Replacing rings on the trimmer Stihl. Clutch clutch

How to remove a mowing head from a trimmer for STIHL grass

Lubricate a trimmer gearbox for the grass at least once a year, but it is better to inspect the lubricant after every 20-25 hours of work or when the gear noise in the motorcade gearbox appears. How to lubricate the gearbox gearboxes. For lubrication, at first you need to clean the cork itself and the place around the traffic jam and the remnants of the grass, so that they do not fall inside the gearbox when filling it with grease. Then you need to turn out the cork for the lubrication of the gearbox (for example, the Echo lawn mower is a key for “17”, in Husqvarna-a 6-garnet on “5”, for Chinese lawn mower-the key on “12”). It is better to use the same manufacturer as your trimmer for grass or just from world-famous brands, such as Oleo-Mac, Stihl, Husqvarna, Oregon, Liquimoly, Litol-24, Azmol 158 and T.D., If only it was not a fake! The tube, if new, print, removing with your fingers a cork or piercing the cover with the back of the lid in the nose of the tube. Then we put a trimmer for the grass on the left side, and rotating the knife with one hand (so that the gears are smashed and the entire volume is filled), squeeze the lubricant from the tube with the 2nd hand through the hole inside the gearbox before its full filling. Then we twist and clamp the trimmer gearbox for the grass and a tube plug with a lubricant. If the lubricant is not in the tube (and, for example, in the jar), take a honey syringe without a needle, take out the piston, fill the lubricant (with your finger) in the syringe, and then fill the gearbox of the trimmer for the grass from the syringe from the syringe.

The engine hold 4 screws installed on the bottom of the chainsaw of the Stihl 180 chainsaw. To remove them, it is necessary to spin them, and then carefully remove the engine from the seat and the rubber pipe of the carburetor.

For disassembling the engine, 4 screws of the crankcase are spinning, and it is removed, then you can remove the crankshaft assembly with seals, bearings and piston rings.

Removing bearings and oil seals usually does not require additional tools, but if the bearings have been tuned to the shaft with an effort, then a special puller is needed to dismantle.

To remove the piston from the connecting rod, you need to remove the locking ring from the planting nest, using a thin screwdriver, then the piston finger is squeezed out from the opposite side, after which the piston is removed to the side.

Signs of unbalancing

Carburetor debugging is certainly done in the manufacture of the device. Texas 330 Lawn mowed Carburetor adjustment. Usually, the owners will find out about the need to adjust the supply of fuel with their own hands only after rather severe breakdowns, in the process of correcting which, the module was removed and, for example, was cleaned.

Signs of a malfunction in the settings are the following:

- It starts, but the engine stalls here. since the engine can only work when a certain amount of gasoline is submitted, with a very “poor” combustible, in other words, overlapping the supply channel, the motor will stop;

- A very large fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the consistency. In this case, there is a lot of fuel, on the contrary, and the mixture comes out extremely dense.

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor thank you for your views.

STIHL FS 55. Carburetor adjustment (idle)

Adjustment of the carburetor of the trimmer for the STIHL FS 55 grass in the video is executed in order to adjust the revolutions of the idle.

STIHL, Makita, Husqvarna and others tuned with adjusting screws. Sometimes a prerequisite for disruption of work is a violation of fixation-due to vibration or damage to a protective cap. You can find such a breakdown by just trying a bit to turn the screw: if the fixation is not hard, it is worth checking the setting.

Do.it.yourself carburetor adjustment

The setting of the module does not apply to the repair and the change of spare parts is not required. In this case, the karburetor’s remark is not useful.

- L. is regulated first, because it is responsible for the supply of fuel at low speeds;

- H. he is responsible for supplying gasoline at high speeds, also for fuel consumption and temperature;

- T. with it, the idle speed is debugged.

There are options, usually a carburetor of a Chinese lawn mower, when only one screw remains for debugging on the housing. for the idle option. Valve adjustment on a lawn mower. This does not mean that the module is adjusted by automatic. this means that even such a type of repair as debugging will be problematic. In the photo. adjusting the carburetor of the Chinese lawn mower.

- The module setup is carried out only with a heated engine: for this, the device is used to be included for 10 minutes. Carburetor adjustment Japanese trimmer for grass. Lawn mowing trimmer for grass ignition adjustment. If the mowing head is idle at idle, then they start debugging immediately: turn the screw T counts the clock until the rotation ends.

- Adjustment starts with a screw l. The screw turns on the right and to the left until it finds such a position in which the idle speed does not become the highest.

- Then the screw is turned on ¼ turn against the watch. This will be his working position.

- The idle stroke must be configured by turns against the sentry for the growth of speed numbers and the clock. to reduce. Its debugging consists in achieving such a regime in which a sufficient number of revolutions are performed before the rotation of the mowing head. Lawn mowers gasoline self.propelled speed adjustment. With all this, the engine should work stably at various positions.

- The position of the screw L is determined by the latter. at the highest revolutions the trimmer for grass should not work for more than 10 seconds. The throttle is revealed, the screw is cramped clockwork, very slowly, until a decrease in the number of revolutions is established by ear.

- Then also slowly the screw spins against the sentry until the time the motor starts to work with failures. After that, the screw is on the back of the time, until the engine again earned normally.

If there is a tanometer, and if the product is indicated in the product passport, coooreecration can be carried out more accurate, focusing not by ear, but on the testimony of the device.

6 Комментарии и мнения владельцев on recording adjustment and repair of the carburetor of the lawn mower

Please clarify. In the section adjustment p.5, screw l error? You should read the screw a? Thanks to.

Tell me the original position of the screws h l la

Tell me the original position of the screws h l la

Signs of unbalancing

Carburetor debugging is certainly done in the manufacture of the device. Texas 330 Lawn mowed Carburetor adjustment. Usually, the owners will find out about the need to adjust the supply of fuel with their own hands only after rather severe breakdowns, in the process of correcting which, the module was removed and, for example, was cleaned.

Signs of a malfunction in the settings are the following:

- It starts, but the engine stalls here. since the engine can only work when a certain amount of gasoline is submitted, with a very “poor” combustible, in other words, overlapping the supply channel, the motor will stop;

- A very large fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the consistency. In this case, there is a lot of fuel, on the contrary, and the mixture comes out extremely dense.

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor thank you for your views.

STIHL FS 55. Carburetor adjustment (idle)

Adjustment of the carburetor of the trimmer for the STIHL FS 55 grass in the video is executed in order to adjust the revolutions of the idle.

STIHL, Makita, Husqvarna and others tuned with adjusting screws. Sometimes a prerequisite for disruption of work is a violation of fixation-due to vibration or damage to a protective cap. You can find such a breakdown by just trying a bit to turn the screw: if the fixation is not hard, it is worth checking the setting.

Do.it.yourself carburetor adjustment

The setting of the module does not apply to the repair and the change of spare parts is not required. In this case, the karburetor’s remark is not useful.

- L. is regulated first, because it is responsible for the supply of fuel at low speeds;

- H. he is responsible for supplying gasoline at high speeds, also for fuel consumption and temperature;

- T. with it, the idle speed is debugged.

There are options, usually a carburetor of a Chinese lawn mower, when only one screw remains for debugging on the housing. for the idle option. Valve adjustment on a lawn mower. This does not mean that the module is adjusted by automatic. this means that even such a type of repair as debugging will be problematic. In the photo. adjusting the carburetor of the Chinese lawn mower.

- The module setup is carried out only with a heated engine: for this, the device is used to be included for 10 minutes. Carburetor adjustment Japanese trimmer for grass. Lawn mowing trimmer for grass ignition adjustment. If the mowing head is idle at idle, then they start debugging immediately: turn the screw T counts the clock until the rotation ends.

- Adjustment starts with a screw l. The screw turns on the right and to the left until it finds such a position in which the idle speed does not become the highest.

- Then the screw is turned on ¼ turn against the watch. This will be his working position.

- The idle stroke must be configured by turns against the sentry for the growth of speed numbers and the clock. to reduce. Its debugging consists in achieving such a regime in which a sufficient number of revolutions are performed before the rotation of the mowing head. Lawn mowers gasoline self.propelled speed adjustment. With all this, the engine should work stably at various positions.

- The position of the screw L is determined by the latter. at the highest revolutions the trimmer for grass should not work for more than 10 seconds. The throttle is revealed, the screw is cramped clockwork, very slowly, until a decrease in the number of revolutions is established by ear.

- Then also slowly the screw spins against the sentry until the time the motor starts to work with failures. After that, the screw is on the back of the time, until the engine again earned normally.

If there is a tanometer, and if the product is indicated in the product passport, coooreecration can be carried out more accurate, focusing not by ear, but on the testimony of the device.

6 Комментарии и мнения владельцев on recording adjustment and repair of the carburetor of the lawn mower

Please clarify. In the section adjustment p.5, screw l error? You should read the screw a? Thanks to.

Tell me the original position of the screws h l la

Tell me the original position of the screws h l la

Caliber company. Brand’s base and popularization

Enterprise OJSC Caliber was founded in 1932. From the very beginning of its appearance on the market, the company aimed at the production of high.quality and inexpensive economic and industrial equipment. During the war years, the company’s plant provided production services: sharpening the tool, as well as turning, milling and heat processing of parts for Soviet weapons.

Today, in the assortment of the company you can find electric and gasoline equipment for home and garden, as well as operating machines in production. Gasoline and electric trimmers for grass are very popular among brand products. They are distinguished by high reliability, modest consumption of fuel and electricity, as well as stability during operation in severe conditions

Another important advantage is low for brand technique. The correct pricing policy of the company makes it possible to purchase its products to almost everyone

Description of the piston group of the chainsaw of Stihl 180

On the chainsaw of the Stihl 180, the piston group has a diameter of 38 mm. The dimension of the CPH of the chainsaw is determined by the diameter of the piston, the cylinder is slightly larger. In the standard configuration of the CPG MS 180, it is supplied with the piston finger, two piston rings and two stopping.

The inner surface of the cylinder should be perfectly polished and have a glossy shine, which you need to pay attention to when buying a spare CPG for the Stihl MS chainsaw. If there is damage on the inside of the cylinder, it is not necessary to install such a cylinder

A distinctive feature of the CPG on STIHL MS 180 is that it has two compression rings, while almost all its main competitors have only one. As the manufacturer assures, installing a pair of rings, allows you to better stabilize the piston in operation, strengthen its cooling and increase the compression in the engine, due to which the launch improves.

Causes of malfunctions of the piston chainsaw

There are many reasons for the failure of the CPG, which are customary to divide into two main categories: natural wear and artificial malfunctions. The first type of malfunctions, as can be seen from the name, belongs to the physical wear of the rubbing parts of the piston group. The second category is more extensive and means:

- strong overheating of the internal combustion engine and, as a result, the appearance of thermal bully on the piston surface;

- bummer of the lower part of the piston (skirt) due to the duration of the chainsaw at maximum speed;

- getting into the combustion chamber of foreign particles and the occurrence of mechanical damage to CPH;

- the bummer of the compression (piston) ring due to severe wear or exceeding the permissible speed of the saw;

- The inconsistency of the recommended portions of gasoline and oil in the preparation of the fuel mixture.

Experts do not recommend disassembling the CPG for no reason. However, if the tool has significantly lost power, a metallic ringing in the internal combustion engine arose or when the starter jerks of the crankshaft does not turn, the piston chainsaw should be diagnosed. First of all, to identify the motor malfunctions, it is necessary to measure the compression in the cylinder. With a significant deviation from the values recommended by the manufacturer, it can be safely argued that there are scratches, production, and darling on the surface of the cylinder or piston. It is the decline in compression that is the basis for the complete disassembly and repair of the piston group of the chainsaw.

For operational diagnosis of CPG for a breakdown of a compression ring of a chainsaw or bully in the cylinder, professionals advise removing the muffler and evaluate their condition through the final window.

Gasoline trimmer for FS 55 grass

This is a model from a lightweight ruler this price of a braid for grass quite justifies, especially if you use the knives with an attack. Productivity grows to such an extent that the fuel ends after an hour of work. Everything in the trimmer is thought out to the smallest detail and is most balanced. This explains its popularity among buyers of many countries. The design is based on a reliable and unpretentious internal combustion engine, which has a volume of 27.2 cubic centimeters. To increase wear resistance inside there is a special chrome coating. As a result, the service life of the product is extended.

Given many years of experience, the carburetor has been finalized, preventing pipe clogs. Manual pump provides ease of supply of gasoline during the cold launch of the motor.

In order for a trimmer for grass to instantly start in any, even the most difficult circumstances, an electronic ignition system in the airtight case is provided. The use of high voltage support made it possible to quickly receive a spark and extend its combustion, which reduced the amount of exhaust gases thrown into the atmosphere.

DIY potato.cutter for a walk.behind tractor

To increase comfort when using the Motokos “STIHL FS 55” has developed an effective depreciation system. It extinguishes the vibration of the engine even when pumping areas with great sloping.

For the manufacture of all parts, high.quality durable materials are used. Direct rod is made of forged steel. This allows you to withstand a significant load on a stable high rotation speed of a knife or fishing line. For maximum accuracy and performance with mowing, a trimmer for grass is equipped with an ergonomic bicycle handle. For convenience, there are anti.slip rubber hands on it. One of them is a control center with switches that regulate the operation of the device. Thanks to this, you can work with a motorcycle one with one hand.

The popularity of a trimmer for the grass of a real model is explained by its versatility and convenience:

- Engine power 1 horsepower.

- Tank capacity 0.33 liters.

- The largest width of the mowing strip 0.4 meters.

- The length of the trimmer for grass is 1.7 meters.

- Weight 5 kilograms.

- Noise level of no more than 90 dB.

Despite the rather high power, fuel consumption is 150 milliliters per hour. And this is at the maximum load, which makes such a trimmer for the grass among the leaders among such a tool.

The Stihl FS 55 lawn mower can successfully work on a garden or near the house, rolling out low and medium grass. She will cope with young wild weeds. Small sizes suggest the use of this trimmer for grass in constrained conditions: near fences, on pedestrian paths, around landscape plantings and in other inaccessible places.

Large sales are due not only to technical characteristics and versatility should be noted components that are in the set of supply of the unit:

- Autocut head, which is its own development of the company. She uses a high.strength fishing line for a trimmer.

- Forged steel knives.

- Plastic protective glasses.

- Convenient carrying and mowing provides a shoulder belt.

- Set of maintenance tool.

Features of snowpock nozzles for one.time tractor

For mowing dry grass up to 0.25 meters high and weeds with solid trunks, you can buy a two.way knife.

How to adjust the carburetor of the Stihl FS 55 lawn mower

The trimmer for the grass does not apply to complex household appliances, since most of its malfunctions are mechanical and can be successfully eliminated with their own hands. Even if the engine fails for good reason. For example, damage to the piston ring, repair is reduced to the replacement of parts.

And in a relative design, such a part of the device as the carburetor should be adjusted.

How does it work

Carburetor. This is the energy system module in which liquid fuel and air are mixed before supplying to the engine cylinders. Depending on the instrument and its operating mode, mixing and supply are regulated accordingly.

Carburetor cutter is uniform in almost all cases. The price of FS 38 for recreation should be adjusted using a carburetor screw. Belongs to the category of floating devices. How to adjust the carburetor on a scooter. Honda part AF-34. The latter provide constant characteristics of the finished consistency.

The mechanism of the module is as follows.

- The air enters the body of the tube with an air damper. Adjustment of the carburetor of the cooler of the trimmer for grass FS 55 in the video How to adjust the carburetor. The latter increases or decreases the flow of air depending on its position.

- In the zone where the gas supply hole is formed, the tube has a hood. diffuser. Adjustment of a trimmer for the grass of the carburetor carburetor fs 55 in the video is performed to adjust the blank speed. Here the flow rate increases.

- Fuel from the float chamber through the nozzle is supplied to the pipe. The level of the float determines the amount of fuel supplied. How to adjust 24, I removed the carburetor from the diode, I do not know the rings on the pistons of Honda Dio 34. Since the pressure in the chamber is normal, and in the pipe is low due to a large air vacuum, the gas is absorbed through the nozzle.

- The accelerated air flow collects fuel and spray it, forming the fuel.air mixture of the corresponding density.

- The mixture is sucked into the cylinder through the pipe.

The larger the air damper in the pipe is open, the higher the density of the air flow and more fuel enters the cylinder. A carbon tunnel settings are reduced to the damping coefficient, in which the consistency of fuel becomes good.

Signs of imbalance

Carburetor adjustment, of course, is carried out in the manufacture of the device. Typically, the need to regulate owners will be able to independently deliver fuel only after serious breakdowns, during which the module was removed and, for example, cleared.

Signs of a malfunction in the settings are as follows:

- It starts, but the engine stops here. Since the engine can only operate when a certain amount of very “bad” gasoline is supplied, in other words, blocking the supply channel, the engine stops;

- Very high fuel consumption, many exhaust gases. The result of incomplete combustion of consistency. In this case there is a lot of fuel, and the mixture is very thick.

Carburetor gasoline braids are quiet, Makita, Husqvarna and others are regulated by adjusting screws. Sometimes a prerequisite for a malfunction is a violation of fixation. due to vibration or damage to a protective cap. You can find such a breakdown by just trying to turn the screw a little: if the lock is not hard, you must check the settings.

Repair of a trimmer for STIHL grass with your own hands and operating instructions FS-38 and 55 (STIHL FS), carburetor adjustment

It is inherent in a person to ennoble the place in which he spends the lion’s share of his time. Residents of cities resort to the services of designers, or they themselves try to change something in their home, buy new furniture, wallpaper, so that, having arrived home after a difficult day, one could mentally relax and relax in a favorable atmosphere. Residents of their own houses behind the city line have completely different worries and demands. It is necessary to download shrubs, grass, various dryness, carefully monitor the state of the personal plot and garden. It is clear that this requires slightly different means of achieving comfort. And then a new brainchild of engineering thought comes to the fore. STIHL mowers of the company.

Hi Dear friends! My past post for repairing a chainsaw has collected many questions, many answers and 150 subscribers. I continue to dilute the community of repairs of benzo-instrumentation. In one commentary, they asked to show how to change the oil seals not with a stihl gas station, just I had to repair the Stihl FS55, the instruction is also suitable for Stihl FS38/44.

So, we went, the preface: the lawn mower was brought to this before the upcoming season, she started, worked, and only occasionally there were not big problems with long work, she began to live her life, did not obey the pens of gas, but it soon worked and she worked again.

Carry out that (replacing filters, candles, lubrication of bearings, cleaning, purging, adjustment). show how I will not be done, everyone should know this.

Find a defect that causes “your life” of the lawn mower.

Near the carburetor and under the lids, dust was visible, the carburetor and the inlet tract was completely serviceable. So we will get to the seals. To do this, remove the starter.

Then we unscrew the screws below the braids for the grass that are marked.

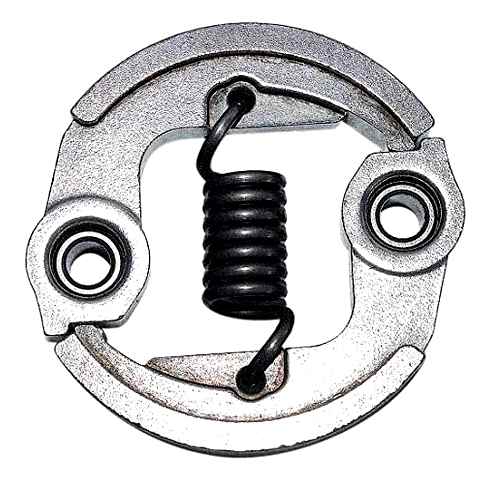

Remove the casing of the upper and lower. Next, we take the suitable torx in size, insert it into the clutch drum and twist it, the right carving, that is, the usual.

Next, the clutch pads go, if there is no pneumatic control, then we pinch the flywheel carefully in the vice through wooden spacers, and unscrew the gas key, the right thread is right.

If the flywheel itself does not fly away, then we take the kiyanka and slightly beat it, it is easily removed, from the side of the header, the head of the starter’s ratchet, the right thread, is right.

So we got to the oil seals, visible around them oil with dust, so the seals are missing, the client said to change.

We pull out the old oil seals with a thin screwdriver, we clean everything, we take new oil seals (size 12227.3, these are on China with 26 and 33cm3 braids), lubricate with oil and inside, fill the suitable head.

We collect everything in the reverse order. I launched it, heated, gazed, works like a clock.

Carburetor cleaning and adjustment, gear lubrication 300r

I do not praise Stihl, but I asked how long this braid for the grass has and how much it mows, a braid for herbs is 5-6 years old, in the summer it harvests hay, it mows 3-4 days a week, burns up to 5 tanks with interruptions only for refueling.

Trammers for grass professional and light

It is sometimes impossible to make a choice in favor of a device without elementary information on the main technical parameters of equipment that interested the user.

It will be advisable to compare these two categories of devices, choosing two from a number of models, on an example of which you can trace all their similarities and differences. The most popular model from the group of low.power gasoline trimmers STIHL is FS 55.

The devices that are popular due to optimal power and performance and used for processing large areas include FS 250. The main differences characterizing these two units are laid down in the constructive features of the engines.

So, in a household trimmer for grass FS 55, an improved type 2 MIX, which ensures a decrease in harmful exhausts and increases the efficiency of fuel consumption, is equipped with a direct drive shaft. The engine is working on the oil bosinzin mixture.

The engine power of this model is 1 liter. With., and volume. 27 cubic meters. cm, which allows you to successfully use it not only in the garden, but also on small lawns.

The duration of the average working session of this device is 2-3 hours of work in an area of up to 6 acres.

This is also facilitated by a tank for fuel with a volume of 0.33 liters.

The FS 250 device is equipped with a 2.15 liter with the previous model with a gasoline two.stroke 2 MIX engine. With. and with a volume of 40 cubic meters. cm.

The hard shaft and the piston group persistent to wear and significant loads allow the use of the unit in territories with an area of up to 20-25 acres for 6 hours of continuous operation.

Fuel container contains 0.64 l of fuel. The trimmer for the grass copes with advanced vegetation in any climatic conditions.

Most often, equipment of this type is trusted by complex communal work on the improvement of the territories of city parks and forest parking zones.

The similarity of the engines of these models is the presence of a smooth starting system Elastostart. This allows you to minimize uncomfortable jerk.shaped movements at starting, loading the muscles of the hands and back of the user.

The presence of the fuel pump for the trimmers in question provides the ability to pump fuel to the carburetor manually, which greatly facilitates the launch of the engine after a long break in operation.

The ergostrat mechanism, which is equipped with the FS 55 model, is responsible for the light and quick start of the engine thanks to the spiral spring in the design of the starting device.

The FS 250 unit is equipped with an anti.vibrational STIHL system, using special rubber linings of the extinguishing harsh shocks and fluctuations that occur during operation.

Due to this, the high efficiency of the operator’s long.term work is achieved without the sensations of fatigue and stress. Also, the structural features of the described trimmer for a professional class grass include a special regulatory authority. a compensator.

It prevents the saturation of the fuel mixture when filter pollution by harmful substances, providing a long.term period of operation. The surface of the filter surface is required to reach the level of pollution in 80 %.

Both of the under consideration trimmers are not inferior to each other in terms of convenience of use. The multifunctional handle present in the models is equipped with all the necessary controls, which gives the operation an operational and effective move.

Attention! The handle here is T-shaped, double, providing maximum maneuverability and adjustability. It is this type of handle that is optimal for frequent mowing of grass in vast territories

Equipment component by practical shoulder diluted belts with soft pads allows the operator to work for a long time without fatigue. These belts are also equipped with a convenient carrying system.

If necessary, it is possible to use portable belts with a tool bag and the mechanism of quick removal and fixing the trimmer for grass. All STIHL technique is necessarily equipped with special glasses that ensure the safety of the operator during operation.

The described trimmers for the grass are close and in their overall indicators. So, the STIHL FS 55 model has a length of 172 cm without equipment, and the FS 250 device is 177 cm. Without tools, the weight of a light model is 5 kg, professional. 6.3 kg.

Both units have a straight bar, cutting head Autocut 25-2, the ability to equip a GSB 230-2 with a two-blade knife and fishing line. The width of the herbs mowing is, respectively, 30 and 45 cm.

The Stihl 180 chainsaw control key has broken. how to eliminate

Frequent breakdown of the Stihl chainsaw, which happens through the fault of the operator, is a malfunction in the operation of the engine control mechanism. precisely, when the seat for the control lever is being broken down due to its design features, to solve this problem you will need to replace the saw building, which is quite difficult to do on your own. Consider the repair algorithm with our own hands, according to which the chainsaw housing is being replaced:

- The case is freed from the block of the handles;

- The starter is removed, for this, the lids are removed from the fuel and oil tank and the screws of the starter mounting are promoted;

- Further, through the candle hole, a piston stopper is installed in the cylinder, the flywheel is spent and removed from the engine shaft;

- The leading star is removed and the clutch is untwisted;

- Two 8 mm nuts are promoted, holding the air filter housing and carburetor, modules are removed from seats;

- At the next stage, 4 screws are promoted, holding the engine on the case. Special bushings are mounted in the installation site of the STIHL 180 chainsaw at the installation site of the engine mounting screws, which can independently fall out and get lost.

- The last moment is the removal of the oil pump, the rubber knee of the carburetor and the fuel and oil tanks.

Install parts in the new case with a reverse sequence. In parallel to eliminate the main malfunction, you can check the rubber knee of the carburetor, the part that has developed its resource and has lost elasticity must be replaced.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not enter the cylinder, but the candle works normally, this may mean that:

To clean this node, remove the fuel hose and check the stream. If it is weak, the filter needs to be removed through the pouring hole of the fuel tank and cleaned or replaced in case of complete wear.

This is nothing more than a hole in the lid of the fuel tank, which is cleared with the help of an awl.

- The air filter was clogged (in this case, it must be removed, washed with water, dried and put in place);

- The settings of the carburetor were lost (it means this node must be adjusted again);

- the integrity of the carburetor membrane is violated (subject to mandatory replacement);

- Carburetor channels clogged (it must be disassembled and cleaned by all parts and nodes).

Damage of the chainsaw engine

During operation, the part of the cylinder-piston group of saw due to friction, high temperatures and loads fail. If, when starting, the tool does not develop full power and stalls at idle, a possible malfunction may be breakdown in engine parts. To disassemble the power unit, it is necessary to unscrew 4 bolts and extract the cylinder. The owner needs to carefully inspect his inner working surface for the presence of chips, nicks and cracks.

STIHL MS180 cylinder piston group

When diagnosing the ICE, we also perform a visual inspection of the piston and compression rings. Made of duralumin alloy and cast iron, respectively, they are more subject to abrasive loads, unlike the steel cylinder. With a breakdown and excessive wear of piston rings, it is necessary to replace them.

If, during visual inspection, the ovality of the working surface of the cylinder is observed, it will need to melt it. To do this, measure its diameter by larger size, select the piston and produce subsequent mechanical processing.

Dot in the lubrication system of the chainsaw 180: Causes and repair

In the process of cutting wood, the cutting part of the tool is subjected to high loads. In order to reduce the friction forces and subsequent wear of the chain of the stihl ribbon chain, it is equipped with a lubricant system that gradually supplies oil to the tire. Fast loss of teeth of the cutting properties and the absence of traces of lubricating fluids may indicate its leakage or clogging of pipes.

First of all, when diagnosing the lubrication system for the chain for the ms 180 chainship, we pay attention to the oils supplying oil and their fixation sites. Damaged pipes are not subject to repair, and therefore they should be replaced

Cleaning oil canals can be by means of compressed air. For these purposes, we use a compressor or a regular car manual pump.

Due to its simplicity of operation and repair, the chainsaws of this model were widely recognized among professionals and lovers in the field of woodworking.

Piston chainsaw replacement algorithm

If it is time to replace the CPG of the chainsaws, you need to know that for each specific model there is an individual algorithm of action. To facilitate the disassembly/assembly work, it is necessary to prepare a candle key, a large flat screwdriver, a hammer, a compressor for cleaning the parts of the unit, a set of rock and end keys. Regardless of the manufacturer and the design features of the model before removing the chainsaw cylinder, the following work must be done:

- Dismantling the upper protective cover;

- Spinning candle twisting;

- Removing the side cover;

- With the help of a large flat screwdriver, stoppers from shock absorbers are removed;

- In the candle channel, place the cranberry lamp and unscrew the clutch and nut of the flywheel;

- Dismantling the leading star of the chain;

- We remove the carburetor with an air filter;

- Remove the ignition module and exhaust system.

After removal from the base of the power unit, unscrew the pallet and take out the crankshaft with a piston from the cylinder. Using a locksmith tweezer or screwdriver, dismantle the piston fingers.

Before dismantling the Piston, it is necessary to remember its location in the cylinder in order not to spend time subsequently on re.disassembling and assembly of a power unit.

Sealant for fixing the shaft of the chainsaw

Before starting the assembly, compressed air, rags and other means to clean the parts and assemblies of the unit from dirt, remains of sawdust, dust. The first stage of replacing the piston chainsaw is to install the piston on the crankshaft. We fix it on the connecting rod with a steel finger that is included. In order to prevent the arbitrary loss of locking rings, it is recommended to install them with a cut down. Next, we mount the compression rings on the piston, but due to their fragility and brittleness to this operation, you need to approach as carefully as possible. To prevent the formation of scratches before installing the piston in the cylinder, grease the piston with oil. Before installing the crankcase (pallet), it will be necessary to degrease its mounting surface and apply a layer of heat.resistant sealant. The assembly of the chainsaw is carried out in the reverse algorithm described above.

Often the replacement of the piston of the chainsaw, crankshaft and compression rings solves problems with the idle stroke and with a problematic launch of the internal combustion engine.

It seems to have found a piston, maybe not everything is so scary))

Please tell me, replaced the piston and the sleeve, started it, worked for about 5 minutes, I couldn’t start it again, the autopsy showed the grooves on the sleeve and the piston. the rolling pin broke off the edge of the intake window and struck the sleeve. Reason 2 replacement of the piston-the same, the lack of compression, the reason is scratches from some kind of metal chip. They are, before assembling a file, you need to go through? What kind of trouble is?

I can assume this. one. The quality of the spare parts is no 2. Lack of oil in gasoline 3. When heated, the piston expanded and caught the wedge, perhaps not the correct size or overheating.

I think to change the piston 3 times, or is it easier to buy a new engine. Thanks.

How-to Stihl trimmer clutch repair (Step by Step)

When installing a little oil, I greased all gasoline diluted with oil more before installation, I would look like the piston in the cylinder itself on the cold air filter and a good.legged runner

When you need a piston replacement

The reasons why the piston must be replaced, as well as completely piston, there may be quite a lot, but all of them can be divided into natural and emerging as a result of improper operation. Natural, this wear is formed due to the prolonged operation of the Stihl 180 chainsaw. There are much more artificial ones, for example:

overheating of the engine and the appearance of thermal bullying;

- entering the cylinder of a foreign body and the appearance of mechanical bullying;

- the bummer of the piston ring as a result of exceeding the maximum engine speed;

- the wreck of the piston skirt due to excess revolutions;

- the use of poor.quality fuel, as a result of which the piston group of the chainsaws wears out from the side of the intake channel in the cylinder;

- Operation of a stihl chainsaw with contaminated fuel filter, as a result of which the percentage of oil in the fuel mixture is reduced;

Diagnosis of CPG is necessary if the STIHL MS 180 has sharply lost power or does not start, while the tool starter does not turn. If the starter is turning, but the saw does not start, while there is a spark and fuel enters the cylinder properly, it is necessary to measure the compression in the engine.

9.5. 11 atm. It is considered a normal indicator in which the StiHL chainsaw is regularly launched and gives out maximum power, if the compression is lower, there is a possibility that there are bunches on the cylinder.piston group, or its wear is large enough. In any case, with reduced compression, for further diagnosis, it is necessary to completely disassemble the saw.

Determine the presence of bully on the piston, as well as the wreck of the piston ring, if you remove the muffler and conduct a visual inspection of the visible part of the piston, while the rings for elasticity can be checked by pressing them with a small screwdriver. A small walk will be observed on the working rings, there will be no defective or clamped piston ring.

Installation of rings on the piston of a scooter

It is worth starting here with the fact that these rings can have a different section depending on the place of their installation, it is very fundamentally directed to this. Apart from this, there is also a special bean on the rings of the scooter, which shows to the upper layer of the part. Installation procedure

from the lower ring to the upper. When installing them, there is no need to stretch them or bend, the entire process is carried out very carefully

Installation procedure. from the lower ring to the upper. When installing them, there is no need to stretch them or bend, the entire process is carried out very carefully.

There are locks in the grooves for these spare parts, the task of which. prevent the turn of the element during operation. Therefore, the gap for fastening should be specifically in their. Nowhere else to put a piston ring will be possible.

Carburetor check and adjustment

In service centers, carburetor adjustment is made on special equipment. For each saw, the values of the rotation angles of the adjusting screws are different (they are indicated in the operating instructions). The need to adjust the carburetor does not arise very often, especially if the saw was bought from a proven seller. All our Husqvarna saws are sent to the service center before selling, where experts set up revolutions.

However, a violation of fixation of adjusting screws sometimes happens.

Causes of violation of adjustment of the carburetor of the chainsaw:

- Strong wear of the engine (piston). In this case, it is necessary to take a greater extent to fix the engine, however, the carburetor adjustment can improve the functionality of the saw for a certain amount of time.

- Blockage in the carburetor due to damage to the air filter, the use of poor quality gasoline and the formation of scale.In such a situation, in addition to adjusting the carburetor, it will also be needed to flush.

- Strong vibration of saw or damage to the protective cover. This is extremely rare, but there are still cases.

SAVE AND DIY! HOW TO REPLACE THE CENTRIFUGAL CLUTCH ON ANY #HUSQVARNA #STIHL OR #ECHO WEED EATER

Signs that indicate the need to adjust the carburetor of the chainsaw:

- The engine either does not start, or starts up and immediately stalls. This is due to the use of poor fuel mixture.

- A significant increase in fuel consumption and an increase in exhaust volume. the amount of exhaust gases suggests that the fuel does not completely burn out. The reason for this can be oversatuity of the fuel.

The carburetor adjustment scheme for different models of the chainsaws is different and described in the operating instructions. However, the general principle remains the same: it is necessary to change the quantity and quality of the fuel mixture supplied to the engine cylinder.

Three screws will help us to adjust the carburetor:

- “L”. LOW, to configure low speeds

- “H”. High, to configure the upper revolutions

- “T” (“LA”, “S”). to configure the idle stroke (the models that have only one screw have exactly the “T” screw)

When adjusting the carburetor of the chainsaw, the following rules should be followed:

- Make sure that the cutting chain of saws is directed in the opposite side of you

- Put the saw on a stable even surface, the cutting part should not touch any objects.

Please note: the instructions indicate the exact angles of rotation of the adjusting screws. Accurate compliance with the instructions of the instructions will avoid engine damage.

The process of adjusting the carburetor itself includes two points: basic (with a non.working engine) and final (with a heated engine).

Why is the stihl chainsaw is not started after replacing the piston

If the saw does not start after replacing the piston, it is necessary to check the fuel supply to the chamber, as well as diagnose the ignition system. Very often, when installing the control lever on the chainsaw, the masters forget to connect the wires coming from the ignition coil, as a result of which the spark disappears and the saw does not start.

Also, the problem can be hidden in the overflow of the fuel supply hose or if it is not connected at all. Of course, there can be many reasons, but it is worth remembering that in the event that all the work on replacing the piston is carried out correctly, the tool should start without any problems and work normally.