Than Cutting Polycarbonate At Home

Electric jigsaw

A household, most ordinary electric jigsaw is also quite suitable for working with polycarbonate letters, only you need to install a file with fine teeth on it, otherwise the material will tear, not cut. This tool, like the angle grinder, is quite easy to use, but in order to be completely confident in the quality of work, it is advisable to also practice in advance. An electric jigsaw is very much in demand, especially when you have to cut monolithic polycarbonate of complex decorative shapes or do it by rounding.

When only one letter needs to be cut, the risk of cracking increases significantly. To prevent damage to the material, you need to work only with a very well sharpened tool. There are craftsmen Who, when working with polycarbonate, use scissors. This is also perfectly acceptable. The main thing is that the tool used does NOT break the structure of the canvases.

Tools

Hacksaw

Beginners are usually interested in: is it possible to cut and how to cut cellular polycarbonate with a hacksaw or a hand saw? In the event that there is no experience, it is advisable NOT to use these tools: the canvases along the cuts may crack. Work best with power tools. But both beginners and experienced professionals need to fix polycarbonate sheets well so as not to allow vibration and stress in the material, which is also fraught with bad consequences.

How and how to cut polycarbonate at home?

Cloths of polymer plastic, more familiar to everyone under the name polycarbonate, are becoming more and more popular every day. It is no coincidence: the relative cheapness and excellent properties of the material brought it to one of the first places in sales. It is also of great importance that almost anyone can work with it, if there is a desire. But since this is a new material, not everyone knows how to correctly and how to cut polycarbonate at home in order to get a high-quality cut and NOT spoil the material.

Stationery knife

Perfectly cuts polymer plastic canvases and a stationery knife. over, even beginners can cope with this. The main thing is that the knife is of good quality, and the work is not done in a hurry. the blade of such tools is very sharp and it is impossible not only to make an incorrect cut, but also to get seriously injured. The stationery knife is suitable for honeycomb sheets with a thickness of 4-6 mm, but with 8 mm it is already quite difficult to work with. On thicker sheets, cutting polycarbonate is almost impossible, therefore, experts recommend using a knife only where it is necessary to trim the material, and even then, on leaves up to 10 mm.

Angle Grinder

The very first tool that almost everyone has and that can work with polycarbonate is an angle grinder. over, it is not at all necessary to use an expensive tool: even an inexpensive and small angle grinder will do all the work perfectly. To make even cuts, you need to set the circle 125, intended for metal. The only thing you need to pay attention to is experience, since the tool is distinguished by high revolutions, and if you did NOT have to work with it before, it is advisable to practice cutting from this material before cutting the polycarbonate. Where can I get them? Contact the craftsmen who are engaged in the manufacture of polycarbonate structures.

Laser cutting

In addition to the listed methods, you can also cut with a laser. But, to work with a laser machine, you need to have the Appropriate skills. In addition, not every craftsman has such a tool, therefore, laser cutting of polycarbonate is available only to those who deal with polycarbonate professionally. But, if there is an opportunity to perform the work with a laser, you must definitely use it, since this guarantees:

- High speed of work;

- No defects;

- Excellent cutting quality;

- Cutting accuracy: when working with a laser, the dimensional accuracy is maintained up to 0.05 mm;

- When working, it is not necessary to fix sheets.

Any cutting material intended for work on metal or wood can be applied to the blades of solid polycarbonate, even a standard cutter for metal.

How to cut correctly?

Before cutting polycarbonate, experts prepare the workplace well beforehand. It is necessary:

- Remove all foreign objects from the site: branches, pieces of planks and boards, even small pebbles. Ideally, the place should be clean. This is necessary so that there are NO dents, scratches and other damages on the polycarbonate canvases. It is best to pave the working area with sheets of chipboard, fiberboard or another suitable material for this purpose.

- Use a marker and a long ruler or a second object on the panels to mark up. If you have to move along the canvases during this, it is necessary to lay a wide board and walk only on it so that dents do NOT appear on the polymer surface.

- Before cutting polycarbonate to size, it is necessary to put boards under both sides of the markings applied with a marker, the size of which should NOT be less than 4 × 10 × 220 cm.On top of the canvas, in the same places, boards are again placed and, only then, you can will move on them.

- If the cut is made on an even mowing line, you can work with an angle grinder, rounded parts go through with an electric jigsaw, and if you need to make a slight adjustment, a clerical knife will do.

- If the work is performed on material with a laminated or mirror surface, it is very important to correctly position the canvas in the workplace: the laminated or mirror coating must be returned upwards. What is better for this kind of polycarbonate dust? The same tools as other types of material, but using a hacksaw is not acceptable: mirror or laminated layers can peel off.

- When working with canvases of cellular polymer plastic, if the cut is made along the length of the sheet, the markings can be omitted: the honeycombs themselves will serve as a guide. Thanks to this, it will not even work on the surface of the material.

- After completing the sawing work of honeycomb blades, it is necessary to blow out all the seams with compressed air to remove dust and chips that have got inside.

And most importantly, before cutting polycarbonate with an electric jigsaw or an angle grinder, you need to wear safety glasses to protect your eyes from microparticles and dust. And one more thing. you should always remember the popular wisdom, which says that before you cut it off, you need to measure it seven times. this will help save both money and time.

Polycarbonate. what it is

Polycarbonate is a hard transparent or translucent plastic, which is very durable and, in comparison with glass. Less weight.

There are two main types of this material.

- Monolithic. is a solid sheet of polycarbonate.

- Cellular (honeycomb) polycarbonate. hollow cells with partitions are located in it between the solid upper and lower layers of material. A letter can have one, two, three rows of cells, sometimes even more. The walls of the cells also play the role of stiffeners.

Types of cellular polycarbonate

Table. The main dimensions of polycarbonate sheets.

| 6.05×2.05 | monolithic | 2, 3, 4, 5, 6, 8, 10, 12 |

| 6×2.1 | cellular | 4, 6, 8, 10, 14, 16, 25 |

| 12×2.1 | cellular | 4, 6, 8, 10, 14, 16, 25 |

How to cut polycarbonate at home?

At the moment, polycarbonate is one of the main materials used in the construction and arrangement of private households, personal plots and greenhouses. Working with it begins with cutting, and not only the appearance, but also the strength of the polycarbonate structure depends on how correctly it is done. After every summer resident or owner of a private house, it is extremely important to know how and with what tools to cut this material.

Cutting Polycarbonate Angle Grinder

The next most popular tool after the knife is the angle grinder, better known as the “angle grinder”. It is well suited for sawing large sheets of polycarbonate on straight lines. If you need to make a cut with rounded elements, for example, to cut out the end wall of an arched greenhouse, then it is better to use a knife or an electric jigsaw.

angle grinder

To cut polycarbonate Use metal cut-off wheels, preferably one that is designed to work with aluminum. This is explained by the fact that when using them, the temperature in the cutting zone will be lower than when using a wheel on steel. Accordingly, the risk of melting the edges of the polycarbonate sheet will also be less.

To make the chances of melting even less (and at the same time to reduce the likelihood of burrs) will help the use of an “angle grinder” at low speeds.

Prepare a letter and a platform for work as described in the instructions in one of the previous sections of the article. When working with an angle grinder, fit props and plank scaffolding to the left of the cut line. DO NOT remove the protective film from the sheet.

The letter should be placed on props

Test the Angle Grinder on cuts or unnecessary pieces of polycarbonate. This will give you some practice and a little experience with a similar material and an angle grinder. After that, it will be much easier and safer to correctly cut the main sheet.

Marking before starting cutting is mandatory

Turn on the angle grinder, let it reach the required number of revolutions and bring the cut-off wheel to the end of the sheet along the cut-off line.

Start the cutting process. Slowly slide the Angle Grinder cut-off wheel forward along the cut-off line. I control the position and do not rush, otherwise there is a risk of leaving a large burr. When cutting cellular polycarbonate along the stiffening ribs, the cutting line should be positioned so that the cut-off wheel “angle grinder” did not crash into the walls of the cells. Wear protective goggles to keep plastic shavings out of your eyes.

Start cutting polycarbonate with an angle grinder

At the end of the cutting process, turn off and power off the angle grinder. As a rule, the letter is cut off immediately and completely; additional work with a knife is not required.

Completion of the cutting process

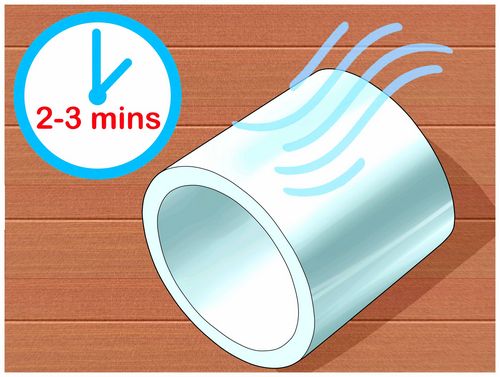

If you are cutting cellular polycarbonate, then after completing the process, remove plastic chips and dust from the cells. To do this, use a jet of compressed air, vacuum cleaner or fan.

Cover the edge of the honeycomb polycarbonate sheet with construction tape.

You can cut with a circular saw in a similar way. Choose fine-toothed saw blades designed for metal or plastics. Immediately before starting to insert the disc, let it gain the required number of revolutions. The base plate of the tool will help you to increase the accuracy of cutting, which you need to hold down to the letter.

How to cut polycarbonate?

One of the advantages of this material is that tools for working with it can be found in almost every home, and therefore it will NOT be difficult to cut polycarbonate at home.

The following tools are successfully used for marking and cutting polycarbonate:

- Stationery / construction knife;

- Electric jigsaw;

- Angle grinder, more commonly known as “angle grinder”;

- A circular saw;

- Hacksaw for metal.

Industrial equipment suitable for THESE purposes are CNC milling machines and special types of lasers.

Polycarbonate Cutting Tools: Hacksaw, Circular Saw, Band Saw

Along with this, there are tools that cannot be used in any case to work with polycarbonate, otherwise there will be a risk of damaging the letter and getting extremely unsatisfactory results.

- Hacksaw for wood. its teeth are too large, they DO NOT cut the polycarbonate as much as they tear. In total, you will have a lot of nicks, burrs and cracks on the edges.

- Construction scissors or plastic shears. they are suitable exclusively for thin monolithic sheets of material. Otherwise, when squeezing polycarbonate (especially cellular) from both sides, the sheet is deformed near the cut.

A hacksaw cannot be used

Now let’s take a closer look at the preparation and the cutting process itself with the most popular tools.

Cutting polycarbonate with a hacksaw

A hacksaw for metal with small and frequent teeth is sometimes used to cut polycarbonate sheets into straight square and rectangular pieces. The process is similar to cutting with a construction knife, so if you decide to use a hacksaw, then read the corresponding Step-by-step instructions above.

Hacksaw for metal

In this case, consider two nuances:

- Hold the hacksaw at an angle of approximately 30 °;

- Secure the polycarbonate letter as well as possible; if there is a workbench and a vice or clamps, then use them.

But it is more convenient and, most importantly, it will be better to cut the material using an electric jigsaw or a construction knife with a retractable blade.

Stages of cutting and installation of polycarbonate

Cutting polycarbonate with a knife

The knife is the most readily available tool for cutting solid or honeycomb polycarbonate. For such work, they use clerical or construction knives with retractable and replaceable blades. It is better to take a construction one, as it has a comfortable handle and a more reliable blade locking mechanism. It’s a good idea to cut polycarbonate with a boot knife.

Shoe knife

Regardless of the type of tool, it must be well sharpened. a blunt knife Not only will significantly slow down the process, but also leave a lot of burrs on the material. The utility knife is best for working with small leaves, cutting and adjusting them to size.

Replaceable blade construction knife

But, compared to an electric jigsaw or “angle grinder”, cutting polycarbonate with a retractable knife is time consuming. It is not very convenient for them to work with letters of a large area. It should also be borne in mind that clerical and construction knives are suitable for cutting polycarbonate with a thickness of up to 6-8 millimeters, but no more.

Prepare a work site. Detailed instructions on how to do this are outlined in the section above. Let’s mark the polycarbonate with a black marker.

First you need to prepare everything

Let’s test the knife for scraps of material or that part of polycarbonate that will NOT be used. it is necessary to check the sharpness of the tool. If it is not enough. replace the blade (for office and construction knives) or Sharpen (for a boot knife).

Polycarbonate can be fixed with electrical tape

Attach a rule or a thick metal ruler to the cut line. If not available, use a level board or building level. When working with letters of a large area, keep the rule and the letter itself Your assistants should. so the accuracy and quality of cutting will increase.

Alternatively, you can mark the cut line with the same tape

Move the knife blade to the ends in the cut line. When working with thick polycarbonate, hold the tool perpendicular (or nearly perpendicular) to the plane of the sheet. If the polycarbonate is thin, then it is permissible to hold the knife at an angle of 30-45 °. Slowly insert the knife into the end of the sheet to leave the initial notch there.

Open with a knife

Guide the knife from the notch along the cut line. A rule or ruler will help you to follow the pattern.

When cutting with a knife, it is convenient to use a long ruler or rule

Cutting speed should be low, accuracy is more important here. When working with rounded elements, wind the knife on the “turns” carefully, do not allow burrs or cuts along the line drawn with a marker. DO NOT be afraid to leave too much. trim after.

Use a ruler or rule to cut polycarbonate with a knife

If the cut polycarbonate letter does NOT separate from the rest of the material, run the blade again along the cut line. It is prohibited to break or bend the material. there is a risk of cracks and other defects.

Trim any burrs, if any. Trim any excess to fit the letter. If cellular polycarbonate was cut, then glue the ends with construction tape or electrical tape so that dust and debris miss the cells.

If the thickness of the polycarbonate (only monolithic!) Is less than 30 mm, it can be cut with large scissors

Job is done

Preparation and markup

This step-by-step guide to preparing the workplace is common to all types of tools used, except industrial laser and milling machine.

Clear debris and unnecessary items from the work area. This is necessary not just for reasons of cleanliness, but so that they do NOT interfere with the process and do NOT leave dents, scratches or other marks on the back of the sheet.

Workplace preparation

Lay the letter plywood, particleboard or fiberboard on the pad. The cutting area is now as flat as possible.

Transfer and stow the polycarbonate letter to the workplace. If it has a laminated, mirror or UV coating, then it should “look” up. DO NOT remove the protective film from the cutout letter.

Perform preliminary marking in the form of a diagram on paper, observing the scale.

Polycarbonate sheet cutting drawing

Transfer the layout from the paper to the polycarbonate. For measurements Use a tape measure, a metal ruler and a rule to draw cutting lines. a black marker.

Polycarbonate sheet marking

When working with letters of a large area, place a board on top (at least 100 mm wide) and walk only on it, so as not to damage the polycarbonate surface. Examples of cutting material for the gable of greenhouses Shown in the image below.

Cutting letter polycarbonate on greenhouse gable

Not far from the mowing line of the cut, to the left and right, put boards under the polycarbonate with a height of at least 4 cm and a width of at least 10-15. Their ends should “look out” from under the sheet on both sides. The boards act as props to ensure that the tool does NOT cut directly into the backing material.

As with marking, when cutting polycarbonate, move not along the surface of the sheet, but along a wide board lying on it. Working as a kind of “ski”, it reduces the risk of damage and deformation of the material under the weight of the cutter.

An example of using a substrate from boards

Cutting polycarbonate with an electric jigsaw

The choice of an electric jigsaw as a tool for cutting polycarbonate sheets can be called a kind of compromise between the cutting speed of the “angle grinder” and the safety (as well as relative simplicity) of working with a construction knife. In addition, the jigsaw is great for sawing semicircular / round elements and complex parts.

Using an electric jigsaw to cut polycarbonate

The main thing is to choose the right pollen. First, notice the shape of the teeth. Straight or wavy prongs will give you an even and clean cut. just what you need. With adjustable teeth, the opposite is true. they are intended for working with wood, therefore an electric jigsaw with such a file will NOT cut, but the break is polycarbonate, leaving in it a lot of chipping, burrs and other defects.

Second, pay attention to the number and size of the prongs. They should be frequent and small. These properties are determined by the TPI parameter. the number of teeth per inch. In our case, give preference to files with TPI from 9 to 13 and more.

Thirdly, ask the seller what material the saw is designed for. You need the canvases that are designed to work with metal, plastic or plexiglass. Choose specialized saws whenever possible. they will give a clean cut with a minimum of defects.

Saw for working with acrylic glass, plastic and polycarbonate

Layout polycarbonate letter and prepare your workplace.

Install the pollen in an electric jigsaw. It is advisable to use a new and sharp blade. Fix it carefully and adjust. if not properly fixed, the saw will vibrate and leave defects on the polycarbonate.

Jigsaw connected to the mains Bring the cutting line to the end of the sheet along the cutting line. For greater convenience, make a notch in this place in advance with a sharp knife with a retractable blade. Do not remove the protective film from the sheet until the cutting process is complete.

Cut polycarbonate for 4 m greenhouse Kremlevskaya

Press the base plate of the jigsaw against the material. Make sure that the force applied to the tool is not excessively large, otherwise the polycarbonate will bend along the cut line. It is advisable that your assistants or clamps hold the letter, allowing it to move or vibrate.

Turn on the electric jigsaw and let the saw speed up. As soon as it does this, start cutting into the material along the cut mowing line, slowly and carefully move it forward, presses the base plate of the jigsaw against the polycarbonate plane. Take special care in curved sections. It is a good idea to pre-practice cutting rounded parts on polycarbonate cuts and waste. a good idea that will give you experience and simplify your business.

Start cutting a complex shape element with a jigsaw. Finish cutting polycarbonate with a jigsaw. If you do not want to stand on the material, even if there is a scaffold board, then first make a cut on one side, then on the opposite

After finishing work with the electric jigsaw, turn it off and disconnect the power. Clean the cells of the polycarbonate sheet from chips with a vacuum cleaner or a jet of compressed air. Cut off the excess with a knife and clean the edge of the sheet from defects. Glue it with construction tape to protect the cells from dirt and dust.

Laser

The most accurate, fast and high-quality tool for cutting polycarbonate sheets is an industrial laser. Using modern technologies and numerical control, it provides cutting accuracy up to 0.5 mm, high speed of work and, most importantly, perfectly smooth edges along the cut line.

Photo of polycarbonate laser cutting machine

However, equipment with such Outstanding characteristics and advantages is very expensive, therefore it is impractical to purchase it for one-time or rare use. Another thing is if you are going to open a workshop for the manufacture of greenhouses, roofs, canopies and fences made of polycarbonate. It should be understood that working with an industrial laser requires Appropriate skills, which are almost impossible to learn on your own.

Cut by weight and then fold sheets

Some advisors say / write in discussions on the forums that they did not cut the polymer canvases to the end (the tool was blunt or narrow), and then cut the excesses of the place. to achieve the final result. After reading or hearing this, you should do everything exactly the opposite. for this reason, polycarbonate will not say “thank you” and may respond with cracks, bending in unnecessary places, etc. P.

Cutting options

So, when the place of work is selected and prepared. dried from moisture, cleaned of debris, you should carefully lay the polycarbonate sheet and, focusing on correct and accurate measurements, draw. marking the place of the cuts with a black or other bright marker. over, if you only have a clerical knife or a hacksaw in your hands, then it is important to mark up on both sides of the canvas (it will be clear later why this is done).

Stationery knife or hacksaw

These devices are quite suitable for cutting thin (up to 6 mm) plastic sheets. But provided that they are very well sharpened (hacksaw) or completely new (clerical knife).

There are times when it is necessary to carry out work immediately. suitable weather, a rare day off, and the like, but there is a “more serious” tool at hand. Then the question is. how to cut cellular polycarbonate, and even a decent thickness does not arise, they work with what is at hand. But even in this case, you can “get out”. mark the polymer canvas on both sides as accurately as possible and cut along the honeycomb (air cell, not the partition), first from one side, and then from the other side. In this case, the plate should be turned over very carefully. in four hands, and during cutting itself. hold the polycarbonate in a fixed position.

Various saws

The fact that it is not recommended to use an ordinary saw for wood is written at the beginning of the article, but some types of such a tool can be used very well. For example, a metal saw with fine, frequent teeth will NOT make the owner-builder ask and find out how to cut monolithic polycarbonate, so as not to allow a single crack or hold. However, using a circular saw is also acceptable. But both in the first and in the second case, it is necessary to fix the polymer sheets in the most careful way.

Use special scissors for plastic

Yes, I must admit that there are special scissors (guillotines) for cutting plastic products. But they can be “taken into circulation” only for cutting a sufficiently thin and monolithic polymer, but cellular or thick cast polycarbonate should be dissected exclusively with single-acting devices. That is, choose tools that would NOT squeeze the plastic plate on both sides (knife, saw, etc.). Among other things, it is worth remembering about the price. not every simple summer resident will be able to afford such a purchase.

Laser

If the two tools described above can be attributed to household appliances, then this one rather belongs to specialized devices and is a priority exclusively for professionals who constantly work with polycarbonate. Plus to everything. this device is quite expensive and it is not worth purchasing it for a pair used in h.

But if it is possible to use a laser, then it should not be neglected, since the spray is very neat, even, accurate, without defects or damage, and even the polymer sheets will NOT “walk” and tremble with all the effects of the laser on it.

What not to do

Some summer residents who have experience working with polycarbonate think of themselves as “great specialists” and give advice that can simply deteriorate thermoplastic sheets. So listen to all the “parting words” not worth it, but before starting work with polymers it is better to “turn on the brains”.

How to cut polycarbonate at home. simple tips for beginners

Most people who want to build some kind of polycarbonate structure in their summer cottage or suburban area ask the same question. how to cut polycarbonate at home. After all, it is almost impossible to learn anything concrete from professionals, and this happens for two logical reasons. Firstly, some would-be builders do not want to admit that they cut polymer sheets with ordinary sharpened or standard office knives. And secondly. they simply do not want to reveal, so to speak, the “secret of the company”. so that more people turn to specialists for help, and do not do the work with their own hands.

In fact, everything is quite simple and there is no special method for cutting plastic canvases, but you should still beware of some tips. for the safety of your future polycarbonate structure.

Saw for fast cutting

Many consumers, wondering how to cut polycarbonate for greenhouses, do NOT choose the most suitable tools, because the prospect of a long and accurate cut can discourage anyone, even the most patient worker. And what are they doing? choose saws with sparse and high teeth.

It is highly discouraged to do this, because such rough and intended for wood tools can easily damage. tear the polymer sheets. In total. new costs for roofing material, plus. the purchase of Special cutting elements.

Before describing the correct work with polymer letters, it is important to note that all manipulations should be carried out on a dry, even, dense and clean floor, and not “undressing “polycarbonate, ie without removing the protective factory film, which is an additional barrier against damage and cracking.

Bonding sheets at home

In some cases, polycarbonate is glued, and the sheets need to be glued to each other. For this, a polyurethane-based glue is considered optimal. With its help, a reliable coupling of polycarbonate with a similar letter, with glass or metal is provided. This achieves a high mechanical and chemical resistance of the compound.

Tips for Fixing Polycarbonate

Fixation of polycarbonate sheets should be done with self-tapping screws with sealing washers. It is noteworthy that the diameter of the self-tapping screws should exceed the cross-section of the hole in the polycarbonate by 1-2 mm. This allows you to compensate for the expansion of the material when heated.

In addition, it is very important that the self-tapping screw into the polycarbonate sheet is free. Otherwise, a hole that is not drilled properly may result in deformation of the material.

Laying polycarbonate should be done end-to-end, but gaps should be left for thermal expansion of the material. This approach will allow you to avoid mistakes in the installation of polycarbonate.

Use neoprene or silicone tapes to seal material joints. DO NOT use soft PVC sealing materials, since as polycarbonate is used, they release substances that gradually destroy the material.

Sealing compounds for insulating polycarbonate joints can only be silicone and no other.

How to cut polycarbonate. safe cutting methods, suitable tools for the home

Such a modern material as polycarbonate is actively used in construction, as well as decorating buildings and various structures. In this article, we will talk about how to cut polycarbonate at home in order to get pieces of material of the right size. We will describe several types of tools, as well as give some tips for installing polycarbonate.

Saw or hacksaw

Among the tools than cutting solid polycarbonate, saws and hacksaws are considered the least suitable, so they are used only as a last resort. Power tools such as a low speed circular saw would be more acceptable.

A saw or hacksaw is not very suitable for cutting polycarbonate, as the material can crack and crumble at the cut.

The need for proper cutting of polycarbonate

In the process of any work, it is almost always necessary to cut polycarbonate in order to fit it to the size of the structure. It is advisable to perform this procedure correctly the first time. this will save you time and effort in the first place.

In case of improper cutting, the material may be damaged, deformed, which will make it impossible for its further use. And since polycarbonate cannot be called cheap, the costs are quite tangible.

Laser cutting

The newest way to cut polycarbonate is laser cutting. This requires special equipment that generates a laser beam, and cuts the polycarbonate sheet.

Among the advantages of this method are:

- Perfectly smooth edge;

- The ability to cut material of various thicknesses;

- High manipulation speed.

However, there are some disadvantages to laser cutting:

- Special expensive equipment is required to carry out the work. It is advisable to purchase it only if it is planned to use it professionally in the future.

- Before starting cutting, it is necessary to correctly configure the equipment. this requires certain skills.

Thus, laser cutting is acceptable for only a small number of users. Of all the options for cutting cellular polycarbonate, you should still choose an angle grinder or an electric jigsaw. After some training with such tools, you can make a beautiful, high-quality cut.

Having dealt with the basic tools, we will tell you how to cut polycarbonate with one of them.

What and how best to cut. Key recommendations

When cutting polycarbonate, you should follow these steps:

- The work area must be clean and NOT contain any debris. This will avoid cracks, dents and deformation. For convenience, you can put drywall, chipboard or fiberboard under the polycarbonate letter.

- Before starting cutting on polycarbonate, mark it with a marker, which will be clearly visible.

- In those cases when in the future it will be necessary to move along the polycarbonate sheet, the floor of it needs to be covered with a boardwalk, which will allow you to distribute the load. Then no dents or cracks in the material will appear.

- Cutting must be done from the side of the laminate or mirror finish. By the end of the work Also, do not remove the protective film.

- After the cutting of the material is completed, it is necessary to remove waste and dust from the surface of the sheet, as well as shake out the debris from the cells.

If you need to drill polycarbonate, you will need standard metal drills. Even a beginner can do this process.

Pay attention to just a few nuances:

- You need to make holes in the intervals between the stiffeners;

- From the edge of the sheet, you need to retreat at least 4 cm so that the piece of the plate does NOT break.

Slicing with an angle grinder

Cutting polycarbonate at home with an angle grinder is a fairly common way of working. To do this, use a circle 25 for metal.

It is difficult to overestimate the value of this tool. in the right hands, it can be used in a variety of construction processes.

Using an angle grinder can cut polycarbonate very quickly. The main thing is not to put pressure on the material so that it does not burst, especially if your tool is operating at high speeds.

It is recommended that you practice cutting into small pieces to determine the pressure. In any case, do not press hard, making the cut as carefully as possible.

Jigsaw

Sometimes the only acceptable option for polycarbonate dusting is an electric jigsaw. With this tool, you can cut material of any type and thickness. over, the jigsaw allows you to perform figured cutting of monolithic polycarbonate of any complexity in the shortest possible time. However, in the process of work, you need to use the smallest nail file so that the material is NOT damaged.

As is the case with the angle grinder, it is better to stuff your hand into the polycarbonate cutting on small pieces of material. Having acquired the necessary skill, it will be possible to proceed to making cutouts of a complex configuration.

Experienced builders cut thin sheets of polycarbonate 4 mm thick, folding them in several layers and cutting everything together. This makes work easier and faster as thin sheets DO NOT break or deteriorate.