What disk cut a steel pipe. Cutting pipes at different angles

Metal cutting technology corner grind

Corner grinding machine (angular grinder), or angular grinding grinder, as it is commonly called, an indispensable and universal tool in construction, is designed for cutting and processing solid materials. But this is one of the most dangerous types of equipment, therefore, cutting metal with corner grinding and other types of material requires all safety rules.

For proper and clear work, it is necessary to purchase a tool suitable for power and diameter of the cutting abrasive circle and functionality. You need to decide for which work the tool is needed.

For home repairs, the masters can do with a low.power corner grinder, and for professional construction you will need serious multifunctional equipment.

Low.power units are connected to a 220 V household outlet, powerful ones are connected to an industrial three.phase network, with a capacity of 380 V. In low.power Bulgarians, the disk often jams, when cutting thick metals, this is dangerous because the device can break out of the hands, injure, or break the disk.

Advice to beginners to buy a corner grinder for a 125 mm disk with a capacity of 0.8–1 thousand. W and the number of spindle revolutions 10 thousand. about./min. This power is enough to cut iron.

Used for cutting metal, stone, glass, as well as with this apparatus, they make a peel, grinding and cleaning. Having fixed it stationary, it is easy to drag incisors, jail knives, etc. D.

When choosing a corner grinder, it is necessary to pay attention to that it lay comfortably in the hand. The quality and safety of work also depends on this. If possible, you should choose a model with rubber handles.

Choice of a disk

For each type of robot, a certain disk is assumed, with the desired diameter and thickness. Small diameter. 125 mm, and large or often used. 250 mm. The thickness of the cut and its depth depends on the diameter of the disk.

For cutting metal, it is necessary to purchase a cutting disk with a thickness of 1 to 1.2 mm, for professional up to 2.5 mm. If it is supposed to make a figured thread on thin metal, then you will need a disk with a small diameter or worked out.

Regardless of the size of the disk, a protective coating is placed. a casing, it is used in metal cutting. During the cutting of the metal, the scattering of small particles is involved in order to avoid damage by small metal scraps, a shield is installed.

General recommendations of specialists

Corner grinder

The use of corner grinder is a very popular mechanical method, which is used both at home and in production. Cutting corner grinding requires maximum caution from the master. You should carefully approach the issue of protecting the hands and eyes with gloves and glasses.

It is also important to adhere to the following rules:

- Work with corner grinder is obliged to carry out a master who has experience with this tool;

- it is important to fix the equipment tightly;

- You can not process concrete or stone with a disk, which is originally designed to cut metal;

- In order to avoid “jumping out” of the disk, it is necessary to control the direction of movement of the corner grinder, it must coincide with the direction of rotation of the disk;

- The tool must be closed with a protective casing, otherwise it is impossible to conduct work.

Roller pipeline

In this tool, the current components are videos. They cut off, moving in a clip installed in the place of the future section. The pressure with which the rollers will be pressed against the material is controlled using screws. For this, swinging movements are made up and down, at the same time, the videos are pressed to the material.

Cutting high temperature

This method of cutting is highly performance and low energy consumption.

Cutting gas

This method is best suited for cutting large pipes. Burning, fuel melts metal and with a stream of gas removes it, blowing off the cut. When laying highways from pipes of very large diameter, the use of manual equipment is absolutely ineffective and costly. In such cases, large machines are used.

This solution allows you to make a cut of high accuracy, while increasing the speed of cutting the pipe.

Cutting the material with plasma

The temperature that can be melted of metals is created by a stream of substance, brought to a plasma state. Air is used to form plasma. Information by ions is carried out by the exposure to electric discharge. As a result, this process forms a high temperature. Plasma cutting of pipes is considered one of the best.

A metal pipe in this way is processed with 100 percent quality.

User use

Laser machine. fully automatic system. Using such a device, you can cut, milling, drill, process edges.

This tool can be processed by pipes of the following parameters:

In this way, stainless pipes are best processed.

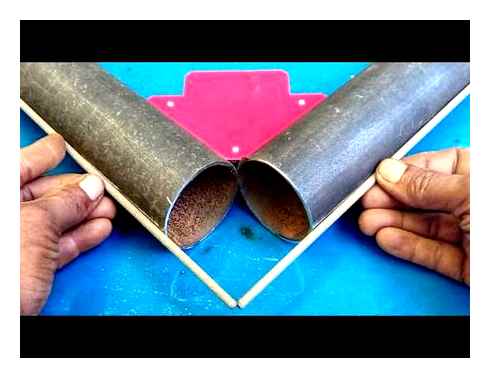

Profile pipe: how to do it exactly?

All the above.above cutting options are suitable for cutting profile pipes. It is especially difficult to cut not round, but square profile pipes. The accuracy of marking is extremely important here. By doing it manually, you can make mistakes and cut off incorrectly. In this case, the elements of the future pipeline during assembly do not work.

To exclude possible errors in the work, the master recommends creating a template from a piece of the same type of profile with a large section.

Manufacturing such a template is a simple process.

- Gorlomer on the trim of the pipe measure the angle of forty.five degrees.

- Make an incision of a corner grinding, then polish the edges of the pruning.

- At the end of the grinding, insert a pipe from the profile with a smaller diameter into the prepared template.

- According to the created gorlomer with a devil, create a full marking.

- By this workpiece, cut the pipe with a corner grinder.

- At the end of the work, carefully grind the edges so as not to get hurt about the burrs.

How to cut a corner grinder?

Transportation of disks; 2. External disca of the disk; 3. The diameter of the circle must correspond to the permissible corner grinder; four. Compliance with the maximum permissible revolutions; 5. Use of the disk for its intended purpose; 6. The use of a “non.fresh” disk is not acceptable; 7. Inspection of the workplace; eight. Hanging parts of workwear; 9. Position with a cut; ten. Provide for the rebound of the tool; eleven. Direction of rotation of the disk; 12. Try not to deepen the edge into the depths of the cut; 13. Adhere to a given trajectory of disk rotation; fourteen. Turn off the corner grinder when changing the position; fifteen. When changing the disk, de.energize the corner grinder; 16. Grind only the disk provided for this; 17. Use a protective casing when working; eighteen. When working with a corner grinder, always be with glasses.

Consider each of the listed points, and remember that each of them is important at least the other.

Transportation of disks.

Typically, the entire tool is in one box, without fail, take a separate compartment for disks that does not allow strikes on them. Which can lead to damage not noticeable by eye.

External disk examination.

Before installing, make an attentive visual examination of the disk for the presence of a broken, you can slightly beg, and if it is broken, it will immediately be revealed, of course, such a disk is not allowed to use. If there are potholes on the cutting edge, it is better to reject, the cost of the disk is penny, and the consequences can be the most deplorable.

The diameter of the circle must match the permissible corner grinder.

The corner grinder indicates the maximum allowable diameter of the circle used. Never set a circle more than indicated in this meaning.

Compliance with the maximum permissible revolutions.

Both on the corner grinder, and on the very cut.out circle, there is a marking pointing to the maximum permissible turnover per minute. On a corner grinder, this is the value of the spindle rotation, on a circle. at what maximum speed it can rotate. In the first picture, the result of non.compliance with this rule. That is, if the forty rotation of the spindle is 10,000 rpm, then the circle should be equal or large, but in no case no less.

Using the disk as intended.

What is meant here? The fact that the disk intended for cutting metal is not permissible for cutting stone, glass, marble, tiles, porcelain tiles, for this there are special discs with diamond tips on the teeth. And vice versa, a diamond disk is not permissible to cut a metal pipe. It is also not permissible to install various mills on the corner grinder, saws. a visual consequence in this picture: and in a conditionally named second picture, the man sawed the tiles with a cutting disk for metal, in addition, without a casing. I don’t do tile work, so I don’t know what speed of rotation of the cutting disk should be when cutting the tile, on the forum one of the specialists indicated that no more than 3000 rpm, and by itself a special disk for this. What led to an unfortunate man who was neglected by this rule themselves.

It is not acceptable to use the “non.fresh” disk.

What does that mean? I found, for example, a disk in a garage or under the bathroom, or where. break it and throw it out, that’s the whole fairytale, not to jerk fate for anything!

Inspection of the workplace.

Also not unimportant nuance, cutting out pipes in the apartment of workplaces, in the toilet, in the bathroom, in the kitchen. Inspect the first. PARTOVO for the absence of hanging wires, ropes. It is no secret that people like to be tied to pipes, so you need to remove it away from sin, you will be intact. Some kind of crap for a rotating element of a corner grinder, it will fly out of her hands and you won’t have time to blink.

Hanging parts of workwear.

I think it’s not worth it to explain what can be fraught with. The buttons are fastened, the holes are sewn up, the fringe on the legs, no sleeves.

Position with a cut.

Clear stump, when dismantling, you try to get by the least amount of cuts, but never, you hear never being on the trajectory of the disk, no matter what you are, you will not provide for everything, there are all sorts of cases. The next point to the place.

Provide the rebound of the tool.

Just in case, provide where the tool can fly off if it “bites” the disk. And if you are not sure, do not do the cut to the end (the pipes are often in suspense), leave a small jumper, you can always break the gas key with the help of a gas key. Do not relax, at the end of the cut, hold the corner grinder tight.

Direction of the disk.

Who cuts like, a matter of habit, and sometimes otherwise there is no way. The video clearly shows that I cut. sparks on myself. This is not very convenient, but there is much less likely that the disk will “bite”, and if it “bites”, then the corner grinder will fly from the cutter, and not on it. So think about the amenities in this case.

Try not to deepen the edge into the depths of the cut.

Well, here regarding the pipes of large diameter, do not deepen the cutting edge more than necessary, less likely that the disk will break.

Hold the specified drive trajectory of disk.

This condition is unequivocal to execution, no changes in the trajectory of rotation, that is, how to cut, in the same position it is necessary to finish the cut. And one more point, if there is no professional skill, you should not try to get into an unfinished car for a second time, and in no case do not insert a disk and then turn on the “start”, don’t go straight to the grandmother. the saddle is waiting.

Disconnect the corner grinder when changing the position.

I made a cut, you need to change your position, turn off the corner grinder, wait for the stopping of the disk rotation, only then move. Took a different position, made, turn on the angular grinder. This is the only way, not otherwise. If health is expensive, otherwise you can stumble.

When changing the disk, de.energize the corner grinder.

Be sure to remove the fork from the outlet, install another disk. It is not appropriate to be lazy here.

Grind only the disk provided for this.

To cut the threads, it is necessary to remove the chamfer along the edge of the pipe, often “slop” to install the grinding circle provided for this, and in vain, pulling it with a cut.out circle, you will become thinner, which is not good, fraught with the same “vulgarity” for pieces.

What are the cutting disks for corner grinders

The main tool for corner grinders are cutting circles. It is no secret that the quality and speed of the work performed directly depends on the correctness of the selection of consumables. Therefore, before going to buy a disk for a corner grinder, it is recommended to get acquainted with the main types and characteristics of consumables.

In order for the owners of the Bulgarians to be able to correctly choose consumables in accordance with the upcoming work of this tool, manufacturers of cutting discs apply a special marking on them.

Abrasive discs

From the marking, you can draw the following information.

- The material from which the nozzle is made is indicated by the first letter: a. corundure, used for metal cutting; AS. electrocorundum (white), cuts stainless steel; C. silicon carbide, cuts stone and concrete well. Metal using this abrasive nozzle cannot be cut.

- Further, after the letter denoting the material, the figure is going on. It means how many abrasive grains are in a unit area. Respectively, the smaller the grain, the greater the figure. If you need to cut steel, then choose a disk with smaller grain. 40 or 60. Coarse.grained discs are used mainly for cutting non.ferrous metals.

- The next parameter is the hardness of the ligament. Denoted by the letters of the Latin alphabet (H, I, J, K, L, M, N, O, P, Q, R, S, T). The closer the letter is to the beginning of the alphabet, the softer the ligament, and vice versa. To process soft materials, the ligament should be solid, and for strong and solid materials. soft.

- The latest letters mean the type of ligament. Ceramic is marked by the letter V. Such discs are distinguished by good water resistance, refractory and resistance before chemicals. Bakelite ligament is designated by letter b. Such circles have good strength for bending and compressing, but are destroyed when using a coolant with an alkaline environment. Also, bakelite.based ligaments have low heat resistance. At a temperature of 200 degrees, it becomes fragile, and at high temperatures. begins to burn out. The third type of ligament. bakelite with increased strength. is marked as BF or BU.

- The maximum speed that cannot be exceeded for this consumable. The linear velocity of the edge in m/s or in the number of revolutions per minute may be indicated.

- Circle dimensions in mm: external diameter, thickness and diameter of the seat.

- The date of manufacture. It is usually indicated on a metal insert located around the landing hole. It is not allowed to install an expired circle on a corner grinder, since it may lose strength over time and fly apart during operation.

- The purpose of the nozzle. It is indicated for cutting what materials is the tool intended.

- Color labeling: Blue color is used for cutting steel, for stone cutting. green.

Color marking of diamond discs

Diamond circles are marked with the following colors:

- orange. for cutting bricks;

- blue cuts concrete and marble well;

- Green is used to cut granite;

- Gray cuts tiles, granite and ceramics;

- yellow. alabaster and tile.

Varieties of cutting disks

Cutting circles for an angle grinding machine can be both from abrasive material and all.metal. Depending on the type of processed material, the type of cutting disk is also selected.

For metal

If you need to cut the metal, then always use consumables on bakelite bunch with the presence of strengthening elements. In this case, there should be at least 2 reinforcing nets.

For ferrous metals, ordinary corundum is used, which, in addition to aluminum oxide, impurities of chlorine, iron and sulfur.

For cutting stainless steel, the presence of the above impurities in the cutting circle is unacceptable, since they cause burned steel (overheating). As a result, stainless steel can fade from stainless steel, and it turns into ordinary steel, as a result of which the cut place begins to be covered with rust. Therefore, it is important before buying a disk to carefully familiarize yourself with the information applied to it. The cut.out disc for stainless steel is always marked with the letters “as” and the word “inox”.

For cutting non.ferrous metals, discs with large particles of abrasive are used. For example, a cut.out circle of aluminum, in addition to a large abrasive, has special fillers that prevent the cutting edge.

Often users of corner grinding machines are wondering: which cutting disks for metal are best used? An ideal disk for corner grinder should have:

- Bakelite reinforced bunch (BU);

- Correctly selected type of abrasive: for stainless steel, white electrocorundum (AS), for ferrous metal. ordinary corundum;

- disc thick from 1.6 to 2 mm;

- external diameter 125 mm;

- Small.fractional abrasive particles if cutting steel structures is required.

It is not recommended to use corrugated circles for cutting corrugated circles for cutting corrosive circles, since the cut place is overheating, and zinc is burning out of it. the main element that prevents corrosion. To reduce the overheating of the material, some craftsmen use a circular metal disk for angular grinders with small teeth. But in both cases, the cut place should be treated with a special anti.corrosion composition, which can be purchased in a store where profiled metal sheets are sold.

For cutting stone

For cutting stone in domestic conditions, an abrasive disk made of silicon carbide is suitable (marked with the letter C).

This cutting disk is used for small stone work, since it quickly wears out. But, thanks to a low cost, this consumable is quite popular among Bulgarian owners.

For professional operation, the abrasive disk is not suitable for stone. For these purposes, it is recommended to choose an all.metal detachment circle with diamond spraying.

By concrete

Classes for cutting concrete and reinforced concrete are made of high.strength hardened steel, with application to the cutting part of diamond crumbs. Also, these cut.off circles can be segmented and solid.

Before cutting concrete, it is necessary to determine its type. It can be ordinary or reinforced (containing a metal mesh). It is also worth considering the age of concrete.

- Young concrete has abrasive properties, so quickly wears out the tool. To cut it, it is necessary to use diamond segmented discs by concrete of increased thickness.

- Old concrete is very solid material. For processing it, it is better to use a circle to an angular grinder of moderate thickness.

A universal diamond circle is installed for cutting reinforced concrete.

For cutting tiles and porcelain tiles

It is best to use solid cut circles with diamond spraying for cutting ceramic tiles. On such disks, “wet cut” is usually written. As practice shows, this tool makes remarkably even, with a minimum of chips, cutting in tiles even without the use of water, although at the same time a lot of fine dust forms.

A continuous diamond disk can also be used according to porcelain tiles.

By the way, this circle can be used not only by ceramics, but also for cutting thick glass.

According to the tile, of course, you can use segmented (dry) and turbo disks, but the cut quality will be very low, since chips will inevitably form along its edges.

For cutting plastic

Plastic is well cut by the usual abrasive metal tool. But there is a special saw circle (three.tooth), designed for cutting wood, plywood and plastic. It can be used not only for cutting, but also for longitudinal drinking material, especially fat.

When installing this tool, it is important to correctly determine the direction of rotation of the spindle of the corner grinder.

Use of circular saws with many teeth on plastic and wood is not recommended, due to the high probability of the back of the tool, which can lead to injury.

How to use?

Initial preparation

The operation of the cutting circle of the “corner grinder” begins in compliance with the rules of installation and removal.

Installation

Check the position of the lower counter.player on which the disk falls. Her Slitz should coincide with the helmet of the shaft of the corner grinder. Put a circle on the shaft. The side of the marking data should be visible.

Win the upper counter.gamous. Holding her with a hand, try to crank the disk in the direction of his movement. In the process of cutting the metal, the difference in the direction of rotation of the disk and nuts creates the effect of self.tightening. When installing, pulling the upper nut is not worth the key.

Wait for a complete stop of rotation. Disconnect the corner grinder from the mains. Insert the “horns” of a special key into the holes of the upper counter.hack and squeeze the lock button.

Turn the key to the clock. Когда гайка срывается с места (под воздействием первичного усилия), ее можно отвинтить вручную. Any angle grinding machine is equipped with a connector for the handle. Working with the handle removed is prohibited.

Security measures

Before starting work, you need to think about how cutting will be carried out (the position of the “corner grinding” in the space in relation to the site of the saw), determine the vector of the direction of the sparks, which will be accompanied by the immersion of the disk into the metal. Remove all flammable objects and substances from the spark flow line. If necessary, cover the finishing surfaces on which sparks will fall, with protective means.

Inspect the power tool itself for water, dirt, sand, as well as check the integrity of the power cord of power. Carry out a trial launch to check the uninterrupted operation of the unit and unhindered rotation of the cutting disk. Evaluate the object of the saw: it must be firmly fixed, not have a deforming voltage, to be far from electric wires.

It is strictly forbidden to start working with an angular grinder without observing safety measures and individual protection.

The eyes should be protected by special glasses that give a wide and clear review. It is not recommended to use glasses with darkened lenses. The safest face protection is a shield mask from a transparent plexiglass. In the case of the destruction of the disk during cutting, its fragments are scattered in the direction of the initial centrifugal force with high speed. This mask will protect the front part of the head from their hit. Hearing organs also need protection. For this, construction headphones or silicone bers are used.

The equipment of the operator is a corner grinder must meet the following safety measures:

- Rob from durable and natural material;

- Moderately free, but excessively long sleeves are unacceptable;

- gloves, tightly sitting on their hands, from strong material, capable of restraining primary tied;

- Closed shoes with composite inserts on socks.

Exploitation

Working with abrasive and exposure equipment is associated with a high speed of rotation and requires compliance with safety measures. Before starting work, get acquainted with the precautions indicated by the manufacturer.

- Minors are not allowed to work with cutting devices, people are while intoxicated. Near the place of work, the presence of children, animals is not allowed.

- Perform cutting work away from combustible materials.

- Use cuts exclusively for the purpose.

- Before the start of the operation, inspect the disk, do not use consumables with traces of damage (presence of chips, cracks).

- Do not use circles with expired shelf life.

- Follow the rules for storing consumables.

- When working with a power tool, use personal protective equipment.

Operation Rules:

- Before starting cutting work, securely fix the circle in the power tool.

- Use a tool, the protective casing of which is able to withstand the blow in the event of a circle break and catch the fragments.

- When cutting the metal, fix the metal structure on only one side, this will help exclude excess heating and deformation of the material, and, as a result, jamming of the abrasive disk.

- When performing cutting work, keep the circle directly, using only radial pressure.

- In case of intensive sparking, cutting work should be stopped for 10-15 seconds, after the expiration of the specified time, continue to work with a lower cut rate.

Installation of a cutting circle in an angle grinding machine:

- Disconnect the power tool from the mains.

- By a special button, fix the rotation shaft.

- Install the disk on the seat.

- Twist the locking nut, fix the key.

- Prior to the start of cutting work, check the operability of the disk for 1 minute.

Manufacturers of cutting circles

Bosch

The company occupies a leading position in the market of power tools and related products. The assortment includes abrasive cutting discs for wood, metal and stone, diamond circles and universal models.

The quality of the company’s products complies with international quality standards.

Dremel

American brand products are sold in more than 60 countries. The assortment of the company includes not only high.quality power tools, but also a wide selection of nozzles.

Dremel produces cutting circles for cutting wood, plastic, metal. Diamonds with diamond coating will cope with concrete, ceramics, marble, faor.

The Canadian company specializes in the production of tools for household and professional purposes. The range of products includes a wide selection of cutting disks for metal and stone for household electrical tools.

Fubag

The main direction of the German company is the production of high.quality professional equipment for repair and construction work.

Brand production base are located in Germany and Switzerland, the company’s experience is more than 40 years. The catalog offers the consumer high.quality diamond discs for humid and dry cutting.

Husqvarna

The consumable tool from the Swiss manufacturer is characterized by high performance and strength. In the assortment of the company. a large selection of cutting diamond discs, as well as abrasive products for cutting metal.

The disadvantage of the Husqvarna brand is a fairly high cost.

Makita

The company offers a large assortment of high.quality abrasive discs and segmented circles with diamond coating. In the catalog you can find both budget models and products related to the middle and high price category.

Master

The company has been delivering construction equipment for 15 years. Product catalog includes consumables for cutting metal, wood.

Messer

The company’s catalog includes many models of a wide spectra use of a wide application:

- segmented diamond discs for cutting concrete and asphalt;

- circles with a continuous edge for cutting ceramic products, marble, porcelain tile;

- carbide disks for cutting high.carbon steel;

- turbo diskeinations.

Metabo

The German brand specializes in the production of professional power tools and cutting equipment.

The lineup of consumables provides for a wide variety of abrasive and diamond discs for angular grinding machines, as well as saw wood circles.

The company is the manufacturer and supplier of the power tool and cutting equipment.

The catalog of consumables of the brand offers a diverse selection of universal cutting circles for angle grinding machines, gas tapes and tiles.

Cutting a profiled sheet and metal tiles

Quite often, in practice, one has to face the need to cut a profile sheet or metal tile. These materials are made of steel, which is covered with zinc and polymer protective layers, stained.

Regarding the possibility of using a corner grinder, different opinions are expressed for their cutting. The installation instructions say that the profile cannot be sawn with the help of an angle grinding machine. To do this, use other tools. But they need to be acquired, which is not always justified by the volume of upcoming work, and also requires additional financial investments. Когда никакого инструмента, кроме угловая шлифмашина, нет, прежде чем пилить угловой шлифмашинкой, следует знать возможные негативные последствия.

- If you cut a metal tile or corporate grinding machine, then the protective coating in the sawing area and a little near it will be destroyed, and the cut edge will begin to rust.

- The material is removed from the warranty.

- Spreading sparks can ruin not only the appearance of the rest of the sheet (spread the paint), but also damage the polymer coating.

- The edge of the cut can turn out to be torn.

All considered negative consequences can be minimized if you cut the corrugated board or metal tank with a corner grinder, observing the following recommendations:

- do all the work immediately before installation;

- treat sections with anti.corrosion compounds;

- cover the cut edges with a primer and stain;

- use the disks for the metal of the minimum thickness (up to 1 mm);

- In order for the edges to remain neat, you need to cut quite quickly;

- gently polish the torn edges.

Before sawing, as usual, the sheets are marking.

If you need to cut a square, then do this:

- draw it on the surface of the sheet;

- cut the material along the marked contour of the corner grinder;

- At the end, every corner is carefully cut out.

Circles or other figures cut out, working in the same scheme.

The use of corner grinder for cutting metallic tiles and profiled sheet facilitates the work. It becomes more convenient to perform it, because you can adjust the sheets in size directly on the roof.

In order for metal maker or a professionalist to be warranty, you should measure the object and order factory cutting of sheets. You can also try to choose the material with such dimensions so that cutting is not required.

Cutting metal grinder is a cheap, almost affordable and quite effective way to saw it. In this case, the corresponding discs without defects should be used for each material. Not only the quality of the result obtained will depend on this, but also its own health. Be sure, cutting the metal, it is required to comply with the safety rules and use personal protective equipment. It should be constantly remembered that when working with an angular grinding machine, any shortcomings and inattention can turn into an injury. Therefore, you need to work with concentration and carefully.

Advantages of different types of disks

Positive moments of abrasive discs:

- affordable cost;

- a wide range of;

- do not dull during operation;

- spontaneous cooling due to the presence of a porous structure;

- The aluminum disk consists of special fillers (not polluted, wear resistance and cut quality increases).

Positive moments of carbide disks for metal:

- high speed of work;

- The metal does not heat up;

- cut accuracy;

- a solid disk resource (about 5000 cuts);

- There are no harmful emissions.

Popular manufacturers and high cost of disks

The for consumables for corner grinders vary from the lowest. about 20 r., and up to several thousand. The high cost directly depends on the manufacturer and what material will be in work. The current market is rich in the choice of manufacturers of both domestic and foreign.

Bosch

German company, leader in the production of power tools and related materials. A wide variety of nozzles for Bulgarians: diamond and abrasive cutting circles on stone, metal and wood. The company’s products are answered by ISO.

Canadian manufacturer of a professional and domestic tool. The range is presented by a wide selection of cutting disks for metal and stone.

Dremel

American company. Produces high.quality power tools. The assortment also has a wide selection of nozzles for the Bulgarians:

Husqvarna

Swiss company, known for its high performance and level of strength of products. The assortment has a wide selection of detachment diamond and abrasive discs. A negative point is a high price.

Messer

Korean manufacturer. A rich assortment of nozzles for Bulgarians:

- carbide circles along high.carbon steel;

- segmented diamond in concrete and asphalt;

- Disks for cutting ceramic products, porcelain tiles and marble.

company. Produces power tools and cutting equipment. A wide selection of universal nozzles for corner grinder.

Hitachi Power Tools, Luga Abrasiv Extra

Manufacturer of Luzhsky Abrasive Plant JSC. Great price ratio. quality. In the assortment you can find budget options, which does not affect the quality of products.