from a metal corner or steel strip.

Why an angle grinder is the perfect tool for assembling a DIY tile cutter.

- Firstly, it is the only power tool that can create a disc rotation speed of up to 5000 rpm.

- Secondly, it is a simple assembly that turns a handheld device into a stationary machine.

- Thirdly, when cutting at high speed, microcracks WILL NOT form, which, when laying tiles on walls or floors, can cause large chips of material.

Ceramic Tile Cutting Technology Angle Grinder

The angle grinder can be called a universal cutting tool, although besides cutting it can be used for surface grinding. And when the manufacturer of finishing works is faced with the question whether it is possible to cut tiles with an angle grinder, then, of course, the answer must be positive. And although this is a fairly powerful tool, it can spoil thin wall tiles when cutting, floor tiles and porcelain stoneware are allowed to be cut, taking some of the nuances of the process itself. Of course, it is better to use a tile cutter (manual or electric) for cutting tiles, but if there is one, then an angle grinder will do. So, let’s understand the topic of how to cut tiles with an angle grinder.

Cutting tiles with an angle grinder is both simple and difficult. The main thing in this business is a firm hand and a sharp eye. Of course, this is NOT a tile cutter, but if the latter is available, then you can get by with this tool. In addition, it should be noted that in addition to the appearance of tile cutters on the market, craftsmen usually cut ceramic tiles with an angle grinder. over, it can even be cut into porcelain stoneware. This cannot be done with a manual tile cutter, an electric model is required.