How to Choose the Right Hacksaw Blade. Wooden hacksaw blade

How to Use a Hacksaw

Find out how to use a hacksaw for improved control on difficult cuts.

A popular tool among plumbers and electricians, a hacksaw is primarily designed for cutting through metal, like copper pipes or conduit. However, it can also be used on plastic, like PEX or PVC, making a hacksaw an invaluable tool for anyone that regularly works with these materials.

While there are other power tools, such as grinders or reciprocating saws, that can also be used when working with metal, plastics, and other hard materials, a hacksaw provides the user with better control. This increased control is essential when making precision cuts or working in tight spots. In fact, there are even miniature hacksaws designed specifically for accessing narrow gaps and spaces.

The following guide is an excellent resource for those looking to learn more about hacksaws, hacksaw safety, and hacksaw blades. Follow our detailed steps to learn how to use a hacksaw for your home DIY projects.

Safety Considerations

When working with a new tool or starting a DIY project, it’s important to pay attention to personal safety and the safety of those around you. Limit the number of people in your workspace to reduce the chance of accidental injury. Hacksaws often produce fine metal or plastic dust, so ventilation is another important consideration. Set up a fan and open a window or door to ensure that the area is properly ventilated while you work.

Most risks can be mitigated by taking proper precautions to prepare the area, secure the work material, and wear suitable personal protective equipment (PPE). When using a hacksaw, it’s recommended to wear closed-toe footwear, long pants, a long-sleeve shirt, safety glasses, gloves, and a mask to avoid breathing any dust produced while sawing.

Choosing a Hacksaw Blade

Selecting a blade for your hacksaw is important to the success of your project. If you choose the wrong type of blade, you might struggle to cut through the target material. Similarly, if the blade is the wrong size, it won’t fit on the hacksaw. The first thing you need to consider is the length of the hacksaw. These tools range from 6 inches to 12 inches in length. Choose a blade that’s the same length as the saw.

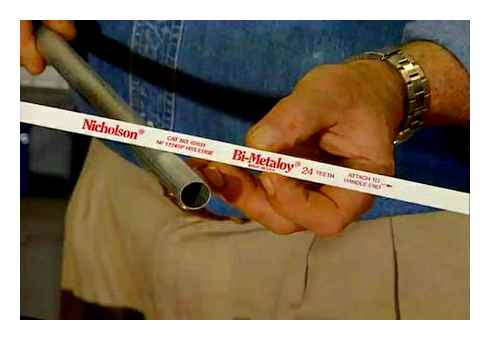

The next consideration is the type of material with which you’re working. Carbon steel blades are great for general-purpose use on hard plastic or soft metals, like copper or lead, but if you’re working with hard metals, like stainless steel, it’s best to opt for bimetal blades or high-speed steel (HSS) blades.

Another factor to keep in mind is the teeth per inch or TPI. The higher the TPI of the blade, the finer the cut. For fast, coarse cuts, go with an 18 TPI hacksaw blade; if you want a fine finish, a 32 TPI blade is best. Users that aren’t quite sure which type would be best can settle for a mid-point position between the two with a 24 TPI blade.

How to Use a Hacksaw

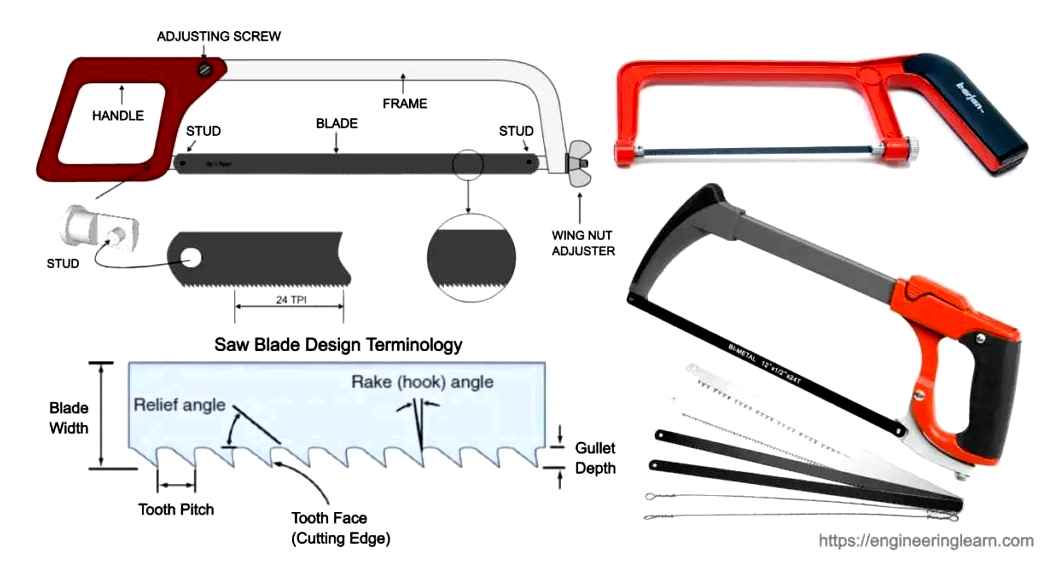

Hacksaws are relatively straightforward tools consisting of two main parts: A metal frame and a removable blade. The frame ranges from about 6 to 12 inches in length, so users can select the right size hacksaw for the job. Hacksaw blades can have as little as three teeth per inch (TPI) or as many as 32 TPI. Typically, blades with a higher TPI are made for cutting finer materials. Follow the steps below to learn how to use a hacksaw.

What You Need

- Material

- Vise or clamp

- Pencil or scriber

- Hacksaw blade

- Hacksaw

- Machine oil

- Deburring tool

- Sandpaper

Step 1: Secure the Material

Unless you’re working on a fixed material, like an existing water pipe, it’s important to ensure that you secure the target material to prevent it from shifting while you saw. You can use a vise to grip the material, though if you don’t have one, you can also use clamps to secure the material to a workbench. This will allow you to work with both hands for power and control without worrying about the material moving under the saw.

Step 2: Select a Hacksaw Blade

Choose a hacksaw blade based on the size of the saw, type of material, and the desired finish. The blade should match the length of the saw, so if you’re using a 12-inch hacksaw, you’ll want a 12-inch blade. Opt for carbon steel for hard plastic and soft metals, or go with a bimetal or high-speed steel blade for hard metals. For a rough cut, you can use a hacksaw blade with 18 teeth per inch or you can get a finer cut with a 24 TPI or 32 TPI blade.

Once you’ve selected the blade, slide it onto the hacksaw frame and secure the blade to stop it from shifting or twisting. Keep in mind that hacksaw blades only cut in one direction. If the blade is properly installed, the teeth of the blade should be facing away from the handle to cut on the push stroke instead of the pull stroke.

Step 3: Align Saw Blade and Start Cutting

With the material secured, measure and mark the precise spot where you want to cut, then line up the hacksaw blade with the mark. Before cutting, make sure to apply pressure as you push the blade and reduce the force as you pull the blade, as the saw only cuts on the push stroke. If you apply the same force on the pull stroke, you may damage the teeth on the hacksaw blade.

Start cutting by moving the hacksaw slowly in short strokes until a groove forms. Grip the handle of the hacksaw with your dominant hand and hold the front of the hacksaw frame with your other hand for improved control. If you’re working with metal, consider applying a few drops of machine oil to the hacksaw blade. This will reduce friction and heat while you’re cutting, allowing the blade to move more freely through the material.

Step 4: Finish the Cut and Remove Rough Edges

As the blade creates a groove in the material, you can begin to increase the length of the hacksaw strokes so that you’re using the full length of the blade. Maintain a steady rhythm as you finish sawing through the material. If there are any burrs or rough edges, you can use a deburring tool and sandpaper to smooth these points on the material.

When finished, wipe down the hacksaw blade to remove any debris left from the material, then store the hacksaw in a safe location. It’s a good idea to either remove the blade or put a blade cover on the hacksaw to protect it while not in use.

How to Choose the Right Hacksaw Blade

A 24 TPI hacksaw blade offers the most range. It’s good for cutting aluminum, steel rods and plates, and more.

A 18 TPI hacksaw blades is perfect for cutting wood, PVC pipes, as well as hardened steel and general workshop cutting.

Good quality 14 TPI hacksaw blade that’s great for cutting thick metals like aluminum, copper and even stainless steel.

A 24 TPI hacksaw blade offers the most range. It’s good for cutting aluminum, steel rods and plates, and more.

A 18 TPI hacksaw blades is perfect for cutting wood, PVC pipes, as well as hardened steel and general workshop cutting.

Good quality 14 TPI hacksaw blade that’s great for cutting thick metals like aluminum, copper and even stainless steel.

A hacksaw blade is available in different TPI (teeth per inch) to best cut a specific range of material thicknesses. Hacksaw blades are usually meant to cut metals, but in very specific rare cases they are used to cut wood.

The higher the TPI, the finer the cut will be. The lower the TPI, the coarser the cut is going to be.

The lower the TPI…the larger the gap between teeth…and the longer the tooth. This allows more material removal and clean-out with each saw stroke, thus saving cutting time.

The higher the TPI…the smaller the gap between teeth…and the shorter the tooth. This allows the blade to cut thinner material thicknesses without getting hung up in the material.

| WOOD AND THICK METAL USE | 14 | 1/8″ – 1/2″ |

| HEAVY METAL USE | 18 | 1/8″ – 1/2″ |

| MEDIUM METAL USE | 24 | 3/32″ – 5/16″ |

| THIN METAL USE | 32 | less than 1/8″ |

| GLASS, CERAMICS, MARBLE, FIBERGLASS, AND STEEL | Carbide Rod | – |

The values provided on this chart are a general guideline. Blade TPI recommendations can be found on each manufacturer’s product packaging. Read the entirety of the article for more details.

Material thickness – not diameter – relates to blade TPI.

An economical and easy method to measure material thickness is to use a rule.

If you’re looking for the best high-tension hacksaws, check out our recommendations.

Best Hacksaw Blade for Mild Steel: 14-TPI Hacksaw Blade Overview

Use a 14-TPI blade to cut thick metal (over 1/8″) will speed up cutting compared to an 18-TPI blade.

| 1/8″ STEEL U-CHANNEL | 27 sec. | 30 sec. |

| 1/2″ REBAR | 24 sec. | 26 sec. |

Speed tests are an estimation based on hand cutting. New Lenox hacksaw blades were used for consistency.

Note 1: I am not sure why Lenox suggests using a 14-TPI blade for cutting wood. After several thick wood cutting tests (softwood and hardwood), I discovered a 14-TPI hacksaw blade is hopeless at cutting wood; the blade constantly gets hung up in the material. I also tried a Morse 14-TPI blade and had the same ineffectiveness.

I find that a 18-24 TPI blade works best for cutting wood, or switch to a dedicated wood cutting hand saw for better performance.

Note 2: A Lenox 14-TPI blade has a minimum thickness rating of 1/8″, whereas a Morse 14-TPI blade has a minimum thickness rating of 3/16″. We tested both brands of blades to find the truth in these guidelines.

- The Lenox 14-TPI blade effectively cuts 1/8″ thick material, as stated.

- The Morse 14-TPI blade struggled to cut below 3/16″ and is ineffective in cutting 1/8″ thick material.

- Used to cut pipe, tubing solids, wood, plastic or any machinable metal

- Increased heat and wear resistance for long life

- Flexible to prevent shattering during use

- 10 blades per pack

Note 3: Finding 14-TPI blades at local home improvement stores may not be possible, and many of the hacksaw blade brands don’t offer a 14-TPI model. Don’t worry, a 14-TPI blade isn’t needed for homeowner projects. However, a tradesman that cuts heavy metal regularly may want to experiment with a 14-TPI blade compared to using a 18-TPI blade.

Best Hacksaw Blade for PVC Pipes, and Steel Rods: 18-TPI Hacksaw Blade Overview

A 18-TPI blade gives you many of the same cutting abilities as a 14-TPI blade, but with less effort and smoother cutting.

Cut a wide range of wood thicknesses. A hacksaw isn’t the ideal choice for cutting wood, but for random projects where precision cutting isn’t needed, a hacksaw will get the job done, e.g. cutting a tree limb, demoing a small wall or building structure.

A hacksaw is very effective for plumbing projects that use PVC. A 18-TPI blade cuts through PVC tubing, whether trying to cut and remove existing plumbing, or cutting new PVC to length for a plumbing project. E.g. replacing a garbage disposal, sump pump, or an outdoor drainage project. A heavy-duty utility knife works well to deburr the PVC after each cut.

- T2 Technology provides a long hacksaw blade life

- Shatter-resistant, bi-metal construction allows saw blades to bend and flex without breaking

- Saw blades cut through black pipe, Unistrut, copper pipe, hardened steel, threaded rod and rebar

- 18 TPI

- 12″ L x 1/2″ W

Note: A DeWALT 18-TPI blade has a material thickness rating of 1/4″ – 1/2″. Most other 18-TPI blades have a minimal material thickness rating of 1/8″, which the DeWALT 18-TPI blade cut effectively too. A confusing discrepancy in DeWALT’s 18-TPI nominal material thickness recommendation.

- Model Number: DWHT20558

- Item Package Length: 13.8582677024″

- Item Package Width: 8.0314960548″

- Item Package Height: 0.2362204722″

Best Hacksaw Blade for Cutting Aluminum, Steel, and more: 24-TPI Hacksaw Blade Overview

A 24-TPI comes standard on hacksaws and from our tests offers the most range. The tooth count and size isn’t too small nor too large.

Note 1: Lenox rates their 24-TPI blade to cut 3/32″ thru 5/16″ for hardened materials, but a wider range of softer materials can be cut.

- The LENOX hacksaw uses an I-beam construction, allowing the blade to tension up to 50,000 psi

- Rubberized handles allow for confident handling, even in wet and cold environments

- Hacksaw accepts any LENOX reciprocating saw blade to be used as a jab saw

- LENOX hacksaw stores up to 5 extra 12-inch hacksaw blades in the I-beam

- All hacksaw come with one 12-inch, 24 TPI hacksaw blade

When you need to cut a metal bar or a rod, a tried-and-true hacksaw gets the job done.

We may earn revenue from the products available on this page and participate in affiliate programs.

The hacksaw is a time-tested hand tool for cutting through metal materials such as pipes, studs, and rebar. The best hacksaw for metal should be strong and durable, and the user should be able to change blades and adjust the blade tension with ease.

Hacksaws lack the “glamour” of other saws, but there is plenty to consider when purchasing or using one. For example, the intense friction when cutting through metal causes a hacksaw blade to become warm, which can make it expand. When it does, the tension will start to loosen, and the user will need to adjust the tension to tighten it before continuing.

This buyer’s guide includes some of the most important criteria to bear in mind while shopping for a new hacksaw. We used these criteria to identify and field-test nine terrific choices for consideration. Read on to learn more about hacksaws and why we recommend these models as among the best hacksaws available.

- BEST OVERALL:DeWALT DWHT20547L 5-in-1 Multifunction Hacksaw

- BEST BANG FOR THE BUCK:Craftsman CMHT20138 12-Inch Solid Frame Hacksaw

- BEST COMPACT:Capri Tools 12-Inch Mini Hacksaw

- BEST FOR PROFESSIONALS:Stanley FatMax 5-in-1 Hacksaw

- BEST FOR CRAFTING:Pasco 4290 Tiny Tim Hacksaw

- BEST SMALL:Milwaukee 48-22-0012 Compact Hacksaw

- BEST HEAVY-DUTY:Klein Tools 702-12 High-Tension Hacksaw

- BEST HIGH-TENSION:Lenox HT50 High-Tension Hacksaw

How We Tested the Best Hacksaws

In compiling our guide for the best hacksaws, we scoured the internet for clues, keeping in mind all the reasons anyone would need such a tool. Our prospects came from search engine results, reputable tool brands, retailer recommendations, and top user reviews. We researched more than 30 hacksaws before whittling down the list to the eight found here.

We determined that the best hacksaw must offer excellent cutting performance for the price, as well as versatility for use in different circumstances. We noted that these tools typically come with a general-use blade that can be replaced easily and cheaply for better performance on different materials. Our tests therefore focused on the hacksaw frame rather than the blade. In total, we spent 5 hours testing the saws in this guide.

We set up three tests in which every saw was used to cut the same materials in the same way as all of the others. The first test involved cutting 4-inch PVC pipe that was laid across sawhorses and held in place by hand. The second test was cutting ½-inch rebar clamped in a bench vise. The third test was flush-cutting 16d framing nails that had been partially hammered into a 2×4 stud. We replicated each cut three times for each saw.

We recorded the physical measurements of each saw, including blade length, saw weight, and throat depth. Our subjective observations answered questions regarding user comfort, maneuverability, difficulty of changing blades, and what we perceived to be the best uses for each saw. We then scored each hacksaw on a rubric based on our notes and compared them to come up with the award titles shown in the guide.

Our Top Picks

To earn a spot in our lineup of some of the best hacksaws, each of the following models had to meet a high standard of quality, durability, and performance. Ahead, find out how each one performed in our hands-on tests.

DeWALT DWHT20547L 5-in-1 Multifunction Hacksaw

We chose the DeWALT 5-in-1 multifunction hacksaw as our top pick because of its rugged build and versatile functionality. The saw features a stout steel frame with ergonomic rubber grips at the rear and front of the frame. Though the product listing states just one hacksaw blade, there are two blades included: a 12-inch 24-TPI bimetal blade and a 6-inch 6-TPI reciprocating saw blade. The saw is like a transformer, as it can switch from being used as a hacksaw to being used as a jab saw.

The saw’s base configuration securely holds the blade at 330 pounds of tension and offers a maximum 4¾-inch throat clearance for cutting larger materials. For more convenience, the saw can be reconfigured easily for low-profile, long-reach, or 45-degree-angle sawing. over, the front handle can be removed from the frame and loaded with the reciprocating saw blade for use as a jab saw.

In our tests, the DeWALT had adequate throat clearance to make square cuts through 4-inch PVC pipe, although the included 24-TPI bimetal blade is best suited to cutting metal. In the 45-degree configuration, it was fairly easy to flush-cut nails protruding from a vertical 2×4 wall stud. The blade also held steady enough to cut through ½-inch rebar. We did experience some wobble and vibration, but the cuts were mostly smooth and clean throughout.

The one design flaw we noted was the stiff sliding mechanism below the handle that makes it somewhat difficult to change blades. Also, with so many available options, we were surprised at the lack of clear instructions for reconfiguring the saw.

The only other saw we tested with similar functionality was a Stanley hacksaw, but it held its blade with less tension in the basic configuration, which led to a less smooth operation. The DeWALT’s high tension and 45-degree setups were very similar to the Lenox and Klein Tools saws, but those saws were more precise because of their significantly higher tensile strength. Taken all together, the DeWALT hacksaw offered great cutting capability for different settings, with custom configurations for user comfort.

- Weight: 2.38 pounds

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI bimetal blade, and one 6-inch 6-TPI reciprocating saw blade

- Heavy-duty steel frame and rubber grips for rugged work in comfort

- Ideal for cutting a wide variety of metals or plastic

- Holds blade securely with 330 pounds of tension for precise cutting

- Easy to reconfigure the blade and handle for different sawing projects

Craftsman CMHT20138 12-Inch Solid Frame Hacksaw

Take advantage of the benefits of a hacksaw without spending a lot of money. The Craftsman 12-inch hacksaw has a full solid-metal frame for durability, even with frequent use, and supports blade tension up to 225 pounds. It also comes with a large wing nut at the base of the handle for quick tensioning adjustments.

The hacksaw has a carbon steel 24-TPI blade that is perfect for cutting most metals and accepts all standard 12-inch blades, which can be ordered online or found at any home improvement store. The large pistol-grip handle is ergonomically curved for comfort, and the saw comes with the ability to turn the blade 90 degrees for easy flush cutting.

In our tests, the Craftsman hacksaw delivered value beyond its price. The lightweight metal frame was reminiscent of the classic pistol-grip hacksaws that were once ubiquitous, but with an updated D-handle and textured plastic grip that felt more secure and comfortable than the old style. Square blade-mount pins held the blade securely, either parallel with the frame or perpendicular (90 degrees) to it for flush cutting. The saw’s simplicity made it fast and easy to change blades or adjust the angle.

The included carbon steel blade did a fantastic job cutting PVC pipe and a good job on rebar. Flush cutting was effective at the 90-degree setting but less comfortable compared to the saws that were capable of 45-degree cutting. Although we had to work a little slower to avoid wobble and vibration due to low blade tension, this lightweight saw makes a great budget-friendly option for occasional use where precision is not required.

- Weight: 1.23 pounds

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI blade

- Affordable price but not cheap hacksaw quality

- Large tensioning wing nut and square retainer pins for a secure connection

- Ergonomic plastic handle with a textured grip for comfort

Get the Craftsman hacksaw at Amazon, Lowe’s, or Fleet Farm.

Capri Tools 12-Inch Mini Hacksaw

For metal cutting in tight spaces, the Capri Tools mini hacksaw doesn’t disappoint. Its slightly adapted design accommodates either 10-inch or 12-inch hacksaw blades. Though this mini saw doesn’t feature a tension adjustment (most of the blade extends in front of the frame), it holds the blade securely for clean cutting action.

The saw comes with a 12-inch 24-TPI blade, and it features an ergonomic padded grip to reduce hand fatigue and ensure a tight hold on the saw. It’s lightweight (less than 7 ounces) but surprisingly durable. The Capri Tools saw is a standout for cutting bars and poles in areas where a standard hacksaw just won’t fit.

In our tests, the design of the Capri mini hacksaw made it easy for us to start a cut at the supported rear of the blade and complete cuts through deeper material such as PVC using the blade tip. The blade fully extends to 8.5 inches, freely beyond the support. It did a quick and competent job on the 4-inch PVC pipe. Because of blade flex at the tip, we used the rear of the blade exclusively when it came time to cut rebar, which worked out fine although slower than that of conventional hacksaws. Flush cutting worked well if we were patient and methodical to avoid placing excessive pressure on the blade tip.

This inexpensive saw is made of two pieces of stamped steel that are riveted together. Such a construction makes for a lightweight saw with a very flat ½-inch-thick profile. It fits easily into a typical tool box. The hollow inside the handle is larger than the saw blade so that when it is retracted, the blade moves around inside. As a result, the saw is slightly less precise than the Milwaukee mini hacksaw we tested but a great choice because of its longer reach.

- Weight: 6.5 ounces

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI blade

Get the Capri Tools hacksaw at Amazon, The Home Depot, or Lowe’s.

Stanley FatMax 5-in-1 Hacksaw

From a name synonymous with quality tools comes the Stanley FatMax 5-in-1 hacksaw. This versatile tool can be configured for 90- or 45-degree sawing and low-profile or extended-reach cuts. The saw accepts 12-inch blades, and its front handle also can be removed for use as a jab saw. One 24-TPI blade and one 6-TPI reciprocating saw blade come with the saw purchase. The saw body offers onboard storage space for up to five additional blades.

The comfort grip handle on the Stanley reduces hand fatigue and helps the user achieve and maintain a firm grip for the lengthy task of cutting metal. Pros or DIYers can remove the front section of the saw to turn it quickly into a jab (reciprocating-shaped) saw for reaching into tight spots. Tension adjustment requires a Phillips-head screwdriver.

The Stanley FatMax 5-in-1 hacksaw looks similar to and is nearly exactly the same as the DeWALT, but it weighs a few ounces less and claims only 220 pounds per square inch (psi) of maximum blade tension. In our tests, these differences did not translate to a noticeable variance in performance. Stanley delivered excellent versatility, good-to-excellent cutting performance, and excellent durability.

We cut through a 4-inch PVC pipe, sliced off sections of ½-inch rebar, and cleanly flush-cut nails protruding from a wall stud. The slight flex of the blade led to some issues with vibration in the work pieces, but the cuts were close to square and fairly clean. Also like the DeWALT, no instructions for reconfiguring the saw were included, but a mechanically inclined DIYer will figure it out quickly enough.

We didn’t love the stiff-sliding blade-attachment mechanism, but again, we worked it out. Overall this heavy-duty hacksaw would make a great choice for consistent hard use and even some abuse.

- Weight: 2.2 pounds

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI blade, and one 6-inch 6-TPI reciprocating blade

- Blade tension is adjustable up to 220 psi

- Ergonomic comfort grip makes working with it easier

- Onboard blade storage is convenient

- Converts to a jab saw easily, making the saw even more useful

Get the Stanley hacksaw at Amazon.

Pasco 4290 Tiny Tim Hacksaw

The Tiny Tim Hacksaw lives up to its name—it’s just 10 inches long, from tip to tip. It holds a compact 6-inch blade, which is a good size for cutting small metal, such as copper tubing, or even for cutting small sticks and dowel rods. In addition, it weighs less than 4 ounces.

The Tiny Tim saw features a one-piece frame that holds the blade and forms the saw’s handle. The handle portion is coated in vinyl to make gripping more comfortable and to offer a bit of nonslip traction. The angular front part of the frame enables the user to cut metal tubing in tight spots. Although this hacksaw may be just the ticket for crafters, it’s not large or sturdy enough to cut bigger metal pipes and rods.

The Tiny Tim hacksaw is ideally designed for cutting thin gauge material. It was way too small for our 4-inch PVC cutting test, since the throat depth tapers from 2 inches to 0, so we scaled down to ¾-inch pipe instead. We performed our standard tests on ½-inch rebar and flush-cutting nails. Overall performance was good, with low-to-moderate vibration and good precision on most cuts.

The lightweight wire-handle design made for excellent maneuverability, and the saw stores easily on a pegboard or in a tool box or drawer. Changing the blade requires either strong hands to flex the stiff handle or a set of slide-lock pliers to make the squeeze. The blades have short posts on either end that slide into slots in the saw handle and are held in place by spring pressure.

- Very lightweight and small, which is perfect for crafters and model makers

- Well suited to cutting tiny rods, tubing, and other small items

- Vinyl-covered grip helps make it more comfortable to use

Get the Pasco hacksaw at Amazon or Big Frog Supply.

Milwaukee 48-22-0012 Compact Hacksaw

The Milwaukee compact hacksaw stores and works easily in cramped quarters. Its unique straight cutting design accommodates either 10-inch or 12-inch hacksaw blades. The blade slides into the handle and quickly adjusts in or out with the flip of a lever.

The saw comes with a 10-inch 24-TPI blade. It features a cast-aluminum frame and an ergonomic rubber nonslip grip to reduce hand fatigue. At just more than 8 ounces, it is lightweight but surprisingly durable. This Milwaukee saw excels at cutting metal, plastic pipe, or plastic rod in snug spaces where other saws will not fit.

In testing, we preferred the thick, round handle of the Milwaukee compact hacksaw over the similarly designed but thinner and lighter Capri Tools model. The solid cast-aluminum saw frame featured a snug slot that allowed the blade to slip freely in and out, without allowing excess movement when sawing.

The toolless blade-attachment system was easy to use, strong, and super convenient. The 10-inch blade adjusts longer or shorter by releasing the lock lever, sliding the blade further into or out of the handle, and relocking. The free space beyond the attachment point ranges from ¾-inch to 5¾-inches—enough to cut a 4-inch PVC pipe. This saw cut at about the same rate as the Capri Tools model did, but with better precision because of reduced blade movement. This tool is a great choice for frequent users.

- Weight: 8.1 ounces

- Blade length: 10 inches

- Blade(s) included: One 10-inch 24-TPI blade

- Compact size fits easily into a tool box or tool belt

- Ergonomic nonslip handle design reduces hand fatigue

- Toolless blade-attachment system for convenient replacement or adjustments

Get the Milwaukee hacksaw at Amazon, The Home Depot, or Northern Tool Equipment.

Klein Tools 702-12 High-Tension Hacksaw

Higher blade tension protects against bending and twisting for faster, cleaner cutting under tough conditions. The Klein Tools high-tension hacksaw has adjustable blade tension up to 30,000 pounds for fast, precise cuts. over, a slot on the front of the frame lets users attach a reciprocating saw blade for use as a jab saw.

The kit comes with a 12-inch 24-TPI bimetal hacksaw blade and a 6-inch 24-TPI bimetal reciprocating saw blade. Two sets of blade mounts accommodate straight or 45-degree cutting. Rubber grips make the saw more comfortable and less likely to slip. An onboard storage compartment holds additional saw blades at the ready, to replace a broken blade or when a different blade type is required.

When we tested the Klein Tools hacksaw, we started by tensioning the blade as tightly as possible by hand. Without a tool to test the pressure, we could note only that it was tight enough to strongly resist manual twisting or bending by hand.

When we cut the 4-inch PVC pipe, it was easier to finish the cut because of a generous throat depth, deeper than that of the DeWALT or Stanley hacksaws reviewed in this guide. With less interior taper, the Klein Tools hacksaw had a throat depth greater than 4 inches along 7.5 inches of the blade, while DeWALT and Stanley, which tapered more, had a 4-inch or greater throat depth for 5.25 inches. The longer length allowed for longer cutting strokes, which made the work go faster.

Additionally, we noted the ease and precision of the cuts. On PVC and steel alike, the tight blade moved much more smoothly and with less vibration compared to other models. This hacksaw was definitely built to tackle harder jobs with ease.

- Weight: 2.0 pounds

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI blade, and one 6-inch 24-TPI reciprocating blade

- Secures 12-inch hacksaw blades with up to 30,000 psi of tension

- Two sets of blade attachment points for a straight or 45-degree cutting angle

- Onboard storage for extra saw blades

- Includes an attachment point at the front of the saw for a reciprocating blade

Get the Klein Tools hacksaw at Amazon, The Home Depot, or Acme Tools.

Lenox HT50 High-Tension Hacksaw

The advanced tension control on the Lenox 12-inch high-tension hacksaw will have users sawing through bars and cutting metal thresholds without a glitch. Turn the tension knob on the 12-inch saw blade to tighten blade tension for making clean, sharp cuts easily. With its durable frame and rubberized secure-grip handle, the Lenox hacksaw makes the cut for the best overall hacksaw for most users.

The saw weighs about 1.85 pounds, hefty enough to hold up to metal cutting but not so heavy as to be cumbersome. It comes with one blade with 24 TPI and room to store five blades in the saw’s handle. The Lenox saw will also convert to a jab saw when fitted with a 6-inch Lenox reciprocating blade (not included).

The Lenox high-tension hacksaw made smooth, clean cuts with ease. The blade tensioner was much easier to operate than the one on the Klein Tools saw because of its position above the handle and its chunky, easy-to-grip size and shape. Judging from the high-pitched sound of the blade when plucked, it was much more taught than any of the other saws.

Weighing less than 2 pounds and equipped with a supertight blade, the Lenox saw was a pleasure to work with. Like the other conventional hacksaws, the blade could be mounted straight or at a 45-degree angle. It easily made straight, clean cuts in all phases of our test. It especially stood out in the 4-inch PVC test because it had the most consistent throat depth of all the saws we tested: greater than 4 inches along 8 inches of the blade. Although it lacks the versatility and tight maneuvering that some of its competitors manage, the Lenox was a top contender for speed and precision on conventional hacksawing projects.

- Weight: 1.85 pounds

- Blade length: 12 inches

- Blade(s) included: One 12-inch 24-TPI blade

- Adjustable blade tension up to 50,000 psi for precision cutting

- Converts to jab saw with a front-mounted reciprocating saw blade

- Stores 5 blades in frame to conveniently cut different materials

Get the Lenox hacksaw at Amazon, Lowe’s, or Acme Tools.

What to Consider When Choosing the Best Hacksaw

The hacksaw is easily identifiable by its C-shaped frame, which is designed to hold a thin blade by securing it at both ends. Depending on the individual hacksaw, the blades can usually be inserted with the cutting teeth pointed in either direction, which allows the user to cut using either a pulling or a pushing motion—whichever best suits the specific cutting situation. As a rule, however, hacksaws often work best when their teeth are oriented in a forward configuration, which allows the user to cut on the forward (push) stroke rather than cut on the backward (pull) stroke.

Although hacksaws—like miter boxes—are straightforward hand tools that don’t come with a lot of bells and whistles, for the best cutting results, it’s ideal if the user chooses a blade that is best suited to their cutting needs. In addition, before starting, the user should consider whether they’ll be able to hold the material securely as they cut. If not, using clamps can secure the material to keep it from moving while sawing.

Blade Type

Hacksaw blades are sold by their pitch, which indicates how many teeth a blade has per inch. Standard hacksaw blades come with 12 to 32 teeth per inch (TPI). Typically, longer blades have fewer teeth per inch, while shorter blades have higher TPI counts.

- Coarse-grade blade: With 12 to 18 TPI counts, these hacksaw blades are made for aggressively cutting through steel pipes and other metal items. However, the low number of TPI can leave small jagged edges on the cut surfaces.

- Medium-grade blade: TPI (20 to 24) leave a smoother cut surface on the ends of pipes and bars, but a medium-grade blade takes longer to cut through materials. The most common TPI for a hacksaw blade is 24, and it is suitable for multiple hacksaw uses.

- Fine-grade blade: With between 24 and 30 TPI, a fine-grade hacksaw blade creates a smooth cut surface, but it is usually limited to cutting small thin pipes and bars, as it takes longer to saw through the material.

- Superfine-grade blade: Useful for cutting fragile metal rods and leaving smooth cut ends, superfine blades average 30 to 32 TPI. It will take longer to cut with these fine-tooth blades.

- All-hard blade: Available in various lengths and TPI counts, all-hard blades are made from hardened, tempered steel. They are well suited to cutting cast iron.

Fixed vs. Adjustable Frame

A fixed-frame hacksaw is made from a solid piece of steel, and it holds just one-size blade, such as a 10-inch blade or a 12-inch blade. An adjustable-frame hacksaw comes with the ability to lengthen or shorten the frame to hold different-size blades. Both types of hacksaws include pins, clamps, or wing nuts for securing the blades in place.

However, even adjustable hacksaws typically adjust to hold blades that are within only a couple of inches of one another. For example, an adjustable 10-inch hacksaw will normally hold blades only up to 12 inches long. It usually won’t accommodate small 6-inch blades. However, exceptions exist, and a few types will hold both long and short blades.

Handle Design

The most common type of handle on a hacksaw is a pistol grip, which allows the user to firmly grasp the handle to exert maximum pressure when sawing. A few models feature a straight stick-type grip in line with the saw blade—often called a “jab saw.” These handles are more common on small or mini saws that are used to cut thin metal.

Both types of handles often feature padded or rubberized nonslip grips that help the user grasp the handle without slipping and reduce hand fatigue. When choosing a hacksaw, keep in mind that a small grip may not be comfortable—even with a relatively short saw. The grip should be large enough for the user to get a firm hold for the best results.

Material

Hacksaws usually are made from lightweight carbon steel or aluminum alloy and feature a variety of materials for handles, such as wood and molded polyethylene.

Like many drill bits and saw blades, the best hacksaw blades often are made from high-speed steel (HSS), which contains alloys such as tungsten and molybdenum that can withstand the high temperatures created by friction. A lot of heat can be generated when sawing through a steel pipe, so blades made from HSS will last longer than older carbon steel–type blades.

Length

Most hacksaws accept blades between 10 and 12 inches long, although compact models will accept blades as short as 6 inches. A few styles come with the ability to extend the blade past the end of the frame for use as a jab saw. Although these hacksaws still take standard-size blades, they also accept reciprocating blades, and they are well suited for sawing in tight spots with just the tip of the blade when the entire saw frame is too large or cumbersome to fit.

Weight

Hacksaws vary in weight from a few ounces for mini models to 2 pounds or more for standard models that hold full-size blades. A heavier saw adds stability when cutting thicker metal pipes and bars, but a lightweight model is greatly appreciated by those using a hacksaw overhead. Still, most hacksaws are relatively light in weight compared to other hand tools.

Additional Features

Users won’t find a lot of extras to choose from when shopping for hacksaws, but a few options are worth checking out:

- Blade storage: One of the handier features is onboard blade storage. When blade storage is available, spare blades typically are held within the saw frame—and are accessible by sliding them in from one end.

- High-tension adjustment: Straight, clean cuts require a firm blade, and some hacksaws come with a high-tension adjustment that tightens the blade to a high degree. Still, most blades need frequent readjusting, since just the process of sawing will loosen them.

- Conversion frames: Some hacksaws come with a frame that converts from a standard hacksaw configuration to that of a jab saw—similar to a reciprocating saw—with the end of the reciprocating saw blade poking out in front. This makes it simpler to reach pipes located in tight spots.

FAQs

A hacksaw is a straightforward hand tool that doesn’t require knowledge or a particular skill to use. While hacksaws are made specifically to cut metal, such as pipes and rods, they’re also suitable for cutting small wood and plastic items. Those looking for a hacksaw with a specific purpose in mind will likely have some questions.

Q. How do you choose a hacksaw?

First, select a frame that’s suitable for the work you’ll be doing—for most DIY projects, a standard frame that accommodates a 10- or 12-inch blade is best. For crafts, a smaller one is preferable. Next, select a blade that suits the material being cut—coarse blades cut quickly but leave jagged ends. Fine blades leave smoother-cut ends but require more time and effort to cut through the material.

Q. Can a hacksaw cut nails?

Yes, in fact, a common way to disassemble wood furniture, crates, or other nailed items is to cut the nail between the two adjoining boards with a hacksaw.

Q. Can you use a hacksaw for wood?

A hacksaw can make cross-grain cuts in wood in a pinch. It’s best suited for cutting small items, though, such as dowels or thin boards.

Q. What is a high-tension hacksaw used for?

High-tension hacksaws are used for similar purposes as lower-tension hacksaws—to cut through metal pipes and rods. However, a high-tension saw holds the blade tighter, keeping it from bending, which speeds the cutting process.

Q. How do you handle a hacksaw?

When the blade is installed with the teeth facing forward (the most common configuration), hacksaws cut on the push stroke. In some cases, the user may want to turn the blade around, in which case, the saw will cut on the pull stroke.

Q. Do hacksaw blades get dull?

Hacksaw blades can and do get dull, but today’s high-speed steel helps them stay sharp longer. A tip for making hacksaw blades last longer is not to saw too rapidly—between 40 and 60 strokes per minute is about right. Any faster than that, and the blade can become overly hot and dull (or snap).

When woodworkers are choosing the correct circular saw blade or jigsaw blade, the number of teeth as well as the teeth shape and angle can impact the finish of the cut. This saw blade teeth guide will help you identify what is suitable for different material applications.

TPI explained

TPI is the number of teeth the blade has per inch. If you’re looking to cut wood or other soft materials, you’ll need a blade with a TPI of 6 up to 20.

For harder materials like metal, a TPI between 14 up to 36 is more suitable.

The number of teeth can be found on the blade.

Are more teeth better?

Generally, the higher the amount of saw blade teeth, the better the quality of cut and finishing. If you’re looking for a faster and rougher cut, then a blade with fewer teeth will be more suitable.

For example, if you are cutting aluminium or high quality finish when cutting laminate, you will want a higher number of teeth compared to blades for soft wood.

When blades have fewer teeth, they have deeper gullets (space in between teeth) which creates a more aggressive chiselling action. Norton Clipper TCT (Tungsten-Carbide Tipped) blades have gullets with a unique shape compared to standard gullets, which reduces the vibration and noise while cutting, as well as reducing the heat on the steel centre which makes it safer for the user.

The difference between tooth shapes

Not all teeth are the same. Different tooth shapes can affect the working speed and are more suited for cutting different types of materials. Make sure you choose the right type for the application and desired finish.

Common teeth profiles of Circular Saw Blades:

Alternate Top Bevel: This tooth design is bevelled on the top, with every other tooth being bevelled in the opposite direction of the adjacent teeth. Blades with these teeth are easy to re-sharpen.

Ideal for: Cross-cutting solid woods and veneered plywood.

For ripping wood. CLIPPER PRO WOOD RIPPING 160×1,8/1,2×20 Z24 (70184608040)

For finishing wood and composites. CLIPPER PRO WOOD FINISHING 250×3,2/2,2×30 Z48 (70184608109)

Tip: A higher tooth count provides a finer cut.

Triple Chip Grind: The trapezoidal teeth cut first, then the flat top teeth clean out chips and widens the cut. These blades are made for heavy duty cuts and can also be re-sharpened.

Ideal for: Really hard materials, like coated chipboards (HDF / MDF) and aluminium. This tooth delivers very clean cuts on laminates and non-ferrous metals.

For ripping. CLIPPER PRO LAMINATE 160×2,2/1,6×20 Z48 (70184608141)/span

For finishing. CLIPPER PRO ALUMINIUM 255×3,0/2,2×30 Z80 (70184608139)/span

Demolition: The cutting material of demolition blades is very complex.

Ideal for: Cutting poor quality chipboard, as well as wood with loose knots and nails due to its anti-kickback design to add safety. The blades also have a chip limiter at the back of the tooth shoulder that limits the maximum tooth bite for controlling the feed speed to the safe rate.

CLIPPER PRO MULTIMATERIAL 190×3,0/2,0×30 Z20 (70184608129)

For added safety, Wood Composites ripping blades in the larger diameters also use this design. These blades feature big teeth bites (the distance between two teeth), so it is necessary to use these on a machine that has a chip limiter to control the feed speed, to prevent the kickback.

Common teeth profiles of jigsaw blades:

Milled: This design is less finely sharpened and tears the wood fibres rather than cuts. It’s more aggressive and results in a faster, but rougher cut. The saw set leaves traces during the movement of the blade from top to bottom, hence delivers a rough cut in the wood.

Ideal for: Metal and denser material as it lasts longer.

JIGSAW BLADE HCS 76 T218A (70184608380)

Wavy Set: This wave design maintains surface contact between the blade and the material to avoid jolting and thus ensures a straight cut.

Ideal for: Cutting thin parts, such as sheet steel or plywood.

RECIP BLADE BIM 228 S1122HF (70184608357)

Ground: This design creates a sharp edge with a very straight alignment of teeth. The edge of each tooth is perpendicular to the cutting axis, which allows each tooth to work over its entire width to deliver fine, sharp and very clean cuts.

Ideal for: Softer materials, such as chipboard

JIGSAW BLADE HCS 100 T101B (70184608371)

Ground Side Set: This design cuts according to the oblique angle of the teeth.

JIGSAW BLADE HCS 100 T244D (70184608375)

It’s all in the angle

The direction of the blade’s teeth, also referred to as the hook angle, are recommended for different material applications. The higher the hook angle, the more aggressively the saw blade will cut the material. This is great for getting through a lot of material fast, especially when you are ripping.

Low (negative) hook angles. those that have teeth that angle backwards (away from the direction of rotation), are good for crosscutting, cutting plywood panels or non-wood materials, such as plastics and metal. If you’re cutting plywood, MDF, OSB, laminate, melamine boards and particleboards, then an angle between.2° and.10° is recommended.

Four steps to selecting the right wood blade:

By understanding whether you need a higher number of teeth and the desired teeth shape, this helps you select the right blade to achieve the desired finish on your material. Download the Wood Range catalogue and follow these steps to choose the right blade for your needs:

Identify the material being cut

From this, you choose the relevant colour coded section with your ideal product.

Which machine will the product be fitted to?

Product information is grouped by machine type, e.g. circular saw

Which size blade is required?

Check the specifications of your machine.

Product dimensions can be found underneath each product line when viewing the product in the catalogue, e.g. 165mm with a 20mm bore.

Which type of cut do you need to achieve?

A variety of cut types are available, such as ripping and finishing. You can also see the teeth design information in the key specification data underneath each product line.

Download Catalogue

Using the saw blade

When working on wood materials, we recommend wearing a mask and safety glasses, as well as ear protection and gloves during heavy duty usage. It can also be beneficial to use a vacuum extraction unit to remove shavings or debris.

Before using any blade, systematically and carefully check your machine and blade conditions.

If a reduction ring is necessary, please thoroughly check its quality and ability to perfectly fit the bore of your blade.

We recommend regularly (if not after every use) cleaning your blades to extend the blade life and maintain the quality of cut.

To help understand the different types of wood, read the beginner’s guide to wood. For further information about wood cutting and choosing the right blade, get in touch with one of our Norton experts.

NORTON CLIPPER NON-WOVEN ABRASIVE HAND-PADS

Norton Clipper non-woven flexible hand-pads are designed to tackle multiple stripping, finishing and cleaning tasks. They are highly durable and flexible, safe and easy to use.

Hiring vs Buying Building Equipment

A guide for construction companies to decide whether to hire or buy construction equipment and tools.

Supporting the UK Construction Industry Post-Pandemic

Norton Clipper is helping builders and contractors get the most out of their building equipment and manage their costs effectively to help recover to pre-pandemic levels.

When woodworkers are choosing the correct circular saw blade or jigsaw blade, the number of teeth as well as the teeth shape and angle can impact the finish of the cut. This saw blade teeth guide will help you identify what is suitable for different material applications.

TPI explained

TPI is the number of teeth the blade has per inch. If you’re looking to cut wood or other soft materials, you’ll need a blade with a TPI of 6 up to 20.

For harder materials like metal, a TPI between 14 up to 36 is more suitable.

The number of teeth can be found on the blade.

Are more teeth better?

Generally, the higher the amount of saw blade teeth, the better the quality of cut and finishing. If you’re looking for a faster and rougher cut, then a blade with fewer teeth will be more suitable.

For example, if you are cutting aluminium or high quality finish when cutting laminate, you will want a higher number of teeth compared to blades for soft wood.

When blades have fewer teeth, they have deeper gullets (space in between teeth) which creates a more aggressive chiselling action. Norton Clipper TCT (Tungsten-Carbide Tipped) blades have gullets with a unique shape compared to standard gullets, which reduces the vibration and noise while cutting, as well as reducing the heat on the steel centre which makes it safer for the user.

The difference between tooth shapes

Not all teeth are the same. Different tooth shapes can affect the working speed and are more suited for cutting different types of materials. Make sure you choose the right type for the application and desired finish.

Common teeth profiles of Circular Saw Blades:

Alternate Top Bevel: This tooth design is bevelled on the top, with every other tooth being bevelled in the opposite direction of the adjacent teeth. Blades with these teeth are easy to re-sharpen.

Ideal for: Cross-cutting solid woods and veneered plywood.

For ripping wood. CLIPPER PRO WOOD RIPPING 160×1,8/1,2×20 Z24 (70184608040)

For finishing wood and composites. CLIPPER PRO WOOD FINISHING 250×3,2/2,2×30 Z48 (70184608109)

Tip: A higher tooth count provides a finer cut.

Triple Chip Grind: The trapezoidal teeth cut first, then the flat top teeth clean out chips and widens the cut. These blades are made for heavy duty cuts and can also be re-sharpened.

Ideal for: Really hard materials, like coated chipboards (HDF / MDF) and aluminium. This tooth delivers very clean cuts on laminates and non-ferrous metals.

For ripping. CLIPPER PRO LAMINATE 160×2,2/1,6×20 Z48 (70184608141)/span

For finishing. CLIPPER PRO ALUMINIUM 255×3,0/2,2×30 Z80 (70184608139)/span

Demolition: The cutting material of demolition blades is very complex.

Ideal for: Cutting poor quality chipboard, as well as wood with loose knots and nails due to its anti-kickback design to add safety. The blades also have a chip limiter at the back of the tooth shoulder that limits the maximum tooth bite for controlling the feed speed to the safe rate.

CLIPPER PRO MULTIMATERIAL 190×3,0/2,0×30 Z20 (70184608129)

For added safety, Wood Composites ripping blades in the larger diameters also use this design. These blades feature big teeth bites (the distance between two teeth), so it is necessary to use these on a machine that has a chip limiter to control the feed speed, to prevent the kickback.

Common teeth profiles of jigsaw blades:

Milled: This design is less finely sharpened and tears the wood fibres rather than cuts. It’s more aggressive and results in a faster, but rougher cut. The saw set leaves traces during the movement of the blade from top to bottom, hence delivers a rough cut in the wood.

Ideal for: Metal and denser material as it lasts longer.

JIGSAW BLADE HCS 76 T218A (70184608380)

Wavy Set: This wave design maintains surface contact between the blade and the material to avoid jolting and thus ensures a straight cut.

Ideal for: Cutting thin parts, such as sheet steel or plywood.

HACKSAW BLADE SPECIFICATION TYPES MATERIAL ( IN HINDI )

RECIP BLADE BIM 228 S1122HF (70184608357)

Ground: This design creates a sharp edge with a very straight alignment of teeth. The edge of each tooth is perpendicular to the cutting axis, which allows each tooth to work over its entire width to deliver fine, sharp and very clean cuts.

Ideal for: Softer materials, such as chipboard

JIGSAW BLADE HCS 100 T101B (70184608371)

Ground Side Set: This design cuts according to the oblique angle of the teeth.

JIGSAW BLADE HCS 100 T244D (70184608375)

It’s all in the angle

The direction of the blade’s teeth, also referred to as the hook angle, are recommended for different material applications. The higher the hook angle, the more aggressively the saw blade will cut the material. This is great for getting through a lot of material fast, especially when you are ripping.

Low (negative) hook angles. those that have teeth that angle backwards (away from the direction of rotation), are good for crosscutting, cutting plywood panels or non-wood materials, such as plastics and metal. If you’re cutting plywood, MDF, OSB, laminate, melamine boards and particleboards, then an angle between.2° and.10° is recommended.

Four steps to selecting the right wood blade:

By understanding whether you need a higher number of teeth and the desired teeth shape, this helps you select the right blade to achieve the desired finish on your material. Download the Wood Range catalogue and follow these steps to choose the right blade for your needs:

Identify the material being cut

From this, you choose the relevant colour coded section with your ideal product.

Which machine will the product be fitted to?

Product information is grouped by machine type, e.g. circular saw

Which size blade is required?

Check the specifications of your machine.

Product dimensions can be found underneath each product line when viewing the product in the catalogue, e.g. 165mm with a 20mm bore.

Which type of cut do you need to achieve?

A variety of cut types are available, such as ripping and finishing. You can also see the teeth design information in the key specification data underneath each product line.

Download Catalogue

Using the saw blade

When working on wood materials, we recommend wearing a mask and safety glasses, as well as ear protection and gloves during heavy duty usage. It can also be beneficial to use a vacuum extraction unit to remove shavings or debris.

Before using any blade, systematically and carefully check your machine and blade conditions.

If a reduction ring is necessary, please thoroughly check its quality and ability to perfectly fit the bore of your blade.

We recommend regularly (if not after every use) cleaning your blades to extend the blade life and maintain the quality of cut.

To help understand the different types of wood, read the beginner’s guide to wood. For further information about wood cutting and choosing the right blade, get in touch with one of our Norton experts.

NORTON CLIPPER NON-WOVEN ABRASIVE HAND-PADS

Norton Clipper non-woven flexible hand-pads are designed to tackle multiple stripping, finishing and cleaning tasks. They are highly durable and flexible, safe and easy to use.

Hiring vs Buying Building Equipment

A guide for construction companies to decide whether to hire or buy construction equipment and tools.

How to cut straight with a Hacksaw. Hacksaw Techniques 1

Supporting the UK Construction Industry Post-Pandemic

Norton Clipper is helping builders and contractors get the most out of their building equipment and manage their costs effectively to help recover to pre-pandemic levels.