What disk to cut the slate flat. Knife -haired

Than to saw the slate of the wave. features of cutting, the choice of disk, how to cut with a power tool, mechanical methods

The slate roof still does not lose relevance. both on utility structures and on the house itself. However, sooner or later, almost any owner faces the tasks of repairing the roof or its new installation, in the solution of which such roofing material cannot be done without proper cutting. We will analyze how to cut the slate of the wave and its flat modification, in what cases it is cut and what are the features of the organization of work, how to choose the right disk for corner grinding, which power tools and mechanical methods can also be used, which safety recommendations must be followed.

The task of cutting the slate sheet arises in the following cases:

- Installation of a new roof-it is rarely possible to lay a multiple number of sheets on the rafter system. In addition, they often have to be cut along or from the corners.

- When repairing a long.operated roof, it is often necessary to lay a whole sheet, but a fragment with a certain notch.

- The construction of a roof of a complex architectural form. Sheets need to be cut at all possible angles.

- Creation of roofing elements for pipes, chimneys, ventilation aerators, etc. P.

- Cutting from old sheets of elements of decorative design and protection of beds, flower beds, greenhouses and other garden structures.

Features of the organization of work

The slate roof is certainly durable, durable, frost.resistant, characterized by good fire resistance and sound insulation indicators. In many ways, the set of such characteristics is due to the asbestos.cement basis. However, he owes her to her increased fragility. the main drawback of the material that complicates its transportation and processing. Therefore, with almost any mechanical effect, it begins to crumble.

If the process is cyclic, then a very light finely dispersed crumb is formed, rapidly picked up by the slightest drafts and for a long time weighed in the air. In addition to the fact that such dust settles on a nearby objects and pollutes the environment, inhaling it with the air deadly for all living things. Asbestos pollen can provoke the development of lung cancer.

It is this main specific aspect that determines the following requirements for the organization of work on how, what, and under what circumstances to saw the slate:

- Master who performs cutting must be in personal protective equipment. This is primarily a respirator, glasses or a mask, gloves and overalls made of dense fabric.

- To reduce the intensity of dust formation, as well as the chipping edges of the cut edging place of the contact of the material with a sawing tool should be periodically or continuously moistened with water.

- The dust should be captured by the hood when working in the room or carried away by the wind into the opposite of the worker. when working on the street.

- When working in the room, all doors and windows leading to neighboring rooms should be tightly locked. In this case, only specialists in special protection should be inside.

The need to cut the roofing slate

The dimensions of roofing slopes are different, so when installing piece elements of the roof, they must be cut into the desired size. You can cut the slate with different methods, the choice of tools depends on the physical properties of a certain model of sheets.

- Asbestos or mineral fibers in the composition are easily cut even with a knife, they are supple;

- frozen binding cement gives strength to the material comparable to the indicators of dense oak wood, tick.

Slate slabs cut along the fibers if they do not fit along the width of the cornice overhang. On the longitudinal lines, you can also cut the slate if the distance from the skate to the overhang is not multiple of the sheet size in length.

Basic cutting rules and method of work without dust

Regardless of the choice of the method of cutting panels, you need to follow the recommendations for the use of tools. This is especially true for electrical species, t. to. In this case, a lot of dust is distinguished. Slate based on asbestos fibers is harmful to health, t. to. The smallest particles do not act well on the condition of the respiratory system.

In most cases, such fibers are fastened with cement grains that reliably hold the threads and do not allow harmful emissions to spread. There is little harmful effect from the roof coating, t. to. The material is in a constrained state of rest. To enhance harmlessness, the slate profile is recommended to paint. But in case of violation of the integrity of the canvas (cutting), the particles of the fibers are released into the air and have a harmful effect on health when inhaled.

The conditions that need to be created to cut off the slate:

- work is performed outdoors, t. to. dust in a closed hangar, the shed is not permissible;

- It is advisable to place the workplace so that the wind takes the dust flow away from the master and nearby rooms;

- Wet material distinguishes much less dust, so the cutting place is necessarily moistened with water, using rags, brushes, waterings for this.

A raw profile is less dust when processing, cut the slate moistened with water, much easier. Wet sheets get additional elasticity, soften.

The panels are located so that the two parts that turn out after cutting have a reliable support. Otherwise, when separating, one half with a sharp edge can injure the operator.

How to cut a wave slate, and how to saw straight sheets

The cut of slate sheets of different configurations has some differences. Since you can’t glue it in an unnecessary place in an unnecessary place, you need to act very carefully and skillfully. Therefore, masters often advise beginners first to practice in the cut (“fill your hand”), trying their strength and skills on the old sheet that is not needed. If it turns out well, get to work.

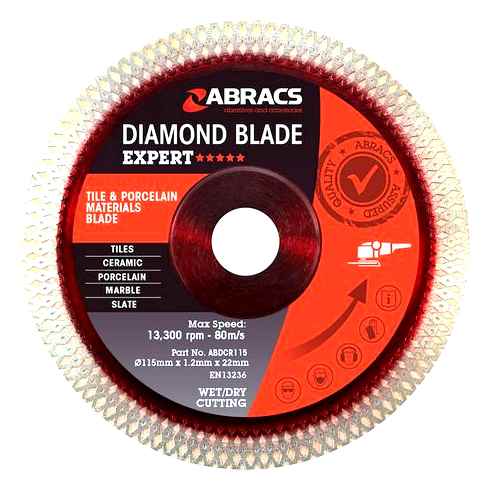

Specialist BASIC Metal Cutting Disc

Step.by.step instructions when cutting the slate during roofing work looks like this:

- We advise you to wet the slate material before sawing in water. It will become elastic and more suppressed to cut. And there will be less dust.

- Then you need to apply a fishing line for a cutter to a cutter sheet. coal or chalk, on the front side.

- Before cutting a flat slate, lay a sheet with markings evenly, stable so that it does not stagger. Saw on the front side. If we cut it near the edge, then you need to put a wooden board under the fishing line for the trimmer cut so that the edge does not accidentally break off.

- We behave the tool, pressing slightly. As soon as we start cutting flat slate, reduce speed. We do the same and at the end of the cut. Reduced turns on the launch and the end of the cut line are needed in order to avoid chips, because the edge of the slate sheet. The most fragile.

- Drink flat slate. easier, but cutting wavy slate. more difficult. Depending on the tasks, it can be cut along the crests or across them. If you need to cut along the wave, then this is the same process as sawing a flat slate.

- Transverse cut through slate crests. A little more complicated. It needs to be performed with a corner grinder with a diamond disk. This is more convenient and safer. First we make cuts on convex waves from the front side along the intended line. Then we turn the sheet with the wrong side, draw a fishing line for a cutting trimmer. And again, cut the bulge along the intended line. Bulge from the inside. These are the hollows of the crests from the front side. Thus, we get a full incision of all bulges and depressions. The slate sheet itself should decompose into two parts.

- The edge of the cut sheet must be sanded. Grinding the edges is performed by a diamond disk.

- Disks after work wet, hot and with a raid of asbestos dust. Be sure to wipe them with a dry rag. Otherwise, the plaque will quickly petrify, and you will no longer be able to use this circle to work again.

How to cut slate with manual mechanical tools

A hand tool is used for small volumes of the processed material or directly on the roof, when there is no way to use the power tool.

Can be used both a hacksaw for wood and a hacksaw for metal, but in both cases the canvas should be made of highly alloyed steel. The main drawback of the usual hacksaw is that the cutting part is quickly stupid, and it must be sharpened.

Therefore, tools are more often used, which have a change in the canvas, and they are mostly designed to cut metal.

It is recommended to use the saw if there is skills in working with it. otherwise, with excessive pressure and skewing of the tool, cracks are formed on the slate.

They can also use a boot knife, an ax with a well.sharpened blade, a disk knife:

- Mark the fishing line for the trimmer breakdown.

- According to the marking several times, they are carried out with a sharp edge of the tool, deepening by approximately 2/3 of the thickness of the sheet.

- A long wooden block is placed under the panel at the cutting site.

- Press their hands on both parts of the sheet, and break it along the line.

- Sharped blade cuts burrs on the edge.

If there are no such simple tools at hand, the old method of separation along the line is used using only slate nails:

- Mark the fishing line for a fault trimmer. If the sheet is broken along the wave, this fishing line for a trimmer is drawn along the hollow.

- Along the line, as close to each other as possible, holes are pierced with nails.

- A wooden block or pipe is substituted under the line.

- Pressing at the same time (better with an assistant) on both edges of the sheet, break it into two parts.

The evenness of the fault depends on the number of holes. To help the separation of both parts, you can first knock with a hammer along the opening line.

Despite the “ancient” technology and fairly large time expenses, this method has an advantage in comparison with the use of a modern electric tool.

With such a fault, very little asbestos dust stands out, although the edges do not look very neat. Therefore, they are “hidden” under the overlap of another sheet so that they stay from the attic. And when arranging the beds, this edge is immersed in the ground.

The same methods are suitable for cutting sheet material. You can even use a well.sharpened ordinary nail, which first cut out a sheet for 2/3 of the thickness, and then broken through the emphasis on the line of separation.

What is good beds from the slate?

Based on the slate, fences are created for long beds. Mount the side parts at one height is simple, because the slate is easily adjusted by level. We note other advantages of slate beds:

- Due to the rapid heating in the sun, the slate heats the soil faster in the garden, due to which the plants in accelerated mode are supplied with the required amount of nutrients;

- asbestos.cement material has high reliability and strength;

- affordable cost;

- Shifer sheets will last more than one decade;

- beds equipped with slate, look more attractive.

If desired, slate sheets are painted with paint, giving the site a large decorativeness.

How can you cut the slate: the most common options

Here are the most common options for cutting asbestos.cement sheets.

Cutting corner grinding

It is more advisable to perform the work with a tool for stone disk together: someone will work with a corner grinder, and the other-moisten the section of the cut with water. The liquid is poured with a thin stream using either a hose or a regular plastic bottle. A similar simple way will help to limit the abundant emission of asbestos dust. mixing with water, dust just drains down down. Otherwise the dust will quickly fly through the air and clog the tool.

The remains of the dirt from the corner grinder and other items must be immediately removed, t.to. After some time, it hardens and it will be difficult to remove it after that.

When using a corner grinder cutting a diamond disk, sawing can be performed in any direction, and the edges of the cuts are also polished in parallel.

When cutting asbestos.cement sheets, a diamond disc is necessarily used by protective means.

As an example, let’s see how to cut the wave slate, using the simplest corner grinder and cutting disk on stone.

Before cutting, the sheet is laid on a table table. Special plank bridges or wooden staircase can be in this capacity.

A improvised tool is made from a wood bar with an emphasis of the required length for the profile marking. For example, if it will be necessary to divide it in half, then this peculiar ruler will need to be promoted in the direction of the sheet width, while making marks on the crests of the waves. When connecting, get a fishing line for a cutting trimmer.

As already noted, the ACL should be sawed wet. Water the material in the process of cutting. One saw, and the second pours water on the cut and a little to the disk to cool it. You can adapt a spray of a plastic bottle with holes in a cork for watering for watering.

It is more convenient to organize sawing as follows: first cut out the convex parts, and then connect the cuts together.

If the cut is performed without an assistant, then on a fishing line for a trimmer of the saw, it is necessary to lay rags moistened with water and leave them for a couple of hours.

Wet asbestos.cement sheet is cut without much effort, so you should not press too much a corner grinder on it.

The technology of cutting the material is greatly simplified in the winter, since it is possible to cut the wave slate with a corner grinder right in the snow, then the dust will mainly remain on the snow cover.

Cutting with a cutting machine

A special circle is installed on the machine, which is used in the sawing of the stone. In a moisturized section, the incision is performed without additional effort. The risk that appears is wetted once again and continue to deepen the incision. The process is repeated repeatedly, after which the depth obtained will be enough to easily break the profile along the intended line.

The use of other tools

For sawing asbestos.cement sheets, an electrician with low speeds or a simple hacksaw are suitable. The main thing is to show accuracy and not overdo it with the use of force in order to avoid breaking or splitting the material.

Cutting flat slate can be performed with a conventional cutter. It is placed on an even plane and outlined a fishing line for a cutting trimmer, say, it is carried out on it with a cut under a ruler, leaving a straight scratch. For several risk passages, it deepens, after which a thin rail is placed under it broken the sheet along the intended line.

This method is also suitable for material with a wavy profile, it must be cut in the direction of the wave. Cutting with a cutter is quite fast and more gentle compared to the use of corner grinding, since the amount of dust formed in the process of sawing is not a very large.

Is it possible to cut this roofing material at all without any tool? It turns out yes. For example, to obtain a cut line, you can use the slate nail, which pierce the holes along it. Any thin object of sufficient length is placed under the profile and neatly break it. How even the incision turns out depends on the frequency of the holes made and on how carefully the breakdown is performed.

Work can not only be facilitated, but also get a more even fishing line for a trimmer of the saw, if you make a device resembling a comb. On a bar of wood with a step of 20 mm, holes are drilled into which the corresponding nails are inserted

The device is put on the profile along the cutting line and carefully beat with a hammer. As a result, the sheet is easily and carefully broke

Practical recommendations

In order to reduce the amount of dust, you need to moisten the surface of the sheet. You can do this with a garden hose or plastic bottle. But it should be remembered that wet asbestos is poorly removed from the surface of the diamond disk. Will have to periodically stop the work to clean it manually. The diameter of the disk should be at least 250 mm, this will cut the waves from one pass and one side.

Sometimes you can find a cutting option, when the crests on one side are cut first, then the sheet is turned over and the crests are cut and cut off on the other hand. Do not do this for several reasons. First, time is much increasing. Secondly, it is likely that during turning the cut sheet cracks. Thirdly, the cut is uneven.

How to cut slate at all without dust

If the wave slate is quite difficult to cut due to its shape, then the flat is so simple that it is easier to break. Why exactly? The fact is that when cutting the slate, a lot of dust stands out, which is harmful not only for the tool, as we just said, but also for your health. And therefore, those who protect both both, find many ways how to do without cutting at all. over, it is precisely because of the large amount of dust of the slate is not recommended to cut in the room-it remains only to break.

Slate really easily breaks. everything is thanks to its fibrous structure

It is only important to do this evenly without damaging the corners. And for this there are as many as three ways:

We break the thin slate

So, the easiest way is to outline the desired fishing line for the trimmer of the cut, draw it with something sharp, put the bar and gently break the slate:

- Mark the place of the future fracture with a pencil.

- Put a rail on a cutting line for a cutting trimmer.

- Put the slate on the table and press evenly on the area of the broken part.

Or just cut a hole in 1 mm. the flat slate will easily break in this place.

We saw a dense slate

- Put the slate on the flat table so that most of the material is on the countertop. Let the assistant hold the hanging part of the slate.

- Take the saw and start cutting the sheet in the same way as a thin wooden board or plywood.

Suitable for cutting slate is also a hacksaw on foam concrete.

Cut the slate with a cutter

If you have to cut flat slate right in the room. forget about power tools, too much dust and noise. Take a cutter of good steel, and follow the following instructions:

- Put the slate of slate on a flat place.

- Attach the ruler, and under it draw a fishing line for a trimmer with a cutter.

- Remove the ruler, and start to press the cutter more strongly, deepening and expanding the fishing line for the trimmer.

- Now put the rail or pipe parallel to the cut line under the sheet, press. And it is not necessary to crush strongly. otherwise the slate will simply split.

- If any piece is not separated, tap along the cut side sideways.

We break the slate with a nail

- Make a marking with a simple pencil.

- Signen this fishing line for a trimmer with a sharp nail.

- Find this nail in a fishing line for a trimmer every 2 cm. The more you make holes, the easier it will be for you to break the sheet later.

- Pressing on a fragment of slate, easily break it on a punctured line.

Alternative methods

From time to time it happens that it is necessary to cut a sheet of slate urgently, and under the hand there is neither corner grinder, nor a jigsaw, nor a hacksaw. The only way out in this case is to break the leaf with your hands. The most experienced masters have two tricks, how to make a broken even:

With a sharp knife. A fishing line for a trimmer is applied to the surface of the slate where you need a section. Then taking a sharp household or stationery knife, they are repeatedly carried out along this mowing fishing line, over and over again deepening risk. When the incision becomes quite deep, the sheet is carefully broken. Using a drill. A fishing line for a trimmer is carried out on the sheet, which marks the place of the upcoming section. With the help of a drill along this mowing fishing line every 5 cm make holes

Later, the slafers are carefully broken down on the resulting penetrated strip. The smaller the step between the holes, the easier it is to break the sheet.

Due to the fault of the flaws in the process of cutting the slate, most of the defective sheets appear, which are not always used. If you do not have experience in cutting, buying a mother, patting 10% of the supplies, which compensates for losses as a result of imprudent actions when cutting.

Read how many horsepower in a chainsaw Ural

Advantages of the material, its qualities and properties

Once again, let’s say about the strength of this material, its wave.like shape makes it possible to withstand quite large loads.

Especially when it comes to bending and blows.

That is why on a roof covered with slate, you can walk without fear.

The positive qualities of the material can also be attributed:

- This material is not subject to changes at moisture and temperature drops.

- It belongs to the category of “non.combustible materials”.

- It does not rot and is not subject to corrosion processes.

- He has a fairly low thermal conductivity. That’s why heaters have never been laid under him. In addition, this quality of slate guarantees that condensation will not be collected under it. And this means that the roofing structure will be used longer. This is especially true for its wooden elements.

- The mount is carried out in the upper wave. And this is one hundred percent exception of the flow through the mounting holes. For this, special roofing nails with a wide hat are used.

- Simple mounting process. The weight of one sheet is 26.1 kg, an area of 1.98 m².

- This is an absolute electrical insulator.

- He has good sound protection. Falling drops of rain and hail are not heard inside the house.

- Compared to other roofing materials, slate is the cheapest.

- It lends itself well to processing. It can be painted, cut to the required size.

Why this simple roofing material is a carrier of such a wide range of advantages?

Everything is all in the components from which it is made.

But the market was always present not only with a wave option.

True, it was not used as a roofing.

He served as a fence, the wall panels, inter.ceiling inserts were produced from it.

Used a flat option as a building material, when the case concerned the partitions, aviaries.

Today it is used as a finishing material, such a slate can be painted in several layers with multi.colored colors.

Plus, at present, many manufacturers have become offered by the Sentwitch Paneli from the flat slate.

All the positive properties and qualities of the wave.like species, which were mentioned above, correspond to the flat option.

So in this regard they are the same, the difference in only one position is the low strength of the second due to its flat structure.

How to cut slate at all without dust

If the wave slate is quite difficult to cut due to its shape, then the flat is so simple that it is easier to break. Why exactly? The fact is that when cutting the slate, a lot of dust stands out, which is harmful not only for the tool, as we just said, but also for your health. And therefore, those who protect both both, find many ways how to do without cutting at all. over, it is precisely because of the large amount of dust of the slate is not recommended to cut in the room-it remains only to break.

We advise reading: ventilated roof: the design of a cold and insulated roof, cornice, hoods

Slate really easily breaks. everything is thanks to its fibrous structure. It is only important to do this evenly without damaging the corners. And for this there are as many as three ways:

We break the thin slate

So, the easiest way is to outline the desired fishing line for the trimmer of the cut, draw it with something sharp, put the bar and gently break the slate:

- Mark the place of the future fracture with a pencil.

- Put a rail on a cutting line for a cutting trimmer.

- Put the slate on the table and press evenly on the area of the broken part.

Or just cut a hole in 1 mm. the flat slate will easily break in this place.

We break the slate with a nail

- Make a marking with a simple pencil.

- Signen this fishing line for a trimmer with a sharp nail.

- Find this nail in a fishing line for a trimmer every 2 cm. The more you make holes, the easier it will be for you to break the sheet later.

- Pressing on a fragment of slate, easily break it on a punctured line.

We saw a dense slate

- Put the slate on the flat table so that most of the material is on the countertop. Let the assistant hold the hanging part of the slate.

- Take the saw and start cutting the sheet in the same way as a thin wooden board or plywood.

Suitable for cutting slate is also a hacksaw on foam concrete.

Cut the slate with a cutter

If you have to cut flat slate right in the room. forget about power tools, too much dust and noise. Take a cutter of good steel, and follow the following instructions:

- Put the slate of slate on a flat place.

- Attach the ruler, and under it draw a fishing line for a trimmer with a cutter.

- Remove the ruler, and start to press the cutter more strongly, deepening and expanding the fishing line for the trimmer.

- Now put the rail or pipe parallel to the cut line under the sheet, press. And it is not necessary to crush strongly. otherwise the slate will simply split.

- If any piece is not separated, tap along the cut side sideways.

If you lack of at hand, other equipment, most often flat slate is sawn with small.toothed with a hacksaw. True, it will have to be sharpened from time to time.

How to cut slate with special tools

So, how to cut a flat slate, if you still have to cut it?

Cut the corner grinder: select the disk

So, to cut a large amount of flat slate, take an angular grinder with a diamond disk. Cut the slate will be quickly, neatly, evenly and safe. The only negative when working with this tool is a lot of dust. But a relatively cheap angular grinder easily copes with such a task.

When working with a corner grinder, take it by one handle and drag it on yourself. under your own weight of the instrument, everything will be good:

Diamond circle cuts flat slate easily and quickly. As for the speed of the disc, 2000-3000 allow you to work easily and the tool does not heat up. By the way, with the help of a corner grinder and a diamond disk, you can grind the edges of the slate right away. Tip: When working with a corner grinding, we also put on protective headphones. the sound will not be pleasant.

One of the most affordable and practical options is a cutting circle on stone, which can be inserted into the cheapest simple corner grinder.

Another good way that is often practiced today is to make only an incision on the cipher with a corner grinder, and then break the sheet.

Cut with a saw: select the coating and teeth

Perfectly cuts slate saw with a special Teflon coating, which on the one hand protects the saw blade, and on the other, significantly reduces friction with the material. And less friction. less dust and easier work. Such a saw is not much more expensive than usual.

Secondly, you should pay attention to the teeth of the saw: the larger they are, the faster the slate will saw. And already definitely faster than a simple hacksaw.

Cut with an electric saw and chisel

This slate is cut traditionally with a bite and a disk electric saw:

- We take a ruler, a sharp chisel and on both sides of the future section we make notches.

- We place the slate on a flat base with a sharp bar or a line so that the lines coincide.

- Carefully break the slate.

- If the slate could not break, we cut with a disk electric saw, from time to time cooling it with water.

Cut with a gearbox

Another suitable instrument is a breeze. He has a built.in diamond disk that is able to reach a high speed speed. But, t.to. This “toy” costs is expensive (because professional), and therefore home craftsmen do something like it themselves: connect a parquet and small-toothed circle on wood. Cutting the slate with this tool is quite convenient.

Cut an electrician

But the worst of all, the usual cheap electric one copes with such a task. wears out too quickly. Most of all for such work is an electrician with a HCS saw of high.carbon steel, which is designed to work with soft materials.

Electrolobesik with a saw also copes with a sharp flat slate, for each tooth of which a winning tip is soldered. With such a tool, it is convenient not only to cut the sheets according to certain parameters, as well as make roundings and arcs.

Another good option, especially if you have to work often and professionally with slate, it is an electrician with a BIM saw. Such a tool when cutting sheets will never break even thin corners in a flat slate.

Of the incisors, it will be easiest for you to work with carbide, which can be found in any store. You can use an electrician for this purpose, if you purchase it with a special file with diamond spraying. True, but it will not work to cut it quickly.

Cut on a home circus

Cutting flat slate is also not difficult also on a conventional circular, 2 kW. Put a circle with carbide wood attacks so that there is more teeth. It turns out everything quickly and without any problems. Put on protective glasses, clothes without wide sleeves and durable gloves. It is only important that the sheet itself is fixed.

If you use a manual circular, then set the speed within 3500-4000. So the slate will be spread evenly and much cleaner than with maximum turnover 5500.

Electric tools

For processing wave.shaped sheets, angular grinder is most suitable. It’s easier to cut them, choosing a disk for cutting stone or a diamond circle.

The first nozzle is more suitable for cutting in a longitudinal position. To facilitate the process, a fishing line for a trimmer is carried out. She lies on top of the wave. Then the sheet is installed on a rigid base. According to the safety rules, a permanent stream of water is organized. She must drain to where the cutting disk touches the slate. So it is possible to simultaneously cool the metal, and prevent the formation of dust that is dangerous to human health.

The easiest way to organize the desired process is to put an assistant, hand him in his hands a garden hose and ask him to hold him over the cut line. When there is no one nearby, you will have to come up with a device that will allow you to fix the hose in the right position.

Everyone should know how and how to cut the wavy slate in the direction across the location of the waves. In this case, cutting is carried out according to the following algorithm: first, an incision of protruding ridges is made, then the sheet is turned over, and the operation is repeated.

note! After cutting, the disk must be removed and wiped well with a dry rag. It is useful and the very corner grinder to clean from dust. If this is not done, asbestos spraying will be petrified over time, getting rid of it, then it will be extremely problematic.

The preference for the choice of a diamond circle is given when it is necessary to cut the workpiece and at the same time sanding the edges of the cut. Such a procedure, experts assure, helps to renew the life of the roofing material. For its implementation, the sheets are previously abundantly moistened. This increases the elasticity of the slate, makes it more pliable cutting. If the operation is carried out in winter, it is advisable to carry it out by putting the blank over snow flooring. Then most of the dangerous dust will remain on the wet cover.

There are other electric tools that can replace the corner grinder. This is a detachment machine. But work with her will not allow to cut the material at once in one approach. The procedure will have to be repeated again and again, each time deepening more and more fishing line for the trimmer of the cut. To achieve the result, you will have to make three, four approaches. After each you need to soak the material well.

20 Gross Vintage Hygiene Trends

Another electric tool is an electrician with a file in a small tooth. Using it, it is important to set a reduced transmission mode, and then smoothly conduct a tool, avoiding strong pressure. It is difficult to work with an electrician, so its choice is justified only when you need to cut one, two pieces.

Mechanical tools

Not everyone knows how to cut the slate when there is no special construction equipment at hand. You can solve the problem in such a situation using:

- Hand hacksaw with shifts of canvases with small teeth (they will constantly clog asbestos crumbs and stupor when cutting, so it is advisable to stock up in advance at once by several interchangeable).

- Manual cut (it is difficult to work with it, you will have to make several approaches in order to make an incision of the desired depth, everyone must alternate with wetting the slate). Когда разрез будет углублен на две трети, под леску для триммера среза нужно подложить деревянный брус и произвести нажатие на края листа – если все сделано правильно, он распадется на две части.

- A nail and a hammer.

note! Only a special roofing nail is suitable for creating holes. Unlike simple, it has a special configuration of the rod and there is a soft head. When clogging the roofing nail, the slate does not crack.

When you need to cut a large number of sheets, a comb from a wooden rail and roofing nails is created to speed up the process. The use of such a device significantly accelerates the cutting of sheet material.

Mechanical tools

If the cutter cuts are carried out indoors, or the power tool suitable for work is not available, classic techniques come to the rescue than cut the slate.

In this case, the wet sheet can be cut in the following ways:

- Manual hacksaw. For this, a tool with interchangeable canvases and small teeth is suitable. You should stock up in advance with a few such canvases, since in the course of work they are quickly blurred and clogged with asbestos dust. During the saw, it is recommended to avoid pressure, otherwise fragile material may break.

- Manual cut. In this case, it will take several times to deepen the incision on the marking. Between the approaches it is necessary to moisten the fishing line for the trimmer of the incision. When the cutter deepens at 2/3 of the thickness of the sheet, it can be broken. To do this, a wooden bar is placed under the slate, just along the cut line: after pressing the edges of the sheet, it can easily decay into two parts.

- Hammer and roofing nail. To do this, a fishing line for a trimmer of marking in many places carefully breaks through with a nail. It is advisable to make as many such holes as possible. this will only contribute to the quality of the fault. When applying holes in the longitudinal direction of the slate, the slate is unfolded so that this wave passes below. After applying a series of holes under them, a wooden block or rail is placed: by clicking on the edges of the sheet, it is broken. To facilitate this procedure, it is allowed to tap a fishing line for a trimmer for a hammer with a hammer.

To implement this method, special slate nails will be required. They are distinguished by the presence of a special shape of the rod and a soft head, which avoids splitting sheets during clogging. To speed up the process of equipping the slate with a series of holes, roofing nails are stuffed into the bar. Such a kind of comb is usually used in constant work with slate sheets.

Cutting flat slate at home

To separate flat slate sheets, any method of cutting wavy slate can be taken into service. However, it is most convenient to cut an even slate to cut a corner grinder with a stone disk. To carry out the procedure, a flat surface is selected on which the material is laid. it can be a simple wooden flooring, or a dense soil platform. The main thing is that the lower base is not expensive, since during cutting it will certainly be damaged. When cutting near the edge of the slate under it, it is advisable to put the wooden rail of the desired length. Before cutting flat slate at home, you need to organize the supply of water to the place of work, to reduce the volume of asbestos dust

Regardless of what disk the slate is cut, it is important to avoid haste and show maximum accuracy. Any careless movement can lead to cracking of sheets, which, as you know, cannot be glued. If such work is carried out for the first time, you must definitely familiarize yourself with the recommendations than to saw off the slate. If possible, it is better to practice at first on an unnecessary old piece of material.