Make A Hiller For A Tiller With Your Own Hands

Variable width attachments

The machine with a variable working width is convenient for tilling, because it is equipped with an adjustment mechanism. It allows you to change the position of the wings.

It can be adjusted to suit the row spacing. The disadvantage of the apparatus is its high energy consumption. This happens due to the work of the wings, which move the soil to the side, after passing by the hiller, the earth crumbles back into the furrow. As a result, arms and back get tired faster and the engine is wasted. Despite this, such hillers are one of the most popular among gardeners.

To the menu

Disk devices

Disk models have the following advantages:

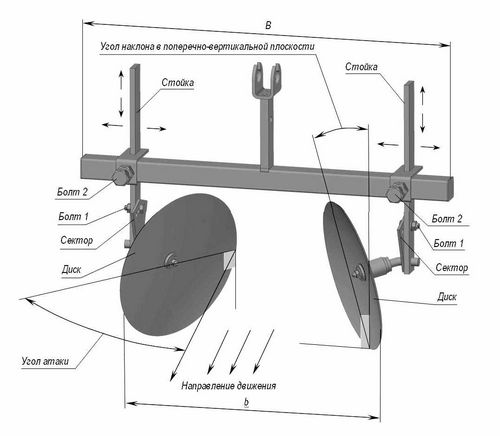

Diagram of a disc hiller for potatoes

- Convenient to use (to work with this toolkit you need a minimum of effort, they move forward by themselves, do not require additional pushing from behind)

- Universal (with their help you can do hilling after planting tubers during the period of active growth of the aerial part of the plants)

- They are successfully combined with a tiller (if you use a disc hiller at a reduced speed of the cultivator, its power increases. This increases the efficiency of cultivation and improves the operation of the unit).

When choosing from a huge assortment, it is advisable to choose the models that are made of alloy steel, equipped with rolling bearings with a large thickness and disc diameter.

To the menu

Lister hiller

The lister unit is the simplest type of tool, it has a fixed working width. The design of this apparatus consists of two connected and spread wings, which are fixed to each other.

The tool wings are stationary, so the working width cannot be adjusted. It will NOT work to adjust the hiller to the row spacing. In this case, when working with the tool, adjust the row spacing.

The width of the lister hiller is 25. 30 cm. This is not the most convenient option, because for growing potatoes, a row spacing of 50. 60 cm is recommended.

A feature of such a device is the presence of thin racks, in this case the cultivator does NOT reboot at the moment the hiller is buried in dense soil. Some lister hillers have a streamlined shape that is more practical.

To the menu

What are the types of hillers?

After the winch and plow, the hiller is the second most important unit. It helps to cut furrows for planting, which are then covered with planting material. There are several options for this tool:

Measurements of the lister potato hiller for the tiller

- Lister;

- Products with a variable gripper tire;

- Disk models;

- Propeller-type hillers

propeller-type hiller

Propeller-type hillers are used for cultivators and tillers in which there are two forward gears. This is necessary so that in second gear with a power of up to 180 rpm, it was possible not only to loosen, but also to transfer the soil into the beds from the row spacing. Such a do-it-yourself potato hiller will perfectly cope with the tasks set.

To the menu

How to choose and make your own potato hiller?

Potato is one of the most popular among agricultural crops; it is grown in our country and in Eastern Europe. In the process of long-term potato cultivation, various Agronomic technologies were created.

They helped to facilitate the processing of the crop, as well as increase yields. For an industrial scale, the cultivation of a crop takes place using a tractor with nozzles. cultivators, and on personal plots, hillers for potatoes to a tiller are used, which can be made with your own hands.

How to make a hiller for a tiller with your own hands?

Do-it-yourself hiller can be done using fairly simple designs. This is not difficult. To create a traditional unregulated hiller, you need to cut the halves of the product from metal 2 mm thick using a template.

Drawing of a plow-hiller for a tiller

Next, bend these parts into coincidences of radii, then scolds in 3 passes. Seams are processed with an angle grinder. In the end, the total should be an even layer of metal.

A do-it-yourself disc hiller can also be made. To do this, you must select the type of wings. Plowshares, plows, or discs are steel sheets 1.5. 2 millimeters thick, in which the lower edges are bent.

The main thing is that the disks are symmetrical. Otherwise, then the structure will lead to the side, which will greatly complicate the work. To create the unit, you can use the plowshares, which served as a seeder.

The plowshares must be installed at an angle, maintaining a distance between the lower points that corresponds to the width of the wheel track, equal to the width of the row spacing.

To connect the elements to each other, a bolted connection or a quarrel is used. Discs are connected using adjustable adapters.

In addition to the disc, the main parts of the tool are: screw turnbuckles, stands and a T-shaped leash. Lanyards are needed to adjust the vertical rotation of the disc. Homemade hiller is attached to the tiller with your own hands using a beam with wings.

The manual disc hiller is made on the basis of the drawing, while it is very important to provide for the ratio of the mounting structure and dimensions.

The tool can be made in two ways: with variable wing width and fixed. In the first method of arrangement, the distance between the discs can be changed due to the SYMMETRICAL rearrangement of the racks.

To facilitate the work with the tool, it is necessary to arrange plain bearings. To increase the reliability of the product, you can install bearings, rather than sleeve bushings.

Hilling potatoes with a hiller to a mini tractor

To attach the homemade hiller to the tiller, use the bracket to the hitch without the Gryadil. The unit leash is attached to the bracket using a stopper and bolts with washers. A corkscrew is inserted inside the square tube and pressed tightly against the outer surface.

After that, the do-it-yourself tiller for the tiller is ready to work. Tiller traction can be increased by operating in first gear. If the wheels slip during the hilling process, Sparta needs to.

The hiller for a mini tractor is installed to huddle your potatoes. For the tool to be really effective, it is necessary to plant the potatoes in the correct rows, the distances between the plants must be equal.

In order to process agricultural crops in a mechanized way, a high-performance hiller for a tractor is used. Its main purpose is inter-row cultivation of potatoes from weeds and hilling of tubers to increase yields.

A hand-held hiller for potatoes or other plants will help make work easier and increase yields. A self-made tool (homemade) is a profitable and necessary assistant in agriculture.

To the menu

An example of self-made lister hiller

As you can see, hillers are fairly simple designs. There is nothing difficult in making a do-it-yourself hiller for a tiller.

To create a traditional unregulated hiller, it is necessary to cut the halves of the product using a 2 mm thick metal template

These halves should be bent into matching radii, and then scolded in 2-3 passes. Weld seams should be machined with an angle grinder and, if necessary, welded and re-grinded. The result should be a perfect even layer of metal.

The tool wings are also cut from 2 mm thick metal and connected in the same way.

The result should be this design. For clarity, the thickness of the elements and all dimensions of the tool base are indicated

Option # 1. lister hiller

This is the simplest type of tool and has a fixed working width. The design consists of two connected and slightly spread fixed wings. Since the wings of the tool are stationary, you cannot adjust the working width by adjusting the hiller to the row spacing. Therefore, when working with such a tool, the row spacing is adapted to the capabilities of the hiller, and not vice versa. Traditionally, manufacturers produce products with a working width of 25-30 cm, which is also far from the most convenient option, because the technology of growing potatoes provides for a row spacing of 50-60 cm.

Such tools are designed to work with motor cultivators, the power of which does NOT exceed 3.5 HP, and the total weight of the unit is 25-30 kg

A feature of the design of lister hillers is also the presence of thin racks, which prevent overloading of the cultivator when the hiller is buried in layers of dense soil.

Some models of lister hillers have a streamlined shape, which is more preferable, since when working with such a tool, the soil turns out and dries out less.

Option # 4. propeller-type hillers

The principle of operation of the tool lies in the work of Special propellers, under the action of which the soil is first crushed and weeds are combed out, and after that the beds are spud with loose soil

Such hillers are designed to equip tillers and motor cultivators, which have two forward gears. This is necessary so that in the second gear with an increase in power up to 180 rpm. With the help of the tool You can not only loosely, but also transfer the soil to the beds from the row spacing.

Option # 3. disc models

Disk hillers are an order of magnitude more expensive than their traditional counterparts, but the efficiency of working with such tools is many times higher

The main advantages of disc hillers are:

- A successful combination of the tiller with the tool itself. Using a disc hiller, when the speed of the cultivator decreases, its power increases. This not only increases the efficiency of cultivation, but also has a positive effect on the operation of the unit itself.

- Ease of use. To work with such a tool, you need to make a minimum of effort: it pushes itself forward without requiring additional pushing from behind.

- Versatility of application. With this tool, hilling can be done both after planting the tubers and during the period of active growth of the aboveground part of the crops.

Choosing among a variety of assortments, it is advisable to give preference to models made of alloy steel, equipped with rolling bearings (and not sleeve bushings), with a large diameter and thickness of discs.

Option # 2. products with variable working width

Such tools are more convenient to use, since they are equipped with an adjusting mechanism with which you can change the position of the wings. This allows the tool to adapt to different row spacing.

Such hillers are designed to work with more powerful tillers with an engine of 4.0 HP. And more, the weight of which exceeds 30 kg

A significant drawback of such structures is their high energy consumption. The reason for this is that in the process of operation, the wings of the tool move the soil to the side, part of which, after its passage, nevertheless crumbles back into the furrow. As a result, the back and arms get tired more quickly, and some of the engine power is wasted on useless work. But despite this, they are one of the most popular models among most gardeners.

Different models of hillers

The hiller is the second most important tool after the plow and winch. With its help, you can first cut the furrows for planting, and then fill them with planting material.

Carrying out the hiller along the row spacing of evenly planted rows of potatoes, you can observe how the wings of the tool quickly pour soil into the holes with tubers

On sale you can find several options for the models of this tool.

How to independently design a hiller for a tiller: parsing a couple of options

Potatoes are one of the most popular agricultural crops grown not only in our country, but also in many countries of Eastern Europe. Throughout the three hundred year history of potato cultivation, Agronomic technologies were created, with the help of which they tried to facilitate the cultivation of crops and increase its yield. If on an industrial scale for growing potatoes today, tractors with replaceable cultivator nozzles are used for hilling plants, then on personal plots you can use a do-it-yourself hiller for a tiller.

A simple model of a disc hiller to a tiller

To make the tool, you must select the type of wings. Discs, or plowshares, dumps, are steel sheets 1.5-2 mm thick, having bent lower edges.

When arranging the structure, you can use plowshares removed from an old seeder.

Plowshares are installed at an angle, keeping the distance between the lower points corresponding to the wheel track width, equal to the row spacing

Connect the elements together using a bolted connection or through a quarrel. The disks themselves are connected using adjustable adapters. In addition to discs, the main elements of the tool are: T-shaped leader, screw turnbuckles and stands. Lanyards are needed to adjust along the vertical axis of rotation of the discs. The tool is attached to the tiller using a beam with wings.

When manufacturing and assembling parts based on the drawing, it is important to provide for the size ratio and the fastening design. There are two options for making the tool: with fixed or variable wing width. With the second method of arrangement, the distance between the discs can be changed by symmetrical rearrangement of the racks.

The main assembly elements: 1. processed row, 2. disc, 3. fist, 4. T-shaped bracket, 5. post, 6. steel scraper, 7. bridge beam, 8. locking bolt, 9. Handle-Gryadil

To facilitate the work with the tool, it is necessary to provide for the arrangement of plain bearings. Installed bearings, not sleeve bushings, can improve product reliability.

In the process of assembling the structure for attaching the tool to the tiller, the hitch bracket is used without Gryadil. To do this, a hiller leash is attached to the bracket using a stopper and bolts with flat washers. The stopper is inserted inside the square pipe and pressed tightly against its outer surface.

The hitch bracket itself is turned with bolts, and the leash is placed along the longitudinal axis of the tiller

The unit is ready for operation. Working in first gear, by reducing the forward speed, you can increase the thrust of the tiller. If the wheels slip during the hilling process, Sparta needs them.

What are the types of hillers

There are such types of this technique:

- Single row;

- Double row;

- Propeller;

- Rotary;

- Disk;

- Lister.

Rotary

In this tool, the wheels are replaced by helical-toothed rotors. In practice, this hiller has shown impressive performance levels in furrowing, loosening soil and hilling potatoes. Can be used on a 3-speed tiller (two speeds and reverse). At the lowest speed, the tool spuds the planting, and at the next, it pushes the soil out of the row spacing.

Lister

Endowed with a fixed tillage width. It is often used on rather weak tillers, whose power does NOT exceed four horsepower. It can handle beds about 30 cm wide. It has a thin stand and a pair of side wings. The stand protects the tool itself from overload and mechanical damage. This type of hiller can only be used on dry soil. soil adhesion will greatly interfere with the work of moving parts of the structure.

You can also find lister nozzles on which you can control the width of the tillage. They’re meant for the more powerful tillers. that’s four horsepower. Such a tool can also be used for working with moist soil.

Double row

Before planting crops, it makes a pair of furrows. In addition, it is used for loosening and hilling soil. The device includes a frame on which two hillers are fixed at once. Due to this feature, the processing process with such a tool significantly saves time. The tiller can be attached with a hitch. However, this type of hiller needs a lot of resistance to work. After it is used often together with lugs.

How to install and use a hiller

When installing the hiller on the tiller, it is important to correctly orient it. parallel to the mowing line of the ridges.

Before starting work, the tool must be installed in the tiller hitch and secured with bolts or pins. To make installation quicker, it is convenient to use hollow axles with cotter pins.

You can adjust the angle of, for example, the disc view of the tool by tilting the frame in relation to the tiller. This partly affects the depth of the furrows. The hiller is regulated by the movement of the sole in the vertical plane using the fixing holes made in the rack. And by moving the brackets, you can control the width of the passage.

It will NOT be superfluous to check the tightness of the bolt connections before work. To do this, it is necessary to carry out a trial processing of an area where there are no plants. In the process, you need to carefully monitor how the individual nodes work. If errors are found, tighten Loose connections or re-adjust the tip.

In particular, during the processing of ridges, the following rules must be observed:

- For long distances, move the equipment only disassembled;

- DO NOT make sharp turns;

- Move in transport position.

Do-it-yourself hiller for a tiller

Disk

It is versatile for soil cultivation. Working part. steel concave discs. Plunging into the soil for a given distance, they loosen it, thus forming a ridge. To make the use more efficient, it is necessary to install the discs at an angle vertically and towards the direction of movement of the equipment.

Making a disc hiller for a tiller with your own hands is described below. Drawings and dimensions along with a photo are attached to the description of how to make the tool.

Single row

This variety is often used for light soil types. Furrows can be made by completing preliminary loosening of the soil with a cultivator.

Disk

Having undertaken to make such a hiller, special attention should be paid to the molding of the discs themselves. They can be made from circular saws or used cutters from a seeder.

- Disks;

- Adapters;

- Welding machine or fasteners.

What do we have to do:

- Discs must be placed at an angle, keeping the distance between their lowest points. It is important that they are located symmetrically. Otherwise, the tiller will lead in different directions.

- All parts, including screw starleps, stands and leash, must be fixed with a welding machine or bolts. Connect the discs with controlled adapters.

- It is required to use a beam with wings to fix the tool on the tiller.

Another key point is choosing the right angle of inclination and diving depth. To make this choice, it is enough to put movable parts with bolt fixation on the bracket.

After reviewing the below, you can find out how to make other types of hillers, including single-row manual:

Disk variety

This type of tool has the following advantages:

- It goes well with the tiller. If the disc hiller is used at a reduced tiller speed, the power of the tool becomes even greater. Due to this, the efficiency of digging up the soil increases, and also has a beneficial effect on the working process of the tool;

- Convenient use. When loosening or digging with this device, it is not necessary to exert much effort. He moves forward himself and does not need to make additional support from behind;

- Universal purpose. This tool can be used to loosen the soil, both before planting potatoes (Read about how to make a manual hiller for potatoes in this article), and after planting during active cultivation for additional loosening.

Drawing

Click on the picture to enlarge

Before you start making your own disc hiller, you need to familiarize yourself with the drawings of this tool.

Thanks to them, it is possible to make this tool with the greatest accuracy the first time, and it will serve for a long time.

Lister type hiller

The design of this device is considered the most simple. It has a fixed working width.

Consists of two wings attached, branched and fixed to each other. Due to the fact that the wings are fixed, it is impossible to set the size of the grasping width by adjusting the device to the size of the row spacing. It is for this reason that while working with this hiller, you have to adjust the row spacing to the size of the hiller, and not vice versa.

Basically, all manufacturers produce models with a working width of 25-30 cm.This is not very convenient, because the technology of growing and planting potatoes has a width of 60 cm between rows.

In this design, there are special stands with a thin design, which prevent overloading of the tiller when loosening the hiller of deep layers of hard soils.

There are devices that have a streamlined design. This is most convenient because such models can be adjusted to any size of the row spacing.

Lister hiller

In order to make this device, you need to cut two equal parts from a sheet of steel with a thickness of 2 mm. Then you need to bend them so that their radii coincide.

Then their seams are welded and processed, so that the result is a perfectly flat surface. In the future, these tools can be used for single row tillage. You can make two such devices, which can later be used for two-row processing of potatoes.

Self-made. Do-it-yourself hiller for a tiller. drawings

Hilling and digging a land plot is quite hard work, which takes a lot of strength and health.

Many summer residents and owners of land plots use such a convenient device as a tiller on the farm. They can easily dig up the entire area in a matter of hours. And if you attach various devices to it, for example, a hiller, lawn mowers, potato planters and much more, then the work will be much easier.

In this article, we will look at how to make such a convenient tool as a disc tiller for a tiller. The first step is to find out what models of this tool are, and only then figure out how you can make it yourself. There are 4 varieties of this device.

Propeller hillers

The whole principle of operation consists in the work of propeller elements. Under their influence, first of all, the earth is dug up and weeds are cleared, and only then the single-row beds themselves are loosened.

These models are mainly used for front-wheel drive cultivators (Read more about cultivator varieties here) and two-gear tillers. This is explained by the fact that in second gear the power level rises to 180 rpm.

When the power level is at its maximum, this tool can be used not only for hilling the soil, but also for throwing the soil from one bed to another.

Read here what you need to know about Wood Crusher.

Manufacturing methods

Hillers can be done in two ways:

- With fixing working width.

- With adjustable or variable working width.

Consider these manufacturing methods in more detail.

Read here how to make a cultivator for a mini tractor.

How does he work?

The device is attached to the tiller on the clutch bracket without the tractor. This is done by a locking element, two bolts and flat washers. The most convenient workflow with it is carried out in the first low gears.

The principle of operation of THESE hillers is as follows: disc elements during movement rake in the soil and make a roller when hilling, sprinkle the plants with earth.

Rotational movements of the disc elements provide crushing of the soil and additionally loosen it.

- Due to it, high and even ridges of row spacings are obtained;

- Ease and convenience when working;

- Low energy consumption.

However, not everything is so good, there are also negative sides. These devices, in comparison with other types, are 3, and sometimes even 4 times more expensive. Of course, the cost is influenced by a number of factors:

- Size of the diameter and thickness of the disc elements;

- The material from which the tool is made. steel of a simple or alloyed type;

- Adjustment devices.

When buying, you must take into account all the nuances. If it seems that this device is too expensive, then you can make it yourself. over, the manufacturing is not so difficult.

With variable working width

If we talk about a hiller, the width of which can be changed, it should be noted that they are used to work with powerful units weighing more than thirty kilograms.

Types of hillers, their characteristics

With the help of this unit, the process of making furrows on the soil surface and filling them with material for planting is carried out.

If you use a tiller, then the rows of planting potatoes will be even and spaced at an equal distance from each other. You can list several main types of hillers.

To choose the right tiller for a tiller, you need to note for yourself their main features and characteristics. There are many models of hillers, but the most common are the following:

- Lister;

- Disc hillers;

- Propeller type;

- With variable working width.

Lister

This type is the Most Simple. They differ in that they have a strictly exposed furrow width, which will be covered by the device, and it cannot be changed. It does not depend on the distance between the rows. Usually the delight of such a hiller is no more than thirty centimeters. A characteristic feature. the hiller is equipped with installed stands, which DO NOT allow overloading the tiller during operation.

Disc tiller for tiller

The same type is more efficient. The lower the speed of the cultivating unit, the greater the power of the tiller itself. This helps to significantly extend the service life. In addition, disk drives are easier to handle and require less effort in the process. And the most important advantage of this type is its versatility. The unit can be used both before planting and at a time when the part located above the soil increases.

Tiller Hiller

a tiller is a truly indispensable unit when cultivating land before planting it. Hiller is a type of additional equipment used on tillers, which will speed up and improve the process of planting potatoes and pre-planting work in general.

Propeller type

Propeller hillers are used on those tillers that are equipped with two forward gears.

When choosing tiller potato hillers, a few more points should be taken into account. It is better to use equipment with a streamlined shape (a plow-shaped hiller is well suited), because they turn the soil out with less intensity, which does not allow it to lose moisture.

In addition, it is worth giving preference to steel tools with a letter of greater width and with the presence of bearings. The size of the tiller is related to the size of the tiller and the length of the cultivated strip of land.

DIY hiller

How to make a hiller for a tiller with your own hands? For this, there are many drawings and diagrams. In general, there is no difficulty in making a hiller with your own hands. Having picked up the right tiller, choose a scheme and get to work.

Below is an example of a lister type tiller.

Take a metal layer two millimeters thick. Then cut out the halves of the part from it according to the proposed template (Taking into account the dimensions). Important! The halves must be symmetrical, otherwise this will affect the operation of the device in the future. Then bend both halves until the radii match, and then weld the x, making two or three passes. Next Process the welds.

It is very important to choose the correct drawing for the future product in order to avoid any discrepancies (during work, the structure will begin to lead to the side, etc.). With high-quality and careful manufacturing, homemade equipment does NOT create any difficulties and hindrances when hilling.

You can also easily construct a do-it-yourself disc hiller for a tiller.

To create such a device, you can take plowshares (discs) from a seeder that has already served its life. Or they can be made directly from metal sheets (no more than 2 mm thick), then bend the edge of the lower edge. The distance observed between the points of the lower supports corresponds to the width of the track itself. Then the discs are fastened to each other, but at the discretion that the connecting elements can be adjusted.

In addition, for disc hillers for the tiller, screw turnbuckles, stands (in which it was already mentioned) and a leash in the shape of the letter T are needed. Turnbuckles are attached directly to the motoblock device. The above type is better for cutting furrows than others.

Do-it-yourself tiller hillers are always pleasing to the eye, and working with them is much more pleasant and faster.

Making a disc hiller

When creating such a model, special attention is paid to disc molding. Used cutters from a seeder or circular saws, which are attached to bearings with oil seals, are well suited for them.

- The discs must be installed at an angle, keeping the distance between their lowest points. Also an important condition is their symmetry, otherwise the tiller may lead a little in different directions.

- All elements need to be connected by welding or bolts, discs are connected by adjustable adapters.

- Screw tarleps, leash and stands are also fixed.

- Next, you need to use a beam with wings to attach the tool to the tiller.

An equally important point is the correct selection of the angles of inclination and depth of immersion, for which movable elements with bolt fixing are mounted on the bracket.

Hiller to Tiller

The hiller is one of the most effective helpers for planting potatoes. This attachment is used on different types of tillers and allows you to bring the process of planting potatoes to automatic operation. Hillers for tiller potatoes need to be purchased separately, but some craftsmen prefer to make equipment with their own hands. Below we will consider how to make homemade hillers, and what you need in this case.

Making propeller hillers

To work you will need high-quality thick metal, an angle grinder and a welding machine.

- First, wasps are made, which need to be adjusted to the tiller.

- Then you should make a stand and a base, which are welded by arc welding.

- You should immediately choose the distance between the nozzles, the shape of the lugs and the angle of installation, which will allow the most efficient loosening of the earth.

For convenience, you can make several bushings with brackets and different sets of blades, which will allow you to perform various types of hilling.

In order to correctly make a hiller for a tiller, you should also look through. In which you will find a complete instruction on how to create a hiller.

How to install a hiller on a tiller

Installing the hiller on the tiller requires correct adjustment of the angle of attack and the depth of immersion, which should be less than in the plow.

Before working with a hiller, you should carry out the following work:

- Wheels and a hitch should be installed on the tiller, then attach the hiller.

- the tiller is placed on an equal surface, and the hiller is lowered to the ground and fixed to the hitch.

- When installing the equipment, it is necessary to make sure that the hiller stand is vertical, which will ensure the setting of the desired angle of attack.

- Further, the equipment is lowered to ground level or slightly deeper into it, so that it is below the supporting surface of the lugs.

You should conduct a test hilling and see: if the equipment goes deep into the ground, tilt the stand forward, slightly Raising the toe. In the event of exiting the ground, the stand is tilted back by lowering the toe.

It is important to consider the width between the rows by adjusting the active parts of the installation.

Do-it-yourself hiller for a tiller

For the manufacture of this equipment, you must adhere to Clear rules and, if possible, use drawings. This will allow you to correctly and quickly install all the details, so that later NOT to redo the work. You can independently make models of the lister (classic) or disk type.

Disk

A convenient and very simple tool spuds plants, prepares furrows for subsequent planting of seeds. Its design consists of special discs that are installed at an angle.

Today this model is the most effective for hilling, but at the same time it has a high cost.

Lister (fixed width)

The equipment can be used on units with a capacity of up to 3.5 liters. C., it is suitable for processing narrow row spacings (width 25-30 cm). The structure consists of two special wings, which are fixed and securely fixed. The model stand is very thin.

The disadvantage of the equipment is the adhesion of the earth at its high humidity.

Variable width furrower

The equipment allows you to adjust the row spacing, so it can be used to handle the beds, the size and width of which are various.

The hiller is suitable for different types of tillers, for example, for Neva MB 2 and MB 1 aggregates, Agro, it is also used for models with high power.

The disadvantage of the device can be called high energy consumption.