Lawn mower ignition system. Are Lawn Mower Ignition Coils Interchangeable

Are Lawn Mower Ignition Coils Interchangeable?

Are you looking to replace the ignition coil on your lawn mower but not sure if it’s interchangeable with other models? This is a common question for DIYers, so let’s break down what’s involved with replacing an ignition coil and whether or not you can use one from another model.

What is an Ignition Coil?

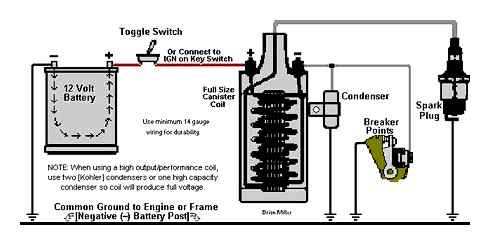

An ignition coil is a type of transformer used to convert low-voltage energy from your battery into the high-voltage energy needed to ignite the fuel in your engine.

It consists of two coils of wire wrapped around an iron core, and when the current passes through them, they create an electromagnetic field that produces the voltage required to spark the fuel in the combustion chamber.

Are Ignition Coils Interchangeable?

It is important to understand whether or not lawn mower ignition coils are interchangeable when dealing with mower repair. That said, the answer is somewhat complicated.

While some larger mowers may not be able to use parts from other makes and models, many of the small engine brands have standardized coil systems that can be interchanged between different types of ignitions.

Although compatibility across all brands cannot be guaranteed, a qualified technician should be able to confirm the interchangeability of two ignition coils before any work is completed.

Ultimately, it is best to check with both the manufacturer and a knowledgeable individual before attempting a DIY repair.

What Happens if You Use the Wrong Ignition Coil in Lawnmower?

If you use the wrong ignition coil in your lawnmower, it can lead to serious engine damage and decreased overall performance. The ignition coil is a critical component of your engine that produces, stores, and regulates electric charges essential for powering up the spark plug which, in turn, ignites the air and fuel mixture in the combustion chamber.

If the wrong ignition coil is used, it won’t be compatible with your engine’s particular configuration and so cause disruption and misfiring, leading to excessive wear on some parts of your lawnmower’s engine.

In addition to the damage done by misfiring, using an incompatible ignition coil may also result in insufficient or no spark at all causing non-combustion of air-fuel mix and ultimately damaging the valves too.

Therefore, it’s important to always use the right ignition coil for your specific model of a lawnmower or you could be looking at costly repairs or even having to replace your entire engine down the line.

How Do I Find My Ignition Coil Model?

To find your ignition coil model number, start by removing any covers or pieces of plastic shielding that may be covering it up. Then, look for a small metal label attached to the side of the unit, this should include information such as size and voltage requirements.

Knowing this information can help you find an appropriate replacement at your local hardware store or online retailer.

What is the Life Expectancy of an Ignition Coil?

The life expectancy of an ignition coil in a lawnmower can vary significantly depending on factors such as operating environment, frequency and quality of maintenance, and the type of coil used.

Many factors that impact an engine’s overall performance can also affect the lifespan of the ignition coil. For example, if the filter is not changed regularly it increases strain on the engine and speeds up ignition coil degradation.

Regular preventive maintenance is key in extending ignition coils’ life. Generally speaking, the average lawnmower owner can expect to get anywhere between 3-5 years out of their ignition coil depending on the above-mentioned contributing variables.

To ensure you’re getting the most longevity possible out of your mowers’ ignition system, always double-check instruction manual recommendations regarding service guidelines and maintenance schedules.

While most lawn mower ignition coils are interchangeable between models, it’s best to match your replacement as closely as possible with your existing unit.

To find out which model fits yours, look for a small metal label attached to its side which should include size and voltage requirements. With this information in hand, you should be able to find a suitable replacement at any local hardware store or online retailer.

How to diagnose a weak ignition system

The following issues can present in different ways or operating states, but the most prevalent ignition problems include a cracked spark plug porcelain or weak ignition wire insulation.

Ray Bohacz is a technical writer in both the automotive and agricultural industries and has been featured in more than 44 different magazine titles with over 3,000 published technical articles. Additionally, he has authored three books and delivered countless seminars to the two communities.

At one time or another, we have all been stymied by a gas engine with either a no-start or a hard-start condition, or another performance issue that seems to elude logic. The engine has fuel, spark, and compression. It should either run or not have the performance issue that it does. Often that simple logic does not apply in the real world. Something else is going on, and there is a very strong possibility it is with the ignition.

The ignition system is considered to be passive. The spark plug only takes from the ignition coil what it needs to create an arc across the plug’s electrodes. It must be recognized that ignition demand is determined by the following:

- Cylinder pressure

- Engine speed

- Air-fuel ratio

- Ignition timing

- Spark plug gap

Cylinder pressure is not meant to be confused with compression ratio. Cylinder pressure is the cumulative result of the load on the engine in relation to the volumetric efficiency and mixture strength. Compression ratio is a design function of the difference in the volume of the bore with the piston at bottom dead center, compared to when it is at top dead center. Cylinder pressure and ignition demand are constantly changing with engine load.

At idle, the required energy to arc the spark plug is very low since the cylinder pressure is minimal. This is due to the throttle being almost closed, the engine rpm being low, and the fact that there is no load on the engine.

If the engine was still idled and a load was gently applied (engaging a PTO, for example), the voltage required to arc the plug would increase dramatically. Due to this, the engine may run fine under a given operating state and then buck, pop, and misfire when faced with different operating conditions.

In like fashion, during throttle movement (transient operation), ignition demand spikes just as the throttle plate is evoked. To diagnose a performance issue expediently, you need to remember that electrical demand is linked to load.

What is a misfire?

An engine is considered to misfire when there is not enough electrical energy going to the spark plug to keep it arcing or there is a path- way in the engine for the energy to take that bypasses the plug’s electrodes. Electricity is lazy. It will always take the path of least resistance. If it is easier to go to ground through the insulation on the ignition wire instead of arcing the gap of the plug under high cylinder pressure, it will. When this occurs, that cylinder will not be contributing full power to the crankshaft. The engine will be weak, the unburned fuel will foul the spark plug, and the exhaust will pop. If the mixture is excessively lean, the engine will misfire since the fuel molecules in the intake air are too far apart. When the mixture is lean, the flame cannot expand across the cylinder bore since it requires both fuel and oxygen to accomplish this.

In most instances, the flame does begin since the air-fuel mixture by design is concentrated around the spark plug electrode. Once the flame expands away from that region, it dies out, and the cylinder is no longer contributing any power. The demand on the ignition will increase, and the energy will look for an easier path.

how a plug fires

A spark plug on most engines fires from the center electrode to the side electrode. That side electrode is grounded via the plug threads to the cylinder head. If the primary leads to the coil were accidently connected in reverse, the amount of energy the coil could produce would be greatly diminished. Most times, the engine would idle fine, but as soon as any load was applied, it would misfire.

The proper connection for a coil is that the voltage from the ignition switch goes to coil Then the wire from either the breaker points or the ignition module goes to coil (-). Many modern gasoline engines do not employ a traditional distributor but, instead, have either a coil on each spark plug or a coil pack that fires two cylinders. When an engine has no distributor, it will use a sensor on the crankshaft to identify each firing event; the sensor also recognizes the number-one cylinder. The control unit is programmed with the correct firing order. This style ignition system allows for longer arcing time of the spark plug when measured in degrees of crankshaft rotation past top dead center. When a coil pack is used, it fires differently than a conventional ignition in terms of polarity. It will fire one cylinder from the spark plug center electrode to the side electrode (normal path) and the companion cylinder from the side electrode to the center electrode.

Commonly overlooked ignition problems

The following issues can present in different ways or operating states, but the most prevalent are listed below.

- Cracked spark plug porcelain. This causes misfiring or bucking under load. The engine may run fine at idle and light load.

- Fouled spark plug. This situation causes misfire (no defined operating state) and hard starting.

- Weak ignition wire insulation. In this case, the engine runs fine until engine temperatures rise and there is an increase in workload. The wire insulation then breaks down, and the engine bucks or misfires. However, the engine runs smoothly in cooler temperatures or under less workload. When the insulation fails due to heat, it’s because the molecules have moved farther apart, making an alternative path for the electricity to take if that path is easier than jumping the gap of the spark plug.

- Weak ignition coil. The engine idles fine but breaks up under load. The issue here is a coil that has worn out from the constant charging and discharging cycles. The proper method to check an ignition coil is using an oscilloscope, but an ohm meter works well, too. With the meter, you can check for an internal open in the primary windings or excessive resistance. You will need to check between the primary terminals with the meter leads.

If you have a shop manual for the engine, it usually provides a primary resistance check specification. This is important on pull-type start engines or other small-engine applications.

Keep in mind that it’s possible for the coil secondary to burn open internally. When this happens, the engine will run under light load but will misfire under other conditions. The spark is actually bridging the internal break in the secondary windings, leaving less energy for the spark plug. Older-style ignition coils were oil-filled as a coolant. Later designs were made with epoxy (identified as e-core coils). If you remove the secondary lead from an oil-filled coil and it is wet, the coil needs to be replaced.

Check a no-start

The proper method to check for spark is with a spark tester. It resembles a spark plug but has a sunken center electrode that simulates a load on the coil.

Holding the plug wire and seeing if a spark jumps to ground is inconclusive. The spark is arcing in atmospheric pressure. This is substantially less pressure than the energy required to arc the plug electrode under load.

For an engine to start and run properly, the energy must arc the plug and keep that arc going until all of the combustible mixture is consumed. Anything less and the engine will be weak, run rough, stall, and misfire.

Weak ignition is often confused with a fuel problem since the two systems are codependent. Many times, especially with small engines, the carburetor and the fuel are unjustly demonized for a problem when the ignition system is the real culprit. Think spark first then fuel, not the other way around.

Test the ignition coil quickly and easily with a simple ignition system tester

Family Handyman

Learn how testing the ignition coil can be quick and easy using a special ignition system tester. It’s inexpensive and works for any small engine.

By the DIY experts of The Family Handyman Magazine

How to test an ignition coil

Testing the ignition coil and the spark plug

Connect the tester between the spark plug boot and the spark plug. Then start the engine and watch the tester.

Most people think you can check a small engine’s ignition system by removing the spark plug and grounding it while cranking the engine and watching for a spark. Nope. That just confirms that the spark plug fires in open air. It doesn’t mean the ignition coil is strong enough to fire the plug when under full compression.

Here’s a better ignition coil test. Buy an inexpensive ignition system tester (Briggs Stratton No. 19368; about 18 at amazon.com). Then connect the tester between the spark plug boot and the engine. Watch for a spark in the tester window as you pull the starter cord. To test the operation of both the ignition coil and the spark plug, connect the tester between the spark plug boot and the spark plug. Then start the engine and watch the tester window. A spark plug misfire will immediately be evident in the tester window. You can use the tester on any small engine (mower, snow blower, chain saw, string trimmer, etc.).

Required Tools for this Ignition Coil Test Project

You’ll need an ignition system tester.

Lawn Mower No Spark – Fix Easily in Seconds

Winter has finally passed, and you can now start thinking about getting the garden back into Spring and Summer condition. Being a responsible owner, you decide to check that the lawnmower is running well before you need to put them to use.

If a lawn mower doesn’t have a spark, it can only be one of four wrong things. The spark plug is damaged or faulty, the high-tension wire connecting the spark plug to the ignition system fault is broken, the start/stop switch is not working, or there is a problem with the ignition system.

You fill the lawn mower with fuel check that the blades are good enough to give a good cut for another season.

When you are ready, you set the choke, pull the cord, pull the cord, and pull the cord. After straining your patience and your back, you sit down to consider what could be wrong.

How To Fix A Lawn Mower No Spark?

Internal combustion engines need three things, delivered at the exact time to work. These are.

If any of these is not present or is delivered to the cylinder in the wrong sequence, the engine won’t start.

In a nutshell, these are the factors a mechanic would check to find out the cause of the problem.

For this article, we will assume that fuel and air issues have been ruled out, and a test has shown that the lawnmower has no spark.

To start the engine, you need the ignition system to send a sufficient electrical charge through the high-tension cable to the plug, which will, in turn, set off a spark.

As in all electrical circuits, there must be no breaks or unintentional changes in resistance to cause the ultimate spark.

The four elements which need to be investigated are.

- The Stop/start switch and the wiring connecting to the ignition system

- The ignition system

- The Spark Plug itself

- The Spark Plug Wire

If any of these items are broken, the circuit won’t close, and the plug will not create a spark.

How To Check The Stop/Start Switch And Its Components?

The stop/start assembly includes the following components.

- Bail Throttle Control Lever

- Cable

- Stop/Start switch

- Flywheel brake assembly

- Coil control wire

Bail Throttle Control lever

This lever can become disconnected from the throttle cable, either because the adjustment is out of whack or, more likely, the control lever itself is broken. To fix this, source a new one and replace it on the machine.

The Cable May Be Broken

If the throttle cable is broken or stretched, it will not close the circuit, and a spark will not be produced.

The Flywheel Brake Assembly May Be Faulty

If the flywheel assembly is faulty, it could very well just be an adjustment issue where the cable is out of spec.

If this happens, the bail lever won’t move the switch to the off position, and therefore no spark will be generated.

The Stop-Start Switch Itself

Most lawnmower engines have a start-stop switch that connects directly to the flywheel.

When the Bail control lever is activated, it pushes on the stop/start switch and closes the circuit to the coil; this allows the engine to start.

If the switch has broken, a spark will not be generated.

You can test the switch by carrying out the following steps.

- Attach the spark plug lead to the spark tester and connect the tester’s ground lead to the engine (to ground it).

- First, turn off the switch.

- Pull on the cord or turn the starter motor over and watch for a spark in the tester window.

- If you see a spark in the tester, the switch is not switching off.

- Move the switch to the ON position and repeat step 3.

- If you don’t see a spark, the switch is not closing the circuit and needs to be replaced.

How To Check The Ignition System?

The ignition system sequences the spark exactly when the gas and air mixture is in the combustion chamber.

If the spark is not generated or occurs at the wrong time in the combustion cycle, the engine won’t start.

Most modern lawnmowers have ditched the old contact breaker ignition system in favor of solid-state unis; It has no moving parts, and the machine’s reliability is increased. Solid-state units use a tiny transistor positioned in the coil or armature to close the electrical circuit that travels through the spark plug leading to the spark plug(s).

First Test The Coil

If your lawnmower is not producing a spark, you should test the coil; this is very quickly done as follows.

- Clip the spark tester to the ignition cable and the cylinder head.

- If it sparks, the coil is working, and you can move on.

Check The Solid-State Ignition Unit

With no moving parts, these units are very reliable. If it does fail, it is probably because of incorrect fitting, which has caused it to get too hot.

If you have tested everything else and this is the last potential culprit, we suggest that you take the lawnmower to a dealer who will have the necessary equipment to find out what is wrong.

How To Check The Flywheel Brake Assembly?

The main issue which affects lawnmower flywheels is a sheared flywheel key.

The flywheel key’s function allows the flywheel to move on the crankshaft when your mower blade hits a hard obstruction, such as a root or metal outpost.

If the mower blade is loose, it may generate enough shock energy to shear the flywheel key.

To check the flywheel key, follow the manufacturer’s instructions and replace it if necessary.

How To Check The Spark Plugs?

The spark plug must be in good order and set to the correct gap to generate the spark required by the engine.

In a real-life situation, we would not wait until this late stage to check the plug because they are easy to replace and reinstall.

- When checking the plug, make sure that there are no carbon build-ups between the ground and center electrodes.

- Check that the ceramic insulator is not cracked or chipped.

- Check that the gap between the ground and center electrodes is within the lawnmower manufacturers’ specs.

Spark plugs are not expensive, and if you have any doubt about the one fitted in the lawnmower’s engine, buy a new one with the exact specifications.

If this doesn’t fix the problem, it is elsewhere on the engine, but you have eliminated one factor.

Checking The Wires To The Coil

There usually are three wires which lead to the coil.

- The High-Tension Spark Plug Lead.

- The power wire connected to the ignition unit

- The ignition switch wire.

If any of these are broken, the ignition system will be disabled, and there will be no spark.

Conclusion

In this article, we have discussed all the possible reasons why a Lawn Mower has no spark. Likely the cause will be relatively simple, and when investigating, we recommend checking the most straightforward possibilities before investigating the more complex possibilities.

If in any doubt, ask a qualified lawnmower technician to diagnose the problem for you.

Author

Jason is an expert writer and is passionate about Smart Homes and Home Improvements writing as well as lifestyle and Lawn Care. He spent the past twelve years living in Hawaii, where he worked closely alongside event planners and resort owners to perfect his knowledge of luxury products and aesthetics. He discovered his passion for DIY projects and home improvement there. Currently, he lives in Washington D.C with his family and 2 pets. View all posts

Lawn Mower Parts

Search and shop all the parts you need for your riding lawn equipment and Gator UTV including lawn mower blades, filters, belts, spark plugs, oil, and home maintenance kits.

Find Parts

Search part numbers and John Deere parts diagrams to identify exactly what you need to keep your equipment running smoothly.

Quick Reference Guides

As a John Deere owner, when it’s time to maintain, service or repair your equipment we have easy-to-use information sheets that keep your John Deere equipment running well.

Home Maintenance Kits

Feel confident in tuning up your lawn mower or garden equipment this season with our Home Maintenance Kits. Easily find the right product so you can DIY and save!

Looking for your Serial Number?

Finding your lawn mower’s model number and serial number is as easy as locating the identification tag on your machine. As seen in the example, the model number will be displayed below the MODEL heading (Example: Z235), and the serial number will be underlined on the top-right corner of the tag (Example: 130002).

If you’re looking for the engine number, that can be found directly on the engine itself.

Home and Garden, eat your heart out.

Get the latest on how to care for and enjoy your yard and garden. The articles and videos are informative and the ideas are amazing.

MowerPlus Mobile App

MowerPlus is the app you need to keep your John Deere riding lawn mower running well and your lawn looking great this season. The app tracks and records yard tasks and serves as a one-stop shop for seasonal care tips and maintenance activities. Know your mower and know how you mow with John Deere’s MowerPlus app.

The Right Part. The Right Price.

At John Deere, you get the value of choice for your maintenance and replacement parts for all makes and ages of machines – at any budget.

Genuine Parts

Genuine John Deere Belts Blades are your best choice for your newer machines.

Alternative Parts

Alternative Parts are an economical solution for your John Deere equipment.

The John Deere Easy Change™ 30-Second Oil Change System

Never drain engine oil again.

We’ve changed the oil change. Revolutionized it really. See how fast and easy changing your oil can now be on 100 Series Riding Lawn Tractors with the John Deere Easy Change™ 30-Second Oil Change System. Only from John Deere. Included on the E120, E130, E150, E160, E170, and E180 models.

Briggs and Stratton Ignition Coil Replacement. Murray Lawn Tractor

Step One. Take it off.

Lift the hood. Make sure the engine is cool, then, twist to remove. It’s that simple.

Step Two. Twist and lock.

Grab the new Easy Change™ Canister, twist and lock into place. Make sure the arrow on your Filter System aligns with the arrow on your engine.

Step three. Done.

Close the hood and mow. John Deere recommends the Easy Change™ 30-second Oil Change System every 50 hours or at the end of your mowing season. Don’t drain engine oil ever again.

Draining engine oil is so 2017.

The engine modifications and new technologies are in. The re-envisioned oil filter with a media designed to resist breaking down in oil over time is here. The thousands of hours of testing are done. The end result is an all-in-one, oil and oil filter system like no other. The first of its kind. And thanks to the new John Deere Easy Change™ 30-Second Oil Change System (“System”), you’ll never have to drain the oil from 100 Series Riding Lawn Tractors again.

Here’s why: The new System captures contaminants and recharges your engine with nearly a quart (0.8qt) (0.76 l) of new oil. In fact, this System increases the amount of oil in the engine by nearly 40%. 2 Your engine likes that.

What do you mean, I will never have to drain oil from my engine again? How is that possible? The answer is simple. We have developed a better filtration system and filter design for our 100 Series Riding Lawn Tractors 1. This fully synthetic filter media has greater surface area which increases its capacity to hold harmful contaminants. What’s more, the filter media is designed to resist breaking down in oil over time. Which means you’ll get a cooler running engine. And a cooler running engine and better filtering helps increase engine oil life. John Deere’s recommended oil service for 100 Series Riding Lawn Tractors 1. is to change the System every 50 hours or once a season, whichever comes first. Remember, the System replaces a portion of your engine oil. And that’s plenty.

The System uses John Deere Turf-Gard™ Oil. Using John Deere Turf-Gard™ Oil ensures you are using the exact oil specified by John Deere engineers.

Testing. Testing. Testing. Thanks to thousands of hours of rigorous and extensive testing, you can feel confident your engine will run for years to come.

1 The John Deere Easy Change™ 30-Second Oil Change System is available on E120, E130, E150, E160, E170 and E180 Lawn Tractors today.

2 Compared to similar V-Twin engine models that do not have the John Deere Easy Change™ 30-Second Oil Change System. That includes equivalent Deere 2017 models and 2018 models without the System.

No spark on lawn mower engine. Ignition coil replacement

Frequently Asked Questions:

What is new with John Deere Riding Lawn Equipment?

We are excited about the exclusive John Deere Easy Change™ 30 second oil change system. Exclusive to John Deere and only available on certain models of the new 100 Series Lawn Tractors. These tractors are designed for ease of use for both operation and maintenance. The John Deere Easy Change™ System (“Easy Change”) allows the user to easily complete the recommended engine oil and filter maintenance in 30 seconds.

What is this new oil change system?

We changed the oil change. The all-in-one oil and oil filter system gives the owner the ability to change a portion of the oil and the filter in less than 30 seconds.

What happens to the rest of the oil in the engine when the Easy Change system is replaced?

The Easy Change system replaces.8 quart of oil. The remaining oil in the engine is refreshed by the charge of new oil included in the replacement Easy Change system. Combined with 40% more engine oil capacity, improved filtration and cooler running temperatures which help extend oil life, it is no longer necessary to remove and dispose of all the oil in your engine during service.

What makes the Easy Change system unique from other filters?

It is not just a filter. It is a newly developed technology system that allows a new “filter” to come already charged with oil and allows you to remove an existing filter and the contaminants inside without tools and without making a mess. Beyond the filter, technology within the canister and on your engine makes this possible.

Models with the Easy Change oil system use a fully synthetic filter that has more capacity to trap and hold contaminants. The larger surface area of the Easy Change canister acts like a radiator helping the oil to stay cool.

Does the Easy Change system somehow decrease the life of the engine?

The John Deere 100 Series lawn tractor models, with and without Easy Change, are specified for the same lifetime and are rigorously tested to the same standards to ensure the life of the tractor meets expectations.

Can I add the Easy change system to an existing tractor?

Because this system also requires unique features within the engine, the Easy Change system cannot be added to an engine that was not equipped with it at the factory.

Can I change all the oil if I choose to?

You could if you wanted to. There is an oil drain plug. It is not required for maintenance.

How often do I need to change the Easy Change canister?

Every 50 hours or once a year. The 100 Series Lawn Tractors with and without the Easy Change system have the same maintenance schedule.

What type of oil is recommended?

We recommend only John Deere Turf-Gard™ 10W30 Oil. The Easy Change canister comes pre-filled with John Deere Turf-Gard™ 10W30 oil.

How do I recycle the old oil?

Many local government recycling programs, authorized retailers, auto repair stations, and auto parts stores will puncture and recycle used oil filters and oil.

Do I ever need to add oil?

Yes. Consistent with our service recommendations for this product, you should check oil level daily and add oil if required.