Lawn mower drill team. H541Air Hoe Drill

H541 Air Hoe Drill

John Deere has the seeding solutions that go above expectations with a complete line of everything needed in small grains. Offering a variety of openers for your chosen practice in a variety of configurations and sizes. All with integrated technology throughout the seeding train allows for effortless setup and seamless documentation.

Total seeding solution

Setting up a John Deere seeding train is quick and easy with the plug and play technology. All data and technology operate through the Gen 4 display and ultimately up to John Deere Operation Center™ that can be viewed from anywhere at any time. Not only does the complete John Deere seeding solution all operate through one display but it eliminates the difficulty and time-consuming tasks of setting up extra displays and harnesses.

John Deere tractor paired with John Deere tool and cart

With a complete John Deere seeding solution, there are multiple different onboard and offboard technologies shown below that improve the overall seeding production step. Many of these technologies are exclusive to John Deere. Each of these technologies bring different customer value that overall lead to the ultimate John Deere seeding solution!

On the go, quick adjust downforce with TruSet™ from the cab

- Adjust downforce pressure to improve uniform emergence

- Set presets to quickly adjust from field to field

TruSet downforce display

DIY Electric Drill Start for a Lawnmower

Monitor blockage row by row from the cab with RelativeFlow™

- Seed with confidence while monitoring each row

- Detect blockage early and know exactly where it is

RelativeFlow blockage sensors

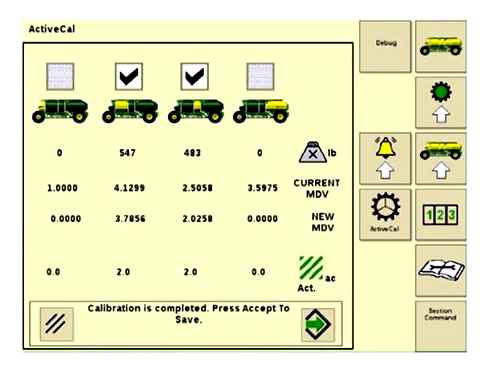

ActiveCal™ display

- Calibrate the meters from the cab utilizing the tank scales

- Improved confidence the correct seeding rates are being met

ActiveCal display

SectionCommand™ controls seed and fertilizer output

- Controls seed and fertilizer output by closing and opening gates on the meters

- Minimize skips and overlaps leading to reduced inputs

Example of seeded field with SectionCommand

Drill Start your mower ( no more pull start!)

AutoTrac™ Implement Guidance and AutoTrac Turn Automation

- Make every operator an experienced operator

- Precisely placed implements for more accurate seeding, less operator fatigue, and more productivity

- Hands-free turns within field headlands (with AutoTrac Turn Automation enabled)

AutoTrac Turn Automation display

John Deere Operation Center™

- Setup and manage your farm operations: equipment, team, fields, and crop inputs

- Plan work in advance to increase job quality and efficiency with Work Planner

- Map based prescriptions can be used with variable rates

- Analyze this season’s results to improve next season’s crops

John Deere Operation Center web and mobile

Operation Center Mobile

- View your data on the go; remotely monitor job quality, productivity, machine performance, and quickly make informed decisions

- Manage and monitor from anywhere at any time with near real-time field and machine updates

Operation Center Mobile

Connected Support

- Expert Alerts proactively notifies your dealer of any issues

- Remote display access allows for easy on the go support

Connected Support

For more information regarding Large Tractors and Precision Ag, view the following landing pages

Flexible frame allows for consistent seed depth

Seed depth uniformity

Diagonal frame flexibility keeps openers engaged

Producers are more attuned to the importance of seed depth than ever before. A uniform-looking field is not the only goal; yield is too. Proven yield penalties across the world range from 5 percent to 25 percent, depending on depth variance.

The H500 and H500F feature diagonal mainframes and wing flexing – helping openers maintain their depth over uneven terrain.

Side-to-side flexibility demonstrated by H500

The life requirement of these robust machines is four times longer than previous models. That is why the John Deere seeding group has built even more durability into the H500 and H500F Air Hoe Drills.

An advanced and rigorous testing program has proven the machine durability to the extent that John Deere now offers a three-year frame warranty with each H500 and H500F that rolls out of the factory.

Robust ball joints

Cast rank tube connectors

Robust ball joints connect strong fore-aft tubes to 100-mm x 100-mm (4-in. x 4-in.) rank tubes, which are joined to one another by pivoting rank connectors. Both the mainframe and wing sections share this durable construction that enables the frame to flex diagonally, relieving stress on solid frame members and avoiding frame failures.

Seed Smart with confidence that the H500 and H500F will endure the field conditions.

Control the depth of seeding with TouchSet™

Setting depth is one of the most critical adjustments an operator will make to a seeding tool. John Deere understands every operator needs dependable, repeatable depth control that is easily adjustable. That is why John Deere provides a choice of two depth control options on the H500 and H500F.

Mechanical depth shims are repeatable and reliable

Adjusting mechanical depth shims

Often-heard are Комментарии и мнения владельцев from producers who say they prefer the positive mechanical depth control offered by the 1820. This popular concept is base equipment on the H500 and H550 air hoe drills.

Two indexed depth shim packs on the mainframe are not only easy to set, but reduce the number of adjustment sites over previous designs by up to 60 percent.

Less time adjusting means more time seeding.

TouchSet™ depth control

Changing field conditions such as moisture levels and soil types can make setting depth a challenge. TouchSet depth control makes adjusting depth in response to changing field conditions easy and profitable. On 8R and 9R Series tractors, the operator uses selective control valve (SCV) #1 and the SCV TouchSet control panel to perform all the depth control functions from the seat. Considering yield penalties of 5 percent due to seeding 2.5 cm (1 in.) too deep or too shallow, the convenience of in-cab adjustment pays nicely.

NOTE: Repeatability is /- 6 mm (0.25 in.) to preset depth. If your seeding operation requires accuracy greater than /- 6 mm (0.25 in.), the use of shim packs is recommended.

How does it work? The operator uses the TouchSet (SCV setup panel) to set or change the operator depth.

With the implement nine-pin connector connected to the tractor, start the tractor; a P will appear in the window of the control panel under SCV #1.

After operating depth is measured at the ground engaging tool and the desired depth obtained, press the lower set button on the control panel. That depth is now set.

Implement raise height selection uses the upper set button on the control panel to preset the distance the implement is raised above the operating depth.

Preset the raise height to:

Remote position sensor

A remote position sensor (1) is located at the rear of the drill; electronically monitors the positions of the implement.

An electrical connector is used for easy hookup of TouchSet depth control sensor on the implement to the tractor system (8R Tractor illustrated).

Ground-engaging openers provide benefits of low-disturbance seeding

Knife bodies and points

Knife body

Knife body with 10.2 cm (4 in.) point

Many producers enjoy the moisture-saving benefits of low-disturbance seeding. To make it easier for them to reap the rewards of low-disturbance seeding, factory-installed knife bodies are available for H500 and H500F Drills.

The knife bodies are available in 2.5 cm (1 in.) or 10.2 cm (4 in.) spread points.

Use the 2.5-cm (1-in.) point for low disturbance or, if a wider spread pattern is desired to increase seedbed utilization, use the 10.2-cm (4-in.) point. The points can be quickly changed with a single roll-pin fastening system and feature carbide tips to ensure long life.

The knife bodies also feature a positive hose retention system with provisions for a hose clamp to hold the hose in place.

These knife bodies may not perform as designed in wet, sticky soil conditions.

NOTE: Points and roll pins are not included. Points and roll pins are available through Service Parts.

Perma-Loc™ spoons and sweeps

Perma-Loc spoons and sweeps from John Deere offer reduced maintenance because the Perma-Loc design enables a change-out up to five times faster than traditional bolt-on components.

They also offer cost savings because with Perma-Loc spoons and sweeps, there is no more purchasing hardware each time spoons are changed out. This can save 309 USD list price when changing out the spoons on a 18.3-m (60-ft) tool with 19-cm (7.5-in.) spacing.

Save time and money and seed Smart with John Deere Perma-Loc spoons or sweeps.

10.2-cm (4-in.) Perma-Loc spoon

10.2-cm (4-in.) Perma-Loc spoon

Shown is the 10.2-cm (4-in.) Perma-Loc spoon; 7.6-cm (3-in.) spoons are also available.

Spoons are not included in base price and must be ordered separately.

Below is the seedbed profile that can be expected if using a 10.2-cm (4-in.) spoon in conventional tillage with the H500F Separate Fertilizer Placement (SFP).

10.2-cm (4-in.) Perma-Loc spoon

- Tilled soil

- Disturbed soil packed over seed row

- 25.4 cm (10 in.)

- Separate fertilizer placement nitrogen

- 10.2 cm (4 in.)

- 50.8 cm (20 in.)

- Seed

- Seed-placed phosphorus

30.5-cm (12-in.) Perma-Loc sweep and boot

Seedbed profile. H500 and 30.5-cm (12-in.) Perma-Loc sweeps

- Disturbed soil packed over seed row with 14-cm (5.5-in.) semi-pneumatic packer

- 25.4 cm (10 in.)

- Tilled soil

- Seed-placed phosphorus

- Seed-placed nitrogen

- Seed

- 17.8 cm (7 in.)

- Seed floor created by sweep

Perma-Loc removal tool

Perma-Loc removal tool

This handy Perma-Loc removal tool should be ordered for each drill ordered with Perma-Loc components.

High-productivity sweeps easily moves through tough residue giving growers confidence

High-productivity bolt-on sweep

High-productivity Perma-Loc™ sweep

The high-productivity sweep from John Deere was developed to meet current tillage practices and compete in the high-productivity, high working speed market. Thanks to its low profile, curved wing shape, the high-productivity sweep:

- Performs best at a speed of 11.3 km/h to 16.1 km/h (7 mph to 10 mph)

- Easily moves through tougher and higher volume residue

- Retains its shape and width during its wear life

- Wear life is longer than Tru-Width™ sweeps and equal or better than competitors

- Excellent weed control performance

The high-productivity sweeps for the John Deere H500 Air Hoe Drill comes in 178-mm (7-in.), 229-mm (9-in.), and 254-mm (10-in.), and 305-mm (12-in.) widths, both in the bolt-on and the Perma-Loc version. They fit all 47-degree standards with 44.5-mm (1.75-in.) hole spacing and 11.1-mm (7/16-in.) that currently take Tru-Width sweeps, both John Deere and other makes.

The high-productivity Perma-Loc style sweeps use the current Perma-Loc adapter for 47-degree curved standard N237614. Tru-Width sweeps with the Perma-Loc adapter can seamlessly move the high-productivity sweeps.

The high-productivity sweep also exerts less draft than Tru-Width and major competitors, reducing engine horsepower requirements and diesel consumption.

Air hose routings increase hose life and reduce downtime

Pinched hydraulic hoses lead to costly downtime. John Deere is aware producers expect machine reliability and a visually pleasing appearance when investing their hard-earned money in a new seeding tool. That is why the John Deere seeding group has placed extra emphasis on securely routing hydraulic hoses on the H500 and H500F.

P-clamp

D-ring

All H500 and H500F frames are manufactured with weldments to accommodate hose securement sites like the P-clamp and D-ring shown above.

Velcro strap and protective sleeve

Innovative solutions like this Velcro® strap and protective sleeve ensure the reliability of the H500 and H500F measure up to John Deere standards. A machine-down repair that takes two hours to fix can mean over 20 ha (49 acres) of lost seeding time.

At a custom rate of 12 per hour, that is at least 600 of lost revenue, or lost yield, if seeding is delayed past mid May (wheat) for many locations.

Velcro is a trademark of Velcro Industries B.V.

Reduce transport height

Transporting large machines on public roads can be a little stressful. Passing motorists, mailboxes, overhead lines, and trees can all contribute to potential hazards.

With so much to FOCUS on, the H500 Air Hoe Drill operator should not have to worry about openers engaging the pavement when lowering a machine to clear an overhead obstacle.

With the optional transport height reduction feature, the operator does not need to worry. This handy feature can also serve to set the height for storage inside.

How it works

Transport height reduction assembly

Simply setting the pin in the appropriate hole will stop the machine from lowering when the openers are a safe distance above the pavement.

The operator can FOCUS on the overhead obstacle and other hazards such as passing motorists near the machine. This can prevent a potentially damaging encounter with the road surface or even an accident.

How to Charge Your Lawn Mower Battery, Power Tools and

Behind every healthy lawn is a healthy lawn mower battery.

Actually, every house project relies on batteries. The drill you used to hang the TV runs on a battery. So does your cordless sander. Batteries take your tools farther than any cord, as long as they’re healthy.

Here’s how to get more life out of your batteries.

Why you should charge your lawn mower battery before spring

You can get years more out of your lawn mower battery, if you follow two simple steps:

Your riding lawn mower comes with the same essential parts a car has. It has an internal combustion chamber, an alternator, a 12-volt lead-acid battery, etc. A riding lawn mower with an especially small engine may have a 6-volt battery. The lawn mower‘s alternator keeps its battery charged. A few hours of mowing recharges it the same way hours of highway driving can keep your car battery mostly charged.

You might not mow the lawn in winter.

That means your lawn mower battery may be totally drained.

Lead-acid batteries drain themselves when they’re not used. That’s bad news. They need to stay charged or they’ll lose the ability to hold electricity. You can try to charge them if that happens. Still, they may be too weak to start an engine.

How much longer will your lawn mower battery last?

Let’s check! Bring your lawn garden battery to any Interstate Batteries ® location for a battery test. Let’s see how many summers your battery has left.

Lithium-ion batteries drain themselves, too, when they’re not in use, just not as quickly. Keeping your rechargeable lawn mower fully charged for months isn’t healthy for the lithium-ion battery inside. Letting it drain to zero percent damages it, too.

Whether your lawn mower uses a lithium-ion battery or a lead-acid battery, charge it in January or February. Charging your lawn mower battery keeps it healthy for years.

- Leave the battery in the mower. You don’t have to uninstall the battery to charge it.

- Clean the terminals. Use baking soda and a dry cloth.

- Check the voltage and amp settings. Your battery’s label will say if it’s lithium-ion or if it contains lead. You’ll also see if it’s 12 volts or 6 volts. Set the charging amps to less than 2 amps if the charger has the settings for it. Charge slowly to protect the battery.

- Follow the charger’s instructions. The manual gives you any other steps your charger needs.

- Last-minute safety check. Take off jewelry. Put on gloves and safety glasses. Make sure there’s decent airflow around you.

steps to charge your lawn mower battery

A trickle charger makes it easy to keep your lawn mower battery ready. It charges lead-acid batteries for days at a time to protect the battery’s lifespan. You could leave your lead-acid lawn mower battery on the charger all winter long if it has a float setting. The charger will top off its charge for months and keep it from losing power while it sits on the shelf.

A Smart charger will recharge a lawn mower battery in hours. Adjust the voltage and amp settings if you’re charging a 6-volt lawn mower battery instead of a 12-volt one.

Want to protect your lead-acid lawn mower battery? Keep it 100 percent charged.

Want to protect your lithium-ion lawn mower battery? Leave it 70 percent to 80 percent charged while in storage. Being fully charged or totally depleted hurts lithium-ion batteries. Check the manual for charging instructions.

Need mower power? Start with Interstate ®

We’re the reason the grass is greener. Pick up an Interstate lawn garden battery to power up your lawn mower, clipper or tree trimmer.

The nice part is you can just recharge your lithium-ion lawn mower if it doesn’t start. You’ll never need to jump-start a riding lawn mower with a lithium-ion battery.

Now, you can jump a lawn mower if it has a lead-acid battery. Aquí le enseñamos cómo.

How you can safely jump-start your lawn mower battery with your car

You can jump your lawn mower with your car. It’s the same steps as a regular jump-start — with three big differences.

- Turn off the car before connecting cables to your lawn mower. The car’s alternator generates too many amps and can damage the mower’s parts, including the battery. Never jump-start a lawn mower battery from a running car. Don’t even leave the key in the ignition.

- Protect the positive cable from touching anything but the battery terminals in the car and mower. The positive cable is usually the red one. You’ll connect it first to the mower, then the car. Otherwise you could damage your car battery.

- Run the mower for at least two hours after disconnecting the cables. John Deere, Ryobi, Cub Cadet — all gas-powered riding lawn mowers have an alternator. Mowing will charge their starting battery.

Jump-starting should be the last resort. Wait if you can. Connect your lawn mower’s battery to a charger. Then do a different home project with your other power tools.

Time to talk about your other power tools.

Tips to make your power tool battery last longer

Take care of your power tool batteries, and your tools will be ready any time you need them.

Power tools run on three different types of batteries:

- Nickel cadmium or NiCd batteries

- Nickel-metal hydride or NiMH batteries

- Lithium-based, including lithium-ion or lithium-polymer batteries

Now, each battery type needs different care. It’s easy to assume one tip for one battery type will work for all batteries. The truth is each battery type needs something different.

Attention! This is not a drill!

Is your cordless drill turning into a screwdriver? Don’t toss your power tool. Let’s rebuild its battery instead. Available at select Interstate All Battery Center ® locations, we put the power back in your power tools.

You might be reaching for a screwdriver sooner than you expect if you give your cordless drill the wrong kind of TLC.

The right way to care for your NiCd battery

A NiCd battery needs to be run hard. Charge it up and drain it to zero percent every month or two. Then store your NiCd battery when it’s fully drained.

NiCd batteries are one of the few types that like being stored on empty. They also drain themselves quickly when they’re not in use. Don’t bother recharging it if you only used it for two minutes.

Fast charging doesn’t stress a NiCd battery. So put it on the charger right before you run your leaf blower or cordless sander. Then use every bit of energy before putting it back.

Sitting on a charger can damage a NiCd battery. Its insides can crystalize and resist turning back into electricity. That might be why your NiCd battery doesn’t last as long as it used to. A pulse charger can heal your NiCd batteries if you’ve kept it charged too long. You might not get the battery back to perfect health, though.

Instead, keep fast-charging your NiCd battery and draining it to zero.

Exercising it protects the material and gives your cordless power tool batteries a much longer lifespan.

The right way to care for your NiMH battery

A NiMH battery needs to stay out of the heat, to charge with its original charger and to be drained to zero percent every few months.

If you’re using your power drill for a few hours every day, a NiMH battery is perfect. NiMH batteries are handy for power tools. They weigh less, carry more power and last longer between charges than a NiCd battery.

They don’t do well in storage. NiMH batteries will drain themselves. It’s not as quick as a NiCd battery. All the same, you’ll want to use your NiMH-powered drill every other day to get the most life from the battery.

Recharging NiMH batteries uses a special algorithm. Don’t use a NiCd charger on a NiMH battery. It can hurt the battery’s lifespan if not overcharge it. Keep the charger that came with the power tool. You can replace it, but make sure it’s specifically made for NiMH batteries.

Mow power to your lawn mower and weed whacker battery

You just jumped your riding lawn mower? Might be time for a new battery. Go for lawn garden batteries and power tool rebuilds, available at select Interstate All Battery Center ® locations.

NiMH batteries struggle with heat. That’s a problem because a NiMH battery will heat up as it runs power or charges. Be gentle with it. Take it off the charger early if the case feels warm. Also, let it cool down before you recharge after it charges.

You can expect a long, full life out of your NiMH battery by keeping it in use and near its original charger.

The right way to care for your Li-ion battery

Lithium-ion batteries weigh the least and offer the longest life overall, but they’re sensitive to getting dropped, overheated or overcharged. How you protect your phone battery would work on your lithium-ion power drill:

- Keep it away from heat.

- Don’t leave it on the charger.

- Don’t let it ever run down to zero percent.

Store a li-ion battery at 80 percent power, not 100 percent. This battery type doesn’t drain itself that quickly. It’ll hold charge for weeks.

The way to take care of your lithium-ion battery is to charge it before it drops to 20 percent. Keep it charged between 40 percent and 80 percent. You can top it up to 100 percent before you sand the deck or trim the hedges. Just don’t leave it fully charged.

Staying at 100 percent corrodes the active materials, which means the battery can’t hold as much electricity as before. The same happens if it ever drains to zero, but faster. Check the power level while you work. Stop and recharge it if you’re close to 25 percent left.

Take care of your lithium-ion battery, and it’ll keep powering on.

Leaving your power tools on the charger does not help the battery.

Trying to charge a battery that’s already full can damage it. Most battery chargers will stop charging if the battery is full.

The built-in protection means it should be safe to leave it on the charger, right? Not quite.

Only lead-acid batteries like to stay fully charged. The other battery types need exercise. They’ll drain themselves, even if sitting on a shelf. That’s okay, depending on the battery type. All battery types need exercise. Leaving them on the charger robs batteries of that exercise.

A battery on the charger will go through short run-and-recharge cycles. It’ll drain to 99 percent, recharge, drain again and recharge again. Those short cycles hurt most batteries. Instead, your power tool batteries need to keep the electrons flowing.

Consider it another good reason to do those house projects today.

Revive your power tools.

All rechargeable batteries wear down. But you don’t have to throw out your favorite tool! Rebuild its battery at select Interstate All Battery Center ® locations.

Sharpening Services in York County, PA

Cooke’s Sharpening and Grinding Service is your go-to source for a full range of products and tools. Whether you need to renew your kitchen knives or need lawn mower blade sharpening in York County, PA, we have you covered. Our team will sharpen or grind anything you bring in!

Tools

When your tools are dull, the job is twice as hard. Why not cut down on the time and effort by bringing your tools to us? A quality saw sharpening in York County, PA will make your next lumberjack job a cinch. If you’re working on more detailed projects, our services make your precision tools precise again. When we return your tools, you’ll be amazed at how much smoother your next project flows. Contact us today to sharpen:

- Axes

- Circular blade saws

- Dado blades

- Drill bitts

- Garden tools

- Handsaws

- Hatchets

- Lawn equipment

- Machetes

- Saw blades

- Woodworking tools

Knives

Whether you are carving chicken in the kitchen or your most recent catch in the wild, a dull knife can make the job extremely frustrating. Cut down on your hassle by allowing us to restore your knives to like-new condition. There’s no need to buy a new set. Bring them to our professional sharpeners today. We work with:

Small Engine Repair

Is your lawn mower unreliable? Do you have other equipment that could use some TLC? For expert small engine repair, contact the experienced team at Cooke’s Sharpening and Grinding Service. We’ll make the necessary repairs, and, if your product needs blade sharpening, we can do that too!

Sharpen Your Finishes

Cooke’s Sharpening and Grinding Service is ready to save you time and money by renewing your tools. Bring us anything you need sharpened, and our expert team will assist you. Stop in today or reach us at 717-792-8245.

If you don’t find the tool you would like sharpened on here, please feel free to contact us about anything else you need sharpened!

The Best Reel Mower for Your (Small) Lawn

We’ve reviewed this guide, added competitors, eliminated older models, and reconfirmed our decisions on our picks.

Reel mowers aren’t for everyone. They’re designed for small, flat lawns, and they take some effort to push around. But they provide exceptional cut quality and a completely unplugged mowing experience, so they offer things no other mower can. We think the best one is the Scotts 2000-20 20-Inch Classic Push Reel Lawn Mower.

For the healthiest grass

The Scotts makes the cleanest cut, has the widest cutting path, and jams the least of any reel mower, and its unusually tall 3-inch max cutting height makes it more versatile for different grass types.

Buying Options

At the time of publishing, the price was 145.

During initial tests with a golf course grounds crew and in years of follow up use, the Scotts-branded mower has the best cut quality of any of the mowers we’ve tested, and its unusually tall maximum cutting height of 3 inches makes it a versatile choice for different types of lawns and grasses. It has a 20-inch cutting swath—the widest available—and at 34 pounds, it’s light and easy to maneuver. It was also the only mower in the group that didn’t jam during testing.

Good cut, less elegant

This mower cuts almost as well as our main pick and has a taller cutting height, but it’s bulkier (making it harder to turn around) and more expensive.

Buying Options

At the time of publishing, the price was 250.

If our main pick is sold out or otherwise unavailable, we also really like the Fiskars 18-Inch StaySharp Max Reel Mower. Its a solid mower with a 4-inch cutting height is higher than any other reel mower’s. In testing the Fiskars cut well, but it wasn’t on par with the Scotts and didn’t handle tall grass quite as well. It’s also heavier and bulkier, making it more of a chore to turn around, it also costs more than the Scotts.

For the healthiest grass

The Scotts makes the cleanest cut, has the widest cutting path, and jams the least of any reel mower, and its unusually tall 3-inch max cutting height makes it more versatile for different grass types.

Buying Options

At the time of publishing, the price was 145.

Good cut, less elegant

This mower cuts almost as well as our main pick and has a taller cutting height, but it’s bulkier (making it harder to turn around) and more expensive.

Buying Options

At the time of publishing, the price was 250.

Why you should trust us

We spoke with Jason Kruse, assistant professor of environmental horticulture and turfgrass specialist at the University of Florida. As his bio states, Kruse’s responsibilities include “managing the University of Florida turfgrass Envirotron teaching and research facility, planning and implementing turfgrass educational field days and leading the statewide turfgrass teaching design team.” The guy knows a lot about grass.

For testing, we enlisted the aid of the grounds crew of the Diamond Hawk Golf Course in Cheektowaga, New York, a bunch of people who are serious about mowing. While using the mowers, they picked up cut blades to carefully examine how cleanly the mowers cut; they also bent down to compare the color of the turf after each one made a pass, and pushed all the mowers around on various lengths of grass.

Here at Wirecutter, we’ve been covering lawn equipment since 2014. As for the specific topic of grass-cutting implements, we’ve written extensive guides to both lawn mowers and string trimmers in addition to reel mowers.

Since the first version of this guide, we’ve recommended the Scotts as well as the runner-up Fiskars, and we’ve continued to use both models in assorted locations, paying attention to their long-term performance and any ongoing maintenance needed.

Who should get a reel mower

Before getting a reel mower, you should be aware of their pros and cons. Simply put, a reel mower is not a direct replacement for a regular mower.

As one of our long-term testers said, “I love [my reel mower]. It makes mowing feel more like a pleasant way to spend time outside and less like something I need to grit my teeth and power through.” On the other hand, a second long-term tester stated that he regrets purchasing a reel mower and has “frequently considered selling it to get a cheap electric mower.”

Reel mowers are better for the lawn’s health. They snip the grass blades like scissors, while rotary mowers tend to shred grass blades. According to University of Florida assistant professor of environmental horticulture Jason Kruse, “The scissor-cutting action of the reel mowers results in less damage to the leaf tissue, which in turn puts the plants under less stress.” He continued, “They lose less water, are less susceptible to disease, and generally look better when cut with a reel mower.”

Reel mowers are also good for the operator’s health. Because you hand-push the mower and it isn’t motorized, it takes effort to use, especially if you have a large lawn. Keep in mind that the turning wheels are what rotate the blades, which adds to the resistance. So the task is not as simple as, say, pushing an empty furniture dolly, where you’re pushing the wheels and nothing else. According to a Livestrong.com article, (which in turn credits Harvard Medical School, among others) a person weighing 175 pounds would burn approximately 251 calories by pushing a reel mower—which the article refers to as a hand mower—for 30 minutes. This is 51 calories more than someone weighing 185 pounds pushing a mower with a powered blade for the same amount of time.

Reel mowers also require minimal maintenance and are much, much quieter than regular mowers. Aside from lubricating and sharpening the blades every few years, you don’t have a lot of upkeep to do on a reel mower. As for the noise, many users of reel mowers cite the gentle snipping sound the tool makes as a key benefit. Gas mowers, on the other hand, require gas, regular tune-ups, oil changes, and winterizing. They’re also noisy and smelly. As one of our long-term testers said, “I love [my reel mower]. It makes mowing feel more like a pleasant way to spend time outside and less like something I need to grit my teeth and power through.”

But for a reel mower to be practical, you need a fairly small lawn. Anyone with more than a quarter acre (roughly 10,000 square feet) will find weekly mowing with a reel mower exhausting. One long-term tester stated that he regrets purchasing a reel mower for the size of his lawn and has “frequently considered selling it to get a cheap electric mower.”. In contrast, another of our long-term testers has approximately 1,000 square feet of lawn, and mowing takes her about 20 minutes.

A reel mower works best with a strict adherence to a regular cutting schedule. If grass gets overgrown, a reel mower will merely push it down and roll right over it, so if you tend to go a while between mowings, you should stick with a regular push mower. One long term tester had to wait so long for the reel mower to arrive that once it got there, the grass had grown so high they needed to hire someone to cut their grass. And the necessary diligence goes beyond the schedule: Reel mowers can’t mow over twigs and leaves as gas mowers can, so additional attentiveness to pre-mow lawn cleanup is required, as well.

Reel mowers are troublesome on sloped or bumpy lawns. The torque that turns the blades comes from the wheels as you roll them along the ground. On an uneven surface, the wheels lose contact with the ground as they bounce or as the weight shifts on a slope. As one of our long-term testers put it, “Small dips can lead to grass getting missed, so I often end up mowing from two or three different angles to try and get it all.”

In fact, the results in general may not be what you expect. One of our long-term testers said that their mower “often totally misses taller strands of grass” and that they “have to go back and snip those with a pair of shears.” Also, on most reel mowers, the blades are inboard of the wheels, so you’ll have a wider gap of unmowed grass against a fence or a stone wall.

How we picked and tested

To figure out how to pick the best reel mower, we spoke to Scott Dunbar, superintendent of Diamond Hawk Golf Course in Cheektowaga, New York. He explained that reel mowers can cut much closer to the ground than rotary mowers. At the golf course, the crew uses reel mowers to cut greens and approaches but uses gas-powered rotary mowers for the rough. But the average homeowner isn’t cutting the lawn for use as a putting green—in fact, cutting your lawn too low is terrible for its health. Turf experts suggest never cutting off more than a third of your grass’s length; cutting too close to the ground can cause the grass to dry out and get scorched in the summer. This means that a mower’s minimum cutting height isn’t a useful measurement, since you’re unlikely to use that setting.

The maximum cutting height was a crucial detail. We used this spec as our primary factor in eliminating mowers from contention. Few reel mowers are able to get above 2½ inches, which may not be good for your lawn. “[Cutting height] is one of the primary complaints I have against the majority of reel mowers that are marketed for home use. Most residential grasses (both cool- and warm-season) have recommended heights of cut that are at the upper limit or even exceed the height of cut that is possible with some of the mowers,” said University of Florida turfgrass specialist Kruse. “While it would be possible to use the mower, the long-term health of the turf could suffer significantly,” he continued.

Other factors were also important:

- How easy is the mower to adjust?

- How hard is it to push?

- How wide is it?

- How much does it weigh?

- What have other reviewers said about it?

We took our final four mowers to a golf course. There the grounds crew helped us adjust the blades to the exact same standard they used on their mowers so that the blades could cleanly slice a piece of paper. Over the next three hours, we pushed all four mowers back and forth on different-height grasses. On hand were course superintendent Scott Dunbar, a member of the grounds crew, a mechanic who maintains the course equipment, and an equipment salesman who happened to be at the course that day. These guys are all turfgrass experts who deal with grass and mowing equipment every day. They really took to the task of comparing these mowers, examining every aspect closely and answering all our questions about turf and cut quality.

Our pick: Scotts 2000-20 20-Inch Classic Push Reel Lawn Mower

For the healthiest grass

The Scotts makes the cleanest cut, has the widest cutting path, and jams the least of any reel mower, and its unusually tall 3-inch max cutting height makes it more versatile for different grass types.

Buying Options

At the time of publishing, the price was 145.

The Scotts 2000-20 20-Inch Classic Push Reel Lawn Mower is the reel mower to get. Of the tested mowers, it offered the cleanest cut and the easiest adjustments, and it was the only one that didn’t jam. It also has a wide, 20-inch cutting swath—the widest we found—as well as height adjustments between 1 and 3 inches, which is a more versatile range than we saw on almost all of the other available reel mowers. At 34 pounds, it’s light and easy to turn around at the end of each mowing row, but it’s heavy enough that it doesn’t bounce around on slightly uneven turf.

The quality of the cut excelled against the competition. When our lawn experts were going back and forth with the mowers on a variety of grasses and lengths, they noticed that the Scotts model would leave a swath of totally trimmed grass with each blade snipped evenly across, no ragged edges to be seen. In contrast, the other mowers would leave a bunch of blades sticking up like chimneys after a house fire, requiring the testers to back up and go over the area again. The Scotts mower also never jammed up during testing, whereas all of the other mowers did.

The Scotts 2000-20 also snipped a wider path than most of the others. The Scotts is a 20-inch-wide mower, the widest size available (the measurement refers to the blade width, not the overall width). We tested another 20-inch model, the Lee Valley 20″ Mower, but that one was harder to push, and its cut quality was worse.

Our testers also gave the Scotts 2000-20 high marks for overall usability. At 34 pounds, it lands in the middle of our test group in weight but manages to hit the sweet spot between maneuverability and stability. The Fiskars StaySharp Max is heavier and harder to turn around at the end of a mowing row; by contrast, the lighter Lee Valley model bounced around on uneven ground and left a ragged cut as a result.

All of the adjustments on the Scotts mower are easy to make. For cutting height, it has two levers, one for each wheel. One other model we tested, the 16-inch Great States 415-16, required us to unbolt it each time we wanted to change the cutting height. Also, the height settings on the Scotts model are accurate; the 1-inch setting on the Fiskars, in contrast, actually cut much lower, practically scalping the lawn, before we readjusted it to a higher setting.

The Scotts 2000-20 has a cutting range of 1 to 3 inches. The vast majority of reel mowers top out around 2 inches, so we appreciated the ability to go taller, either for the health of the grass or for a less manicured look. A DIY Network article lists the ideal cutting heights for a variety of warm- and cool-weather grasses, and the capabilities of the Scotts land nicely in the strike zone for every grass mentioned. Our runner-up, the Fiskars StaySharp Max, has an even higher maximum cutting height at 4 inches, but it’s a much heavier mower with more difficult maneuvering, and it doesn’t cut as nicely.

The Scotts is easy to assemble, and doesn’t require any tools. The bolts that attach the handle have large plastic wing nuts, so tightening by hand is simple. If you ever need to take your mower apart—to fit it into a compact space like a car trunk or a small storage area—we found that the Scotts was easy enough to disassemble, too. You might need pliers to remove the small C-clips that attach the handle to the body of the mower, but otherwise it shouldn’t be a hassle.

Scotts stands behind their products. Erin Price, then Wirecutter’s Audience Development Manager, had a wheel fall off her Scotts push mower and the company replaced the entire mower for her. She told us, “I love my reel mower and perhaps love it even more now that the company was so helpful.”

It has performed well in long term testing. Two other Wirecutter staff members, who both happen to be women, also have Scotts Classics in their personal tool sheds, and they appreciate the mower’s simplicity and ease of use. Senior Photo Editor Rozette Rago had never used a reel mower before picking up the Scotts for her small, flat yard in LA, and found it quick to get used to. It was easy to figure out for two people who have never used it before. Wirecutter Producer Beth Niegelsky, who has used both the Fiskars and the Scotts, prefers the latter, “ I actually like the Scotts significantly more because it is SO much lighter.” She explained, “With the Fiskars, I basically couldn’t mow the hill of my front yard without feeling like I was doing something dangerous. It’s basically no problem with the Scotts.”

Senior Software Development Engineer Joshua Brewer had the Scotts for three years and recently replaced it for our lawn mower pick. Throughout his three years of usage, he highlighted that the Scott was “kinda fun to use.” He appreciated that it was easy to storetash, didn’t require fuel, and was quieter than a traditional lawn mower. However, the Scotts did squeak despite thorough maintenance, required multiple passes on his lawn, and his foam handle disintegrated after the first year. Overall, Brewer says The Scotts 2000-20 worked, but was much more laborious to use with a lush and dense lawn and worked a lot better when the lawn was more sparse. He’s much happier with the Ego LM2135SP now.

Supervising Editor Josh Lyon also has a Scotts and said there are bumpy parts of his lawn that he needs to go over one or two additional times, but that “the mower is so light and has such a smooth roll that even with the extra passes it takes half the time to do our entire lawn than with the gas-powered mower we used to have.” Overall, Lyon is very happy with the Scotts and says he’ll never go back to a gas mower.

Finally, even though it wasn’t a major factor in our decision, testers liked how the Scotts looked better than the other mowers (some found the Fiskars model’s oddball form to be off-putting). The Scotts 2000-20 is covered by a two-year warranty, and user reviews suggest that the manufacturer, American Lawn Mower, issues free replacement parts whenever a problem crops up.

Flaws but not dealbreakers

We analyzed the negative Комментарии и мнения владельцев at Amazon and found that most of the complaints center on the aluminum handle breaking, a plastic gear in the mechanism stripping out, or simply the realization that a reel mower is not the right choice for the owner’s particular lawn.

We investigated the plastic-gear complaint by removing the wheel of the Scotts mower and taking a look at the gear. As you can see in the photo above, it’s a pretty robust gear with deep teeth, and it interfaces with the teeth on the inside of the plastic wheel. The wheels turn as you push, and those teeth turn the plastic gear, which rotates the blades. Stripping it out is an issue to be aware of, but under proper use, the gear shouldn’t be a problem. And if it becomes one, replacing the gear is a 10-minute repair job. While it would be nice if both the wheel and the gear were made of metal, such a design would likely add money to the price tag and a significant amount of weight to the mower.

One of our long-term testers also noted that when the Scotts arrived, many of the screws holding the handle together were loose and fell out within a month. Once they were replaced, no further problems surfaced.

A close reading of the user complaints suggests that owners who were using the Scotts mower on tall or tough Southern grass had the most problems, but such difficulties are likely to be common among all push mowers and not just the Scotts.