Lawn mower governor adjustment. How to Adjust an E Z Go Golf Cart Governor

How to Adjust an E Z Go Golf Cart Governor

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 11 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 614,970 times.

Adjusting the governor can make your golf cart go 5–10 mph (8.0–16.1 km/h) faster. If you do this to an E-Z-GO golf cart, you might be able to go from 15 mph (24 km/h) to 22 mph (35 km/h). It will only take about 5 minutes to do it.

- Find the governor in the 4-stroke engine of your golf cart. Look for a small spring that’s coiled around a metal rod.

- Boost your cart’s speed by adjusting the nuts attached to the spring. Loosen up the smaller nut while tightening the larger one.

- Tighten up the smaller nut once you’re happy with your cart’s overall speed.

- Improve other types of cart engines by adjusting the small metal rod near your clutch pedal.

Adjusting the Common 4-Stroke Engine

Tighten the governor spring located in the engine of most golf carts to adjust your cart’s top speed. 90% of EZ Go Carts have simple springs which limit the speed of the engine. To raise the top speed of your golf cart, all you need to do is locate this spring and tighten it slightly. If you cannot find this spring, you likely have a newer model that is more difficult to adjust, though this is rare. [1] X Research source

Lift up the seat. Remove the seat cousins, which hide the engine. You may have to unscrew the seat in newer models. [2] X Research source

Remove the screws from the black plastic cover at the rear of the seat. There should be five screws in most models. The engine is in the front of golf carts, underneath this panel. Take off the plastic cover and set it aside with the seats.

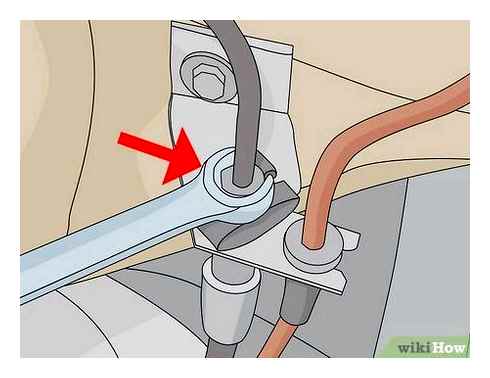

Loosen the small nut and tighten the larger nut. The more you tighten the larger nut, the faster your cart will go. Start slowly, only tightening the nut a quarter turn to start. You can over-stress the engine if you try to run it too quickly, and it will skip and potentially burn out if you are too eager. [3] X Research source

Tighten up the small nut on the governor to keep the spring in place. Test the speed of the cart. After you are satisfied with how fast your cart goes, tighten the small nut back up. As you test, listen for whining noises, skips, or odd clunking movement in the cart this means you’ve tightened the governor too much and need to dial it back. [4] X Research source

Replace the black cover to start driving. Put the cart back together how you found it and enjoy your ride.

Know that upping a cart’s top speed will cause the engine to wear faster. You’ll likely need to get repairs and replacement parts faster on a cart with an adjusted governor. In addition, any cart that can go above 19mph is officially a motor vehicle, and you legally need seatbelts and inspections. This shouldn’t be a big problem, but it is worth knowing. [5] X Research source

Adjusting Other Engines

Remove the seat and plastic covering over the engine. Sometimes you’ll need to remove screws while some models have seats that pop right out. Expose the engine so that you can get to work adjusting the motor. If you don’t have a central governor spring, you can still get your cart to move a little faster.

Locate your clutch pedal and line. The clutch is the pedal (sometimes a handle near your knee) that you use to put the car into reverse or change speeds. You can adjust the clutch to send more gas to your engine, moving you faster.

Find the small metal rod right next the clutch and the attached cable. The length of this cable determines how much gas flows into your engine. Again, you should remember that the cart’s motor will struggle the faster you make it move. So test every change and listen for clunks or stalls to make sure you protect your motor. [6] X Research source

Loosen the nut attaching this cable to the metal protrusion to increase the speed. You should see the cable lengthening slightly. This will make your cart faster. Tighten the nut to make the cart move slower. [7] X Research source

Know that you cannot adjust the governor if this cable or the governor spring are not visible. This is most common on modern, all-electric engine. Many manufacturers, including EZ Go, do not want consumers tampering with their engines, and have thus hidden the governors in the spark plug ignition. This is very difficult to adjust without ruining the engine, and should be left to trained professionals. [8] X Research source

Community QA

See if you have room to re-route as much of the cable as possible, so that it is farther away from the motor.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Just adjust the throttle idle screw until the engine runs but the cart does not move. Turn it in to increase the idle speed, and turn it out to slow and eventually stop the engine.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Depending on whether it has a power source to itself, if it has a personal power source, then just add duct tape or anything that will make it stay onto the 2002 EZ Go Golf Cart. And if the throttle scale doesn’t, then just search it up.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Lawn Mower Engine Surging – Check this easy fix first!

Lawnmower engine surging is a right pain in the Jacksie; it’s an engine that runs erratically and revs up and down by itself uncontrollably. In some cases, it may only happen under certain conditions, for example, only after the mower gets hot or only when the fuel level gets low.

So what causes the lawnmower engines to surge? The most common reason for a surging lawn mower engine is a blockage in the fuel supply, but there are other possibilities:

Often you’ll find playing around with the throttle helps or applying some choke. You are not on your own; this is a regular complaint. In this guide, we will cover the diagnosis, likely causes, and solutions.

Try the easy fix first – replacing/cleaning gapping the spark plug before attempting carburetor work. If your mower engine is a Honda or Kohler, the fix is simple. Honda and Kohler’s surging is commonly caused by a blocked idle jet see “Gas starvation” towards the end of the page.

If you need more help, check out the “How to fix a surging mower video.”

If your surging mower is a Honda, check out the “Honda mower surging video.”

For many mowers, the fix is to replace the carburetor, and as carburetors are inexpensive, it just makes sense to swap it out and save a ton of messing around. You can check out the quality carburetors available and conveniently delivered to your door by Amazon.com.

Need more info on the fuel system, carburetor components, and how they work, you can check them out here.

Briggs Stratton Surging

Surging BS Classic 450, 500, or 550Some engine types are famous for surging; the Briggs Stratton 450, 500, and 550 series engines are fitted with a metal fuel tank and priming bulb-style carburetor. If you have one of these types of engines and it’s surging – You’re in the right place.

Where is a Golf Cart Governor Located?

If you don’t have this type of carburetor, skip this section and jump to “Surging Test” below. These engines are fitted with a metal fuel tank and carburetor combination. The gasket sandwiched between the tank, and carburetor distorts over time, allowing a vacuum leak.

The vacuum leak causes the surging; replacing the gaskets and cleaning the carburetor/tank will leave it like new, I promise. In this tutorial, we’ll remove the tank/carburetor unit, clean it and replace the gaskets. Just some basic tools are needed, but get yourself a can of carburetor cleaner; it makes the job a lot easier.

In the workshop, I use WD40 carb cleaner, and you can check out all the tools and parts I use here on the “Small engine repair tools” page.

Tools You’ll Need

Here’s a short list of tools you’ll find useful to complete the task of fixing your surging mower. These tools aren’t essential, but they do make the whole job a ton easier; you’ll need:

Fuel treatment – Every small engine owner should use gas treatment. Most people don’t know gas goes off, and gas left in small engines can cause real problems, as you already know.

Using a gas stabilizer will keep the gas in your mower and your gas can fresh for up to two years.

Carburetor gasket – If you’re fixing the BS Classic engine, then you’ll need this gasket set.

Complete carburetor – As an alternative to replacing your BS Classic carburetor gasket, replace the complete carburetor instead; it includes the replacement gasket.

Manifold – This will only be needed if you have confirmed it has failed. Note there are a few different types of manifold pipe, so be sure to check before ordering.

You can check out all these tools on this page “Carburetor Surging Repair Tools.”

This carburetor style is fitted to a few engines and is prone to gasket failure. The job of replacing is simple and will solve the surge. The process is as follows:

Remove the spark plug wire – prevents the mower from starting.

Remove – Remove and clean the air filter and filter housing – Clean it using soapy water, and when dry, smear some engine oil over the surface of the foam. This helps trap dirt.

Remove tank bolts – They hold the fuel tank to the engine.

With fuel tank bolts removed – pull the tank unit straight out gently and remove the governor control link.

Remove the black rubber elbow crankcase breather pipe. Remove the manifold seal and keeper ring. Sometimes they will come loose and get stuck on the manifold pipe.

Remove – Remove carb screws from the carburetor and set aside.

Using a can of carburetor cleaner – clean all the ports on the surface of the fuel tank.

Empty the tank and rinse it out with fresh gas.

Pull the Siphon from the carburetor; they can be stubborn. Remove both gaskets and use carburetor cleaner to clean the siphon metal filter and all ports of the carburetor. Check the primer bulb for damage; mice like to eat them.

Spray – Spray the carburetor with carb cleaner.

Remove – Remove old gaskets and discard them.

Careful of this spring; it lives under the gaskets, and it can drop off and be tricky to find, as I know only too well.

The gasket is a two-part kit; the rubber-type gasket faces the tank. (carb fitted here for demo only)

The Siphon pushes back into the carb with a click. If you don’t hear the click, it’s not right – try again.

Refit the carburetor to the tank. Don’t over-tighten the screws, as this will distort the gasket. Fit manifold seal and keeper. Smear a small amount of oil on the seal; it helps it seat.

Clean the intake manifold. The grey tube in this shot is manifold. Inspect it for any signs of damage; they are prone to cracking. This will also cause a surge.

To fully inspect the pipe, you need to remove the pull assembly.

I would only do this if there was obvious damage to the manifold or if I had replaced the carburetor gasket and the engine was still surging.

This manifold is cracked and will cause a surge.

Before refitting the tank, fit the keeper ring and O-ring seal. Lube the seal before refitting the gas tank.

Offer the carb/tank unit up to the manifold and attach the governor link and spring. Now push the unit firmly onto the manifold. Fit both bolts.

Refit the air filter and spark plug wire. Use only fresh gas; make sure your gas can is clean. Gas older than three months is stale.

If, after fitting the gaskets, you still have a surge – Replace the Manifold.

Surging Test

As you know, gas starvation causes an inconsistent flow of fuel which in turn causes erratic running. And you also know a vacuum leak will cause erratic running, but it is a much less common cause; however, some carburetors are prone to vacuum leaks.

As engine manufacturers strive to make their engines more efficient, they have also made the carburetors more likely to clog; this has become a common issue.

To quickly diagnose which problem you have, a clogged carb or vacuum leak, follow this simple test.

You will need a helper to hold the bail lever or improvise with duct tape. CAUTION careful where you place your fingers and toes; the engine will be running, so the blade will be spinning.

Your mower will have a Manual choke, Auto choke, or a Primer bulb. Identify which type your mower has; the test is slightly different for each.

If you have a manual choke – apply half choke with the engine running.

If the engine now runs without surging – Gas starvation is the likely fault. If it runs just the same – A vacuum leak is a more likely fault.

If you have an Auto choke – Remove the air filter cover and filter – place a clean rag over the intake while the engine is running.

If the engine now runs without surging – Gas starvation is the likely fault.

If the engine runs just the same – A vacuum leak is the more likely fault.

If you have a primer bulb – you can still do the test – while the engine’s running (need a helper); give it some extra gas by pressing the bulb.

How to Adjust Governor on EZGO RXV Gas Golf Cart | Speed Increase

If the engine now runs without surging – Gas starvation is the likely fault.

If it runs just the same – A vacuum leak is a more likely fault.

Gas Starvation

If the test revealed gas starvation, it also showed that your problem is likely a dirty fuel jet in the carburetor, or the gas may be stale or contaminated by water.

Cleaning the main jet usually does the job.

Idle Jet Surging – Honda and Kohler use a relatively easy-to-access idle jet that clogs up and causes surging. The Kohler is easier to access than the Honda.

The Kohler is easier to access than the Honda.

Briggs has fitted a plastic carburetor to a range of engines which also clog up and cause surging.

All of these carburetors can be repaired by cleaning, which I’ve covered previously in videos (links below). Videos cover step-by-step removal, cleaning, refitting, and adjusting your carb.

Fixing this is not difficult. Sometimes you can get lucky by just draining and cleaning the gas bowl, which only takes a few minutes.

I have written a complete guide to Carburetor cleaning with pictures; it includes the gas bowl clean-out, which, as said, is worth trying first.

If cleaning doesn’t work out for you, go ahead and swap out the carburetor for a new one. Check out “New lawn mower carburetors page,” here, I’ve listed good quality replacement carburetors for all the most popular engines.

Carburetors aren’t expensive; messing around with them doesn’t make sense.

You might find this page helpful too – “Carburetor repair tools” I’ve listed some really useful tools that make the job easy. Some of these tools I’ll bet you already have some.

But do try cleaning the gas bowl before removing the carburetor.

Finding a Vacuum Leak

Air that enters the combustion chamber without passing through the carburetor is un-metered. This means the fuel-to-air ratio is unbalanced and, in turn, causes erratic engine performance.

When air sneaks in like this, it causes the engine to run lean (lacks gas). A lean engine runs hot, which isn’t good for an engine, especially an air-cooled one.

Vacuum leaks usually occur because of damaged gaskets. Gaskets are sealing materials fitted between the mating surfaces of engine components. Their function is to create an airtight seal.

They are commonly made from paper, felt, cork, Teflon, neoprene, metal, and rubber. The material type is dependent upon where the gasket is to be used.

Gaskets wear out and break down, and that causes surging.

Extreme Caution – You need to be careful, the engine will need to be running, and so the blade will be spinning when running this test.

A vacuum leak check is performed with the engine running and a can of carburetor cleaner; WD40 works, too, (is there anything WD can’t do?)

Spray the cleaner around all carburetor gaskets anywhere the carburetor meets the engine. The trick is to hear an instant change in engine note; that’s the sign of a vacuum leak.

This can be challenging; you must train your ear to notice the instant change in engine note (and not the surging).

Just do a small section at a time; this will allow you to pinpoint the failure area. Jumping the gun and replacing gaskets without finding the actual leak may work out for you or leave you with the same problem after the rebuild.

You’re right in thinking carburetor gaskets usually cause the problem, but other components, such as manifold pipes, can crack or become loose, causing surging.

Fixing A Vacuum Leak

If a leak is detected, replace all carburetor gaskets, and as you have the carburetor removed, go ahead and clean it. Replacement gaskets are available online; you will require the make and model numbers from the engine.

All manufacturers will have a model number printed on a sticker placed on the body or on the engine. Have a poke around; you’ll find it. Most engine manufacturers will stamp the model numbers in an accessible area. Briggs Stratton stamp their numbers on the metal engine cover.

A new carburetor comes with new inlet gaskets; I like to fit original parts where I can; they fit and are guaranteed.

If, after replacing the carburetor gaskets, the engine still surges, you’ll need to go a little further and replace the manifold intake and gasket.

It’s not a big job, and they don’t give a lot of trouble, but they do crack as they get older. I wrote a step-by-step guide showing you everything you need to know – “Briggs Manifold Replacing.”

Related Question

Honda lawn mower surging fix? To fix a surging Honda lawn mower engine, clean the carburetor, gas tank, and fuel filter. Use fresh regular gas or e10. What causes a lawnmower to run slowly? The most likely cause is a throttle linkage bent out of shape by bumping into the shrubbery or a throttle spring has detached itself.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!

Lawn Mower RPM Too High (Why What to Do)

So you started up your lawn mower, and it sounds like it’s over-revving. If your lawn mower RMP is too high, your mower will create an unusually high engine sound. There are a few common causes of this problem and luckily, they can usually be fixed quickly and easily. So, let’s dive in.

Why is My Lawn Mower Revving High? (The Short Answer)

High RMP stems back to the governor. A build-up of grass, bad springs, poor adjustment, and a damaged governor lever can all lead to high revving.

What is a Governor?

The governor controls the engine speed as loads are applied, such as when engaging blades or going up a hill. The governor will cause increased throttle by introducing additional fuel and airflow to the carburetor to maintain a steady RPM. The governor is controlled by the movement of the throttle, a set of springs, and link arms. So, how does the governor malfunction?

Common Causes of a Lawn Mower with RPM That’s Too High

Any time the governor is obstructed or damaged, the engine cannot adjust itself. A high RPM results from the governor’s inability to adjust the throttle. Let’s look to see what could cause this.

Debris on the Governor

You first want to check for a build-up of debris around the governor. In my experience, grass loves to collect in this area. As a result, you’ll need to get to the governor, which may require removing the air filter, fuel tank, or engine cover if the mechanism is hidden behind them.

With these removed, you should have easy access and be able to see any build-up of grass and junk. Next, you can check to see how the governor is working by moving the throttle from fully closed to fully open. If the governor is blocked, then the mechanism will not move correctly.

Checking the Two Springs

Different lawn mowers use different setups, but they all achieve the same job. Your spring could have worn, or it could have been damaged by debris. If the governor opens the throttle but can’t close it, the RPM will stay high.

To check this, you can see if the springs are under tension. If the springs are slack, they will not recall the throttle and the governor. If you have access to the springs with the mower fully assembled, then it’s best to check with the lawn mower running. This will show you exactly how the springs react.

Adjustment of the Governor Lever

The governor lever connects to the throttle linkage and the governor shaft, and controls the air-fuel flow and engine speed. The lever is mounted to the governor shaft, usually using a small bolted clamp. If the lever is loose or damaged, it will be unable to provide the correct adjustment to the engine, causing your lawn mower to rev too high. Inspect the lever to see if it has moved on the shaft or if it looks damaged.

How to Fix a Lawn Mower That is Over Revving

Before starting any fix on the governor, you’ll need to know what over-revving is. Your ears are a good gauge to identify a problem, but they’re not reliable enough to accurately carry out a repair.

For example, if you make a repair to solve a high RPM, you could accidentally end up setting it too low. As a result, you’ll be causing more problems because the lawn mower won’t have enough power.

Typical lawn mower engines have a range of around 2700-3000 RPM. You can confirm this with your specific engine. However, since your lawn mower doesn’t have an RPM counter, you’ll need to have an alternative solution to gauge it.

Inductive Tachometer Gauge

This inexpensive gauge connects to the spark plug lead and provides an accurate reading of engine RMP. It removes any guesswork when making adjustments to the governor. I’ll explain when to use a tachometer gauge on the specific fixes below.

Gaining Access to the Governor

With any repair to the governor, you’ll need unobstructed access first. Next, check if an engine cover, air filter, or fuel tank is getting in your way. If they are, then they’ll have to be removed. A small socket wrench or screwdriver should work fine, depending on your situation. Once the obstruction is removed, you can set them aside and move on to the fixes.

Tools to Remove Obstructions

Cleaning out the Governor

Removing debris from the governor isn’t tricky, but it’s best to be gentle and not cause a new problem. If you had to remove the air filter, the carburetor’s inside will be exposed, and you’ll need to prevent debris from getting in. Let’s cover this in more detail.

Steps to Cleaning Out a Governor

First, start by removing the debris with your hands. I suggest you wear gloves since you might find something like a mouse nest that appeared over winter.

Be careful with the mechanism; remove what you can, making sure what you’re pulling out isn’t wrapped around a spring. The springs are delicate, and you want to avoid damaging them.

When you have the bulk removed, you can move on to using an air compressor or leaf blower to get the remaining junk out. Just be extra mindful if you have an exposed carburetor. Placing your hand over the carburetor opening should keep any debris out. Finally, once it is all cleaned out, give the mechanism a good coat of spray lubricant, making sure it doesn’t get into any exposed engine parts.

With this done, you can go ahead and put the lawn mower back together and test the RPM. Connect the tachometer gauge as per the instruction and start your engine. With the engine set to FULL, check the reading. It should be reading in line with the engine recommendations.

Tools Required to Clean out the Governor

Repositioning the Springs

You’ll notice that the governor lever has several small holes where you can attach the springs at different intervals. These allow you to adjust the tension of the various springs. By repositioning the springs, you will adjust the governor lever’s movement and, consequently, the engine’s RPM. Let’s go over how to adjust the springs to reduce the engine RPM.

Reducing the RPMs Using the Spring Adjustment

Start by attaching your tachometer gauge to the lawn mower, and start your engine. Take note of the RPM with the engine on full throttle. Once you have this reading, you can go ahead and turn off the lawn mower.

Next, take your needle-nose pliers, move the spring to the next hole, and take a new reading by starting your engine. Continue this process until you can get the RPM into the desired range. If you cannot achieve the desired RPM, you will need to move on to replacing the springs and checking the lever.

Tools Required to Adjust the Springs

Replacing the Governor Springs

I strongly recommend using new springs if you have identified that the governor springs need to be replaced. Any little fixes you do with your old springs may or may not last. Let’s look at the steps you’ll need to follow to get your governor working as it should.

Steps to Replacing Springs

Start by taking a pair of needle-nose pliers and removing the springs. Make a mental note of which spring goes where and its orientation. You’ll want to get the new springs back on the same way the old ones came off. They may get caught up if they go on backward.

Next, take your new springs and hook them into position using your needle-nose pliers. It’s that simple. With this done, give the governor area a good clean and spray it with a coat of lubricant.

Finish the fix by putting the lawn mower back together and testing the RPM. Take your tachometer gauge and check the RPM the same way you did after the cleaning process above. With the new springs properly in place, you should no longer have a lawn mower over-revving.

Tools Parts to Replace Springs

Governor Lever Adjustment

The governor lever adjustment is the final fix to try if your lawn mower’s RPM is too high. Now, this isn’t adjusting the lever plus or minus. It’s simply adjusting the lever to be in the correct position. The governor shaft is usually square or half-round; this means the governor lever can only fit in one position. So, if yours isn’t in the correct position on the shaft, you’ll need to carry out a fix.

Positioning the Governor Lever Correctly

Start by using your needle-nose pliers to remove the attached springs and throttle arm. This will keep them out of the way, so they are not damaged. Then, use your wrench to loosen off the nut and bolt on the lever.

Once loosened, you can remove the lever from the lawn mower and inspect it for any damage. If you find that some damage looks beyond repair, I recommend using a new part. If you find the lever is bent, you’ll probably be able to straighten it by hand since it is made of thin metal.

Take either your new or repaired governor lever and place it back onto the governor shaft, ensuring it’s lined up correctly. Continue by fastening the lever’s nut and bolt and reattaching the springs and throttle arm.

To finish, clean and lubricate the area and reinstall the obstructed parts you removed from the lawn mower. Finally, take your tachometer gauge and check the RPM, as explained earlier.

Riding Mower Revs Too High: Causes Solutions Specific to Ride-Ons

You may be asking, what about a riding mower that revs too high? Well, the fixes are just the same. The only real differences are that the engine is usually covered, such as with a tractor hood, and the size of the engine is larger in terms of horsepower. When it comes to governors, they tend to all work the same and follow the same principles. So, the next time you hear your lawn mower revving high, you’ll have four very quick and easy fixes for it.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the lawn mower guru (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Leave a Reply Cancel reply

Copyright © 2010. 2023 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.

TECUMSEH GOVERNOR FAILURE

When this happened to my mower, I went online to see if others had reported similar issues. All I found was guidance on how to adjust a working governor, plus one small engines expert that would offer advice for a fee. So, I’m posting my experience in hopes of helping others.

SYMPTOMS:

I was just mowing along as usual, and all of a sudden the engine started to run away. It roared as though I had given it full throttle, and revved way up. I cut the throttle immediately, and was relieved the ignition cutoff still worked. Upon further fiddling I found that the engine would run at idle but the instant I moved the throttle just a hair above idle the engine ran away and I’d have to cut the throttle back again.

DIAGNOSIS:

I expected to find that a link had come loose or a spring had broken or some such, but did not find anything out of sorts with the linkage. The burning question: Did I miss something, or is the problem really inside the engine? Obviously, you want to make very sure the problem is inside the engine before you go to the effort of opening it up.

Clarity arrived when I disconnected the linkage from the governor lever and the lever flopped over in the CCW direction as shown in this photo:

That’s too far CCW; it shouldn’t be able to move that far. That confirmed that the governor inside the crankcase had failed somehow and I’d need to open up the engine to fix it. What’s more, if I cranked the engine over slowly, the lever would bump up a little bit a couple of times per turn. That told me that the governor spool was AWOL and the lever was bouncing over the flyweights on the governor gear.

TO DO NOW:

If you’re even thinking about disassembling this engine, here’s something you need to do right now. There are several bolts holding the oil pan or crankcase cover to the crankcase; on my engine there are eight 1/4 bolts with 3/8 hex heads. On my vertical shaft engine, the heads are facing downward, the threaded ends point up. Some of them thread upwards into bosses on the outside flange of the crankcase so you can see the threaded holes on the top side of the flange. Right now, go out there and spray some Liquid Wrench into those holes so it can begin soaking down into the threads. Get up from your ‘puter desk and go do it! Steel bolts threaded into aluminum castings are a recipe for seized bolts, and breaking bolts during disassembly makes this job a whole lot more difficult than it should be.

The Clymer manual on Tecumseh engines says to reinstall these bolts with Loctite 242 (blue), and so did a slip of paper that came with the replacement oil pan gasket. I won’t be doing that. Rather, I’ll be reinstalling those bolts with anti-seize compound.- just in case I ever have to get in there again.

TEARDOWN:

- Drain the oil.

- Drain the gas, or pinch off the line and remove the tank.

- Remove the pulley or whatever is affixed to the shaft of the engine. The key must be removed, too.

- You’ll probably need to remove the engine from whatever it’s mounted on.

- Remove the crankcase cover (horizontal shaft engines) or oil pan (vertical shaft engines). It was eight bolts on my engine.

- Fix whatever’s wrong with the governor and reassemble.

FINDINGS:

Upon removing the oil pan I found the spool broken as shown in the photo at the top of this page. The spool had neatly broken into three pieces; one remained on the governor shaft while the other two were just sitting in the sludge inside the crankcase. Since they hadn’t been shattered or chopped into a zillion pieces, it was easy enough to just pick the two pieces out of the crankcase; no extensive cleanup needed.

Before the teardown, I pondered whether or not the failure might be a wear issue; that the lever riding on the flat upper surface of the spool had just completely worn through it. As you can see in the photo below, wear on the surface of the spool was negligible. This part broke just because it’s a plastic part that had too many years on it.

- The plastic is exposed to sunlight; plastics don’t like UV radiation. Not a problem inside this crankcase.

- The plastic is exposed to excessive heat, causing it to get brittle. That might be a factor here.

- The plastic is exposed to incompatible chemicals, typically hydrocarbons or oil additives. That may be a factor here as well, although I’ve always used the recommended oil in this engine.

In my experience with the Jaguar V12 engine, I’ve seen the arch in its timing chain tensioner fail for little or no good reason. I believe it’s the same material as this spool, and for the same reason: These parts have metal sliding across them, and the plastic is a special formulation that is supposed to minimize wear in such situations. Both the Tecumseh and the Jaguar V12 are from the same era, so it was probably the state of the art at the time.

THE GOVERNOR GEAR AND SHAFT:

I replaced the governor gear while I was in there even though the old one was in good working order. Why? Because it’s plastic and it was 28 years old. It only costs about ten bucks, and I’d just as soon not have to do this again.

The spool and the gear spin around a shaft that is pressed into the oil pan. On mine, you pry off one clip and the spool comes off, then you pry off another clip and the gear comes off. According to the Clymer manual, though, some governor shafts don’t have the second clip. Rather, they have a boss around the shaft that retains the gear. As a result, the only way to get the gear off is to remove the shaft which is a press fit into the oil pan. If this were the case in my engine, I dunno if I’d replace that gear or not. Pulling the shaft and pressing it back in to a specified depth is not a trivial matter for a home mechanic, and entails more risk of damaging the oil pan in the process. If I decided to go for it, I’d have a spare shaft on hand.

REPAIRS:

The replacement governor gear was black. Here’s the governor reassembled with new gear and new spool:

- Black vs. white (I suspect the old one only looked yellow due to age)

- The flyweights are castings rather than stamped plates.

- The gear teeth directly outboard of the flyweights have little posts sticking up that prevent the flyweights from swinging farther out; they can’t lay out flat like the ones on the old gear in the picture at the top of this page. These little posts should only make a difference during assembly, I think; they hold the flyweights in the correct position for installation of the spool. Once assembled, the spool limits the motion of the flyweights.

The governor lever rides against the flat surface on top of the spool; as the spool rises, the lever moves to close the butterfly on the carburetor.

After the engine was reassembled, the governor lever would no longer move as far CCW:

That’s as far CCW as it’ll go. Compare this with how far it would move CCW with a broken spool in the picture at the top of this page, and you’ll see why it became obvious that the governor had failed and the engine had to be opened up.

As an aside: Upon reconnecting the linkage to this lever, I realized that the linkage was not adjusted correctly. In the Clymer manual it clearly stipulates that the linkage should be adjusted so that when the governor lever is fully CCW.- the lever inside the engine is in contact with the stationary governor.- the butterfly should be at wide open position. In this case, when the butterfly was wide open the lever was perhaps 3/8 from its fully CCW position.- and that’s probably half its total travel, meaning the lower half of the governor’s control range was inoperative. The governor had to move from its stationary position to about halfway raised toward its fully extended position before it’d even make contact with the governor lever. I’m quite sure this linkage has never been fooled with; I believe it was out of adjustment when it was originally purchased. One could hypothesize that there was some difference in the dimensions between the new vs. old governor parts, but I don’t think so.

It’s easy to adjust: Just loosen the screw on the governor lever (visible in the photo above behind the bottom end of the spring) and then hold the butterfly wide open and the lower portion of that lever (from the screw downward) CCW as you retighten the screw. After adjusting the linkage properly, the governor operation seems considerably better than it has ever been. Specifically, it seems that I can adjust the running speed higher than I could before without starting to close the choke.

The following are presented as reference material related to the governor repair described above:

GOVERNOR OPERATION:

Understanding how this governor works is helpful, but most of the descriptions.- either in the Clymer manual or online.- are clear as mud. So I’m going to provide my own description here in hopes it’ll make it more understandable for some.

- Governor (inside crankcase)

- Governor lever (part inside, part outside crankcase)

- Butterfly (in the carburetor)

- Throttle lever

The governor lever consists of a metal rod that passes through the crankcase wall with a stamped metal lever attached to it on the outside. The portion of the rod inside the crankcase is bent and shaped to ride on the surface of the governor spool.

The butterfly is the item on the carburetor that actually controls how much air and fuel is allowed into the engine, and hence how much power the engine develops.

The throttle lever is the device the control cable connects to. It’s the thing the operator moves to control engine speed. On my engine it also engages the choke when moved past the full-throttle point, but on other engines the choke may be separate. There’s also an electrical contact that shuts off the ignition when the throttle lever is moved to the OFF position.

The first thing to know: The governor lever and the butterfly are firmly connected to one another by a link. There are no springs or any other ifs, buts, or maybes in this connection. One cannot move without the other moving, period.

Governed speed control is a matter of balance between two opposing forces. The throttle lever pulls on a spring that is trying to speed the engine up; the farther the throttle lever is moved by the operator, the harder the spring is trying to pull the governor lever (and hence the butterfly) to the wide-open position to speed the engine up. Meanwhile, the governor is trying to slow the engine down. The faster the governor is rotating, the harder it’s trying to push the governor lever (and hence the butterfly) toward the idle position to slow the engine down.

Hence, when the governor breaks.- the spool fractures and drops into the crankcase.- the spring connected to the throttle lever is free to speed the engine up unabated. Runaway engine.

There is a spring on the butterfly itself that’s moving it towards idle, but this spring is very weak and is not a significant player during speed-governed operation. However, when the operator moves the throttle lever all the way to idle, the spring that pulls on the governor to speed the engine up goes totally slack. The engine is turning slowly enough that the governor isn’t doing anything, but the light spring on the butterfly will actually move the butterfly to idle and lift the governor lever completely off the spool on the governor. Hence, idle is not governed, but rather is set using an idle stop screw on the carburetor.

THIS PARTICULAR ENGINE:

My engine is a vertical-shaft 8HP cast iron sleeve model TVM195 purchased new in 1987. It was installed on an already-clapped-out Sarlo 21 walk-behind lawn mower chassis that a local mower shop sold to me for scrap value. The self-propelling mechanism was discarded; this is a mower you’ve gotta push. No safety interlocks, no grass catcher.

8HP on a 21 mower may sound like overkill, but the purpose here wasn’t just to cut grass. My property is 73 acres of woods, and I assembled this mower for the express purpose of cutting walking trails through those woods. It’s expected to cut pretty much anything and everything I can roll it over, including shrubbery, tree roots, small woodland creatures, you name it. I have used it to cut paths through chest-high weeds. The 8HP Tecumseh was chosen expressly because it’s the largest engine I could find that would fit between the tall wheels on the Sarlo. The exhaust blows out through the spokes on the right side wheel because there’s no room to route the exhaust any other way.

It actually has rather low hours on it; I probably don’t run it more than 20 hours a year, and even less lately because my woods have thinned out and the trails don’t require as much upkeep. When it’s run, though, it’s run pretty hard, and the governor probably gets a pretty good workout between patches of nothing and patches of heavy ground cover.

Overall, it’s been a good engine. I’ve had to replace the starter cord and handle a couple of times. Before this governor issue, the only serious problem I’ve had was a carburetor float that started leaking and sank. When I replaced the float I also rebuilt the carb, and it turned out one of the parts in the carb rebuild kit was defective, so that task turned into a fiasco until I finally figured out what the problem was. Once sorted, though, it resumed starting easily and running strong.

I’m probably not as scrupulous about changing the oil as I should be. I never change it more than once a year due to the low hours.- no need to change the oil when I’m not using the mower.- and sometimes it probably goes a couple of years between oil changes. The oil always comes out still looking oily, though; I’ve never waited so long that it came out looking watery or gooey.

REPLACEMENT PARTS:

I mention the part numbers of the governor gear (30591) and spool (30588A) in this page. These are the parts that fit my TVM195. However, it’s my impression that these same governor parts fit all Tecumseh engines. Smaller engines presumably have smaller camshaft gears, which means the engine would have to turn faster to turn the governor at the same speed. Hence, the same governor would efficiently control a smaller engine at a higher RPM, which is usually what you’re looking for anyway. Pretty Smart design on Tecumseh’s part, I think.

Replacing the governor requires a new oil pan gasket. In the case of the TVM195, this gasket is part number 37342.- which superceded 35262 or 35262A, which superceded 33253, otherwise known as G310 or 470-443. Clear? Actually, I suspect there are minor differences there; for example, the 37342 I received has odd little red rubber beads printed on one side, while I suspect the earlier gaskets were plain paper. Whatever, my decision was to apply Hylomar to both sides, as Hylomar should make it easier to come back apart later. I’m not a big fan of having to carefully scrape old gaskets off machined aluminum mating faces, and it shouldn’t ever be necessary if the correct gasket dressings are used during assembly.