What Stihl Chainsaw Files Need

The choice of a round file should be approached more carefully, while there will be slightly less requirements for a flat file. For example, for Calm saw chains, it is the round file (its upper end) that should protrude at an angle of 20 ° to the surface of the angle of the worker. However, you do not need to forget about the considered step of the chain, which traditionally has 0.325 inches. The following steps with proper selection of sharpening:

- selection of file length depending on size. Popular among the existing five types are samples No. 5 and No. 4;

- note that a longer file will show itself better during sharpening. the amplitude of hand movement increases, respectively, the quality of sharpening improves;

- notched and chopped teeth are used as notches on the file itself. The best option is considered notched. They guarantee the minimum fluctuations in the cutting angle, which is important in the process of sharpening;

- high-quality sharpening should be made of tool steel according to GOST 1435, referred to as U13A or U13.

Why is it important to choose the right file for sharpening the chain?

We talked about how to choose a file for sharpening a chain of a chainsaw. Now we consider the objective factors of the correctness of the choice itself, and what consequences may arise if sharpening does not correspond to the spectrum of work assigned to it:

- The parameters of the tool must meet the characteristics of the saw chain, otherwise the grinding process will be impossible to carry out correctly and accurately.

- The accuracy and correspondence of the angles on the processed cutting gear will subsequently affect the quality of cutting, as well as the functioning of the chain, its rapid wear and even breakage, if the file is selected incorrectly and with its help sharpening was also incorrect.

- When sharpening yourself, using a file as a special grinding tool, it is important to understand the degree of wear of each individual tooth. These are always different elements from one another, but the essence of the process is to refine them to complete identity.

- If the sharpening is chosen correctly, then even with minimal experience, the owner of the chainsaw will be able to carry it out, having patience.

- Illiterate selection of the file and the result of its work can completely change the factory "settings". the angles of the teeth, and just ruin the chain.

- The wrong choice is inaccurate sharpening, and as a result. poor-quality work, operational wear on the chain and a lot of time spent.

If you once chose a high-quality file, then your chain will always be ready to perform work, you will save time and tackle yourself, if you take care of it in time and control the degree of erased teeth, it will last much longer. It is worth deciding on a specialized point of sale, before how to choose a file for sharpening a chain. KosiKosa always exhibits only professional files. Buy a chainsaw sharpening with us mono promptly and profitably from anywhere in the country.

Choosing a file for sharpening a chain is easy with specialists "Kosi Kosa"

Visitors to our site always know how to choose a file for sharpening the chain: we post the maximum of useful information on the pages of the catalog and in article materials. At the same time, the client can learn all the nuances about the process of sharpening itself, the rules of work for a high-quality result. The advantage of choosing the KosiKosa website is the following characteristics:

Proper sharpening is described in our next articles. read them, and your chain will return to its previous working condition.

When is chainsaw sharpening needed?

In the process of working with a chainsaw for any, even the highest quality tool, the chain eventually loses its original sharpness and needs to be sharpened. By what signs can you understand that the chain of a saw or chainsaw has become dull and it’s time to sharpen it?

The following are the main signs that it’s time to sharpen the chain:

- during operation, the saw loses stability, breaks out of the hands and vibrates violently;

- a chainsaw or saw produces chips of only small sizes, but does not produce large chips;

- the saw part gets stuck in the material, sawing is impossible to produce efficiently and quickly;

- the deepening of the chainsaw into the wood does not occur by itself, in order to perform a longitudinal cut, the tool has to be “sunk” with your hands into the material, applying force and pressing the blade;

- during sawing a cut curve is formed;

- the chainsaw heats up quickly and hard;

- chain wear is much faster;

- fuel consumption increases.

If you have marked several of the described features on your home tool, then it’s time to sharpen the chain.

The original chain of the chainsaw can be sharpened several times, it will retain all the working properties. the sharpness of the cut, the quality of the cut, the speed of rotation on the tire.

A few important tips that will help you not to sharpen the chain on a chainsaw longer:

- Do not use a new chain with an old sprocket and vice versa;

- if during operation of the chainsaw you have already sharpened two chains, replace the sprocket with a new one;

- the chain must be run-in before the full operation of the chainsaw with a normal load (run-in is carried out immediately before sawing, 1 minute at low speeds, and then 1 minute at medium speeds);

- after cooling a new chain of the chainsaw, check the degree of tension;

- always use chain lubrication for chainsaws, quality oil;

- keep the normal tensioned position of the links, because during operation the chainsaw is often tilted in different directions, which increases the likelihood of the chain slipping off the tire;

- control the position and direction of the cutter depth gauge, after the 3rd or 4th sharpening, check the limiter parameters.

Chain Tooth Characteristics

Chain teeth have several important parameters. These parameters include:

- device of the cutting link (consists of a base attached to the chain, a scapula blade with two cutting edges, a depth gauge that controls how deeply the blade cuts into the tree, the end and upper blade), the cutting action is performed not by the chain itself, but by the links, i.e. teeth. They move on a chain, as on a base, on a tree, and the link cuts the tree;

- the angle of the end blade, which allows the chain to cut the tree (it is because of this angle that wood chips are formed when cutting).

To carry out the correct sharpening of the chain, the owner needs to know:

- type of metal chain (soft, hard, medium);

- chain pitch

- depth gauge distance.

These two parameters determine how to sharpen the chain. The softer the metal of the chain on the chainsaw, the more carefully you need to handle the file with manual sharpening. The upper edge of the file during grinding should be located at an angle of 90 ° in the vertical plane and 30 ° or 10 °. in the horizontal.

Chainsaw sharpening angle video

This video shows how to sharpen a chain of a chainsaw, the main parameters of the saw chains are indicated.

The following video from the owner of the chainsaw on how to sharpen the chain of the chainsaw yourself

The rake angles of different types of chains can range from 60 to 85 °. The greater the degree of the rear corner of the upper blade of the chain, the more it will be tilted back, on average, the value of this angle is from 50 ° to 60 °. For the implementation of the cutting process, the most important indicator (degree) of the rear angle of the upper blade, and the upper blade itself is very important for high-quality sawing.

The main condition when sharpening a chain of a chainsaw or saw: cutting performance is directly proportional to the angle of sharpening, that is, the higher it is, the better the chainsaw will cut the material. The smaller the sharpening angle, the smoother the tool will be, and the less vibration will be during operation.

Avoid sharpening angles between more than 35 ° and less than 25 °. In chains for longitudinal sawing, an exception for the sharpening angle is allowed, in these chains the sharpening angle can be 10 °.

Sets of necessary tools, templates and accessories for sharpening a chain

Most popular chain sharpening tools:

- round file;

- flat file;

- holder;

- template for depth gauge;

- hook for removing sawdust.

The sizes of files for sharpening chains of chainsaws are different, but in ordinary life for household needs and home use for sharpening chains with increments of ¼, 0.325 ″, 3/8 ″ and 0.404 ″ files with diameters of 4.0 are recommended; 4.8; 5.2 and 5.5 mm. For some chains, cylindrical files with a diameter of 3.2 mm are used. For manual sharpening with your own hands, an ideal option would be a file 200 mm long with a diameter of up to 5 mm.

Some manufacturers sell these tools with sharpening sets, and you can also purchase them individually. A round file is one of the most popular tools with which many owners sharpen a chain no worse than on machines. Each set is designed for a specific step of the chain and its size. To choose a set for sharpening chains, you need to know these two parameters.

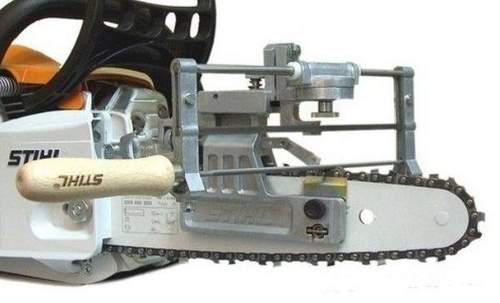

Markings are applied to the holder. they help the owner of the chainsaw to determine the correct angle position for sharpening the chain. The holder is installed simultaneously on the upper part of the limiter and the tooth, and a round file is placed under it immediately near the blade. The holder holds the file at the desired height, according to the standards it should be 1/5 above the blade.

To sharpen the chain of the chainsaw at home, the tire is fixed with a vise or clamp. It is important to maintain tool immobility during sharpening. The holder is put on the markup, and then the file is moved along the chain 2-3 times from itself. Each tooth is treated equally. From time to time, the file is turned on the other side so that it does not grind unevenly.

For convenience, the teeth are sharpened evenly on one side, after which they turn the saw over and level them on the other side.

Sharpening begins with the smallest tooth, since the length of the remaining teeth should coincide with it. When the blades are sharpened, limiters are machined. A template from the set is placed on the chain so that the stopper falls into the hole, all protruding edges are ground with a flat file from the grinder set.

Other accessories for sharpening chains, tool-grinding tools and devices:

- roller grinding device;

- files of various companies (round, flat);

- file holders;

- handles and guides for files;

- plastic cases, containers for storing tools;

- file. a small file, an elongated device with a diamond notch, most often files are used to file very small parts, and are often sold in sets.

Popular models of inexpensive sharpening machines

Popular manufacturers of inexpensive chain sharpening machines: Dnipro, Einhell, Sadko, Vitals, Forte, Intertool, Eltos, Zenit, Grand, Stern, Temp.

We offer you a short rating of chainsaw sharpening machines from the low-cost category:

All described models are suitable for chain sharpening on saws and chainsaws. To place the machine, a small workplace is required: a stable table and a power source for connecting the device to the network.

Oregon chainsaw sharpening machine. video with an overview of the device. The Oregon device is suitable for sharpening type 91VX chains; 91VPX in steps of.255 ″ and 3/8 ″; LPX in increments of.325 ″ and 3/8 ″; 3/8 ″ BPX, LGX.

Video about the machine Dnipro-M NSM-550

Types of sharpening chains of chainsaws and proper operation with them

Video: What Stihl Chainsaw Files Need

Next, we will talk about several popular methods of sharpening a chain that can be performed both at home and in production.

Manual file sharpening at home

For tooth restraints, a flat file can be used. The template for sharpening is attached to the turning element.

Stages of manual sharpening a chain of a chainsaw at home:

- fasten the chain (bar) so that it is completely stationary;

- do not change the angle of sharpening during the whole sharpening;

- do 2-3 file forward movements with a light touch;

- turn the file in different directions;

- sharpen according to the size of the smallest tooth.

How to sharpen a chain of a chainsaw with a do-it-yourself file. about this video below:

Professional sharpening on the machine

Sharpening on the machine can be done with a hand machine or a professional machine.

Professional machines work from the network. The principle of sharpening is almost the same as with manual sharpening:

- chainsaw chains are fixed in the guides;

- then adjust the width of the groove and select the angle;

- lower the sharpening disc;

- the chain is moved along the holder, clamped, each tooth is processed.

The grinding element in professional machines is sandpaper. A good automatic machine is not cheap, because professional sharpening equipment is mainly located in services and workshops. Buying this for home use is not rational.

Video on how to sharpen a chain of a chainsaw on a machine

Sharpening with a grinder or angle grinder

The process of sharpening a chain of a chainsaw with a grinding machine or an angle grinder is carried out using a special nozzle, the same grinding disc that is used as a nozzle in professional machines. Of all the turning methods, the method with an angle grinder is the simplest, however, requiring some skills.

For sharpening you will need an angle grinder and a 2.5 mm thick metal disc. Sharpen the chain at minimum speed, alternately processing each tooth on the chain. When using the angle grinder, wear a protective plastic mask or glasses, as well as gloves.

Video on how to sharpen a chain of a chainsaw angle grinder

Sharpening as a business service. what you need for this

To provide mass sharpening services, that is, to create a business in this direction, a lot of equipment and conditions are required. The following are the basic materials, equipment and consumables that will be required to create a mini-workshop:

- a room heated with electricity, a place for a machine, chair, shelving (minimum area 2 square meters, mains voltage 220 V);

- machines with washers for various disks (electric sharpener);

- grinding wheels, including diamond;

- grinding wheel;

- mounts for tools such as skates, scissors, chainsaws;

- Settlement. die for manual sharpening;

- hammers;

- small tools (hacksaws, screwdrivers, keys, etc.);

- vise;

- spindle oil;

- fixtures;

- punch;

- storage boxes, baskets, furniture.

Tips and tricks for sharpening at home

Andrey, Melitopol:

“I noticed that on the boxes from under the chains different sharpening angles are indicated, they differ for different chains. The factory angle, for example, is more than 25 degrees, everyone writes that it is not less than 35, and in order to cut the pine well, I set the angle to 40 or 45 degrees. Some machines do not move the chain back and forth, so do not stand near the factory sharpening at all! The thickness of the grinding wheel is also individually selected, and the shape of its edge must be constantly controlled. ”

Valentine, Dnipro:

“My opinion, as a master, is that file sharpening is the best in the world. Machine tools are, of course, good, but still follow the advice of an expert, I’ve been working with chains for ten years now, no less. The machine will give you only 30 degrees horizontally and 45 degrees vertically sharpening, and a file up to 10 degrees horizontally. The file vertical is the same in degrees, but the shape of the cutting edge does not change, and the working blade becomes wider. No other nozzle will give this! Second: the machine always gives overheating, which is bad for steel, but there is no file. Third: the file spares the teeth, if used, the chain will last about six sharpenings, two longer than after the machine.

The main minus of work. to work with a file, you need to train! Practice and practice only. ”

Chainsaw Sharpening Video

Chain sharpening reviews

Ivan, Poltava:

“During the use of the chainsaw I realized that no machine can grind better than hands! I’ve been with saws for 20 years, but only sharpened it with a machine tool when it was necessary quickly and without sharpness standards. He began to work with the Urals and Taiga, even worked on felling, and after that to this day I am engaged in log cabins and generally wooden structures. All these machines are bullshit, especially when the speed is large and the circle is spinning in one direction. ”

Home »What is the Diameter of Chain Sharpening File

Related posts

What is the right angle for sharpening chainsaw chains?

Chainsaw. the necessary tool for domestic needs, He will find a worthy application in the country. A chainsaw is just sawing wood for a stove or fireplace. She also shows herself perfectly when felling. Each owner of such an assistant should know the correct angle of sharpening chains of chainsaws. It’s worth a lot of money to call a specialist at home, and, all the more so, to a country house. Therefore, you have to do it yourself.

Although it is better to entrust a sharpening to a specialist, some lumberjacks learned this craft without the help of others. If the specialists in logging have to sharpen the chain 3-4 times a day, then the ordinary gardener does not have such a need due to the fact that he occasionally uses equipment. How can you master the craft yourself? There are some tips for this.

Features of the chainsaw

Cutting a tree is like working with a planer. With all this, the cut size is dependent on the thickness of the limiter. When the saw chain operates in saturated mode, the teeth become blunt faster. Sharpening the chain. Diameter of file 5 file for sharpening the chain. This is clearly manifested when the soil surface melts on the path of the chain. To completely blunt the teeth, it’s enough to “hook” on the ground for a couple of seconds.

If the ability to often sharpen, then chain will serve even longer, since very little metal will be removed. In addition to the question of what angle of sharpening the chainsaw chain should be, this also needs to be known!

There is no need to work with blunt equipment for a number of reasons. At first, this affects the quality of the cut, while not in the best direction. Also, lethargy is rapidly occurring, which is felt not only in the hands, but also in the body.

One more reason. unjustified overspending of fuel. All parts will work in heavy duty, which inevitably leads to their rapid wear. Performance drops dramatically, which also happens when using a defective circuit.

Features of the structure of the chain

To perfectly be able to sharpen the chain of a chainsaw, you should know the structure of its teeth. Do not do without knowing the angle of sharpening. Each tooth has a complex structure. Its geometry is represented by the following components:

- base;

- shoulder blade;

- depth gauge.

With all this, the blade consists of 2 blades: front and top. At the same time, between them there should be a correct angle of sharpening the chainsaw chains, in order to provide it with the desired performance.

How can I guess now. the chain doesn’t saw wood, as it serves as the basis for fixing the cutting links, moves them with the highest speed. The links themselves have sharp blades, with the help of which the tree species is cut.

How to find out when necessary sharpening?

It is possible to determine whether the teeth of the chain are knitted or not, according to some characteristic signs. Of course, it all depends on how much the chainsaw is used. It is worth taking a look at what kind of shavings it leaves. Its uniformity and square shapes indicate sharp teeth. If the chain is sharpened, then it usually leaves behind wood dust, and the sawdust itself resembles the needles that a “handsaw” “produces”.

If the cutting speed is reduced, then this is also considered a sign of blunting the chain. There is an increase in the load on the instrument itself and the appearance of vibration. Beginners are not always able to notice some of these signs. Therefore, they should pay more attention to the quality of the chips. Sometimes it is a brown hue, which is already guaranteed to indicate that it is time to sharpen the chain.

Sharpening Methods

To sharpen the tool, you can turn to the services of craftsmen who not only know what angle of chainsaw sharpening is needed, but also do all the work quickly and professionally. As a rule, the cost of such services is not so high, but the quality, on the contrary, is very high! This option is suitable for those lovers of logging who do not want to mess with their tools.

Read the same

Everyone else will be interested in trying their hand at such a thing. Professionals in this regard always choose automatic equipment that is characterized by maximum efficiency and accuracy. Of course, not every lumberjack can afford it, and therefore they can be handled in different ways. And here, among many fans, discussions are underway on the topic of which methodology is better to give preference:

Do not neglect the signs of dullness, and when necessary, proceed with surgery chain saw sharpening. This will allow you to use it as long as possible.

Correct sharpening angle

The angle of sharpening chains of chainsaws is not a constant value, does not depend on the manufacturer or model of equipment. It is selected taking into account which tree to deal with. You can choose some average value, but the efficiency of the cut may be ineffective. For this reason, it is necessary to choose the correct value, taking into account the specific species of tree.

If we are talking about solid wood, including those trees that have been “freezing” for a long time, it has a high resistivity. In this regard, the sharpening angle should be reduced. This will practically avoid the appearance of vibrations, and the chain stroke will be softer. The minimum value is 25 °.

What kind of file is needed to sharpen the chain

How to choose file for sharpening chain for JOIN VSP GROUP PARTNER PROGRAM chainsaw:

Two files of different diameters for correct sharpening the chainsaw chains

We have gathered the best experience. sharpening chains and summarized everything in one video. Showing fixture for perfect

In relation to soft types of wood, you can increase the angle of sharpening, but not more than 35 °. Productivity will increase significantly. Parameters of the file for sharpening the chain. What file sharpening (degrees) degrees. The diameter of the file depends on what you need to know for manual sharpening of the chain of which company. As for the angle of sharpening the chainsaw chains for longitudinal sawing, the value is 10 °. In this case, the cut will be as even as possible, and the vibration of the equipment is minimized. Knowing such features, we can proceed to consider different ways of sharpening.

Manual method

This is the easiest and slowest method for grinding chain teeth. However, the method is good when sharpening is done on site in the forest. Do not carry the whole machine with you all the time ?! But here it is worth to be more precise. not just one tool is meant, but a whole set, which includes:

- flat file;

- round file;

- template.

Each of them performs its duties. The main purpose of a flat tool is to sharpen the depth gauge.

The round file is already performing the main operation, making the cutting edges sharper. over, for each circuit a certain diameter tool:

- ¼ inch pitch. 4 mm;

- pitch 0.325. 4.8 mm;

- 3/8 inch pitch. 5.2 mm;

- pitch 0.404. 5.5 mm.

For Picco chains with which chainsaws are equipped "Stihl" 180 in 3/8 and quarter inch increments, a 4 mm file is also suitable. It is important to keep it right. With respect to the vertical plane, the file must be placed strictly perpendicular to the chain, and with respect to the horizontal plane. at a small angle (about 30 °). The specific grinding angle is selected depending on the needs, but within 25-35 °.

Unlike chain saw sharpening on the machine, the angle here can be set using a template that is considered a useful helper. To do this, it is equipped with two slots: SOFT / S (for softwood) and HARD / H (for hardwood). The template should be fixed over the chain, which gives it the privileges of a limiter.

It should only be borne in mind that this method is not intended for continuous use, but serves only as a straightening blade. Too frequent use of the file over time leads to chain wear, and the teeth themselves will be sharpened unevenly.

angle grinder is a good alternative

Professional lumberjacks consider this method to be primitive and time-consuming. It is used in the most extreme case, since the angle grinder cannot be fixed on the template. For this reason, it is very difficult to achieve compliance with a constant angle and depth of sharpening.

Read the same

The tire is firmly fixed in a vice in order to exclude its mobility during operation. It is not necessary to attach a new cutting disc to the angle grinder, it is better to use the old wheel 1.5–2 mm thick.

It is better for beginners not to use this method at all. they will be more intact. There is a risk of serious injury to yourself. In addition, there is no way to do without the skills to work with such equipment.

Modern method

Almost every layman cares about the angle sharpening chain chainsaws on the machine? It is not possible to use the file constantly, the angle grinder is difficult to use, and for beginners this procedure is completely dangerous. There is nothing to be done, one has to use machines that can be either mechanical or electric.

You will have to work with a manual machine for “eternity”, and you will enjoy using an electrical analogue. File for the chain. The most important file parameter for sharpening a chain (Stihl 180). Today, there are a variety of models to choose from, which provide

- correct sharpening angle;

- high level of work quality;

- high speed sharpening.

It is also worth noting that sharpening is performed evenly in relation to all links. All that is needed is to plug the equipment into the network, set the required angle, enjoy the sight or do other things. The cost of such machines varies from 2 to 4 thousand rubles. But the most important thing is to determine the angle of sharpening chainsaw chains "Stihl" on the machine is not difficult.

Though it takes a long time to tinker with manual equipment. the process is very long, but it costs several times cheaper. In appearance, the machine resembles a beam saw, but instead of the blade. a round file. The smallest tooth is also taken as a basis. At the same time, two or three movements are enough for sharpening, after which you can proceed to the next link. If necessary, process the stop. the file changes (the round changes to a flat one).

Sharpening rules

The homogeneous sections of each link should undergo uniform processing. Otherwise, if there is an unnecessary selection of metal in any one area, this ultimately leads to an imbalance, uneven running and jerking during the operation of the chainsaw. The load on the mechanism increases at times, which in turn threatens to break the chain.

Therefore, the operation should be carried out at the required angle of sharpening the chain of the Stihl 180 chainsaw (as well as any other tool) with extreme caution, avoiding excessive force. The procedure itself is performed sequentially, that is, you need to start on the one hand, then finish on the other.

In some cases, it can be observed that a single cutting edge (or several) has sharpened more. This happens when the chain in its path bumped into a knot, which occurs when cutting hardwood. Then it is necessary to determine which of the teeth has been knocked out the most and equalize all the other links.

After sharpening is completed, blow the circuit with air from the compressor or pump, and then place it in a container with engine oil for a short time. Usually few people do this, but for the chain it will be useful.

Useful Tips

Some useful tips will help keep your equipment in good condition and eliminate the risk of personal injury. In addition to the question of what angle of sharpening the chain of the chainsaw should be, this should also be known! Of course, know the correct angle of sharpening chainsaw chains "Stihl" necessary. But timely care of the tire is also important:

- It is necessary to control the chain tension. Especially if during operation the chainsaw leans to the side. Poor tension can pose a threat to humans.

- Timely sharpen, without putting everything off the bat. It may be unprofitable, but it is better to give preference to electrical equipment.

- Lubricate the entire chain regularly, otherwise it may fly off (its speed is about 100 km / h). Everyone will make conclusions himself.

- Do not use used automobile oil or any product of dubious quality. You should choose only specialized lubricants. The most important parameter of a file for sharpening a chain is which file is the diameter. As the best tool. autol.

Before you start working with a chainsaw, the chain should be run-in. Let her run at minimum speed for 40-50 seconds. Lubrication will reach every detail, and chains with an asterisk will heat up a bit, they will rub against each other.

All these expert advice should not be ignored if you want to stay safe and sound!

Finally

The angle of sharpening chains of chainsaws is selected based on which tree you need to saw. If you have free time and desire to restore the performance of the equipment is not difficult. Even an amateur who at least once in his life worked with a file can handle the job. Of course, for this you will have to spend from 30 to 700 rubles to purchase a sharpening set. The approximate cost of chain sharpening services in a company is 200-300 rubles. The final choice is the lumberjack.