Lawn tractor starter motor. How to Start a Lawnmower with a Bad Starter

How to Start a Lawnmower with a Bad Starter?

All homeowners with lawns know pretty well that lawnmowers are unmatched machines for tending your yard. But it is only fun when the mower is working fine and smooth. When a mower is not running correctly or having problems, mowing becomes tedious and rather unenjoyable. Lawnmowers, like all machines, run into all sorts of issues. But could there be a more frustrating problem than the mower not starting at all? One of the reasons for this could be a bad starter. But don’t worry, even with a bad starter, there are ways to start your mower.

How to Start a Lawnmower with a Bad Starter:

- Clean the battery leads and seal any leakages, then try again. Replace the battery if it is faulty beyond repair.

- Bypass the solenoid and start the mower using the starter motor only.

- If the starter motor is faulty, you’ll have to get a new starter motor.

- Replacing the entire starter with a new one is better than replacing just the motor.

- In case of a faulty ignition switch, try to make its connections tight. If it is defective beyond repair, get a new ignition switch.

Reasons for a bad starter:

The starter is responsible for using the energy of the battery to start the engine. A bad starter won’t do this job, and the ignition system won’t get any energy, which means that there will be no spark and the engine will not start. A starter can go wrong because of these causes:

The final solution to a bad starter can be to replace one or more parts, but techniques like bypassing the solenoid can let you start the mower for now, and you can do the replacement later. To do that, you’ll need to get some basic information about a starter and its working. This article will surely help you in this regard.

What is a Starter?

The starter is an essential component in a lawnmower that transfers electricity from the battery to the ignition system, thus allowing the engine to start. A starter has two main components, a starter solenoid, and a starter motor.

Starter Solenoid:

Solenoid gets current from the battery and transfers it to the motor. When the ignition button is pushed, a current is sent from the battery to the solenoid through the wiring and then from the solenoid to the motor.

Starter Motor:

The starter motor is the starter component that is linked directly to the spark plugs. It sends current from the starter to the engine.

These two components are independent but work together to power the spark plug so that a spark can be generated in the combustion chamber, producing power from fuel. Though the starter solenoid and motor are independent, the chain is disrupted if one fails, and the engine won’t start when you push the ignition button. But because these two components are separated, the mower can still be turned on if one goes bad.

Before making any repairs or changes, you need to know what’s wrong. A lawnmower with a bad starter will show specific symptoms that can help you see the problem’s root cause.

Symptoms of a Bad Starter:

A satisfying rumble sound is always expected when starting the engine, but a mower with a bad starter will make abnormal sounds when it is being started. The sounds can be used to judge the nature of the underlying problems.

Abnormal Solenoid Clicking:

When the ignition button is pushed, the solenoid transmits an electric spark that starts the motor. The motor starts rotating a smaller gear that engages with a larger gear of the engine. This is how the engine is jump-started. When this process goes normally, a clicking sound is produced, followed by a whirring sound that indicates that the starter motor is engaging with the engine.

If you push the ignition button and only the clicking sound is produced, it is a sign that something is wrong and the motor is not engaging with the engine’s gear.

Whirring sound, but no Catch:

When the whirring sound is produced but is followed by a loud rumbling sound, it is a sign that the starter is not engaging with the engine in the normal manner. This is a sign of the starter’s smaller gear not correctly engaging with the engine’s gear. Another sign of this issue is when the engine starts but stops after just a moment. Broken teeth basically cause these problems on the starter motor’s gear or worn motor brush brushes. If this is the case, these faulty components will have to be replaced.

Not Starting Even with a Fully Charged Battery:

If your mower does not start even though there is no battery-related issue, it is the clearest and obvious indication that the starter isn’t working fine. When this happens, start looking for the cause of problems right away.

Solenoid Not Clicking:

If there is no solenoid clicking sound when you push the ignition button, it is an indicator of loose connections to the solenoid. This means that the current is not reaching the solenoid. If this is the case tightening solenoid connections will get your mower running.

Starting a Mower with a Bad Starter:

A bad starter is caused by electrical problems that can be fixed. Here’s a guide on how to do that.

Flat or Faulty Battery:

The first thing to get in order when your mower is not starting is the battery. If the battery fails to provide electricity, there is no way your mower will start.

Start by looking for leakages. Charge the battery with a charging cable, and if it becomes wet, then the battery is leaking. Small leakages can be sealed, but if the leak is too big, replace the battery. When dealing with leaks, wear safety gloves and glasses to avoid acid burns.

Check the battery voltage too. The battery voltage should be 12V. If the voltmeter reading is less than 12.4V, it is a sign of a faulty battery that needs to be replaced.

Ignition Switch:

Loose connections of the ignition switch wire or corrosion on the back part of the switch can also cause a bad starter. If the issue is not of a severe nature, you can fix it yourself. If the ignition switch has become so bad that it can’t be repaired, it should be replaced with a new one.

Solenoid:

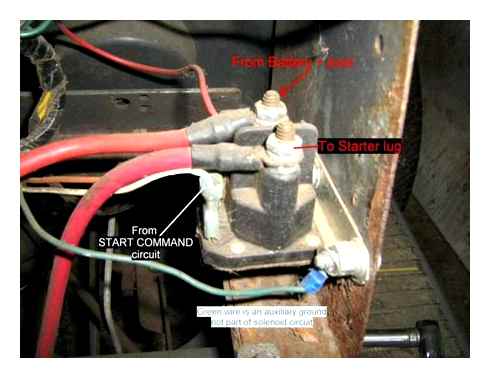

The starter solenoid is a mounted switch that provides current to the engine’s starter motor. The solenoid has four threaded electrical lugs connected to the battery, ground, ignition switch, and starter motor.

Different lawnmower models have their solenoids at different locations. You can locate the solenoid in your mower by following the red battery wire. After locating the solenoid, check its connections and screws and tighten them using a wrench or a plier. Rotate the ignition key. If the solenoid clicks without starting the mower, the solenoid needs to be replaced.

Starter Motor:

The starter motor is attached to the crankcase of the engine. If you have already checked the components mentioned above and they are fine, but your mower is still not starting, the chances are that its starter motor is faulty.

To check the starter motor, connect it to the battery using a jumper cable while attaching a negative terminal screwdriver. You’ll see some sparks, but there is no danger of shock from a 12V battery. If the motor doesn’t start and gives clicking sounds, the motor is faulty.

Sometimes the winding, magnet, brushes, etc., inside the mower can get dirty or burn during use. Fixing them can solve the issue too.

A faulty motor can be rebuild. But this has to be done by a professional electrician.

Bypassing the Solenoid:

Like said before, the starter solenoid and motor are two independent components. If you have determined that only the solenoid is faulty, you can try to start the mower using the starter motor only.

A solenoid has wire connections from the battery/ignition switch. To bypass the solenoid, connect these wires to the motor using a metallic connection. Then try to start your mower. If it produces a whirring sound, it means that the mower can be started. You’ll need to try a couple more times to start the mower.

Use protective equipment while bypassing the solenoid.

Final Remarks:

The lawnmower not starting on a potentially enjoyable mowing day is very frustrating. Mowers fail to start when their starters go bad. But most of the time, starter problems are not too complicated and can be fixed by the user. Follow the guidelines mentioned in this article to get your mower running once again. Checking other electrical components such as spark plugs will help too.

How to Test a Lawn Mower Starter With a Multimeter?

Maintaining your lawn mower and ensuring it’s in good working order is essential for getting the best performance out of it when you need it most. To do this, a quick test to ensure the starter motor and its associated wiring are operating correctly can be performed using nothing more than a multimeter. This blog post will take you through the steps to get your mower ready for cutting season with confidence by teaching you how to use your multimeter to check that everything is as expected. Read on to pick up some essential tips about testing the starting system for optimal performance!

How Does a Lawn Mower Starter Work?

The starter for a lawn mower is responsible for starting the engine. It does this by turning over the flywheel and sending an electrical current through to the spark plugs, which then ignite the gasoline in order to turn on the engine. In order to do this, the starter has a coil that creates an electromagnetic field when it’s energized. This magnetic field interacts with the armature of the flywheel and causes it to spin, thus starting the engine. The starter is powered by a battery connected to it through two wires, positive and negative. When you press down on the start button or pull on its cord, current flows from one wire into the other, creating a circuit and activating the starter. [1]

Safety Tips

When troubleshooting the lawn mower starter with a multimeter, safety should be your number one priority.

Make sure you are wearing gloves and safety goggles to protect your eyes and hands from any possible sparks that may occur during testing.

Additionally, make sure you shut off the power source (battery or wall outlet) before making any connections with the multimeter. When working on the lawn mower’s engine, be aware of any loose wires or components that could come in contact with hot metal parts of the engine.

Lastly, always unplugging the spark plug when testing electrical parts so as not to create an electric shock hazard. Following these safety tips can help make sure that your work remains safe and effective.

After confirming that safety measures are in place, testing the lawn mower starter using a multimeter is straightforward. [2]

Tools

Tools required for testing a lawn mower starter with a multimeter include the multimeter itself, an adjustable wrench or pliers, and insulated wire cutters. Before beginning, make sure to disconnect the spark plug and switch off the ignition system of the lawnmower.

Testing the Lawn Mower Starter

Testing the lawn starter with a multimeter is an easy and straightforward process. First, you’ll need to locate the lawn mower’s starter motor. It should be near the bottom of the engine and look like a small metal cylinder with two wires coming out of it.

Once you’ve located the starter motor, attach one of the multimeter probes to each wire. Set your multimeter to a low voltage setting, such as 2 volts or less. If there is power running through the starter motor, then your multimeter will indicate that there is a current flowing through it by showing some kind of reading on its display.

If your multimeter has no readings at all, this could mean two things: either the starter motor isn’t receiving any power or it is malfunctioning and needs to be changed. If this is the case, it’s best to take your lawn mower to a qualified mechanic who can diagnose and repair the issue.

You should also check for any loose wires which may be preventing power from reaching the starter motor. If you find any, then make sure that they are securely connected to their respective terminals on the lawn mower engine.

After testing your lawn mower starter with a multimeter, it’s important to ensure that all connections remain secure before starting up your machine. This will help prevent damage from occurring as well as ensuring maximum safety when using your lawn mower. [3]

Testing the Lawn Mower Battery

Once you have made sure that the spark plug and other connections are properly working, it is time to test the battery of your lawn mower. To make sure your battery is disconnected, switch off the engine and then unplug the negative terminal from its connection on the battery.

Then use a multimeter to measure the voltage of your battery by connecting one end of the black lead from your multimeter to the negative post of your battery and then connecting the other end of your red lead to its positive post. If you get a reading between 12 – 14 volts, then this indicates that your battery is functioning correctly; however, if you get a reading lower than 12 volts, then it may be time to replace your lawn mower’s battery. [4]

Testing the Lawn Mower Solenoid Frame

You have now successfully tested your lawn mower starter with a multimeter! By following these simple steps, you can detect any issues that may be causing problems and take the necessary actions to keep your lawn mower running smoothly. [5]

Causes of Starter Failure

There are several common causes of starter failure in a lawn mower.

One of the most common is lack of lubrication, which can cause problems such as sticking and grinding gears, or a seized motor. The brushes may also wear out due to high use, and may need to be replaced if they do not work effectively in providing power to the motor.

Corrosion on the parts can also reduce electrical conductivity and prevent them from working correctly.

Testing with a multimeter is an effective way to identify these kinds of issues before replacing any parts.

It’s important to make sure that all wires and connections are secure so that electricity is able to flow freely throughout the system.

Replacing worn-out spark plugs or faulty wiring can also help improve the starter’s performance.

It can be helpful to refer to the manual for your lawn mower to determine which parts need to be tested, as well as what type of multimeter should be used. By using a multimeter and following the steps outlined in the manual, you can accurately identify and diagnose any issues with your lawn mower’s starter. This way, you can make sure that your machine is running efficiently and safely all season long!

Types of Multimeters

There are several different types of multimeters, each designed for a specific purpose. An analog multimeter uses a needle to display the voltage or current being measured. Digital multimeters use an LCD screen that displays numerical values such as AC/DC voltage, current, resistance, etc. Some digital multimeters also come with additional features such as temperature probes and frequency counters. When testing a lawn mower starter with a multimeter, it’s best to use either an analog or digital type since these are able to send accurate readings faster than other models.

When using a multimeter to test a lawn mower starter, you will need to have some safety equipment on hand including safety glasses, gloves and insulated tools. Also make sure to disconnect all power sources before attempting to test any electrical systems.

Testing A Starter Solenoid Could Be Dangerous

With all of the complexity associated with lawn mowers, it is important to remember that testing a starter solenoid could be dangerous. This is because of the power and voltage involved in operating a starter solenoid. If you do not know how to use a multimeter correctly, or are unsure about your safety when working around electricity, please consult an experienced professional before attempting repairs on your own.

It is also important to wear protective gear such as goggles and gloves during any electrical repair work. Doing so will keep you safe from electric shocks or sparks while handling exposed wires and other components.

Once you have gathered the necessary materials and taken the appropriate precautions, you are now ready to begin testing your lawn mower’s starter solenoid using a multimeter.

Benefits of Testing a Lawn Mower Starter with a Multimeter

Testing a lawn mower starter with a multimeter offers several advantages.

Firstly, it provides a more accurate test result than other methods such as visual inspection or manual testing. This helps you determine the cause of any issues quickly and accurately.

Secondly, it’s easy to use, requiring few tools and little to no experience.

Lastly, it can save time and money by avoiding unnecessary repairs or replacements due to faulty parts. Testing a lawn mower starter with a multimeter is an excellent way to keep your machine running smoothly for years to come. [6]

FAQ

How do you test a lawn mower starter with a multimeter?

To test a lawn mower starter with a multimeter, you will need to set your multimeter to the Ohms setting. Disconnect the cables from the starter solenoid and connect one lead of the multimeter to each terminal on the solenoid. The resistance should be close to zero ohms if the starter is working properly. If not, then there may be an issue with either the wiring or the starter itself that needs to be addressed.

What can cause my lawn mower’s starter motor not to work?

The most common cause for a lawn mower’s starter motor not working is a lack of power from its battery. Check that all connections are securely attached and that it has enough charge. Other possible causes include worn out brushes in the starter motor, corroded or broken cables, a faulty solenoid, or a faulty ignition switch. If all of these components have been checked and are working properly, then the problem may lie within the flywheel.

What should I do if my lawn mower’s starter won’t turn?

If your lawn mower’s starter won’t turn, first check that it has enough power from its battery. Also inspect the wiring and connections for any damage or corrosion. If everything appears to be in order, you may need to replace either the starter motor or the flywheel. It is also important to check for any obstructions that may be preventing the engine from turning over.

What is the difference between a starter motor and a starter solenoid?

A starter motor is responsible for turning over an engine to initiate combustion. A starter solenoid, on the other hand, is an electrical switch that sends power to the starter motor when it receives a signal from the ignition switch. The solenoid provides additional protection by preventing direct current from flowing through the battery cables when the engine is not running.

How do I know if the starter on my lawn mower is bad?

Using a multimeter, you can test the starter on your lawn mower to determine if it is in working order. To test the starter, first make sure that all power sources are turned off and disconnected from the lawn mower before testing. Once you have done this, connect the two leads of the multimeter to either side of the battery terminals on your mower and set the meter to “DC voltage”. If your reading is above 12 volts then your battery is charged and working properly.

Can you bypass a starter?

Yes, you can bypass the starter on a lawn mower. To do this, you will need to connect the two battery terminals and the solenoid terminal together with a jumper wire or an alligator clip. Once this is done, your mower should start without having to use the starter. However, it is important to note that bypassing the starter may damage other components of your mower if not done properly. Therefore, it is strongly recommended that you consult a professional before attempting to bypass the starter on your lawn mower.

Can I test my lawn mower’s spark plug with a multimeter?

Yes, you can use a multimeter to test your lawn mower’s spark plug for functionality. First, disconnect the spark plug from the engine. Then, set your multimeter to measure resistance (ohms). Connect one of the meter’s test leads to each end of the spark plug and check for a reading between 5K ohms and 10K ohms. If you get any other reading, replace the spark plug as it is faulty. Make sure to install a new spark plug with correct gap distance according to your manual instructions before reconnecting it. Proper installation is important in order for your lawn mower starter to work properly. You should also inspect all wire connections connected to the ignition system such as those leading to and from the ignition switch, coil or magneto, which can cause starting problems if worn or frayed. Additionally, inspect the spark plug wires for any signs of corrosion or damage and replace them if necessary. Once you have ensured all connections are in good working order, complete an ignition system test using your multimeter. Set the meter to measure resistance (ohms) and connect one test lead to each end of the spark plug wire (or magneto) while it is disconnected from its other connection. If there is any resistance other than 0 ohms, then you know that something is wrong and should inspect the wiring further or replace it altogether.

Why is my starter not clicking?

If you are experiencing an issue with your lawn mower’s starter not clicking when the key is turned, it could be a sign of a faulty connection or bad wiring. Testing the starter with a multimeter can help to determine if there is an electrical problem. A multimeter is an electronic device used for testing and measuring electric current and voltage in a circuit. Before testing the starter, make sure that all safety precautions are followed including unplugging the power cord from its source and removing any spark plugs or fuel lines connected to the engine.

Conclusion

Testing the starter on a lawn mower using a multimeter is easy. After unplugging the spark plug, connecting the test leads to their respective terminals and setting the multimeter to measure resistance, you can get an accurate reading of the starter’s electrical circuit. To ensure that your measurements are accurate, always double-check your readings with other testers such as ohmmeters or continuity testers. If there is any discrepancy in results, contact a professional mechanic for further troubleshooting and repair. Taking these steps will help make sure that your lawn mower’s starter is running correctly so you can enjoy another wonderful season of cutting grass!

- https://electrouniversity.com/how-to-test-a-lawn-mower-starter/

- https://mystolenhome.com/how-to-test-a-lawn-mower-starter-with-a-multimeter/

- https://homeguides.sfgate.com/test-mower-starter-94817.html

- https://www.lihpao.com/how-to-test-lawn-mower-starter/

- https://meterreviews.com/how-to-test-starter-with-multimeter/

- https://www.gardentoolexpert.com/how-to-bench-test-a-lawnmower-starter-step-by-step/

Riding Mower Won’t Start Just Clicks – Mechanics advice with pics

This is a problem that usually arises in the spring, and for most, the fix is really simple. You’ve come to the right place, and you’ll be cutting grass shortly.

So what’s the problem with a riding mower that won’t start just clicks. The most common reason for a clicking sound on a riding mower when you turn the key is a flat battery. Other possible reasons include:

Yes, it’s a long list, but you won’t have to check all of them; I’ll bet your problem is one of the first three; I have listed the likely causes in order of commonality.

If your mower won’t crank and makes no click sound – Check out “Lawn Tractor Won’t Start.”

Bad Starter Sounds Lawn Mower

Bad Battery Connections

Bad battery connections are very common, and by bad, I mean the power is not passing from the battery to the cables because the battery connections are loose, dirty, or damaged.

Loose Connections

Battery cables become loose because lawn tractors vibrate a lot; this is why it’s a good idea to service your mower at the start of every season, no matter how well she runs.

Dirty Connections

Dirty connections are usually caused by the weeping of battery acid at the battery poles. The acid then crystallizes, causing high resistance; it looks like a white chalky build-up on the connectors.

Cleaning Connections

To clean the connections, add a couple of spoons of baking soda and a small amount of water, and pour this onto the acid build-up on the connections and battery poles.

The soda neutralizes and removes the acid; you’ll need gloves and protective eyewear. After removing the acid, go ahead and remove the connectors and give them a good cleaning with a wire brush or sandpaper.

If you have some petroleum jelly, a small coat will prevent a future build-up.

Connector – Mower blades and engines cause a lot of vibration; bolts come loose from time to time.

Check that both connections, positive (RED ) and negative (BLACK – ), are clean and tight.

Cables – Check the cables for damage, and corrosion; mice find them irresistible.

Flat / Faulty Battery

A flat battery is a real pain in the ass. I know what it’s like; you just want to cut the grass, right? The fastest way to solve this problem is to jump-start the mower.

Leaking Battery – Check your battery for leaks before attempting to jump-start. If it leaks and it’s a sealed battery, replace it.

However, it’s usually only wet batteries that leak, so best to check your electrolyte level and top up if necessary. As you know, the acid will burn the skin and eyes, so, you know, gloves, etc.

If the acid build-up is excessive, your battery may be on its last legs, so don’t be surprised if it fails or does so soon.

HOW-TO Replace A Lawn Tractor Starter

But if the leaking is excessive, don’t jump-start; replace it. Batteries are easy to fit; just be sure the battery is the correct size, and the poles are in the proper places.

Jump Starting

You’ll need jump leads and any 12-volt vehicle. Most cars, trucks, and even Hybrids have a regular 12-volt battery fitted somewhere. Sometimes finding it is the hardest part. If you’re unsure of the voltage, when you find the battery, a sticker on the casing will indicate 12v.

Of course, your battery might be faulty, jump-starting will probably get you rolling, but the problem will still be there. You can test using a voltmeter test tool, which I’ve listed here on the “Small engine repair tools” page.

To jump-start – begin by connecting the positive red of the mower to the red of the car.Now connect the negative black (-) on the car to a ground (GRD) source on the mower. (Any bare metal will work)

Connect – If you are not familiar with jump-starting, you’ll find a complete guide here, “Jump starting riding mower.” Add the cables in sequence 1, 2, 3, and 4, start the mower, and while idling, remove jumper cables in reverse order 4, 3, 2, and 1.

Battery Testing

You can check the battery and alternator using a voltmeter. Batteries don’t like sitting idle; they were designed to be charged and discharged continuously. A battery that gets fully discharged will sometimes not come back to life.

Use a voltmeter to check the battery voltage, and connect red to positive and black to negative. I have listed a voltmeter on the “Small engine repair tools page.”

Test – Check battery voltage using a voltmeter – attach a voltmeter to the battery and set it to 20 volts.

If you have a reading above 12.5 volts – go ahead and attempt to start the mower; watch the voltage; a reading below 8 volts is a bad battery and needs to be replaced.

Buying a Battery

When buying batteries – wet batteries will not ship with acid. The acid must be purchased, and the battery must be filled and charged; it’s a lot of work.

I would buy a gel or maintenance-free sealed battery; these can be shipped, fully charged, and ready to roll. Check out quality common ride-on mower batteries on the Amazon link below.

Battery Charging

You’ll need a battery charger to keep your battery in top condition over winter. I recommend a trickle/Smart charger; they’re simple to use; pop on the color-coded crocodile clips, plug it in, and that’s it. Forget it till next spring, then turn the key and mow.

I’ve listed a good-quality Smart charger on the “Small engine repair tools” page that won’t break the bank.

Batteries work best and last longer when their state of charge is maintained; off-season charging is always advised. Check out “Mower winter storage video.”

Charge – Always disconnect the battery before charging. Simply connect red to red, black to black, and plug in the charger. The length of time on charge will depend on how low the battery is and the amp rating of the charger. Usually, 2-3 hours cooking time.

Faulty Solenoid

The solenoid is a large relay of sorts. When you turn the key to start your mower, a 12-volt supply from the ignition switch to the solenoid activates it. The solenoid’s job is to connect the battery to the starter motor and crank over the engine for as long as you hold the key.

The click sound is the solenoid trying to work by pulling in the armature; they fail regularly, and I replace lots of them.

However, the click sound can also be made for a few other less common reasons, and without fully diagnosing, you may find replacing the solenoid doesn’t solve the problem.

Hey, if you feel lucky and don’t want to do the diagnosing part, I understand. So, if your battery is full and the cables are tight, go ahead and replace the starter solenoid. They’re cheap and easy to fit.

Check out, “Mower solenoid repair tools” it lists useful tools and parts that will help you nail the repair.

Solenoid – Solenoids are a universal fit; they give lots of trouble.

On the upside, they’re easy to fit and cheap to buy.

Where’s the Solenoid?

Often just finding the starter solenoid can be challenging; I sometimes think that they hide them for fun. If you don’t find it under the hood, try under the rear wheel, behind the gas tank, or under the seat.

The easiest way – follow the red battery cable from the battery. On some engines, the starter and solenoid will be one unit (Kawasaki and Honda engines).

Where? – Husqvarna, craftsman-like to, hide theirs under the rear wheel fender or the dash beside the steering column.

However, most solenoids will be easy to locate. Fitting is easy, but do disconnect the mower battery first.

Solenoid Test

Remove – The first step in testing the solenoid – remove the spark plug.

If, when removing the spark plug, gas pours from the spark plug hole – move on and check “Carburetor troubleshooting.”

Test – Turn the key; if the clicking sound persists – Go ahead and replace the solenoid.

If, on the other hand, the engine cranks over, move on and check for excessive valve lash.

Tight – Check the solenoid terminals; all wiring should be secure and free from corrosion.

Binding Starter Motor

The gear head of the starter motor can bind against the flywheel; this locks the engine and starter motor together. So when you hit the key, all you hear is the click sound.

Testing

Testing for this condition involves turning the engine by hand anti-clockwise. Some engines will have a cover over the flywheel; if so, try turning the crankshaft with a ratchet and socket from the underside of the engine.

If turning the motor anti-clockwise frees it up – you have found your problem, the starter motor is binding. Usually, a spray of wd40 on the starter gearhead will fix it. If you are lucky, you can get the straw of the WD40 directed at the gearhead without removing any covers.

Starters can bind for other reasons – worn bearings, worn gear head, misaligned or loose starter motor.

Binding – Starters can bind against the flywheel. To fix it – spray the starter gear with wd40 and retest. If it continues to bind, replace the gear head or complete the starter motor.

Turning the engine anti-clockwise by hand will unlock it.

Excessive Valve Lash

Engines have valves that open and close in sequence. The inlet valve allows the fuel/air mixture in. It then closes and seals the combustion chamber. After the power stroke, the exhaust valve opens and allows spent gases out.

What’s Excessive Lash?

The valve lash describes a precise gap between the valve tip and the rocker arm. As the engine wears, this gap gets bigger and must be adjusted. The inlet and exhaust valve lash will usually be different specs.

Correct Lash

When the valve lash is set correctly – you crank over the engine, the valves open, and release cylinder pressure. This allows the engine to crank over at sufficient speed to create a spark strong enough to start up the engine.

When the valve lash is out of spec, the valve is late opening which means pressure in the cylinder is too great for the starter to overcome; that’s when you hear the click sound.

Incorrect Lash

Check out “Valve lash adjusting” it’s for a walk-behind mower, but the process is identical. Adjusting lash isn’t difficult but will require an inexpensive tool called a feeler gauge. You’ll find a link to a good feeler gauge set on the “Small engine repair tools” page.

Test – If you can, place your hands on the flywheel screen – try turning the engine clockwise.

If you’re unable, you likely have excessive valve lash. Lash should be checked every season.

Lash – Adjusting valve lash requires an inexpensive tool called a feeler gauge.

Hydro-locking

A carburetor fuel supply usually consists of a fuel bowl, float, and needle. The float is, as its name suggests, a float. Attached to it, is a needle with a rubber tip.

The function of the float is to lift the needle as the fuel level rises in the fuel bowl. When the fuel bowl is full, the needle will be pushed against the fuel feed port, sealing it.

Hydro-locking – Worn carburetor float needle seals have a habit of leaking gas into the cylinder, and when the cylinder is full of gas, the piston can’t move; this is known as hydro-locking. Because the piston can’t move, the engine will often make a clicking sound as you try to start the engine.

Removing the spark plug and turning over the engine will release the gas, but the carburetor float valve and the engine oil will need to be replaced.

Other signs that your carburetor needle seal leaks are: overfull oil level; white smoke from the muffler; oil leaking from the muffler; gas dripping from the carburetor; a strong smell of gas in the garage.

Fuel Valve Solenoid

Newer model carburetors have a fuel solenoid fitted to the bottom of the fuel bowl; its function is to stop the fuel supply when you shut the engine off. So if you have this newer type of carburetor fitted, you will not likely have a hydro-locking condition.

Leaking Carburetor Valve Seal

Failure commonly occurs in the older type carburetor when the rubber needle seal wears. This results in fuel filling the carburetor and eventually entering the cylinder and crankcase.

Gas in the Oil

If you have gas in the oil, don’t run the engine; the diluted oil offers little protection to internal components. First, fix the issue by replacing the carburetor and then changing the oil.

Check out “Carburetor types” page; it lists popular mower carburetors. Check out “Carburetor troubleshooting” also for more details on the issue.

Check Oil – Too much oil is a sign that your carburetor needle seal is leaking unless, of course, you overfilled the oil yourself.

Needle – The needle wears over time; they turn pink when worn. The fix – replace the seal or the complete carburetor. Using your manual fuel valve will prevent future problems.

Faulty Ignition Switch

A faulty ignition switch can cause all kinds of problems; the click sound can be caused by a bad connection in or at the back of the switch.

Try the Wiggle Test

When turning the key, wiggle the wiring at the back of the ignition switch and see if it makes a difference. It will very often show you where the fault is. Wiring pinouts are specific to each manufacturer.

Wiggle – Try wiggling the wires at the back of the ignition switch while attempting to start the engine; you may need a helper.

Often wires come loose but do check them for corrosion.

Faulty Control Module

Control Modules are not fitted to all mowers. The function of the control module is to receive a start request from the ignition switch and to output a 12-volt supply to the starter solenoid, but only if all safety sensors are in the correct position.

Control Module Test

Control modules do fail and also suffer from loose connectors. Try the wiggle test on the connectors and check for obvious signs of water/corrosion damage. The control module will often live behind the dashboard in a plastic box about the size of a mobile phone.

Wiggle – Like the ignition switch; wires come loose, have a helper attempt to start the engine while you wiggle the wiring connectors.

Check also for damage, water, or scorch marks on the panel itself.

Faulty Starter Motor

A faulty starter can fail electrically, mechanically, or both. Electrically – the copper winding can break; brushes can break or wear out. Mechanically – the top and bottom bearings and the gear head can wear. These issues can cause the starter to bind, so all you hear is the click sound.

Testing the Starter

Checking the starter motor is easy; connect a 12-volt supply direct from the mower battery to the supply wire at the starter. An even easier way is to cross the starter solenoid as per the guide below.

If you find your starter has failed, removing and fitting a new one is simple. The starter motor for Briggs and Stratton offers a good quality starter. Be mindful that BS has two types of starter – plastic gear head or metal; check before ordering.

Starter – Some starters will have a solenoid and starter motor combined in one unit.

To test, use a jumper lead to bring power from the positive of the battery to the positive post of the starter. If the engine doesn’t crank – Replace the starter.

Common – Most mowers will have the starter and solenoid separate.

Solenoids are fitted to the body, usually under the hood.

Test – Cross a metal screwdriver from one connection to the other, as per the picture.

There will be arcing (sparking) as the screwdriver contacts the poles.

RISK OF FIRE – Keep clear of gasCAUTION THE ENGINE MAY TURN OVER – Place the mower in the park with the parking brake applied and the blade off.

If the engine doesn’t crank over – your starter is faulty; replace it.

Internal Engine Damage

If you’re still reading, I fear the worst has happened. It’s unusual for mower engines to fail completely. They’re generally well-built robust units. I have seen failures like the con rod breaking out through the engine casing; the main bearing seizing; the con rod bending; cylinder head failures.

Some of these faults can be repaired, but most are uneconomic to repair.

New Engine

On the upside, if you have a total failure, a complete engine fully built with a guarantee is available, and fitting involves four bolts, two electrical connectors, a fuel line, a throttle cable, and a crank pulley.

BS and Kohler’s engines are of great quality and ready to go. The completed job will take less than two hours. Be mindful that all engines are shipped without oil.

Failure – Total failure doesn’t happen often.A hard life, and low/poor quality oil, without doubt, increase the chances.

Related Questions

Can you jump-start a mower? A flat or bad battery is a more common fault than a starter. Try jump-starting; if your mower starts, the battery needs attention. If jump starting doesn’t work, investigate a faulty solenoid or starter.

Can a bad alternator ruin a battery? A bad alternator can ruin a battery. Alternators have two main components. A voltage regulator that monitors and controls battery charging and the alternator whose job it is to create voltage. Common problems include a faulty regulator, which damages the battery, and alternator diode failure, which drains the battery.

Starter Replacement Guide – John Deere Lawn Tractor

The starter on my John Deere LX172 lawn mower finally gave up the ghost. Here is a quick and easy picture guide for replacing the starter on this lawn tractor. I’ve included photos of the steps as well as the socket sizes needed for all the nuts and bolts, I hope this helps make this job go a little quicker for someone out there!

If you buy through links on our site, we may earn an affiliate commission – at no cost to you. I do not put any other type of ads on this site because I think they are annoying. Thank you.

Part Numbers for Replacement Starters

Check the model number of your John Deere tractor. Depending on the engine and model number, you may need one of the following starters:

- Starter John Deere Lawn Tractors 170, 172, 175, 240, 245, Kawasaki (14HP Engine)

- OEM part numbers: 12498-63010, 128000-4020, 21163-2073, 21163-2073A, AM104559

- Specifications: Type: DD, 12v, 0.7 kW, CCW rotation, 9 teeth/splines

- OEM part numbers: 390838, 391423, 392749, 394805, 491766, 497594, 497595, 693054, AM122337, AM37352, AM39137, LG497595, SM01965, 410-22003, 410-22003R, SBS0001, 5742, 5742N

- SPECIFICATIONS: 12 Volt, CCW, 16-Tooth Pinion, PMDD, 12v, CCW rotation, 16-teeth

How to Replace the Starter on a John Deere Lawn Tractor

Here is a quick summary of the steps, I go into more detail with the photos below, but sometimes it is good to have a summary with the nut and bolt sizes:

- Turn the key to the “off” position.

- Open the hood of the lawn mower.

- Remove the negative battery terminal.

- Locate the starter and disconnect the wiring harness by pressing the plastic tab and pulling it off.

- Disconnect the battery cable going to the solenoid using a 14mm socket.

- Remove the 2 starter mounting bolts (12mm).

- Slide the starter off of the engine.

- If you are only replacing the solenoid, remove the two 10mm nuts to remove it and swap with the new solenoid.

- Put the new starter on by reversing the steps.

Step by Step Instructions for Changing the Starter on a Lawn Mower

The unit I am working on is a John Deere LX172. Here it is with the hood already removed.

Turn the key to the ‘off’ position and raise the hood.

Here is a closer view of the Kawasaki engine.

Disconnect the negative battery terminal.

Locate the starter. This is a closer view of the starter location.

Disconnect the plastic wiring harness. It has a clip you should press, then pull it down and off.

Remove the positive battery cable using a 14mm socket or wrench.

Remove the two 12mm mounting bolts from the top of the starter. Slide the starter down and away from the engine.

Here is a picture of the starter once it is removed.

The part number for the new starter is 21163-2073, and here is the link:

Make sure you order the correct starter.

The correct starter for my tractor was the 21163-2073, which is stamped on the original:

I mistakenly ordered the wrong on originally. Here is a photo of the original starter (top) alongside the incorrect starter (bottom):

The starters look the same from the bottom. The main difference is the mounting hole spacing, and the fitment ring which is too big on the lower one in the picture.

For reference, the starter I needed was the 21163-2073.

The incorrect starter for me (bottom one in the picture) was this style.

Joke Break…

The teenage son walks into the living room and tells his father, “Dad, the car won’t start, there’s water in the carburetor.” The father, knowing that the son is not very mechanical, looks confused, “Water in the carburetor, that’s ridiculous!” But the son insists, so the father continues, “You don’t even know what a carburetor is, but I’ll check it out. Where’s the car?” The son replies, “In the swimming pool.”

Solenoid

If you only need to replace the solenoid, remove the two 10mm mounting nuts, and the 14mm grounding nut at the bottom. The correct solenoid is this one:

Here are some photos of the solenoid.

The solenoid removed from the starter:

To put on the new starter, reverse the steps described.

I hope this helped save you some time and effort!