Lawn mower blade wear. How to Sharpen Lawn Mower Blades

Lawn Mower Blades: The Ultimate Guide (Types, Measuring, and )

Purchasing replacement blades for your lawn mower is a relatively easy task if you know your lawn mower blade’s part number. If you have your lawn mower’s model and serial number, referencing that mower’s model and serial number parts diagram is another fool-proof way to purchase the correct blade.

But, what if you don’t have any of these part numbers to reference? How do you determine which blades will fit your mower?

By the time you are finished reading our Ultimate Guide to Lawn Mower Blades article, you should have all the info you need to purchase a blade that will work perfectly with your lawn mower.

How to measure lawn mower blades

We’ll get into the various types of lawn mower blades further into the article (skip to view types of lawn mower blades). First, we will walk you through measuring the blade on your lawn mower to determine which size blade you need.

Measure mower blades diagonally

The most common mistake we see when people are attempting to measure their lawn mower blade is measuring straight across the blade. This is going to give you an inaccurate measurement!

To properly measure a lawn mower blade, measure the blade diagonally.

Center hole diameter

The next measurement you will need is the diameter of the center hole of your lawn mower blade.

If your mower blade has 3 holes, make sure you are measuring the center hole!

To measure the diameter, measure straight across.

If your mower blade does not have a circle for the center hole, you will need to determine what the shape in referred to. on mower blades without circle-shaped holes in just a second.

If your mower blade has outside holes

If you notice 2 holes on either side of the center hole in your lawn mower blade, you will also need to take some measurements here.

Many push lawn mowers and some other types of mowers utilize these outer holes to ensure the blades do not hit each other while in use. Many commercial lawn mowers use 2 or 3 blades, not just 1 blade.

A perfect example of this is the Exmark Commercial 30. This is an oversized 30 wide commercial push mower that utilizes the center holes to ensure each blade is mounted in the correct position.

Once again, you will want to measure the diameter of these holes.

You will also need to measure the distance between the center of these 2 outside holes. This measurement is referred to as center to center.

Lawn mower blade center hole types

Most lawn mower blades have circles as the center hole shape. If your blade does not, here is a quick reference of other possible mower blade center hole types.

Less common but not pictured center hole types include a square and a 7-point star center hole.

Measuring your mower blades width

The width of a lawn mower blade is usually not relevant to the fitment of the blade but we wanted to make sure you knew where to measure if this is applicable to your mower.

To accurately measure the width, make sure you are measuring straight across and measuring at the widest section of your blade.

Right-hand cut vs left-hand cut blades

Believe it or not, the cutting edge is not on the same side for all lawn mower blades.

how to sharpen a lawnmower blade

Right-hand cut lawn mower blades are overwhelmingly the most common type.

Left-hand cut blades can be found on some mower’s manufactured by Kubota, Woods, Walker, and others.

Lawn Mower Blade Thickness

It is recommended to stick with the specs of the blade that came stock on your lawn mower. If for whatever reason you cannot determine the OEM blade part number, don’t stress about the thickness of the blade. It is not a huge deal, although using a blade that is too thick could lower the RPMs to a point where cut quality is lost.

As you might expect, blade thickness is measured by measuring the top of the blade to the bottom.

If you are bending a lot of blades, you may want to purchase a thicker lawn mower blade or just stop hitting rocks! Believe me, I’ve had 100 employees in my lawn care business over the years and completely understand if you are not sure if your employees are looking at what they are cutting as they are working!

Types of lawn mower blades

Now that you understand how to measure lawn mower blades properly and the various types of center holes you may find, let’s take a look at the different types of lawn mower blades and when you may want to consider each type.

We should mention you may see standard blade in the description of some lawn mower blades. This is basically the middle ground between high lift and low lift lawn mower blades. It is pretty suitable for any type of cutting.

High lift lawn mower blades

High lift lawn mower blades create a lot of lift due to the exaggerated fin on the non-cutting edge side of the blade.

When to use high lift lawn mower blades:

- When you are cutting tall grass ( Grass over 3 tall )

- When you are cutting flimsy grass such as turf-type tall fescue

When not to use high lift lawn mower blades:

Low lift lawn mower blades

Low lift lawn mower blades c reate little lift due to the exaggerated fin on the non-cutting edge side of the blade.

When to use low lift lawn mower blades:

- When you are cutting short grass (Grass under 3 tall)

- When you are cutting rigid grass such as Bermudagrass

- In sandy soil conditions (see flat blades too)

When not to use low lift lawn mower blades:

Gator blades

Gator blades are also referred to as 3-in-1. Gator blades are often used by professional mowing companies in the fall to shred leaves as they mow. S ome companies run gator blades all year long.

Gator blades also shred longer grass blades before being discharged from the mower’s deck. Gator blades do create some lift.

When to use gator blades:

When not to use gator blades:

Mulching blades

Mulching blades mulch the grass clippings to allow for returning the grass clippings to the soil as natural nutrients.

It is important to note, you can certainly discharge the clippings from the mower’s deck back into the lawn without mulching blades as long as you are cutting your grass on a frequent enough basis.

When to use mulching blades:

- When you are not discharging the clippings or bagging

- When you are following the 1/3 rule (only remove 1/3 or less of the grass blade each time you mow)

When not to use mulching blades:

Flat lawn mower blades

Flat lawn mower blades create zero lift due to the blade being completely flat.

When to use flat lawn mower blades:

When not to use flat lawn mower blades:

- Most of the time! Only use flat lawn mower blades when in extremely sandy soil conditions and cutting a rigid grass type

Self-sharpening lawn mower blades

To ensure this article covers all the bases, we wanted to include a new option when it comes to lawn mower blades.

Self-sharpening blades use patented technology to literally sharpen themselves as you mow. The early adopters seem to agree that these blades do in fact sharpen themselves.

Of course, these blades come with a hefty price tag as far as lawn mower blades are concerned. It will be for you to determine if they are worth the investment.

When to sharpen lawn mower blades

Factors such as how much use, what type of grass you are cutting, the length of grass you are cutting, soil conditions, and other factors will determine how often you will need to sharpen your lawn mower blades.

After finishing this article, check out our guide on sharpening lawn mower blades.

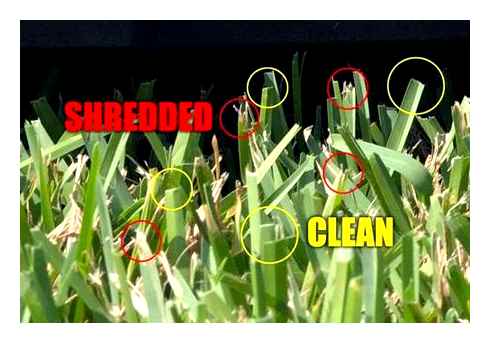

The best way to determine when you need to sharpen your lawn mower blades is by simply looking at the cut quality. This refers to the sharpness of the cut you are getting out of your blades. In the picture above you can clearly see the blades on the lawn mower that cut this grass need to be sharpened as they are tearing the grass instead of cutting it.

How to tell if a mower blade has been sharpened too many times

If you read the manuals, most lawn mower blade manufacturers recommend replacing the blades when there is 1/2 left between the cutting edge and the fin, sail, or lift. The fin, sail, or lift is referring to the part of the blade that is angled up.

If you continue to mow with less than 1/2 of material left, you are putting yourself and others in danger as there is a great possibility this blade could fail and send a piece of the blade flying from your mower. Please take this recommendation seriously!

Even if no one is hurt if this occurs, you very well could be on the hook for property damage costs.

When to replace lawn mower blades

At some point, lawn mower blades can no longer be sharpened and will need to be replaced.

You may need to replace your lawn mower blades because you have sharpened them too many times and have removed too much material from the blade.

Other reasons you may need to replace your lawn mower blades are much more obvious.

For example, if you bend your lawn mower blade, it should be replaced. Please do not attempt to bend it back to being straight once again. The integrity of the blade was lost as soon as it was bent.

Other reasons to replace your lawn mower blades include large chunks missing due to hitting an obstacle or hairline fractures. You should always inspect your lawn mower blades when sharpening or if you know you just hit an object you shouldn’t have!

OEM vs Universal Lawn Mower Blades

Something worth noting about lawn mower blades is that you do not have to stick with the OEM blades that came with your lawn mower!

Some stock blades simply do not provide a great cut quality. The 2 most important factors when purchasing aftermarket blades is that you purchase blades with the same length and center hole diameter. If your blade has the additional outer holes, you need to account for these specs as well.

Above is an example of a universal replacement blade that has an elongated hole instead of a circle. You will often see this on universal blades that account for outer holes because they want the blade to fit as many makes and models of mowers as possible.

Where to purchase lawn mower blades?

Great question. You are in the right place!

iGoPro Lawn Supply has over 900 lawn mower blades in stock.

We more than likely have the blade you need and have the best price you will find online.

Go ahead and shop lawn mower blades now. We recommend searching for the blade you need by part number, but by now you are fully prepared to measure your blades and purchase the perfect replacement blade.

Lawn Mower Blade Conclusion

To wrap this up, let’s just summarize the most important information we covered.

The 2 most important things to note when purchasing lawn mower blades is the length of the blade and the center hole diameter.

Make sure you purchase a blade with the appropriate outer holes as well if your mower requires them.

Use high lift blades if you are mowing cool-season grasses.

Use low lift blades if you are mowing warm-season grasses.

Try gator blades if you are mowing long grass or would like to shred leaves as you mow.

Mulching blades should only be used with a mulching lawn mower or a lawn mower with a mulching kit installed.

Ryan Sciamanna

Ryan is the owner and founder of Lawn Crack, LLC the parent company of iGoPro Lawn Supply. He has worked in almost every capacity within the lawn and landscape industry for small local companies, nationwide companies, and of course, owning his own lawn landscape business which he sold in 2018 before starting selling lawn and garden products online. Learn more about Ryan by subscribing to the LawnCrack YouTube Channel.

Sharp blades all season long will give you the cutting edge you need for a healthy, green lawn.

By Bob Vila Staff and Tony Carrick | Updated Jul 18, 2023 11:38 AM

We may earn revenue from the products available on this page and participate in affiliate programs.

At the start of growing season, part of the necessary prep every homeowner with hopes of a greener yard tacks (or should tack) onto the to-do list involves the cleaning and sharpening of lawn mower blades. If the blades are left dull, each afternoon spent mowing only rips and chews the grass. Coarsely cut grass doesn’t just look bad; it’s also more vulnerable to pests, disease, and drought. Read on for our step-by-step guide on how to care for your largest landscaping tool, and you’ll reap the benefits of a clean cut all season long.

Types of Mower Blades You Can Sharpen

If you own a walk-behind or ride-on mower, then you can remove and sharpen the blade yourself. Both types have a mowing deck that’s equipped with either one or two blades that spin horizontally around a vertical spindle. Remove each blade by loosening a single nut on the spindle. If you happen to own an old-fashioned reel mower, which uses multiple blades mounted to a cylinder, then you’ll need to take it to a lawn mower repair shop to have the blades sharpened.

Project Overview

Working Time: 1 hour Total Time: 1 hour Skill Level: Beginner Estimated Cost: 0 to 12

Before You Begin

Since this job involves working with a large blade and filing or grinding metal, taking the right safety precautions to protect your hands and eyes is key. You’ll be either filing or grinding the lawn-mower blade to sharpen it, so be sure to wear safety glasses to protect your eyes from sparks and tiny shards of metal that might become airborne as you’re working the blade. Since you’ll be using your hands to hold the blade as you sharpen it, you’ll want to wear heavy work gloves to protect your hands.

- Work gloves

- Socket wrench

- Scraper

- Vise

- Safety glasses

- Bastard-cut mill file

- See full list «

- Power drill

- Sharpening stone drill attachment

- Blade balancer

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

How To Tell If Your Lawn Mower Blade Needs To Be Sharpened

How often to sharpen lawn mower blades can vary based on use and other factors, but your lawn will tell you if your mower blade is in need of a good sharpening. All you need to do is look for a few telltale signs of a poor cut.

- Ragged cut: A sharp mower blade should slice cleanly through the grass. If it’s leaving a ragged edge, then the blade is tearing grass instead of cutting it.

- Uncut grass: Look carefully at your lawn after you mow it. If there are sections that appear to be pushed down instead of actually cut, then your mower blade is too dull.

- Uneven height: The grass blades should be at consistent height after you mow the yard. If they’re not, then the mower blade isn’t sharp enough to cut cleanly through the grass.

- Nicked blade: In addition to examining your lawn, you should assess the blade itself. If there are noticeable nicks and dents on the blade’s edge, then it needs to be sharpened.

How to Sharpen Lawn Mower Blades in Less Than an Hour

The type of lawn mower blade sharpener you have in your shed or garage will dictate the best way to sharpen a mower blade. Read on to learn about how to handle this lawn-mower maintenance job using a file, power drill, or bench grinder.

Step 1: Disconnect the spark plug (on a gas mower) or battery (on an electric mower).

This is the most important step in the entire process. Gas mowers start by using centrifugal force, which the user creates by pulling the starter cord. Though very unlikely, it is possible to create that same force by turning the blade. Eliminate any chance of the engine starting by disconnecting the spark plug, which is found on the front of the engine.Those with an electric mower should make sure to either unplug it from its power source or remove the battery if it’s cordless.

Step 2: Remove the blade.

Flip the mower over, so you can access the blade. Holding one side of the blade to keep it from moving, loosen the blade’s mounting nut using your socket wrench. If the nut is on tight or you don’t feel comfortable holding the blade, use a piece of scrap lumber to hold the blade in place so you can loosen the nut.

Step 3: Clean the blade with a metal scraper.

Clean the blade with a scraper and assess its condition. If rocks, branches, and other debris have inflicted deep nicks, you’ll want to replace it. Otherwise, gather the tools you need to sharpen it manually or mechanically.

Step 4: Sharpen the lawn mower blade.

At this point, you have a few options for how to proceed with sharpening, depending on the tools you have at hand.

- How to sharpen lawn mower blades with a file: Clamp the blade horizontally in a vise and run a bastard-cut mill file along the cutting edge, using a one-way down stroke. Follow the existing angle (usually 45 degrees, but you can refer to your owner’s manual for the ideal angle) until the blade has the sharpness of a butter knife. Aim to remove an equal amount of metal from the cutting edge of both ends of the blade. Counting strokes may help you keep track.

- How to sharpen lawn mower blades with a power drill: A faster technique involves a power drill with a sharpening stone attachment. Clamp the blade—cutting side up—in a vise. Secure the sharpening stone in the drill; the stone’s plastic guide should rest against the rear of the blade to ensure the proper cutting angle. Put on safety glasses, turn on the drill, and move the stone from the center of the blade to the tip.

- How to sharpen lawn mower blades with a grinder: The fastest way to sharpen the blade is with a bench grinder. With this method, you’ll need to be careful not to oversharpen the blade or remove too much metal. Oversharpening creates a thin edge, which is easy to damage, and removing too much metal shortens the life of the blade. Hold the blade perpendicular to the rotating wheel as you move it along the cutting edge at the angle of the existing bevel. This throws sparks, so be sure to wear safety glasses. If the blade gets too hot, dip it in a bucket of water to cool it.

Step 5: Check the blade’s balance.

Check the blade’s balance before remounting it, because a lopsided blade will wobble and overtax the mower’s engine. Set a blade balancer on a flat surface and rest the blade on the balancer using the center hole. If the blade dips, use the file, sharpening stone, or grinder to remove metal from the back edge—not the cutting edge—of the heavier side toward the end of the blade.

You can also check the balance by hanging the blade on a wall from a nail through its center hole. If the blade tilts to one side, remove material from that side.

Step 6: Reinstall the blade in the lawn mower.

Reinstall the blade to the spindle under the mower using the mounting nut. Tighten the nut with a socket wrench while holding the blade with one hand. Flip the mower over and reconnect the spark-plug wire or power source, and then get to work!

Final Thoughts

If your lawn mower isn’t cutting it, then it’s probably time to give that blade a good sharpening. This process isn’t difficult if you have the right tools for the job and follow the above instructions. That said, if mower blade sharpening isn’t something you have the tools or time to do yourself, you can have a local lawn mower repair shop sharpen your blade for you for about 15 to 20. If you examine the blade and determine that it’s too worn out or damaged to be sharpened, then you’ll need to purchase a new one that’s compatible with your mower brand and model for about 20 to 25.

The LawnmowerBlade that cuts itself sharp

Any landscaping professional knows that sharper mower blades make for sharper-looking lawns, but blades that maintain their sharpness can also improve a lawn-care business’s on-site efficiency and cut its maintenance costs.

Mowing lawns with LaserEdge® Eversharp™ blades means minimal maintenance and downtime associated with blade sharpening, increasing overall uptime and profits.

Redefining the Cutting Edge

High-quality, hardened steel blades equipped with the LaserEdge® Eversharp™ technology on their cutting edges have demonstrated their toughness and durability in field tests, even in the most abrasive conditions.

In one test, the LaserEdge® Eversharp™ cutting edge withstood 30 hours in severe sand conditions and became sharper during use. In a highly controlled durability test, the blade’s advanced technology performed remarkably, enduring multiple impacts from a 1-inch steel stake traveling at more than 200 mph.

Hours of Toughness

In an intense 50-hour field test in central Florida, mower blades with LaserEdge® Eversharp™ technology proved they “cut themselves sharp” when a new cutting edge emerged as the blade wore down.

In the test, a brand-new mower blade had LaserEdge technology applied on one cutting edge and was left untreated on the other edge. After putting the blade to work for 50 hours, the results were clear. The LaserEdge cutting edge was still sharp, and the untreated side was dulled and worn away.

Results will vary based on grass type, soil type and condition, and geographical region.

Cutting Costs, Boosting Bottom Lines

Increased Fuel Efficiency

Dull blades produce resistance, putting strain on the mower deck and making it difficult to maintain speed and efficiency. Mowing with a dull blade can reduce fuel economy by as much as 22 percent, which increases operating costs and reduces productivity.

Healthier, Greener Lawns

A dull blade shreds and tears grass, leaving it vulnerable to dehydration, browning, and disease. LaserEdge® blades cut grass cleanly, making it easier to deliver high-quality lawn care and in-demand enhancements such as lawn striping.

Blades Stay Sharp Longer

In abrasive conditions, a blade can get dull in as little as four hours, and lawn-care operations can go through dozens of blades a week, resulting in downtime and lost revenue. No matter the environment, a LaserEdge blade “cuts itself sharp,” reducing time spent sharpening.

Less Mower Maintenance

Blade replacement can be a dangerous undertaking. Attacking a dulled edge with a makeshift sharpening tool can irreversibly damage a blade and put workers in danger. LaserEdge blades dramatically reduce the frequency and risk of blade sharpening.

D.H. Steinegger, R.C. Shearman, T.P. Riordan and E.J. Kinbacher, “Mower Blade Sharpness Effects on Turf,” in Agronomy Journal 75 (1983): 479–480.

Savings Calculator

See how much you can save with LaserEdge® Eversharp™ lawnmower blades.

- 432 Saved on Fuel Cost

- 1575 Saved on Blade Sharpenings

- 2625 Additional Revenue Opportunity

- ( 960 ) Premium Spent on LaserEdge Blades

Calculations above are based off the following: type of lawn mower: 3-blade, 60-inch cut, gas-powered. Average gas price: 2.38. Lawn mower blade pricing: standard blade is 16. Average cost of sharpening: 5 per blade. Fuel savings: 11%. Blade removal and re-installation time: 30 minutes.

Frequently Asked Questions

How does LaserEdge ® Eversharp™ maintain a cutting edge that “cuts itself sharp”?

The LaserEdge Eversharp technology is applied to the underside of the cutting edge. As the blade cuts grass, the original blade material begins to wear away and exposes a new LaserEdge cutting edge, which is even sharper than the blade’s original sharpness.

Will I need to sharpen my LaserEdge ® Eversharp™ lawnmower blades?

LaserEdge blades “cut themselves sharp” and require minimal sharpening, but you should monitor cutting-edge wear. Sharpening is only needed if the new LaserEdge cutting edge is not presenting itself.

If I find the need to sharpen my LaserEdge ® Eversharp™ mower blades, how do I do so?

If you choose to re-sharpen your LaserEdge blade, do so in a safe, controlled setting with the proper equipment. Remember to prep the machine and remove the spark plug before removing the blade. Secure the blade to a work surface with a vise or clamp, and sharpen the blade with a file, bench grinder, or professional blade grinder. Ensure the blade is evenly sharpened and balanced before remounting on the mower deck.

New method of sharpening lawnmower blades

How often will I need to change my LaserEdge Eversharp™ lawnmower blades?

The LaserEdge blade is designed to “cut itself sharp” and requires minimal sharpening over its life. The overall life of the blade will vary due to conditions, but its lifespan should be at least as long as a standard blade’s. In several of our tests, we found LaserEdge blades had longer lives.

How do LaserEdge ® Eversharp™ lawn mower blades perform in abusive mowing conditions?

The LaserEdge technology is an extremely hard, wear-resistant material. If you mow in conditions that regularly include rocks, curbs, out-cropping stones, and other hard objects, LaserEdge lawn mower blades may not be suitable for your operation.

A good test to see if LaserEdge is right for your operation is to inspect your worn blades. Worn blades that show excessive gouging, deep gashes, or large scraps may not see all the benefits of LaserEdge.

How long will it take for LaserEdge ® Eversharp™ to take effect?

This is highly dependent on geography, soil type, and cutting conditions. The magic of LaserEdge happens when the base blade material wears away at a faster rate than the harder, more wear-resistant LaserEdge material. In highly abrasive soil conditions (like sand), we have experienced standard blades wearing out in as few as 50 hours with blade sharpenings occurring as frequently as every 4 to 8 hours. In these areas, LaserEdge began exhibiting self-sharpening in as little as 5 to 10 hours. When using LaserEdge, these blades required no sharpening over the entire life of the blade. In less abrasive conditions, LaserEdge technology will take effect but over a longer time period.

How much do LaserEdge ® Eversharp™ lawn mower blades cost?

The price of LaserEdge blades will vary depending on the OEM and blade configuration. Although the LaserEdge will typically be more expensive than a standard blade, the benefits of consistently having a sharp cutting edge and increased uptime surpass the increase in blade price (see Savings Calculator).

Where can I purchase LaserEdge ® Eversharp™ lawnmower blades?

Most lawn mower Original Equipment Manufacturers (OEMs) are currently in the process of adding LaserEdge to their product line-ups. Be sure to talk to your local dealer about LaserEdge.

How do I get more information on LaserEdge ® Eversharp™ blades?

Fill out the contact form at the bottom of this page, and Fisher Barton will email you updates on product availability and news.

Get LaserEdge® For Your Business

Ready to bring this cost-effective, state-of-the-art mower blade technology to your lawn-care business? LaserEdge blades are currently available through select OEMs.

Available for the following brands through their independent dealers: (Click on the logo for information on available part numbers)

Connect With An Expert

We’re here to help and would love the opportunity to discuss your technical questions or application challenges.

Which Side Of The Lawn Mower Blade Is Up? (2023 Guide)

Owning a lawn mower is a great way to save some money and maintain more control over your lawn and yard. But, it can come with some unexpected maintenance, and it’s alright if you don’t already know how to keep your lawn mower in good condition.

If you want to keep your lawn mower working well, you need to know how to install your lawn mower’s blade.

Don’t worry if you’ve looked at lawn mower blades and been completely baffled by them before.

I wrote this guide because I’ve been there, and I know how important proper blade installation can be. After all, getting the installation right is critical for the life of the blade, the function of the lawn mower, and the appearance of your lawn.

In this guide you’ll learn:

- Why lawn mower blade direction matters

- How to tell which side of your lawn mower’s blade is up

- And much more!

Why Does It Matter Which Side Of Your Lawn Mower Blade Is Up?

If you’re in a hurry, this video will help explain why it matters which side of your lawn mower’s blade is up, why it matters, and how to install the blade.

Use the Cutting Edge

Most walk-behind lawn mowers rotate the blade to the right, or clockwise. That means that when the blade is spinning, the cutting edge should spin to the right. However, this isn’t 100% foolproof.

Some lawn mowers do spin counterclockwise. It’s rarer, but you have to know which direction your lawn mower spins to be sure. Your lawn mower’s user’s manual should be able to tell you which direction the blades spin.

The Wings Face Up

On most lawn mower blades there will be a small part of the blade that isn’t flat, but angled up. This little wing on the blade is designed to encourage air movement, helping pull your grass upward for an even cut.

The wings on lawn mower blades are always designed to point up toward the lawn mower’s cutting deck. The same is true for the more extensive wings on mulching blades. If your lawn mower blade has wings, those wings should point toward the lawn mower and away from the grass.

Those three techniques should help you figure out which side of the lawn mower blade is up on pretty much any lawn mower blade. Assuming you know which direction your lawn mower spins the blade, that is the most fool-proof method, but the other two options are usually easier and faster ways to tell.

How To Tell What Kind Of Lawn Mower Blade You Need?

There are two basic kinds of lawn mower blade to choose between, and getting the right one can make a significant impact on your lawn mower’s performance. Most lawn mowers are compatible with both types of blade.

It’s important to remember that not all blades are created equal, and just because a blade is the right length doesn’t mean it’s compatible with your lawn mower. You always need to check your lawn mower for which blades are compatible.

Regular Lawn Mower Blades

Regular lawn mower blades are the simplest option. They are blades that are designed to get the job done without any bells and whistles or extra functions. These blades leave clippings relatively long, but they can also provide a more even mow than more complicated blades.

It’s important to have a good cutting edge on these blades since they are really reliant on cutting power to get good results.

Also called standard or medium-lift blades, these blades are typically on lawn mowers with side-discharge designs.

High Lift Blades

High lift blades are generally used for lawn mowers that have a bagging function because they provide more airflow that helps to move the grass clippings into the bag. These blades also provide higher suction, which means that they cut the grass at a more consistent height by pulling the grass up straighter.

Mulching Blades and Gator Blades

Mulching blades and gator blades both provide even more suction and cutting power in order to process the grass into smaller pieces. Of the two blade types, mulching blades are gentler. They process clippings into smaller chunks to distribute back over your lawn to act as a protective layer over the top soil.

However, mulching blades are not typically a good idea if you’re trying to bag your grass clippings at the same time. They just don’t move the clippings toward the bag very effectively.

Gator blades process the grass clippings even smaller than mulching blades. They are designed to get the clippings small enough to eventually mix into the top soil of your lawn where they will decompose and replenish the soil.

My Final Thoughts On Which Side Of The Lawn Mower Blade Is Up

Knowing which side of your lawn mower is up might seem like a simple thing, but it’s incredibly important. Choosing the right side of your lawn mower blade will help maintain the health of your lawn and can even reduce the maintenance on your lawn mower itself.

Learning how to install your lawn mower’s blade properly shouldn’t be difficult, but it is an important step if you want to keep your lawn mower in good condition. Hopefully this guide will help you decide which kind of blade is right for your lawn, and learn how to install it successfully.