How to choose a circular saw blade

How to choose a circular saw

To choose, give yourself an answer to an important question. for what purpose are you buying a saw. If you sometimes need something to repair with your own hands, sometimes trim something, saw something off, there is no need to buy a powerful hand circular saw with various additional functions, which you will not use.

If you are a professional, engaged in construction on contracts or have a small workshop. in this case you do not need to be stingy, the price of the electric circular saw does not play a big role, with a good tool it will quickly “pay off”.

Therefore, when buying pay attention to its power, because the power is tied to the size of the saw blade. power, larger diameter of disc is set on the saw, because the motor is more stable and gives the necessary frequency of rotation of the shaft, on which the disc is fixed. In addition, the more power of the tool, the more time it can work without the threat of overheating.

In addition to power, when buying, you need to pay attention to the saw’s sole and mounts. These parts should be massive.

Usually, for rare simple tasks it is enough circular saws with power up to 0.8 kW, if work will be frequent, you are in the period of restructuring or repair. it is better to take a tool with a power up to 1.4 kW.

For professional activities, it is better to choose a manual electric circular saw from 2,0 KW, which will give a guarantee and the use of large disks, the ability to cut plastic and aluminum with the appropriate saw blade, the engine will be able to work for a long period without stopping.

In addition, the number of revolutions per minute is also an important condition for the purchase. The higher the number, the easier and cleaner the material will be cut.

Depending on these dimensions we obtain the thickness of the processed material. For the first, light, it will be 40. 50 mm for the middle, the most used 50.65 mm, for professional saws up to 140 mm.

If you work with the saw constantly, professionally, having additional options is a big plus.

-

For example:

- adapter to which you can connect a construction vacuum cleaner for sawdust suction;

- clutch for overload protection during work;

- a device that locks you in place when you change the blade;

- guides when working with the longitudes, you can also make them yourself;

- electronically controlled rotational speed control and more, which helps with operation, protects the mechanism from premature wear and protects the worker from injury.

Basic parameters of a circular saw blade

Outer (outer) diameter

Determined by inside dimension of blade guard. larger diameter blade will not fit on saw with smaller blade guard. Basic dimensions of cutting tools for manual circular saws are in the range of 130-250 mm. Outer diameter has little effect on cutting speed, but does affect depth of cut. With increasing the kerf the engine is loaded considerably, the metal of the disk and the workpiece itself is heated.

Inner, seating diameter

Several sizes: 16, 20, 22, 30, 32. important. diameter should match the size of the drive shaft on the saw for which the blade is being sized. Some rims have extra holes to secure the rim to the pins.

Number of teeth on disc

Affects variables such as cutting speed and cut finish. A fewer number of teeth results in higher cutting speeds, improved chip evacuation, but a poorer cut finish. A higher number of teeth results in a cleaner cut, but the motor workload increases. Conventionally, according to the quantitative ratio, the discs can be divided into three groups:

Discs with an intermediate number of cutters are referred to the universal type. They can be used for soft and hard wood, to make cross and rip cuts, to use for working various wood products.

Tooth inclination

Determined by the deviation of the cutting edge surface from the disk radius. inclined to the backside of the tooth is called negative, inclined to the backside of the tooth is called positive. For longitudinal sawing it is more appropriate to use a tooth with a positive slope, as during processing there is a kind of gripping the material, disk run over the workpiece that contributes to a faster cutting of the workpiece as a whole. Tooth inclination is subdivided:

- standard inclination. the angle varies from 5° to 15°;

- positive, aggressive inclination is 15-20°;

- normal, the negative angle ranges from 0° to.5°.

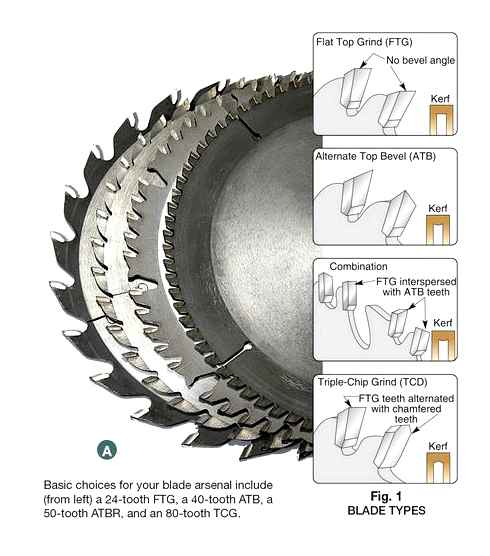

Tooth Configuration

Each type of cutter is designed and made for a specific task. They are subdivided into:

- Flat chisel. used for quick longitudinal sawing in soft or hard wood and marked as FT.

- Replaceable cutter. has alternating shiftable tooth flank in one or other direction. Cutters give a smooth and reasonably clean cut. Used for transversal and longitudinal cutting of wood, plywood, OSB, chipboard and composite boards, marked with the ATB symbol.

- Combi cutter. it is a consecutive grouping of four changeable cutters (ATB) and one flat cutter (FT). Designated as Combi. This blade type is regarded as universal because of its ability to perform various types of cuts.

- Trapezoidal flat cutter. made from consecutive flat teeth. The higher one is sharpened to a trapezoid shape; the lower one is flat. is used for wood and wood-based materials, plastics and soft non-ferrous metals. Designated TCG.

- Replaceable cutter with extra slant lateral. designed for work on material that is prone to splitting and for finish cross-cutting. Identified by HiATB.

Disc thickness

Determines actual kerf width. Standard size is 3.2 mm. The thickness of the blade also has an effect on the toughness of the cutting tool itself. Decreasing the parameter leads to hard operation, overheating of the blade and breakage. Larger blade size causes greater material consumption, i.e., “chip loss.

Circular saw blades are used in a variety of materials. Accordingly the cutting tool is also designed for specific tasks.

Basic circular saw blade specifications

Outer diameter

Determined by inside dimension of blade guard. a blade with a large diameter will not fit on a saw with a smaller blade guard. Basic dimensions of cutting tools for handheld circular saws are in the range of 130-250 mm. Outer diameter has no significant effect on cutting speed, but does affect depth of cut. Higher kerf places a greater load on the motor, heating the blade metal and the workpiece itself.

inside diameter, fitting diameter

There are some sizes: 16, 20, 22, 30, 32. Important parameter. diameter should correspond to the size of the power shaft on the saw, for which the disc is selected. Some designs have a hole in the disc that locks the disc in place on pins.

Number of teeth on the disc

Affects parameters such as cutting speed and finish. Fewer teeth increase cutting speed, the conditions for chip evacuation improve, but the cleanliness of the kerf deteriorates. A larger number of teeth results in a cleaner cut, but puts more pressure on the motor. Conventionally, according to the number of discs can be divided into three groups:

discs with an average number of cutters are of the universal type. They can be used for soft and hard wood, to make cross and lengthwise cuts, to use for working various wood products.

Tooth inclination

defined by the deviation of the cutting edge surface from the disc radius. When deflected to the back side of the tooth, the slope is called negative; when deflected to the back side, the slope is called positive. For longitudinal sawing it is more appropriate to use a tooth with a positive slope, as during processing there is a kind of gripping the material, the disc runs over the workpiece, which contributes to a faster cutting of the workpiece as a whole. Tooth inclination is subdivided:

- Standard tilt. angle varies from 5° to 15°;

- A positive, aggressive inclination of 15° to 20°;

- normal, negative inclination ranges from 0° to.5°.

Tooth configuration

Each cutter type is designed and built for a specific task. They are subdivided into:

- Flat chisel. used for quick longitudinal sawing in soft or hard wood, mark FT.

- Interchangeable cutter. has a sequentially alternating interchangeable tilt of teeth in one or the other direction. Cutters produce a smooth and sufficiently clean cut. Used for cross and rip cuts in wood, plywood, OSB, chipboard and composite boards, marked with ATB.

- Combination cutter. it is a sequentially changing group of a combination of four changeable cutters (ATB) and one flat cutter (FT). Labeled as Combi. This type of blade is considered universal because of its ability to perform various types of cuts.

- Trapezoidal flat cutter. made from consecutive flat teeth. The higher one is sharpened to a trapezoid, the lower one is flat. Suitable for wood and wood-based materials, plastics and soft non-ferrous metals. Marked TCG.

- Replaceable saw blade with extra slant lateral. designed for work on material that is prone to breakage and for finish crosscutting. Designated with HiATB.

Disc thickness

Determines actual kerf width. Standard dimension is 3.2 mm. also the thickness of the disc affects the strength of the cutting tool itself. A smaller setting results in heavy cuts, overheating of the blade and breakage. A larger size causes increased consumption of the machined material, i.e. “conversion to chips”.

Circular saws are used in a variety of applications. Accordingly the cutting tool is also made for specific tasks.

Such tooling is used for cutting of small wooden materials. boards and bar up to 75 mm in height. Small disc size makes it suitable for compact portable circular saws. Here are the wood circular saw blades with this diameter that are fast, clean and make a thin kerf, as well as being suitable for chipboard and fibreboard.

Bosch 2.608.640.633 190×30 mm. quick cut

When cutting speed is the priority, discs with a low number of teeth are the right choice. It has a lower rotational resistance and facilitates cutting the material as fast as possible. But because of the large spacing between the cutting elements the sides to be cut are coarse and need to be ground for finishing.

This saw blade by a German brand has 12 teeth with a tungsten carbide facing and additional reinforcement on the back side. Leaves a 2.6 mm in width.

- Not only suitable for wood, but also for cellular concrete, cementbased fiberboard.

- Even cuts nail boards.

- Very low cost and a trusted brand name.

- Can work with tools rotating at up to 4900 rpm.

- Can distort metal if you saw for too long. the blade has no notches for thermal expansion.

- The cut is not clean and it needs additional post-processing.

- Better suited for longitudinal cuts, tears more fibers in cross cuts, thus affecting the quality.

- Slows down over time. life expectancy 4 years.

- The sharpening seems to be blunt (peculiarity of shape and technology), so it is not possible to determine the quality in the store. only put it on the saw and try it out.

Conclusion. This inexpensive blade comes in handy for making quick cuts in roughing work.

CMT 272.190.42M (190×30/20/16×1,7/1,1 mm; Z42). clean fine cut

Thin discs with a high number of teeth are needed for very fine cuts and clean edges. This tool is used for furniture production, where accurate accurate cuts and efficient material consumption are essential. But the price to pay is the thin cross section of the metal, which can lead to jamming or deformation. This blade should be handled more carefully than others.

CMT 272.190.42M (190×30/20/16×1.7/1.1 mm; Z42) is an extra thin disc with a thickness of 1.1 mm. Has 42 teeth and leaves a kerf width of 1.7 mm. Made in Italy and designed for finish cuts.

Advantages of the CMT 272.190.42M (190×30/20/16×1.7/1.1 mm; Z42)

- Suitable for circular saws up to 8000 rpm.

- Very quiet operation.

- Makes it easy to make longitudinal and cross cuts in different material densities.

- Does not leave any jagged fibers on the edges.

- Price is much higher than similar products.

- Difficult sharpening that is not easily repaired at home.

- Some circular saws require an adapter ring to fit them. the ones included are thicker than the blade itself, so the latter does not clamp all the way.

- No great haste when making cuts, or they would be chipped.

Conclusion. Ideal for the furniture workshop. Gives you the cleanest and most precise cut in OSB and other similar materials. Eight grooves inside the blade provide good vibration damping and contribute to a quiet operation.

about saw blades

Proper selection and operation of the saw blade affects not only the quality and speed of cutting, but also human safety. So it makes sense to take a closer look at the features of popular models.

Cross and lengthwise cutting

unlike metal or stone cutting, the cutting direction is of great importance when cutting in wood. This can be explained by the direction of the fibers, which makes it work quite differently in cross and longitudinal sawing.

The 210×30. or any other size. longitudinal saw blade is designed to saw along the fibers as quickly as possible. Of the features of the design can be noted increased in comparison with other models of the slots (this is necessary in order to quickly remove a large amount of sawdust), as well as a smaller number of teeth.

This tooth configuration is ideal for rip sawing

The angle of the blade is positive, thanks to which the self-gripping effect is at its maximum, i.e. the saw pulls the workpiece toward itself as if it is pulling it, which facilitates the feed and increases the safety of work. If you need to perform sawing of a large volume of lumber with your own hands, it will greatly facilitate the work.

Please note! For cross-cutting sawing a large positive angle of sharpening is not needed at all, it only creates additional problems.

The main difference between crosscut saw blades is the angle of sharpening, which can even be negative if maximum control over the feed rate of the workpiece is needed. A larger number of teeth and smaller sawdust slots can also be noted.

Such a sharpening will give maximum control over the feed rate of the workpiece

In principle, a simple rule applies. the harder the material, the smaller the tooth size, but there are more of them on the disc.

How the shape of the tooth affects the cut

The quality of the cut with the carbide blade is strongly influenced by the shape of the tooth.

It is possible to distinguish such variants of saw blades as:

- 190×30 flattened disc, ideal for cutting very hard wood. The tooth is symmetrical, so the load is uniform on both sides equally;

The flat apex is suitable for hard wood

- bevelled tines. these models have a chessboard-shaped pattern in which the top of the tines is bevelled in different directions. This allows the blade to effectively gnaw into the material, minimizing the possibility of chipping;

Variable bevel

Please note! This blade is not recommended for cutting hard material. The reason is that when the tooth comes in contact with the wood, it will create a significant axial force on it.

- “Triple chip. The blade works like this: first, the teeth with symmetrical bevels remove triple chips, and the next (flat-topped) tooth strips the edges of the cut. The 250×32 blade with this tooth configuration can be considered a universal solution, it is suitable for both plastic and hardwood;

Tooth configuration “triple chip

- If you need ideal quality of cut, you should pay attention to discs where a block of 4 beveled teeth has 1 tooth with a flat top. The main cutting function is on the teeth with the beveled tips, while the flat tip will only deburr the kerf.

Monolithic and carbide discs

quite often the price of discs of the same size differs considerably. Most likely, the reason is that one of them is monolithic and the other one is solid carbide. This explains the difference in price.

In a monolithic disc, the teeth are one piece with the disc itself.

They are cheaper than solid-carbide discs, but the low price is due to several disadvantages:

- They blunt faster, especially when working with hard wood;

- Over time, you need to renew the set, otherwise the kerf will become too narrow, causing overheating and increased stress on the motor.

Teeth and blade form one unit

The advantage of these models is that they can be sharpened several times. It’s true that it’s quite difficult to do it manually without experience.

As for discs with carbide tips, they have small metal inserts of high-strength alloy soldered on the top of the tooth.

It achieves several goals at once:

- Since the width of the bit is wider than the disk itself, there is no need for facing. This makes it easier to maintain;

- the metal of the bit is much stronger than the blade itself, so it will cut much longer than a monolithic saw.

Sharpening is not recommended, but it is not required. If you compare the service life of the 2 types of discs, it turns out that a monolithic disc needs to be sharpened 2-4 times, while the solid alloy disc will last the whole time without sharpening.

So when choosing it all depends on what kind of wood you are going to work with. So if you need to choose the 165×20 disk for soft wood (poplar, linden, aspen) the monolithic disk will do. But for oak, larch, maple, it makes sense to buy a carbide-tipped model.

Circular saw blades

Monolithic disc. Made from high-carbon or high-speed steel. Used for machining wood and wood-based products as well as for cutting plastic products. They have a number of advantages:

- inexpensive;

- simple sharpening of teeth. it is possible to perform this operation by yourself, without complicated special devices;

- re-sharpenable many times, hence have a sufficiently long working life.

A disc with teeth that have a hardfacing hardfacing. Blade is made of durable tool steel. Brazed are steel alloys with high m tungsten carbides or cobalt. This solution has made these discs the most common. They have a number of advantages

- Allows you to cut most of the known materials;

- No tooth setting is required;

- are durable and reliable in operation;

- the service life from sharpening to sharpening is several times longer compared to a monolithic disc;

- They give a cleaner cut;

- Increase the cutting speed;

- Available in a wide range of sizes for all kinds of cutting tasks.

At the same time there is a significant disadvantage. such discs are relatively expensive and special equipment is required for sharpening.

Types of circular saw blades

Monolithic disc. They are made of high-quality high-carbon or high-speed steel. They are used for processing wood and wood products, as well as for cutting plastic products. Have a number of advantages:

- Inexpensive;

- Simple sharpening of teeth. it is possible to perform this operation by yourself, without complicated special devices;

- They can be re-sharpened repeatedly, so they have a long service life.

Circular saw blades with teeth strengthened with carbide inserts. The blade is made of high-strength tool steel. Brazing is high m tungsten or cobalt carbide steel alloys. This solution has made these discs the most common. Have a number of advantages:

- Allows you to cut most of the known materials;

- No need to set the teeth;

- Rugged and reliable in the process of work;

- the service life from sharpening to sharpening is several times longer compared to a monolithic disc;

- Give a cleaner cut;

- Increase cutting speed

- They are available in a wide range of products for all kinds of cutting tasks.

However, they have a serious disadvantage. such discs are relatively expensive and require special equipment for sharpening.

The principle of operation of a circular disc

All electric woodworking machines work on the same principle. Wood disc for circular saw is fixed on the motor axis that gives it powerful rotation. The tools are divided into several groups:

The only difference between these systems is their design. The blade rotation in a handheld unit is mechanically controlled. Electric devices imply the presence of an electric motor. All systems have a special platform for adjusting the depth of cut, as well as setting the desired angle of inclination.

The industry produces the original mini saws equipped with a battery. Such a wood-cutting machine, the disc mechanism of which is not very powerful, can be operated in areas where there is no electricity supply.

Useful tips

When choosing, you should pay attention to all the described characteristics, as well as take into account the purpose for which they are purchased. For example, if you plan to work only with wood, there is no sense in buying expensive hard-alloy blades with special tips on the teeth. The monolithic blades are quite sufficient here.

Choosing a saw blade for a wood or metal circular saw is not an easy task. If there is no experience in this matter, or just can not remove the wheel, it is better to ask for help from a specialist, preferably one who has successfully worked with a circular saw for several years.

How to choose a saw blade for wood

Woodworking companies and many construction jobs require a wood saw blade for machine tools. This tool optimizes and expands the work. But it is necessary to know how to choose a right saw blade for it to be effective. The correct choice of tool also determines the safety of the machine.

Universal saw blades do not exist, although some sellers advertise such products. Hard and soft types of wood can not be cut equally well with the same disc.

For those who want to know how to choose the right wood saw blade, we advise to choose the tool according to the specific task and type of wood. Of course, you will have to buy more than one product, but the result will meet expectations.

For crosscut saws, for example, products with a negative tooth angle are suitable. They are not suitable for sawing tables, because there will be increased vibration and resistance of the lumber.

Also note that saw blades with a negative tooth angle have small slots. Chips can get clogged in them, which will increase stress on the motor.

What Factors to Consider When Choosing a Blade?

Type of blade

Wood circular saw blades can be solid carbide or monolithic.

Monolithic products are most commonly made of high-carbon steel. They may have sharp teeth like a hacksaw, or curved teeth. The former copes well with hard and soft wood, while the latter is good for soft types of wood.

Monolithic saws become dull rather quickly. They can be sharpened only a few times, and some models should not be sharpened at all.

Carbide-tipped wood saw blades are made of high-strength tool steel. They are better able to withstand the stresses than monolithic saws. Carbide saws work effectively on hard wood, producing a clean, neat cut.

The disadvantages are the higher price compared to monolithic saws, as well as the complicated method of sharpening with special equipment.

Outer diameter

Size of the saw’s inner casing must be considered when selecting the diameter. If the blade is too big, it will not fit in the saw, but if it is too small, the cutting results will not be satisfactory. The choice of the outside diameter also affects the cutting depth.

inside diameter

A properly chosen inside diameter provides a firm grip on the cutter. There are disc models with special side recesses for pins for additional fixation.

Number of teeth

Small number of teeth. 14 to 40.

toothed circular saw blades are more suitable for cross-cutting cuts. Longitudinal cuts are best made with a tool with up to 60 teeth.

Type of material

High-value wood is best cut with thin blades. Standard or thickened cutters are suitable for hardwood.

It should be taken into account that thin discs allow making a neater cut, but they are short-lived compared to thicker products.

These are basic criteria for those who want to know how to choose a circular saw blade. To get more useful information, we offer to consult our experts.

You can also buy wood saw blades for CNC machines at an affordable price from us. Visit the online store and you will be satisfied with your purchase.

Types of discs

Finding the right accessories for your saw is an important part of your sawing operation. To avoid faulty workpieces and premature tool failures, the choice of a cutting element must be made responsibly. There are these types of saw blades of large size:

With tungsten carbide inserts. This type is the most common. It is used by specialists in log sawmills or single-disc sawmills.

Without tungsten carbide tips. Characteristic feature of such disks is thinness of kerf and resistance to foreign bodies in wood. Tools over 700 mm in diameter take quite a lot of work to set up. Working time between sharpening operations is relatively short.

With riving blades. This configuration of the blade’s cutting elements promotes a slight expansion of the opening to be sawed. This ensures that the tool does not jam in the workpiece while working, and the free access of air facilitates rapid cooling of the workpiece. This not only increases productivity, but also the quality of the cut.

To buy high-quality large saw blades for stationary machines contact “MultiFrez”. We sell only products from proven manufacturers, so the work with our tools will be done qualitatively.

Quality of the blade

There are several indicators by which you can almost definitely tell if a product is of high quality or made by hand:

- The disk must be marked, and the inscription is made with a laser tool, not with paint.

- The blade should be ground and polished. the finish is visible if you “play” with the blade in the light.

- Cutting tool disc is subject to balancing and calibration procedures, which is roughly similar to balancing a car wheel. The cutting tool will not “beat” after such processing, there is no vibration when working.

- In order to compensate possible thermal expansions, special slots are made on the disc, ending with small relief holes.

- Some manufacturers reinforce the blade with several circular stiffening rings.

- Another indicator of quality is the name of the manufacturer, its brand. To date, these are European, American, South Asian, Russian and Chinese manufacturers (listed in descending order of quality). By the way, some Russian manufacturers produce products, comparable in some parameters with European or American.

In general, choosing the right disc for a circular saw is almost a science. If you have no experience, it is better to consult with professionals, and those who have the skill to work on a circular saw at least 2-3 years.

Articles :

- Adjusting the carburetor chainsaw carburetor. one of the nodes in the fuel supply system in an internal combustion engine. It is designed to form a mixture of fuel and air with the regulation of its supply to the chambers []

- Chainsaw adjustment A chainsaw is a hand-held tool designed to work with wood material. It is equipped with a gasoline internal combustion engine. Is a complex constructional device. В []

- Attachments for mini-tractors The mini-tractor in agriculture is an indispensable friend and helper. What kind of work it has to cope with: it also has to dig over the soil, apply fertilizer, and spray []

- How to sharpen a chainsaw chain A chainsaw chain is a cutting tool designed to cut through wood. Consists of a series of sharpened links which are connected by means of []

How to protect yourself when working with a circular saw

Wood saw blades if handled incorrectly can easily deprive a person of extra fingers or even a limb. Most often the reason for this lies in violations of the elementary rules of working with the device.

The instructions for work include a few simple rules:

- Do not feed short workpieces manually. For this purpose it is better to use special stops;

- It is not desirable to work with an angle grinder with a circular saw blade. This is the most traumatic option. Even if you hold the tool very firmly, then, when the tooth comes across a nail or a knot, it can jerk so hard in your hands that you will not be able to hold it;

It is prohibited to install such saw blade on the angle grinder