Lawn mower engine breakdown. How to Repair Small Engines

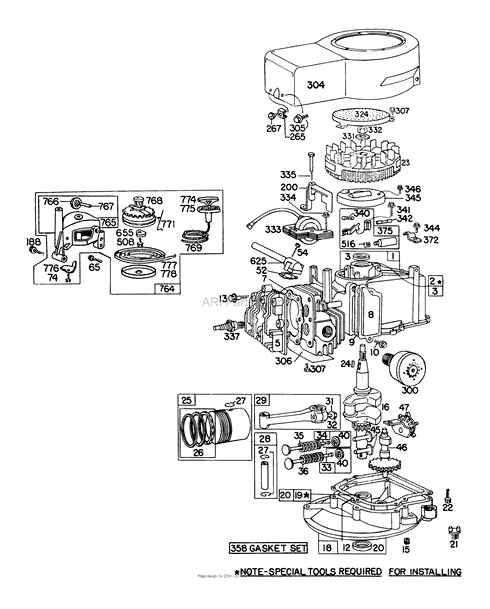

Lawn Mower Engine Disassembly

Choosing a Lawn Mower Motor Lawn mower motor, features vertical shaft asynchronous motors. How to replace a defective mower motor with a new one?

What to choose?

For large. 20-60 hectare. A lawn mower is suitable for gasoline or diesel fuel, and not electricity. If the choice still fell on a trimmer, lawn mowers with an asynchronous engine are cheaper than similar models in which a synchronous motor is built. Asynchronous lawn mowers are mainly equipped with direct drive.

The most popular trimmer of the following companies:

- Honda;

- Briggsstratton;

- Lifan;

- Dde;

- Patriot;

- Mitsubishi;

- Caiman;

- Champion.

So, Honda engines expensive. The motor itself costs from 5 to 30 thousand rubles, depending on the power. American Briggs enginesStratton, not inferior to engines from the same “Honda”, put in devices from Snapper, Ferris, Simplicity and Murray.

For example, if you are changing the motor on a lawnmower that uses a direct drive asynchronous motor, check to see if there are models compatible with yours that use a similar motor and drive. This method is good when your model is already 5 or more years old, it has been discontinued. You can try to restore your old device without purchasing a new one. Self-propelled lawn mowers require more powerful engines than non-self-propelled ones. Part of the energy is spent on the fact that the lawn mower “goes by itself” during operation.

Features of electric motors

An electric motor converts electrical energy into mechanical energy, delivering torque. Through the gearbox, this kinetic energy is transferred to the knives or a drum with line (or cord), which cuts the grass.

The electric motor itself is economical. There is no need to choose whether to burn gasoline, a liter of which in 2019 is approaching 50 rubles, or to consume 10-15 kilowatts from the outlet for the same money. And the price of an electric motor equivalent to all the same 5 “horses” is much lower. The electric motor can be operated from an outlet and from a battery. It is ideal for owners of small summer cottages with a plot of no more than a few hundred square meters.

The electric motor must be turned off every 15-20 minutes for at least 20 minutes. This will allow it to cool down. It heats up much faster under load from the mowed grass than without it. If you ignore the breaks, then such a motor will not work for a long time. Overheating motor windings will gradually burn out.

Synchronous motor

The name of this type of motor speaks for itself, and the principle of operation is as follows: the rotating structure. The rotor. Exactly falls into the oscillations of the induction field generated by the windings of the stator part. The field speed matches the rotor speed.

The power consumption of a synchronous motor is more than a kilowatt, which is explained by its complicated circuit. The rotor winding is designed for a single phase. The winding itself is powered by a direct current source, and sliding contacts. Rings and brushes. Are connected to it. Even with a significant load on the rotor axle, this motor does not reduce the rotor speed (rpm).

In lawn mowers, the motor shaft is positioned vertically. This allows it to transmit maximum torque through a gearbox or belt drive to the working drum.

Lawn mower motor: synchronous or asynchronous

Electric lawn mower. Not the simplest equipment, and if it is not purchased by a specialist (that is, not an electrician), then he is unlikely to be interested in the question of what type of engine is installed in it. The problem becomes relevant only when the engine starts to “junk”. Accordingly, it requires attention. He can:

In any of these cases, the user begins to repair or replace the engine, and then, finally, he finds out what kind of electric motor his equipment has. In order to save you from such unpleasant moments, we have selected tips on which electric lawn mower motor to choose, taking into account your capabilities and needs.

A bit of theory

Before you solve the problem of which lawn mower to choose for working on your lawn, you should know that the electric motor of a lawn mower is of two types:

- Synchronous. It is a motor in which the rotor and the magnetic field rotate at the same speed. Synchronously. Even if the rotor receives a heavy load during operation, its speed does not decrease. The engine continues to run at a stable speed. To achieve this result, sliding contacts are used. Therefore, a synchronous motor is more complex in design, and therefore more expensive in terms of cost.

- Asynchronous. A motor in which the rotor speed does not match the speed of the magnetic field. The stator and rotor are separated by an air gap, there are no slip rings. It is simple in structure, which means that it is not as difficult and expensive to manufacture as a synchronous one.

Which lawn mower motor is better, there is no definite answer. Both types of engine have their own advantages and disadvantages.

For those who do not want to delve deeply into the wisdom of electromechanics, the explanation is quite simple. Each motor has two key elements: the stator (immovable, with windings) and the rotor (movable). The current from the electrical network is supplied to the stator. A magnetic field arises in its winding, which rotates. Thanks to him, the rotor also begins to rotate. And already the revolutions of the rotor are transmitted to the shaft of the device.

In our case, on the vertical shaft on which the lawn mower cutting blade is installed. It turns out that the work of the knife directly depends on the engine speed. Stable rpm. The knife rotates just as stably and powerfully. Weak rotor speed. The knife also begins to weaken, tightens the grass. He simply “does not have the strength” to quickly and efficiently cut vegetation. In a very short way to determine which lawn mower is better, let’s say this:

But this is all a bit exaggerated, and in no way means that the induction motor is worse. An asynchronous motor is the simplest and cheapest of all those previously invented. It does not require complicated maintenance, does not get very hot, it does not have rubbing contacts. And its reliability is within the normal range, if the manufacturer is of high quality and has installed protective systems.

Electric lawn mower with synchronous motor

A synchronous motor always runs at a constant speed. Due to this factor, it is used where stable turnovers are especially needed. In lawn mowers, this moment is key and not necessary. Synchronicity is also important at high engine power. In mowers, this is more than 1 kW. The blade in synchronous lawn mowers is located on a separate shaft. This shaft is connected to the motor shaft by a belt drive. The weak point is the knife shaft bearings.

- Low sensitivity to power line voltage surges.

- Stable rotation of the cutting blade, regardless of the load.

- High efficiency and power factor.

- Complex construction.

- The brushes heat up when rubbed.

- Difficult start. To make it easier, the rotor first starts up asynchronously and then adjusts to the magnetic field.

Electric lawnmower with asynchronous motor

Currently, asynchronous motors are used more and more in lawn mowers. In this case, the knife is placed directly on the motor shaft. The result is a simple and rather reliable design. There is no rotor winding. There are no brushes. Nothing fancy and everything works fine.

- Simple construction. No maintenance needed. Easy repair.

- Low manufacturing and operating costs.

- Heats up less. Even if it heats up, it continues to work, while losing speed.

- The efficiency and power factor are lower than that of a synchronous motor.

- It is difficult to regulate the speed of rotation. Low controllability.

- Turnovers depend on the network.

- Very sensitive to voltage surges in the fixed network.

Thus, when choosing synchronous or asynchronous lawn mowers, you should be guided by considerations of either low cost, or decide which is more reliable in operation.

Spring tension

After installing the spring, tighten it. To do this, perform the following actions:

- Remove the handle from the starter cord;

- Then the rope is inserted into the reel groove;

- Tension the spring by rotating the coil in the opposite direction to the clockwise direction (winding);

- Make the required number of revolutions specified in the operating instructions for the trimmer used and corresponding to the length of the cord used;

- At the very end, the rope is threaded into the hole intended for this, located in the starter cover;

- Put the handle in place, fixing it with a knot.

If after repair the spring continues to fly, then you can get rid of this in the following ways:

- Squeeze a piece of the plate suitable in size into the groove at the location of the spring hook;

- Drill holes on both sides of the groove in the spool, into which to insert the spring hook and fix it with a wire.

How to repair a trimmer starter

Petrol trimmer starter repair may be required at the most inopportune moment. In this case, the problem can be solved in two ways: replace the broken part or change the entire unit. The latter option is more expensive. To repair the device with your own hands, in most cases, you only need a screwdriver with the appropriate tip from the tools. Repair work does not take much time and does not require special knowledge. It is enough to know the device, the principle of operation, the nuances of assembling and disassembling the starter on the trimmer in order to achieve the desired positive result.

Disassembly of the starter unit

The launch mechanism is disassembled in order to install new parts instead of broken ones in the following sequence:

- Unscrew with a screwdriver the screw fixing the pulley with the starter cover;

- Take out the spring and antennae;

- Carefully remove the pulley (you need to turn your head away or work, wearing glasses and gloves first);

- Determine why the trigger has broken;

- If the spring has collapsed almost completely, then it is replaced;

- When the spring comes out of the hook, it is installed in its original place, bending the antennae in front of this (the photographs show the laying process);

- After the spring plate is installed inside the groove, carefully twist it.

To change the spring, you must work carefully and carefully: it can accidentally burst under the influence of the force caused by installing it in place. Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges.

Mechanical repair for all types of lawn mowers

Regardless of the type of engine, the mechanical part of the scythe includes knives, a device for ejecting or accumulating cut grass and a transmission mechanism. Most often, knives fail or line ends.

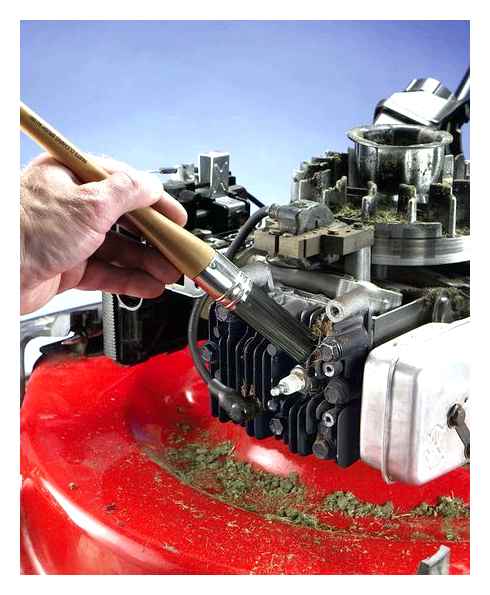

Cleaning the mechanical part of the Bosh lawn mower

Broken or bent knives are visible to the naked eye. Depending on the material and the degree of damage, the knives are replaced or restored by simply folding them back to their original state. With heavy wear, the cutting part can be sharpened. A do-it-yourself lawn mower from a trimmer can fail for many reasons. Most often this is an excess of the maximum permissible load on the torque and engine, since a knife is used instead of a trimmer line.

Restoration of the throttle handle

When inspecting, check the condition of the grass supply duct into the container and, if necessary, clean it. Complex mechanical failures require a complex tool, special equipment, professional skills and it is better to entrust the elimination of such malfunctions to professionals.

DIY electric lawn mower repair

Not only factory, but also home-made electric lawn mowers fail. The main reason for stopping the electric motor is loss of contact and lack of power at the motor terminals.

Therefore, first of all, we check the presence of voltage in the power outlet, the condition of the electrical cord and the absence of its breakage. Then, if a collector motor is used, you need to check the condition of the brushes and replace them with severe wear. The brushed hand lawnmower offers increased durability, but requires regular brush replacement.

Asynchronous motor mowers also have problems. The phase-shifting capacitor often fails, but testing it in the field is problematic. An indirect indication of a capacitor failure is:

- Jerking of the motor at the time of power supply;

- Strong heating of the engine even at low load;

- Reduced speed;

- Characteristic buzz.

Do-it-yourself electric lawn mower is made from scrap materials that can fail. If a malfunction is detected, in any case, you need to make sure that voltage is applied to the motor terminals, and in its absence. Check the operation of the switch.

If there is voltage, capacitor or brushes. Ok, the most likely cause of failure is a burnt-out winding. In this case, the unit will have to be handed over to a repair shop. Home-made electric lawn mowers most often have to be repaired on their own, since when assembling the device, all the nuances of its work are not taken into account.

Do-it-yourself electric and gasoline lawn mowers repair

Repair of both gasoline and electric lawn mowers may be necessary at the most unexpected moment. We will tell you about the main breakdowns of homemade and branded equipment, tell you what to look for, and by what signs you can recognize a malfunction.

How to Repair Small Engines

Small gas engines serve us in many ways. They power lawn mowers, tillers, cultivators, trimmers, edgers, snowblowers, chain saws, pumps, generators, air compressors, and other useful home tools. They also power our fun: outboard boats, snowmobiles, motorcycles, all-terrain vehicles, ultralight aircraft, and other toys. To keep them operating efficiently, an owner of these tools and toys should know about small engines: how they work and what to do when they don’t.

Small gas engines are made up of individual systems that work together to produce power. Each system has many components. Internal combustion gasoline-powered engines require six systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. In this article, we will discuss the systems and components that make small engines work.

Fuel and Exhaust

The fuel and exhaust systems are critical to operation. They furnish the fuel for combustion and remove exhaust gases. The following are components of a fuel and exhaust system.

Gasoline: Gasoline is a combustible liquid that burns relatively slowly. However, when sprayed as a mist and mixed with air, it is quite explosive. All it needs is a spark. Two-stroke engines require that oil be mixed with the gasoline to lubricate internal parts. Four-stroke engines use a fuel-air mixture.

Fuel Tank: The fuel tank stores fuel in preparation for mixing by the carburetor and use by the engine. Some fuel tanks are pressurized with air to help deliver fuel to the carburetor. Other tanks are non-pressurized and depend on a fuel pump to deliver fuel to the carburetor.

Fuel Line: Fuel is moved from the tank to the pump and/or carburetor through a fuel line. Pressurized fuel systems often have a squeeze bulb in the fuel line for building pressure.

Filter: A carburetor jet has a small opening that can easily become clogged. A fuel filter traps dirt and sediment from the gas before it is delivered to the carburetor.

Pump: A fuel pump produces a vacuum that pulls the fuel from an unpressurized tank, then delivers it to the carburetor.

Carburetor: The carburetor has one job: to mix the correct proportion of gasoline and air for the engine. Too much gasoline in the mixture makes it rich; too little gas makes it lean.

Throttle: The throttle controls the amount of fuel-air mixture that enters the engine from the carburetor. The throttle thus controls the speed of the engine.

Primer: A primer injects a small amount of gasoline into the carburetor throat to make the initial fuel-air mixture rich. A primer is used to help start a cold engine.

Choke: Some engines control the richness of the fuel-air mixture at startup by controlling the air rather than the fuel. A choke reduces the amount of air in the fuel-air mixture.

Governor: A governor is a device that automatically opens the engine’s throttle when more power is needed and closes it when the load is light.

Muffler: Small gas engines, especially two-stroke engines, are noisy when they operate. A muffler reduces the sound of the exhaust gases by passing them through baffles.

Spark Arrestor: A spark can exit the exhaust port of a small gas engine, potentially starting a fire on nearby combustibles. A spark arrestor on the exhaust port can reduce the chances of such a fire. Spark arrestors are especially important on chain saws, motorcycles, and all-terrain vehicles operated in dry woodlands.

Ignition

The ignition is a primary system within all small gas engines. It produces and delivers the high-voltage spark that ignites the fuel-air mixture to cause combustion. No spark means no combustion, which means your engine doesn’t run. Below are the components found in small engine ignition systems. Some systems will include breaker point ignitions while others depend on solid-state ignitions.

Magneto-Powered Ignition System: A magneto uses magnetism to supply electricity in ignitions where there is no battery. The magneto is turned by the crankshaft, which rotates when the manual recoil starter is pulled. The three types of magneto ignition systems are mechanical-breaker, capacitor-discharge, and transistor-controlled.

Battery-Powered Ignition System: If your small engine includes a battery for starting, the ignition coil will also use it to supply spark to the spark plugs. A battery stores electrical energy until needed. Battery ignition systems also use mechanical-breaker, capacitor-discharge, and transistor-controlled ignitions.

Mechanical-Breaker Ignitions: High-voltage electricity must be sent to the spark plug at the appropriate time. In mechanical-breaker ignitions, this job is performed through the contact points and a condenser.

Points: As the crankshaft rotates, a cam opens and closes a set of contact points. These points function as an on/off switch: Closed is on, and open is off.

Condenser: Because the spark moving across points can damage their surfaces, the condenser stores voltage to reduce arcing between points.

Capacitor-Discharge Ignitions (CDI): A capacitor is a large condenser. A CDI stores and delivers voltage to the coil using magnets, diodes, and a capacitor

Transistor-Controlled Ignitions (TCI): Transistors are electronic controllers. A TCI uses transistors, resistors, and diodes to control the timing of the spark.

Coil: An ignition coil is simply two coils of wire wrapped around an iron core. The coil changes low voltage (6 or 12 volts) into the high voltage (15,000 to 30,000 volts) needed by the spark plug.

Spark Plug: A spark plug is an insulated electrode that is screwed into the top of the engine cylinder. High-voltage timed electricity from the magneto travels by wire to the spark plug. The base of the plug has an air gap of about 0.030 inch (30 thousandths of an inch), which the current must jump.

Wires: The primary wire from the coil to the breaker point and secondary wire from the coil to the spark plug(s) deliver electricity to the ignition components.

Distributor: A distributor is an ignition system for engines with more than one cylinder and spark plug. It distributes the spark to the appropriate cylinder using a rotor, cap, and individual spark plug wires.

Combustion

The combustion system of a small gas engine is where the work gets done. Components of the combustion system include the cylinder block, cylinder head, camshaft, valves, piston, connecting rod, crankshaft, timing gears, and flywheel. To better understand small gas engines, let’s look at how this vital system works.

Cylinder Block: The largest single part in a small gas engine is the cylinder block. It is a piece of metal in which the cylinder hole is bored or placed.

Cylinder Head: The cylinder head is the top, or ceiling, of the cylinder and is attached to the block with bolts. Depending on the type of engine, the head may or may not include valves.

Piston: A piston is the movable floor in the combustion chamber. Its upward movement compresses the fuel-air mixture. After combustion, its downward movement rotates the crankshaft.

Crankshaft: An engine’s crankshaft is a metal shaft with an offset section onto which the connecting rod is attached. Rotation of the crankshaft moves the piston up in the cylinder. Movement of the piston down in the cylinder then rotates the crankshaft.

Connecting Rod: Between the piston and the crankshaft is a connecting rod. At the larger end of the connecting rod is a bearing that allows rotation around the moving crankshaft. The small end is attached to the piston pin.

Valves: Valves simply open and close passages. A reed valve in a two-stroke engine is activated by changes in air pressure.

Flywheel: At the end of the crankshaft is a circular weighted wheel called a flywheel. The flywheel delivers the engine’s power to devices (wheels, blades, etc.) and helps keep the crankshaft turning smoothly.

Combustion and friction produce heat. Heat and friction.- if not controlled.- can quickly damage an engine’s components. Small gas engines are typically cooled by air. Friction is reduced using movable bearings and lubricants.

Air-Cooling Fins: For simplicity, most smaller gas engines are cooled by air. Metal fins around the outside of the combustion chamber help dissipate the internal heat.

Friction: Friction is resistance that occurs when one surface rubs against another. Friction causes wear. In an engine with many moving parts, friction is reduced with bearings and lubricants.

Bearings: A bearing is a replaceable part that takes the brunt of the friction. A friction bearing relies on lubricants to minimize friction. A nonfriction bearing uses hard steel rollers or balls to prevent wear, though it too requires some lubrication.

Lubricants: Lubricants such as oil and grease reduce surface friction by coating parts with a film. Lubricants in two-stroke engines are applied to surfaces by mixing oil with fuel.

Viscosity: An oil’s viscosity is its resistance to flow. The thicker a lubricating oil or grease is, the higher its viscosity number.

Filters: Friction happens. Moving parts wear, even with the best lubricants. The resulting metal as well as carbon from the combustion process must be cleaned from the oil to ensure long lubrication. Some small engines use oil filters to remove contaminants from the circulating oil.

Regularly servicing your small engine will ultimately save you money and time. In the next section, we’ll review how, where, and when to service this engine.

The Benefits of Regular Small-Engine Maintenance

Purchasing a small engine-driven implement can make a dent in your budget. Tools and toys powered by small engines can cost anywhere from 100 to 10,000. That’s why it’s a good idea to invest in periodic servicing of your small engine. Replacing an engine every couple of years is an annoying and needless expense. Below we will review detailed information on how to service two-stroke gas engines. Following these procedures could help you put more money in the bank and less into your mechanic’s

Benefits of Regular Service

Servicing your small engine tool or toy on a regular basis offers many advantages over the Wait-Until-It-Breaks Maintenance Program.

- By establishing a service schedule, you will gain confidence that whenever you need the unit it will be ready for use.

- By performing a number of service functions together, you will save time. You can pick up all needed parts and lubricants in one trip to the parts store. Then you need to disassemble a component only once to perform numerous service procedures rather than taking it apart many times.

- Regular service gives you a chance to visually inspect the entire engine and related components for damage, wear, and other potential problems.

How, Where, and When to ServiceKnowing how to service is as important as knowing when. Some service procedures can be performed wherever you store your tool or toy: in a garage, storage shed, or tool shed. If the unit is heavy, you can build a ramp up to a sturdy table that is at a handy height for working. Or you can use a ratchet winch to lift the engine. Units weighing less than 40 pounds may be lifted to a workbench or table as long as you lift with your legs rather than with your back. Get help if you need it, and make sure that the unit will remain sturdily in place as you service it. Remember to always put safety first!Servicing a small engine is easy once you know what to do and when to do it. A service chart can help you determine common service requirements as well as track what service has been done. Your engine-powered unit may have a service chart in the owner’s manual or service manual. Typical recommendations include changing engine oil every 25 hours of use and tuning up the engine at least once a year.The purpose of ongoing service, also known as preventive maintenance, is to keep your engine-driven tool or toy in good operating condition. Ongoing service procedures include air cleaner service, crankcase breather service, cooling system service, muffler service, lubrication, and tune-up.Lubrication service means making sure that all moving parts have sufficient lubrication (oil and/or grease) to minimize wear. Lubrication service procedures include mixing oil with fuel in two-stroke engines, and lubricating other moving parts.A tune-up consists of the adjustment and/or replacement of parts critical to smooth and efficient engine operation. Those parts include components in all engine systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. Ignition tune-ups are more important for mechanical-breaker ignitions than they are for self-contained solid-state ignitions. Regular tune-ups will keep your small engine running smoothly and reduce the need for repairs.In addition, you should check other systems and make adjustments as needed to keep them operating smoothly. This includes adjusting the throttle, choke, and governor linkage, and cleaning off debris.Engine-driven tools and toys usually come with an owner’s manual. While some manufacturers’ manuals are more complete and better written than others, most manuals include basic information on safe operation and service. Unfortunately, product manuals are often written to reduce the manufacturer’s liability for accidental misuse rather than to help the owner service the product. In addition, manuals for engine-driven products typically show how to service the nonengine components: the grass catcher, wheel adjustments, blades, chains, and other parts. Service information for the engine may be minimal or nonexistent in the owner’s manual.

What can you do about this lack of information? Fortunately, there are numerous after-market publishers of service manuals for specific models of small engines. If you don’t have an owner’s manual, you can contact the manufacturer directly to purchase one; manufacturers also sell service manuals. Most manufacturers keep product manuals for up to 20 years. If they only have one original copy left, you can often request a photocopy for a small charge.

Knowing how to service the fuel system is an important part of caring for a small engine. Learn how to care for fuel filters, carburetors, and other major fuel system parts in the next section.

How to Repair a Small-Engine Fuel System

The function of a small engine fuel system is to store and deliver fuel to the combustion chamber. Maintaining a fuel system includes servicing the fuel filter, air cleaner, fuel tank, and fuel lines; adjusting the carburetor; and adjusting the governor. Of course, not all small engines have all of these components.

Servicing Fuel Filters

Some small engines have a fuel strainer in the bottom of the fuel tank. Others have a removable fuel strainer in the fuel line. Still other small engines use disposable in-line fuel filters made of pleated paper. To clean sediment from a tank:

Step 1: Drain or siphon all fuel from the tank.

Step 2: With a flashlight, find the lowest point in the tank: the sediment reservoir. Clean all sediment from the reservoir indentation.

Step 3: Wipe sediment from the end of the filter element.

Step 4: Wipe the inside of the tank with a clean rag.

Teardown Of The Blown Up John Deere Lawn Tractor Engine!

Step 5: Refill the fuel tank.

Here is how to clean sediment from a fuel strainer:

Step 1: Find and close the shutoff valve on the fuel line.

Step 2: Loosen the lock nut on the bowl retainer and remove the sediment bowl.

Step 3: Empty and clean the sediment bowl. Clean the filter screen. Refill the sediment bowl with fresh fuel.

Step 4: Reinstall the sediment bowl and bowl retainer, tightening the lock nut.

Step 5: Open the shutoff valve.

Here is how to replace an in-line fuel filter:

Step 1: Find and close the shutoff valve on the fuel line or use a clothespin to pinch the fuel line closed.

Step 2: Disconnect the fuel filter from the fuel line.

Step 3: Replace the in-line fuel filter with an exact replacement part.

Step 4: Open the shutoff valve.

Servicing Air Cleaners

The purpose of an air cleaner on a small engine is to keep large particles in the air from clogging the carburetor. The two types of air cleaners used on small engines are oil bath and dry. Hereis how to service an air cleaner:

Step 1: Remove the cover of the air cleaner, typically by unscrewing a nut on top of the cleaner.

Step 2: If it’s an oil cleaner, remove all oil and contaminants from the center channel of the cleaner, wipe it clean, then replace oil to the indicated level. A dry cleaner cannot be cleaned and therefore must be replaced.

Step 3: Replace the air cleaner cover and make sure all fasteners are securely tightened.

Servicing Fuel Tanks and Lines

Fuel systems with pumps use nonpressurized fuel tanks. Outboard engines typically use pressurized tanks. Fuel lines are usually made of neoprene. Here’s how to service a fuel tank and line:

Step 1: Remove the cap from the fuel tank.

Step 2: Using a flashlight, check for sediment in the fuel tank. If sediment is found, clean the tank and replace the fuel. Replace the fuel cap when done.

Step 3: Check the fuel line and siphon bulb, if there is one, by squeezing them and inspecting for cracks. If damaged, replace with a line or a bulb of the same inside diameter. Make sure it is approved for use with fuel.

Adjusting Carburetors

A carburetor mixes fuel and air in the correct proportion for use by the engine. The three types of carburetors commonly used in small engines are natural draft, updraft, and downdraft. These names describe the direction that air flows from the inlet to the engine manifold. To maintain your small engine, you will want to make sure the carburetor’s speed and mixture are correctly adjusted.

There are many types and models of carburetors used on small gas engines. Some have more available adjustments than others. Depending on the design, some carburetors are set at the factory and don’t include adjusting screws. For example, a carburetor may allow adjustment of high speed, idle speed, and idle mixture while another only allows high and idle speed adjustments. Here’s how to adjust the typical three-adjustment carburetor:

Step 1: With the engine running, open the throttle wide. Turn the high-speed adjustment needle forward and backward until the highest speed setting is found.

Step 2: Move the throttle to the slowest running speed. Adjust the idle-speed needle until the recommended idle speed is found.

Step 3: Once the idle speed has been set, adjust the idle mixture until the engine runs smoothly.

Adjusting Governors

A governor is a device that controls the speed of the engine as the load changes. As the load slows the engine down, the governor opens the throttle to return the engine to a set speed. Governors are commonly used on engine-powered electrical generators where constant speed is important. Two types of governors are installed on small engines: mechanical and air-vane.

How Does A Small Engine Work? 2 & 4 Cycle

Caution: An incorrectly adjusted governor can cause the small engine to operate at excessively high speeds and damage or destroy it.

Unfortunately, there is no universal adjustment sequence for small engine governors. Much depends on the type of governor, whether the crankshaft is horizontal or vertical, the complexity and pivot points of the linkage, and the intended operating range. Because of these factors, refer to an owner’s manual or service manual for your specific engine and application to adjust the governor.

In the next section, learn how the ignition system needs to be routinely serviced so it can deliver a high-voltage spark to help start a small engine.

How to Repair Small Engines

Small gas engines serve us in many ways. They power lawn mowers, tillers, cultivators, trimmers, edgers, snowblowers, chain saws, pumps, generators, air compressors, and other useful home tools. They also power our fun: outboard boats, snowmobiles, motorcycles, all-terrain vehicles, ultralight aircraft, and other toys. To keep them operating efficiently, an owner of these tools and toys should know about small engines: how they work and what to do when they don’t.

Small gas engines are made up of individual systems that work together to produce power. Each system has many components. Internal combustion gasoline-powered engines require six systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. In this article, we will discuss the systems and components that make small engines work.

Fuel and Exhaust

The fuel and exhaust systems are critical to operation. They furnish the fuel for combustion and remove exhaust gases. The following are components of a fuel and exhaust system.

Gasoline: Gasoline is a combustible liquid that burns relatively slowly. However, when sprayed as a mist and mixed with air, it is quite explosive. All it needs is a spark. Two-stroke engines require that oil be mixed with the gasoline to lubricate internal parts. Four-stroke engines use a fuel-air mixture.

Fuel Tank: The fuel tank stores fuel in preparation for mixing by the carburetor and use by the engine. Some fuel tanks are pressurized with air to help deliver fuel to the carburetor. Other tanks are non-pressurized and depend on a fuel pump to deliver fuel to the carburetor.

Fuel Line: Fuel is moved from the tank to the pump and/or carburetor through a fuel line. Pressurized fuel systems often have a squeeze bulb in the fuel line for building pressure.

Filter: A carburetor jet has a small opening that can easily become clogged. A fuel filter traps dirt and sediment from the gas before it is delivered to the carburetor.

Pump: A fuel pump produces a vacuum that pulls the fuel from an unpressurized tank, then delivers it to the carburetor.

Carburetor: The carburetor has one job: to mix the correct proportion of gasoline and air for the engine. Too much gasoline in the mixture makes it rich; too little gas makes it lean.

Throttle: The throttle controls the amount of fuel-air mixture that enters the engine from the carburetor. The throttle thus controls the speed of the engine.

Primer: A primer injects a small amount of gasoline into the carburetor throat to make the initial fuel-air mixture rich. A primer is used to help start a cold engine.

Choke: Some engines control the richness of the fuel-air mixture at startup by controlling the air rather than the fuel. A choke reduces the amount of air in the fuel-air mixture.

Governor: A governor is a device that automatically opens the engine’s throttle when more power is needed and closes it when the load is light.

Muffler: Small gas engines, especially two-stroke engines, are noisy when they operate. A muffler reduces the sound of the exhaust gases by passing them through baffles.

Spark Arrestor: A spark can exit the exhaust port of a small gas engine, potentially starting a fire on nearby combustibles. A spark arrestor on the exhaust port can reduce the chances of such a fire. Spark arrestors are especially important on chain saws, motorcycles, and all-terrain vehicles operated in dry woodlands.

Ignition

The ignition is a primary system within all small gas engines. It produces and delivers the high-voltage spark that ignites the fuel-air mixture to cause combustion. No spark means no combustion, which means your engine doesn’t run. Below are the components found in small engine ignition systems. Some systems will include breaker point ignitions while others depend on solid-state ignitions.

Magneto-Powered Ignition System: A magneto uses magnetism to supply electricity in ignitions where there is no battery. The magneto is turned by the crankshaft, which rotates when the manual recoil starter is pulled. The three types of magneto ignition systems are mechanical-breaker, capacitor-discharge, and transistor-controlled.

Battery-Powered Ignition System: If your small engine includes a battery for starting, the ignition coil will also use it to supply spark to the spark plugs. A battery stores electrical energy until needed. Battery ignition systems also use mechanical-breaker, capacitor-discharge, and transistor-controlled ignitions.

Mechanical-Breaker Ignitions: High-voltage electricity must be sent to the spark plug at the appropriate time. In mechanical-breaker ignitions, this job is performed through the contact points and a condenser.

Points: As the crankshaft rotates, a cam opens and closes a set of contact points. These points function as an on/off switch: Closed is on, and open is off.

Condenser: Because the spark moving across points can damage their surfaces, the condenser stores voltage to reduce arcing between points.

Capacitor-Discharge Ignitions (CDI): A capacitor is a large condenser. A CDI stores and delivers voltage to the coil using magnets, diodes, and a capacitor

Transistor-Controlled Ignitions (TCI): Transistors are electronic controllers. A TCI uses transistors, resistors, and diodes to control the timing of the spark.

Coil: An ignition coil is simply two coils of wire wrapped around an iron core. The coil changes low voltage (6 or 12 volts) into the high voltage (15,000 to 30,000 volts) needed by the spark plug.

Spark Plug: A spark plug is an insulated electrode that is screwed into the top of the engine cylinder. High-voltage timed electricity from the magneto travels by wire to the spark plug. The base of the plug has an air gap of about 0.030 inch (30 thousandths of an inch), which the current must jump.

Wires: The primary wire from the coil to the breaker point and secondary wire from the coil to the spark plug(s) deliver electricity to the ignition components.

Distributor: A distributor is an ignition system for engines with more than one cylinder and spark plug. It distributes the spark to the appropriate cylinder using a rotor, cap, and individual spark plug wires.

Combustion

The combustion system of a small gas engine is where the work gets done. Components of the combustion system include the cylinder block, cylinder head, camshaft, valves, piston, connecting rod, crankshaft, timing gears, and flywheel. To better understand small gas engines, let’s look at how this vital system works.

Cylinder Block: The largest single part in a small gas engine is the cylinder block. It is a piece of metal in which the cylinder hole is bored or placed.

Cylinder Head: The cylinder head is the top, or ceiling, of the cylinder and is attached to the block with bolts. Depending on the type of engine, the head may or may not include valves.

Piston: A piston is the movable floor in the combustion chamber. Its upward movement compresses the fuel-air mixture. After combustion, its downward movement rotates the crankshaft.

Crankshaft: An engine’s crankshaft is a metal shaft with an offset section onto which the connecting rod is attached. Rotation of the crankshaft moves the piston up in the cylinder. Movement of the piston down in the cylinder then rotates the crankshaft.

Connecting Rod: Between the piston and the crankshaft is a connecting rod. At the larger end of the connecting rod is a bearing that allows rotation around the moving crankshaft. The small end is attached to the piston pin.

Valves: Valves simply open and close passages. A reed valve in a two-stroke engine is activated by changes in air pressure.

Flywheel: At the end of the crankshaft is a circular weighted wheel called a flywheel. The flywheel delivers the engine’s power to devices (wheels, blades, etc.) and helps keep the crankshaft turning smoothly.

Combustion and friction produce heat. Heat and friction.- if not controlled.- can quickly damage an engine’s components. Small gas engines are typically cooled by air. Friction is reduced using movable bearings and lubricants.

Air-Cooling Fins: For simplicity, most smaller gas engines are cooled by air. Metal fins around the outside of the combustion chamber help dissipate the internal heat.

Friction: Friction is resistance that occurs when one surface rubs against another. Friction causes wear. In an engine with many moving parts, friction is reduced with bearings and lubricants.

Bearings: A bearing is a replaceable part that takes the brunt of the friction. A friction bearing relies on lubricants to minimize friction. A nonfriction bearing uses hard steel rollers or balls to prevent wear, though it too requires some lubrication.

Lubricants: Lubricants such as oil and grease reduce surface friction by coating parts with a film. Lubricants in two-stroke engines are applied to surfaces by mixing oil with fuel.

Viscosity: An oil’s viscosity is its resistance to flow. The thicker a lubricating oil or grease is, the higher its viscosity number.

Filters: Friction happens. Moving parts wear, even with the best lubricants. The resulting metal as well as carbon from the combustion process must be cleaned from the oil to ensure long lubrication. Some small engines use oil filters to remove contaminants from the circulating oil.

Regularly servicing your small engine will ultimately save you money and time. In the next section, we’ll review how, where, and when to service this engine.

The Benefits of Regular Small-Engine Maintenance

Purchasing a small engine-driven implement can make a dent in your budget. Tools and toys powered by small engines can cost anywhere from 100 to 10,000. That’s why it’s a good idea to invest in periodic servicing of your small engine. Replacing an engine every couple of years is an annoying and needless expense. Below we will review detailed information on how to service two-stroke gas engines. Following these procedures could help you put more money in the bank and less into your mechanic’s

Benefits of Regular Service

Servicing your small engine tool or toy on a regular basis offers many advantages over the Wait-Until-It-Breaks Maintenance Program.

- By establishing a service schedule, you will gain confidence that whenever you need the unit it will be ready for use.

- By performing a number of service functions together, you will save time. You can pick up all needed parts and lubricants in one trip to the parts store. Then you need to disassemble a component only once to perform numerous service procedures rather than taking it apart many times.

- Regular service gives you a chance to visually inspect the entire engine and related components for damage, wear, and other potential problems.

How, Where, and When to ServiceKnowing how to service is as important as knowing when. Some service procedures can be performed wherever you store your tool or toy: in a garage, storage shed, or tool shed. If the unit is heavy, you can build a ramp up to a sturdy table that is at a handy height for working. Or you can use a ratchet winch to lift the engine. Units weighing less than 40 pounds may be lifted to a workbench or table as long as you lift with your legs rather than with your back. Get help if you need it, and make sure that the unit will remain sturdily in place as you service it. Remember to always put safety first!Servicing a small engine is easy once you know what to do and when to do it. A service chart can help you determine common service requirements as well as track what service has been done. Your engine-powered unit may have a service chart in the owner’s manual or service manual. Typical recommendations include changing engine oil every 25 hours of use and tuning up the engine at least once a year.The purpose of ongoing service, also known as preventive maintenance, is to keep your engine-driven tool or toy in good operating condition. Ongoing service procedures include air cleaner service, crankcase breather service, cooling system service, muffler service, lubrication, and tune-up.Lubrication service means making sure that all moving parts have sufficient lubrication (oil and/or grease) to minimize wear. Lubrication service procedures include mixing oil with fuel in two-stroke engines, and lubricating other moving parts.A tune-up consists of the adjustment and/or replacement of parts critical to smooth and efficient engine operation. Those parts include components in all engine systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. Ignition tune-ups are more important for mechanical-breaker ignitions than they are for self-contained solid-state ignitions. Regular tune-ups will keep your small engine running smoothly and reduce the need for repairs.In addition, you should check other systems and make adjustments as needed to keep them operating smoothly. This includes adjusting the throttle, choke, and governor linkage, and cleaning off debris.Engine-driven tools and toys usually come with an owner’s manual. While some manufacturers’ manuals are more complete and better written than others, most manuals include basic information on safe operation and service. Unfortunately, product manuals are often written to reduce the manufacturer’s liability for accidental misuse rather than to help the owner service the product. In addition, manuals for engine-driven products typically show how to service the nonengine components: the grass catcher, wheel adjustments, blades, chains, and other parts. Service information for the engine may be minimal or nonexistent in the owner’s manual.

What can you do about this lack of information? Fortunately, there are numerous after-market publishers of service manuals for specific models of small engines. If you don’t have an owner’s manual, you can contact the manufacturer directly to purchase one; manufacturers also sell service manuals. Most manufacturers keep product manuals for up to 20 years. If they only have one original copy left, you can often request a photocopy for a small charge.

Knowing how to service the fuel system is an important part of caring for a small engine. Learn how to care for fuel filters, carburetors, and other major fuel system parts in the next section.

How to Repair a Small-Engine Fuel System

The function of a small engine fuel system is to store and deliver fuel to the combustion chamber. Maintaining a fuel system includes servicing the fuel filter, air cleaner, fuel tank, and fuel lines; adjusting the carburetor; and adjusting the governor. Of course, not all small engines have all of these components.

Servicing Fuel Filters

Some small engines have a fuel strainer in the bottom of the fuel tank. Others have a removable fuel strainer in the fuel line. Still other small engines use disposable in-line fuel filters made of pleated paper. To clean sediment from a tank:

Step 1: Drain or siphon all fuel from the tank.

Step 2: With a flashlight, find the lowest point in the tank: the sediment reservoir. Clean all sediment from the reservoir indentation.

Step 3: Wipe sediment from the end of the filter element.

Step 4: Wipe the inside of the tank with a clean rag.

Step 5: Refill the fuel tank.

Here is how to clean sediment from a fuel strainer:

Step 1: Find and close the shutoff valve on the fuel line.

Step 2: Loosen the lock nut on the bowl retainer and remove the sediment bowl.

Step 3: Empty and clean the sediment bowl. Clean the filter screen. Refill the sediment bowl with fresh fuel.

Step 4: Reinstall the sediment bowl and bowl retainer, tightening the lock nut.

Step 5: Open the shutoff valve.

Here is how to replace an in-line fuel filter:

Step 1: Find and close the shutoff valve on the fuel line or use a clothespin to pinch the fuel line closed.

Step 2: Disconnect the fuel filter from the fuel line.

Step 3: Replace the in-line fuel filter with an exact replacement part.

Step 4: Open the shutoff valve.

Servicing Air Cleaners

The purpose of an air cleaner on a small engine is to keep large particles in the air from clogging the carburetor. The two types of air cleaners used on small engines are oil bath and dry. Hereis how to service an air cleaner:

Step 1: Remove the cover of the air cleaner, typically by unscrewing a nut on top of the cleaner.

Step 2: If it’s an oil cleaner, remove all oil and contaminants from the center channel of the cleaner, wipe it clean, then replace oil to the indicated level. A dry cleaner cannot be cleaned and therefore must be replaced.

Step 3: Replace the air cleaner cover and make sure all fasteners are securely tightened.

Servicing Fuel Tanks and Lines

Fuel systems with pumps use nonpressurized fuel tanks. Outboard engines typically use pressurized tanks. Fuel lines are usually made of neoprene. Here’s how to service a fuel tank and line:

Step 1: Remove the cap from the fuel tank.

Step 2: Using a flashlight, check for sediment in the fuel tank. If sediment is found, clean the tank and replace the fuel. Replace the fuel cap when done.

Step 3: Check the fuel line and siphon bulb, if there is one, by squeezing them and inspecting for cracks. If damaged, replace with a line or a bulb of the same inside diameter. Make sure it is approved for use with fuel.

Adjusting Carburetors

A carburetor mixes fuel and air in the correct proportion for use by the engine. The three types of carburetors commonly used in small engines are natural draft, updraft, and downdraft. These names describe the direction that air flows from the inlet to the engine manifold. To maintain your small engine, you will want to make sure the carburetor’s speed and mixture are correctly adjusted.

There are many types and models of carburetors used on small gas engines. Some have more available adjustments than others. Depending on the design, some carburetors are set at the factory and don’t include adjusting screws. For example, a carburetor may allow adjustment of high speed, idle speed, and idle mixture while another only allows high and idle speed adjustments. Here’s how to adjust the typical three-adjustment carburetor:

Step 1: With the engine running, open the throttle wide. Turn the high-speed adjustment needle forward and backward until the highest speed setting is found.

Step 2: Move the throttle to the slowest running speed. Adjust the idle-speed needle until the recommended idle speed is found.

Step 3: Once the idle speed has been set, adjust the idle mixture until the engine runs smoothly.

Adjusting Governors

A governor is a device that controls the speed of the engine as the load changes. As the load slows the engine down, the governor opens the throttle to return the engine to a set speed. Governors are commonly used on engine-powered electrical generators where constant speed is important. Two types of governors are installed on small engines: mechanical and air-vane.

Caution: An incorrectly adjusted governor can cause the small engine to operate at excessively high speeds and damage or destroy it.

Unfortunately, there is no universal adjustment sequence for small engine governors. Much depends on the type of governor, whether the crankshaft is horizontal or vertical, the complexity and pivot points of the linkage, and the intended operating range. Because of these factors, refer to an owner’s manual or service manual for your specific engine and application to adjust the governor.

In the next section, learn how the ignition system needs to be routinely serviced so it can deliver a high-voltage spark to help start a small engine.

Lawn Mower Parts Accessories (130 items found)

The key to a lovely looking lawn includes many steps from mowing to raking to collecting and disposing of debris. Although it can involve a lot of work, Ace carries a robust selection of lawn mower parts and accessories to make your lawn maintenance routine a snap.

Essential Lawn Mower Parts and Accessories

A freshly cut lawn makes for a tidy-looking landscape and having the right parts and accessories on hand can lighten your load year-after-year. Ace carries lawn mower and riding mower attachments and accessories from top brands like Briggs Straton, Craftsman, TORO, MaxPower, and more. Make your yard work more efficient with the right equipment, accessories and replacement lawn mower parts.

Necessary Lawn Mower Maintenance

Ensure the health of your investment with regular lawn mower maintenance essentials, including:

- tune up kits for all around maintenance.

- blade sharpeners and replacement blades to keep trimming smoothly and effectively.

- oil and fuel filters and fuel lines for the health of your machine’s engine.

- bolts, bulbs springs and gaskets for necessary maintenance.

- replacement mufflers, drive belts and other important accessories.

We’ve got everything you need to keep your lawn mower up and running. Unsure where to start? Head to a Ace Hardware store near your and ask for one of our expert staffers. They can help you find the right replacement parts or accessories, as well as help you do things like sharpen your blades or replace a part on your lawn mower.

When Should I Replace My Lawn Mower Blades?

Consider replacing your lawn mower blades every year to get the cleanest cuts out of your machine each season. When you purchase a lawn mower, you’re investing in a machine for the long haul. Annual lawn mower blade replacement, and regular blade sharpening, will help ensure the long-term health of your machine.

Grass Catcher Accessories for Easier Work

A well running lawn mower is a reliable tool for any yard work. And with the right riding mower attachments, every job becomes that much easier.

Grass catchers are riding lawn mower attachments used to store grass clippings immediately after they are kicked up by a lawn mower, saving you an enormous amount of time and energy. They come in a range of sizes to fit your needs, allowing you to easily mow without needing to stop and empty as frequently.

Clean up is as easy as emptying the grass catcher when you’re finished mowing. Whether you use a riding mower, hand reel mower, or push mower, there’s a grass catching lawn mower attachment for nearly every model.

Shop Lawn Mower Attachments and Supplies at Ace

Not sure what lawn mower supplies you need? Stop by an Ace Hardware where our knowledgeable staff can help you find the right lawn mower parts near you. Make sure to shop for other items to improve your lawn mower experience, from gas cans for powerful gas mowers to lawn ground rollers for versatile yard maintenance.