Drilling walls in a panel house

How to find out a load-bearing wall or not in a brick house?

The thickness of the brick wall is a multiple of the size of the brick (120 mm.): 120 mm. 10 mm. (Thickness of the vertical mortar joint) 120 mm. etc. Thus, brick walls can have the following thicknesses: 120, 250, 380, 510, 640 mm. etc. finishing layers. The thickness of the brick bearing wall starts from 380 millimeters and above. In 90% of brick residential buildings, interior partitions are made of bricks or gypsum concrete panels with a thickness of 120 and 80 mm. respectively, interroom. 250 mm. brick and 200 mm. made of double panels with an air gap. The load-bearing wall in a brick house can be 380, 510 and 640 mm thick.

Thus, if the thickness of the measured wall in the apartment turned out to be less than 380 mm, then it is a partition, and vice versa.

There are much fewer brick houses built in series than panel houses, and therefore it is much more difficult to find their description. However, most of the brick houses in the capital are Khrushchev and Stalinka buildings with very similar design solutions. Let’s consider them in more detail.

Load-bearing walls in monolithic houses.

How to determine the load-bearing wall in an apartment in a monolithic building? Monolithic houses are the most diverse in their architectural and structural design. In residential monolithic houses, monolithic bearing walls, columns, and pylons (rectangular columns) are usually combined. and beams, etc. Often the pylons are “recessed” in the outer walls and inner partitions. The thickness of the load-bearing walls in a monolithic house is usually 200,250 and 300 mm. Column sizes are even larger.

Thus, if you measured the thickness of the wall and it turned out to be less than 200 mm, then this is a partition. The converse is unfortunately not true. If you measured a wall and its thickness was, for example, 200 mm, then this does not mean that it is load-bearing, because in monolithic houses partitions can reach a thickness of 200 mm. and more (for example, from foam blocks).

If you have a monolithic new building, then the easiest way to find out comprehensive information about the load-bearing walls of your apartment is to ask the management company or the sales department for your floor plan from the architectural section of the building project (“working”):

Usually this is not difficult, but on the plan itself, the internal load-bearing walls, partitions, and dimensions are clearly visible. Structural walls are usually highlighted with separate hatching.

If the apartment is in a new building and its finishing has not yet been completed, then which walls are load-bearing can be determined by visual inspection. Bearing walls in such buildings are made of monolithic reinforced concrete, which outwardly is easily distinguishable from bricks, foam blocks and other materials from which partitions and non-bearing walls are made. Also, on the load-bearing walls in such houses, holes stamped with mortar are clearly visible, which remained from the formwork screeds during the construction of the wall.

How are load-bearing walls indicated on the plan?

Many people ask us the question: “How to define load-bearing walls on the plan?” Unfortunately, there is no special designation of load-bearing walls in the drawings. If this is an architectural and construction plan from a working project for a building (an example is shown in the figure above), then the load-bearing walls are highlighted with the same hatching. Bearing walls on the BTI plan or on ordinary plans from the Internet are usually shown to be thicker than partitions, but not always. The wall in such plans can be drawn thin, but in fact be a carrier. Therefore, we do not advise you to rely on dubious plans in this matter. According to the apartment plan, only an experienced specialist can determine the load-bearing walls. who has seen not a single such apartment and knows their design features.

Of course, there are other signs of defining load-bearing structures, but they already require certain knowledge, experience and skills in construction, and therefore are not given here. I hope you found this article helpful. Let me remind you that you can always ask us your question in the appropriate section.

Load-bearing walls in a panel house.

In most cases, panel and block houses have a standard series, that is, the code of the project by which they were built. First, use this article to identify the series of your home by address. Then find a description of your typical series on the Internet, on our website, on the developer’s website, etc. The descriptions usually show the thickness of the load-bearing walls in a panel house of this series.

So how to define a load-bearing wall in a panel house? To get started, you can use our base of load-bearing walls of typical series of houses. There are given the layouts of apartments in each series with the highlighting of the bearing walls in color.

The second way to find out which walls are load-bearing in a panel house is to measure their thickness. In general, in panel buildings, the thickness of partitions varies from 80 to 100 mm, the thickness of load-bearing walls is from 140 to 200 mm. In 90% of panel houses, the internal partitions are 80 mm thick gypsum concrete panels, the internal walls are reinforced concrete load-bearing panels 140,180 or 200 mm thick. In some older series of panel houses, load-bearing panels with a thickness of 120 mm are found.

Thus, if the thickness of the measured wall without finishing layers turns out to be less than 120 mm, then this means that it is a partition, and if more, then the load-bearing.

It should be noted that the finishing layers of the walls (plaster, wallpaper) can make adjustments to its thickness, but in panel houses they usually do not exceed 50 mm. and do not have a significant impact. However, if possible, it is better to remove the plaster layer for cleanliness of measurements.

If you cannot measure the thickness of the wall directly (let’s say between rooms), then you can measure it through the “third dimension”:

Wall thickness: s = c-a-b;

It should be noted that the demolition of the load-bearing wall in a panel house is unacceptable. This is guaranteed to lead to sagging or collapse of the floor.

Definition of load-bearing walls. How to know the load-bearing wall or not?

How to identify a load-bearing wall. Detailed guide.

A load-bearing wall is a wall on which beams or floor slabs rest. A self-supporting wall is a wall that takes its weight along the entire height of the building and transfers it to the foundation.

Monolithic load-bearing wall and non-load-bearing wall of tongue-and-groove slabs

Often self-supporting walls are also referred to as load-bearing, which we will do in this article. To start agreeing on the redevelopment of an apartment or non-residential premises, and the redevelopment itself as a whole, should be from the definition of load-bearing walls, because their impact can lead to disastrous consequences, including the collapse of the building. Redevelopment of load-bearing walls (partial dismantling, opening arrangement, etc.) in accordance with Article 26 of the RF LC should be carried out on the basis of an appropriate redevelopment project, its approval with the author of the house, etc. Despite this, examples of redevelopments are becoming more common on the Internet every day (for example, ivd.ru). where designers playfully demolish load-bearing walls, not paying attention to the fact that it is illegal and, moreover, can lead to a violation of the strength of the building. In this article we will try to answer in detail the questions “How to find out a load-bearing wall or not?” and “How to find out which walls in the apartment are load-bearing?”

To begin with, we recommend that you find out the type of your house and the material of its walls on the website tipdoma.ru at its address. The simplest and most reliable way for non-professionals to determine load-bearing walls is to measure its thickness.

Table of contents of the article

- 1. Bearing walls in a panel house.

- 2. How to know the load-bearing wall or not in a brick house?

- 3. Bearing walls in monolithic houses.

- 4. How load-bearing walls are indicated on the plan?

- 5. Is it possible to touch load-bearing walls?

- 5.1. Is it possible to demolish a load-bearing wall in an apartment?

- 5.2. Is it possible to move a load-bearing wall?

- 5.3. Is it possible to make a passage in a load-bearing wall?

- 5.4. Structural wall.

- 5.5. Drilling the load-bearing wall.

How to drill without dust: the options are better

Construction work is always accompanied by dust and debris, but using some guidelines and tips, it can be significantly reduced:

- the hammer drill leaves little dust during operation so that it does not scatter around the room at the same time use a construction vacuum cleaner. Some brands of tools have a built-in vacuum cleaner, which makes the task easier;

- using a drill, it is best to either make a jig on the end or a bag, or make an envelope under the hole so that debris falls into it.

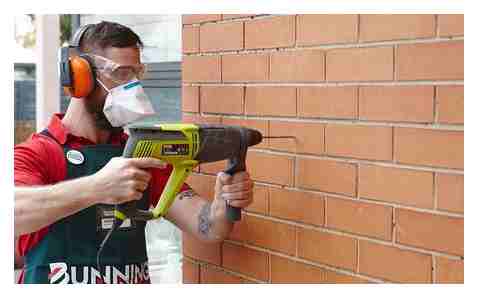

How to drill holes in a brick wall: the choice of tools and attachments

To make a hole in a brick wall, a punch with a drill or an impact drill is suitable, most often the latter is used. Its power must be at least 600 watts, the minimum number of revolutions from 2500 per minute. The best is to use a drill with stepless power adjustment and quick clamping function.

By using the hammer drilling function, the drill becomes identical to the hammer drill. The speed and ease of operation are increased. To make a hole in a brick wall, you need to use the dynamic blow method. Without this, the drill will not be able to catch on the inside of the brick.

Drilling holes in the wall correctly: general rules and recommendations than drilling

In order to properly drill a wall, you need to take into account the material from which it is made, based on this, you need to choose a tool.

- hold the tool correctly when working. For example, the drill in the hands should be straight, and enter the surface in a vertical direction;

- for convenience, use the additional handle;

- depending on the surface material, select the right drill.

- concrete, stone, brick wall. use a carbide drill, more often victorious;

- metal. drill for metal;

- tile, ceramic tiles. special drills for these materials, sometimes they can be replaced with a concrete drill with hardfacing;

- Chipboard, wood. for holes less than 10-12 mm, a drill for metal is suitable, for larger ones, special drills for wood are used.

Work rules: tips

When working with tools, you must follow the safety rules and general recommendations:

- 1) Protect the respiratory system when performing work, dust is harmful.

- 2) If you work outside, then you need to put fences 2.5 meters.

- 3) When working at a height of more than 1.5 meters, use a solid foundation. a forest or a goat.

- 4) When working with a tool, the revolutions must be turned on smoothly, and in no case, must not be turned off when it is in the body of the wall.

- 5) When drilling through plaster, it is necessary to carefully study the communication plan so as not to hurt anything.

- 6) It is strictly forbidden to drill through the decorative coating.

- 7) Choose the right drill for every surface.

- Moisten the drill with water so that it does not overheat.

Tools for work

For work, they use different tools, the main ones: a drill, a perforator, a screwdriver. There are nuances when using each.

Is it possible to drill a hole in a concrete bearing or brick wall of a panel house with a conventional drill, puncher or screwdriver without dust, how to do it

When making repairs in an apartment or house, the question of drilling a wall always arises. Different tools can be used depending on the purpose of the hole and the material from which the surface is made.

There are nuances when working with each tool, especially when drilling a wall. How to make the right hole correctly, and what recommendations to follow?

How to make a hole in a concrete wall in an apartment with a drill

For a small hole, you can use a punch. It will be made, most conveniently, from a drill, diameter 8 mm. The end is sharpened sharply. The drill is placed in the right place, turned, while hitting it with a hammer. Moisten the drill periodically so that it works longer.

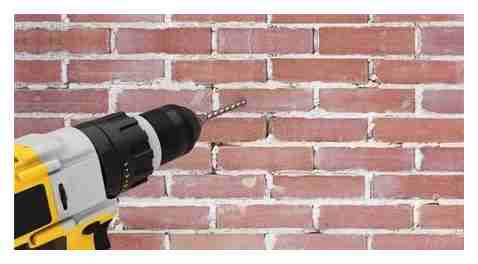

How to drill a load-bearing wall in a panel house with a perforator

In most panel houses, the walls are made of concrete, in order to make a hole with a perforator, you need to use a drill bit.

In addition to them, you can use special crowns. They have soldering around the circumference. When using them, you need to turn off the percussion function of the punch.

Experts use diamond drilling, this requires powerful equipment and skills.

Insulation of the outer walls of a panel house: recommendations for implementation

Before starting wall insulation in a panel house, you should perform the following actions:

- choose the method of insulation, the type of material and its shape;

- purchase materials and additional tools, if necessary;

- insulation of external walls is carried out only at positive temperatures, preferably in summer;

- the walls should not be wet, use a gun for additional drying;

- all decoration should be removed from the walls, for internal walls. wallpaper, paint, decorative finishing materials, for external walls. the facade must also be well cleaned and dried;

- use a vacuum cleaner and a broom to clean the walls;

- before installing the insulation, apply an antiseptic compound to the surface of the walls;

- then a deep penetration primer should be applied to the wall, which will ensure high adhesion of the insulation to the wall.

Make sure that the wall is as dry as possible after the antiseptic before applying the primer. For additional leveling of the walls, plaster is used. Only after it dries, the process of installing insulation on panel walls follows.

Use a silicone based sealant to further seal all joints. Insulation installation technology depends on what type of insulation it was purchased earlier. Slab or roll options are most often fixed to the wall using special fasteners with large hats. Compressor equipment is used to install foam insulation options presented in liquid form.

Next, you should wait until the wall is completely dry and proceed with the installation of the second wall and finishing.

- Wall insulation in a panel house: advantages and disadvantages

- How to insulate a wall in a panel house: the choice of insulation

- Insulation of the outer walls of a panel house: recommendations for implementation

- Heating in the wall of a panel house: insulation with foam

Walls

In order for living in a house to be as comfortable as possible, it must be warm and cozy. Most often, high-quality insulated walls help to preserve the heat that comes from heating devices. The lack of insulation leads to an increase in heat losses and an increase in heating costs. We will talk further about how to insulate the walls in a panel house.

Wall insulation in a panel house: advantages and disadvantages

There are two main types of wall insulation:

- internal;

- outward.

The choice of this or that option depends on the individual capabilities of the room, its area, the type of building in which the work is carried out and the number of storeys. By insulating the walls inside the house, you will get the following benefits:

- weather and climatic conditions do not affect the insulation process in any way;

- reduction of heat losses in the room;

- ease and speed of work, since there is no need to create all kinds of structural elements for wall insulation.

Despite this, internal wall insulation has the following disadvantages:

- a slight decrease in the usable area of rooms, especially important for small apartments;

- internal insulation negatively affects the general microclimate of the room, since in the winter season, condensation forms behind the wall, which, passing through the surface of the insulation, accumulates on the wall and leads to the formation of mold and mildew on it.

In order to avoid the appearance of the latter drawback, a so-called pie should be built during the process of laying the insulation. It contains materials in various types of vapor permeability, while the reduction of this factor is carried out closer to the outer wall.

For example, when insulating a panel house with mineral wool, it is imperative to install waterproofing in front of the insulation. Thus, the condensation that forms in the wall will gradually be discharged through the concrete surface and will not enter the interior of the room. In addition, a high-quality ventilation system should be provided in the room.

Insulation for thermal insulation of internal walls should differ in the following characteristics:

- long service life;

- high level of fire safety and resistance to ignition;

- environmental safety is especially important in internal insulation, since the use of low-quality insulation has a negative impact on the health of people living in the house;

- resistance to rodents;

- keeping the shape;

- low heat loss.

Before buying a heater, we recommend checking it for certificates of compliance with all fire and sanitary safety standards.

If you have the opportunity to carry out external insulation, we recommend that you give preference to it. For its implementation, materials are used that are distinguished by high quality properties. Most often, they are used in a slab or matte finish. Among the advantages of outdoor insulation, we note:

- Prevention of damage to the walls of the house by atmospheric precipitation, low temperature and other external factors. Therefore, the building remains thermally stable in both winter and summer seasons. The service life of the building is significantly increased.

- Cold bridges between the junction of the walls. absent. Accordingly, it reduces the risk of condensation, which leads to mold and mildew on the walls.

- In addition to protective functions, the choice of external insulation allows you to obtain a high-quality soundproofed building. Ensuring the removal of the race point outside the house improves the resistance of the house to moisture and condensation. At the same time, it is possible to preserve the facade finish for a longer time than without the use of insulation.

- It is possible to save usable space in the room, especially for small one-room apartments.

- With external insulation, there are more options for insulation for installation on the facade of a building than with internal insulation. In addition, the insulation will not release substances harmful to human health inside the house.

How to insulate a wall in a panel house: the choice of insulation

Mineral wool is most often used for wall insulation in panel houses. For its production, slag or basalt stone is pressed and thermally processed. Due to the fibrous structure, warm air is trapped inside the cotton wool, thereby preventing heat loss. Distinguish between rolled and slab versions of mineral wool.Due to its non-toxicity and safety, mineral wool is used both for internal and external insulation.

The material is characterized by low thermal conductivity, good vapor permeability, long service life, and fire safety. The only drawback of this insulation is instability in front of moisture, therefore, during its installation, maximum waterproofing of the insulation should be ensured.

Installation of mineral wool indoors reduces its useful area, therefore, if possible, it is recommended to use insulation outside.

Insulation of walls outside a panel house with glass wool has its own advantages. This material is highly resistant to fire and low temperatures. In addition, it has excellent resistance to moisture, rodents, mold and mildew. However, during the installation of this material, special care should be taken, since the smallest glass particles can get on the mucous membranes of the body and cause allergies and irritation. Therefore, when working with this material, you should wear protective clothing and a respirator.

Glass wool has excellent sound insulation characteristics, in addition, it is resistant to shrinkage and is cheap compared to other types of insulation.

Among the advantages of cellulose-based insulation, we note:

- versatility of application;

- environmental safety;

- high thermal insulation performance;

- breathability.

However, this insulation by itself is unstable against moisture, mildew and mildew. Therefore, it is treated with special compounds that help get rid of these shortcomings.

Styrofoam or expanded polystyrene. one of the most economical insulation options. This insulation is distinguished by moisture resistance, good sound and heat insulation characteristics, light weight and ease of installation. Expanded polystyrene is resistant to bacteria, fungi and mold. A small volume of insulation is characterized by high thermal conductivity. Expanded polystyrene is most often used for insulation in the form of plates. If you follow the technology of its installation, then this type of insulation will serve you for a very long time.

The use of extruded polystyrene foam, which is essentially the same foam, but has a liquid form, is distinguished by a higher strength and durability. Special equipment is used for blowing polystyrene foam. The resulting coating is seamless, durable and has good performance.

After drying and pressing the wood shavings, an insulation called fiberboard is formed. To connect the shavings to each other, a binder is used, in the form of Portland cement or magnesia salt. The material is in the form of plates, on the top of which there is a protective film. It is with its help that it is possible to prevent the effect of moisture, fungus and mold on the insulation. With an increase in humidity, damage to the material occurs, therefore, after its installation, it is recommended to plaster the surface. The material is characterized by ease of installation and processing. The base, after its installation, becomes strong and rigid.

Insulation based on cork materials is used to insulate the walls of a panel house from the inside. This insulation option is the most environmentally friendly of all of the above materials. Cork insulation has high strength, low thermal conductivity and vapor permeability. Insulation is in the form of panels that are lightweight, resistant to mechanical damage and shrinkage. The material is functional and has a long service life. After indoor installation, further finishing is not necessary, since the slabs themselves have an attractive appearance. In addition, cork insulation is resistant to all kinds of biological organisms. However, its only drawback is the too high cost, which is fully paid off by the advantages of the material.

To create an insulating barrier that is highly resistant to moisture, insulation in the form of polyurethane foam is used. To apply this material, special equipment and formwork installation are required. Since the material polymerizes very quickly, in order to create a flat surface, formwork should be built from wooden planks.

After applying the foamed polyurethane, its waterproofing and vapor-permeable layer should be ensured. For these purposes, most often the insulation is covered with a layer of polyethylene. Since the material has a low strength, for further wall decoration, walls should be made of plasterboard, so this option of insulation will not only reduce the usable area, but also require additional costs for the installation of walls made of plasterboard or plywood.

Heating in the wall of a panel house: insulation with foam

After preparation of the surface, its leveling and coating with a primer, the installation of insulation follows. At the preparatory stage, make sure that the seams at the joints of the walls are tight. If there is a crumbling finish, it should be removed.

To install the foam on the outer wall of a panel house, prepare several spatulas for applying glue. It is safer to install the insulation using a combined method, that is, using glue and dowels.

You should start work from the bottom of the wall, gradually moving to the top. Install the starter bar on the lower part of the facade. It is best to use a spatula or comb to apply the adhesive.

Try to completely cover the wall with glue, even in uneven areas and seams. Otherwise, through the bridges of cold, the level of heat loss in the house will increase. After surface treatment with glue, the foam board is applied to the wall and pressed. After a few days, work continues. In order to additionally secure the foam, use special fasteners or plastic nails. If there are small gaps, use polyurethane foam to fill them. In order to remove irregularities from the wall after insulation, use a plastic float.

How To Hang Curtains Without Holes In The Wall

Use mesh for additional foam reinforcement. First, with its help, the corners are glued, then the rest of the wall. To fix the mesh on the surface, glue is used, and after it dries, the walls are leveled with plaster or special mixtures and the finishing is done.

The reason is ventilation

To begin with, it is important to check the functionality and quality of ventilation in the rooms. The channels must be clean, no foreign objects. If the ventilation system is not functioning at all, then none of the fixes will help to achieve the best result.

You can often engage in airing the room or forcibly remove moisture from the rooms by opening all windows and doors. If there are improvements, then the problem is precisely in ventilation, its repair will help to cope with freezing walls.

What to do if the wall freezes

It happens that after purchasing a house or apartment, various problems arise. For example, somewhere the curvature of the walls appears, or it turns out that there are not enough outlets. Such problems are not global. But sometimes there are moments that are not so easy to eliminate. For example, the owner notices that his wall is freezing. Despite the seeming simplicity, solving the problem requires a certain algorithm.

- List of reasons for freezing walls in the room

- Determine the source

- The reason is ventilation

- The reason is insufficient insulation

- Poor sealing

- How to get rid of freezing

- We insulate problem areas

- Non-standard solutions

Determine the source

In new buildings, the problem of wall freezing is rare. One of the following factors may be the cause. But the ancient houses made of panels can freeze due to at least two reasons. So what to do if the wall freezes?

The reason is insufficient insulation

The first signal of insufficient heating in winter is the formation of condensation on the walls. If you leave the problem behind, the surface will begin to mold. But how does this moisture appear? From physics, you can recall the concept called “dew point”. It represents the point in the wall where moisture or steam begins to turn into water. The colder it is in the room, the closer the dew point gets. Moisture begins to form on the inside of the wall. If such freezing of the walls is observed, then the only solution would be to insulate them from the outside.

If you carry out insulation from the inside, then this will not solve the problem, but will only eliminate visible signs. However, behind the insulation, the wall will begin to get wet even more, mold will begin to spread.

How to get rid of freezing

Once a problem has been identified, it is important to comprehensively solve it. One option is to grout and apply a layer of plaster. This will eliminate the consequences of freezing. And then we’ll deal with the cause. For this work, you will need the leveling compound itself, a brush, sandpaper, an acrylic-based primer and a spatula.

- The old finish (wallpaper, paint, tiles) is removed from the wall.

- All cracks, breaks and other defects are treated with putty. If the irregularities are serious, plaster is tried on, and putty is applied on top.

- It remains to wait until it dries and grout the surface with sandpaper.

- The final stage is the application of the primer.

The wall is ready for subsequent finishing with new facing material. This way you can remove the consequences caused by the freezing of the walls. But that is not all.

List of reasons for freezing walls in the room

If the owner freezes through a wall in a brick house, the question of what to do here is secondary. After all, this phenomenon has its own reason. With the elimination of the effect, and not the cause, with repeated frosts, the problem will pop up again. So, the wall begins to freeze due to the accumulation of moisture inside. The surface begins to be covered with moisture and freeze. The reasons are as follows:

- Lack or poorly organized ventilation system. Then moisture is not removed from the room, it begins to settle in the form of condensation, and the walls do not dry out naturally.

- The room is poorly heated in the midst of frost. The walls do not warm up enough, but, on the contrary, begin to freeze outside rather quickly.

- Errors generated during the construction of the building. Sometimes builders are incompetent or negligent. They do not pay enough attention to sealing gaps between structural elements of a building or near door and window frames.

- The waterproofing material has become unusable. This is typical for multi-storey apartments located on the upper floors. Then you need to contact the housing office so that the utilities replace the waterproofing layer.

- Cracks formed in the house, and with them bridges of cold. Through them the cold penetrates inside. This is the most difficult and intractable reason for the freezing of the walls. For the solution, it is necessary to make major repairs. If left as it is, the crack will get bigger, longer and wider.

Therefore, there are many reasons for the freezing of walls in a house or apartment. That is why, before fixing the problem, it is important to identify the factors that influenced the problem. But how to find out what is the reason for the violation of the thermal insulation of the building?

Poor sealing

And what when the wall in the apartment freezes due to poor sealing? How to determine this? It is required to check all openings for drafts and cracks: balcony, doors, windows. To do this, it is enough to use a hand (she will feel a slight breath, if there is one) or matches / lighter, then the flame will burn unevenly, and “dance” or go out altogether. The disadvantage of this method is that for a full check, you will need to remove the old finishing material (wallpaper, paint, tiles) from the corners. Nevertheless, if the corners in a brick house freeze, then saving the old wallpaper will still not work.

How to act when it finds the source of the cold? It needs to be eliminated. For example, small gaps are filled with silicone sealant. Large ones are better to cover with plaster. However, in order to get rid of freezing of corners and restore the microclimate once and for all, it is better to insulate the room outside. over, this can only be done with a problem wall (at the corners or at the joints of panels).

There is an opinion that the best option for sealing cracks and seams is polyurethane foam. Yes, it is good for dry rooms. But with high humidity, its use is not rational. It will begin to absorb moisture from the outside and carry it inside the room. This is a kind of cold bridge. As a result, the problem will not go anywhere.

The walls are freezing due to the seams in the panel house, what should I do? The seams are made taking into account small deformations. Therefore, it is not enough to hide them with ordinary putty. Since it will crack again at the slightest movement. In this case, a composition is selected that is not afraid of deformation.

Wall slitting technology

There are several ways to chisel through the wall:

Drill and chisel

A concrete drill is inserted into the drill chuck. Holes are made along the entire length of the groove at small intervals. Then a channel is punched, removing with a chisel sections of concrete between the holes.

Wall chaser

The power tool is equipped with one or two cutting discs. The double-disc chaser allows you to cut channels of different widths. The distance between the cutting discs is manually adjustable.

Perforator

A tip in the form of a spatula or a lance is inserted into the instrument. Working in the mode of a jackhammer, the hammer drill knocks out a groove of the required depth and width in the concrete.

Arrangement of channels for wiring

How to slit the panels so that the volume of work and material costs are the most optimal? There are two ways to make channels in wall panels. In the first version, a horizontal and vertical strobe is broken through. In the second case, the channels are located diagonally from the junction box to sockets and switches.

Diagonal channel position significantly saves labor and material consumption.

Is it possible to chisel the walls in a panel house

So that the interior of the room is not disfigured by wall communications, they are made hidden. To do this, in the enclosing structures, the walls are channeled for wiring and pipes. Is it possible to chisel a wall in a panel house for wiring? Of course, this is possible, but under certain conditions.

The arrangement of channels in the body of partitions in a monolithic house does not cause problems. This also applies to panel houses. A partition is a structure that carries a load only from its own weight and does not affect the bearing capacity of the entire structure.

Another thing is the chipping of load-bearing walls. A significant violation of the integrity of concrete walls will lead to a loss of their bearing capacity, and this, in turn, can cause irreparable consequences.

Top layer of concrete in reinforced concrete slab from 30 to 50 mm

On the Internet, you can find many articles on this topic, asserting in a categorical tone about the impossibility of chipping the walls in a panel house. You should try to refute such statements.

To understand the essence of the problem, you need to know the design features of reinforced concrete walls. The main bearing load is taken by the metal reinforcing cage, “permeated” by the mass of concrete. The top surface layer of concrete plays a protective role. Therefore, if the chasing of the walls for wiring does not expose the reinforcement, then monolithic fences will not suffer from this in any way.

The concrete cover is usually between 30 and 50 mm. For a two-core wire, a channel depth of 10. 15 mm will be sufficient. For laying several cores, a groove should be punched in the supporting wall with a depth of 20. 25 mm. The wider the channel, the more wires can be routed.

It is necessary to make the strobe in such a way that the load-bearing wall does not have channels with bare reinforcement.

Compliance with safety rules

When using electromechanical tools, a number of safety requirements must be met:

How to drill through a wall

- When working with a power tool in rooms with high humidity, it is imperative to wear rubber gloves and rubber-soled shoes.

- To protect your eyes, you need to wear special glasses.

- To prevent the penetration of cement dust into the lungs of the worker, wear a gauze bandage or respirator.

- When performing this type of work, the room must be well ventilated.

- Do not overheat the instrument. Rest the power tool from time to time.

- During breaks in work, all cement dust is removed with a vacuum cleaner. If powerful dust formation occurs, then the nozzle of the switched on vacuum cleaner is held next to the channel during chipping.