How to cut off a bottom rafter correctly. Installation of rafters

Design features

The hip roof is a complex spatial structure that resembles a gable, but truncated along the pediments. Two of the four slopes are trapezoidal, connected in the skate. The other two have a triangular shape and are located along the ends of the building. These elements are called the Dolma from the German Walm. a beveled roof.

There are varieties of holly structures:

- Half.calmes, where the rollers are not completely blocked by the slope, but supplemented by a vertical pediment either in the upper part (Dutch) or in the lower (Danish);

- tent. all slopes are triangular and join at one point.

The rafter system of the hip roof consists of a large number of elements, different in section, length and position in space. It is recommended to start construction only after a thorough calculation of all components.

Pros and cons of holly roofs

Despite the complexity of the construction, such designs are very common both in Europe and they are distinguished by advantages over other types of roofs:

- high strength and rigidity;

- resistance to wind loads due to the streamlined shape;

- The weight from the roof is transmitted evenly to all the walls;

- No need to build pediments, their function is performed by rollers;

- compatibility with various roofing materials;

- the ability to use in different architectural styles.

- technically complex construction;

- large consumption of roofing materials;

- squatness that bended slopes give;

- small volume of attic space compared to a gable roof of the same size.

Hulm structures can be combined with gable, tent or conical. A variety of bloomers, turrets, protruding attic windows and other architectural elements look interesting, at the same time eliminate the squat structure.

Consumable materials for manufacturing

Rafters are made of wood and metal. But there are also universal frames where both of these consumables are combined. Therefore, they are acquired as consumables.

To perform work with your own hands, it is necessary to have simple skills in working with wood and compounds, observing the set parameters for the independent drawing.

Connections are provided:

Of the consumables in the construction of the rafter structure, also come in handy:

The rafters can be ordered in the form of a ready.made frame, or make them yourself. There are 2 types of system formation: inclined and hanging.

Dry board

The work uses trimming boards of different sections. The most common options are 50 x 150 and 50 x 200 mm, and for slopes up to 7-10 m. The wet board is not used, since when drying it gives cracks and bends, significantly reducing the strength of the structure.

In addition, it is easier on dry material to notice the shortcomings (a large number of knots, zabrin, through cracks and rotten places), which should not be.

The best material for strength, endurance and quality for the rafters is pine (ideally Siberian), but the blanks are also made from larch (budget option), beech and cedar (expensive in price).

Metal

The metal rafter system is used to create the greatest strength of the structure. Its quality directly depends on the chosen brand of the material. Most often used carbon steel with galvanized coating, which reliably protects the frame from corrosion.

Taurus, steel corners, pipe rectangular and round section are used to form the base and crate.

Galfalled steel profiles are characterized by steps up to 200 cm, and slopes. from 7 m. The frame on the beams is attached with durable details and welding. Metal structures have a long service life.

The advantage of such a frame is a high level of fire safety (NG group), and minus. a higher price than the wooden.

The material used. ordinary or glued beam (pine, larch, oak, beech, rarely. cedar). Rafter legs are recommended material with a thickness of 5 cm. Width-arbitrary, within 10-25 cm, length-6 m (standard). When working with individual projects, the length is sometimes increased.

Brick for Mauerlat in section. 15 x 15 cm. As auxiliary parts, racks, filly, struts and tights are used, with a cross section of 5 x 10 cm, and the crate is made from boards 2.5 x 10 cm.

All types are also attributed to consumables:

How to make rafter legs correctly?

The production of rafters is carried out in the factory (on machines). The tree is thoroughly polished, polished, dried to a certain degree of humidity, and cut according to the given dimensions. The storage of products is carried out in a special room in which an important requirement is observed. the compliance of atmospheric air 60% of the humidity.

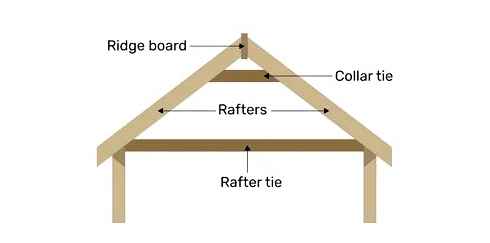

During installation, the rafters are laid by farms. two beams that are connected at the top of the frame in the form of a triangle. On top of them, the installation of the crate is carried out. The angle of inclination of the farm should fully coincide with the corners of the roofing slopes.

According to construction standards, they use such methods for attaching rafters as:

Cutting Valley and Jack Rafters for a Gable Dormer Ep.76

- Hard,

- sliding,

- with extension and strengthening,

- screwing a beam or logs with ends,

- as well as with the help of bilateral strengthening by embroidering.

The rafter leg has a step of no more than 60 cm. One installation board (integral or extensive) can reach a weight of 100 kg. The section of the rafters should be 1.5-2 times less than that of Mauerlat.

Here, when calculating, the specific weight of the used consumables material is taken into account, which can be viewed in GOST tables. The total roof tonnage is calculated by the number of M3 timber and boards used for the project. The gap between the middle of the rafters is on average 0.6 m.

Railing system of a hip roof: structure and installation

The hip roof is perhaps the most popular type of four.skeet roof. It is suitable for blocking private houses of large and small area, baths, even arbors. A recognizable geometry is given to it by a rafter system of a hip roof, a set of supporting elements operating as a frame.

The complexity of this design lies in a large number of components and mounting nodes, requiring special skills and experience. This article will answer questions about what it consists of, what materials are used for construction, as well as how installation work is performed.

The design of the hip roof

The hip roof belongs to the four.scatter type, that is, it is formed from four slopes, planes that have one common side. Two slopes that replace the pediments are called holm or end, they have a triangular shape. And the other two, in the form of trapezoids, indicate the term with facade. A fishing line for a trimmer, in which all four slopes converge. a horse, the highest part of the roof. The design of a holly type consists of:

- Holm slopes, which have the shape of a triangle, are located in a place belonging to the pediments.

- Trapezoidal strokes.

- Skate, lines that form the upper connection of the rafter pairs, the tops of the holly roof.

- An overhang protruding outside the perimeter of the house of a part of the roof formed due to the length of the rafter legs or films. It protects the surface of the walls from melt and rainwater.

- Rafter system of the holly roof, the frame of the roof structure carrier and distributes weight.

- Roofing material, coating, which is laid on the rafters of the hut roof to protect against atmospheric precipitation.

- Drainage systems of water diving accumulating on the roof. It consists of a gutter, a water intake and a drain pipe and tolerates moisture from the surface of the blood to a storm sewer.

- Snow retainers, elements that do not give snow masses accumulated on the roof, collapse and injure people passing by.

Tricks for a direct junction with Mauerlat

A simpler option is to make a connection. To do this, you need to determine the place of the cut and the angle of its inclination. For this purpose, you can apply two options: theoretical and practical.

For the theoretical method, you need to understand well in the geometry and calculate the desired angle on paper. Divide the distance from the skate to the cornice, by the length of the rafters. So, you will receive a mowing of the required angle. In order to transfer it to the workpiece, you can use either the end saw or a special square.

If there is no special tool at hand, make a simple template. Take durable material, for example, a wood-piece plate. On the sheet, mark 500 mm along the lower edge, then determine the tangent of the required angle and multiply by the measured length. So, you will get the second side of the rectangular triangle. Marking all the boundaries and cutting out the workpiece, get the right angle. Written down parts can be mounted immediately or wait until the whole kit is made.

In practice, you can easily mark a separate rafter, putting it on the design position. To do this, set the beam so that its lower part is flush with Mauerlat. Draw a horizontal fishing line for a trimmer from the corner to the lower part of the rafter, it should be strictly parallel to the wall. Now you can calmly saw off any improvised tool and install the part. The rest will serve as a template for the remaining rafters only if the base is even.

Knowledge of geometry helps not only in determining the angle of the rafter leg, but also in determining the height of the roof, the length of individual elements, and so on.

The design of the support points of the rafters

The upper part of the base rafter leg rests on the skate. The design features of the hip roof allow you to do this in several ways:

- If the roof design has one ridge run, then it rests on the skate console.

- If the rafter system has two skating gibberries and ordinary rafters from boards, then wean should rest on the Sprenhel, the foundation of which lies with skating ranks.

- If the design provides for two runs, and the rafters are made of a bar, then instead of a sprenigel is used. This element is made of trimming with a thickness of more than 5 cm and connects ordinary rafters near the skate.

Depending on the landing method, the upper part of the tach is chopped. You can fix the diagonals with nails, while enhancing the wire with a wire or a metal clamp is allowed.

In the lower part, the diagonal rafters of the hip roof with a support on the Mauerlat are attached using metal brackets or corners directly to the Mauerlat or to a specially installed corner beam.

The arrangement of people who are

Through the people, the rollers and the triangular parts of large slopes are formed. In the upper part, the element rests on the diagonal rafter, below. on Mauerlat or Beams of Crossing.

Narodnets are installed in two ways:

- With a cut. In diagonal rafters, nests are cut down at a distance of 20 cm from each other, while it should be remembered that the handicraft of the people of related stingrays should not be performed opposite each other.

- Installation of cranial bars that will act as supports for people. To do this, take bars of 55 cm and stick them to the lower part of the tach. This option is considered more effective, since the handling can weaken the strength and stability of the takus. In addition, the use of this method allows you to arrange people opposite each other.

The fastening of people in the lower part is carried out according to the analogy of the installation of ordinary rafter legs.

Tricks for a direct junction with Mauerlat

A simpler option is to make a connection. To do this, you need to determine the place of the cut and the angle of its inclination. For this purpose, you can apply two options: theoretical and practical.

For the theoretical method, you need to understand well in the geometry and calculate the desired angle on paper. Divide the distance from the skate to the cornice, by the length of the rafters. So, you will receive a mowing of the required angle. In order to transfer it to the workpiece, you can use either the end saw or a special square.

If there is no special tool at hand, make a simple template. Take durable material, for example, a wood-piece plate. On the sheet, mark 500 mm along the lower edge, then determine the tangent of the required angle and multiply by the measured length. So, you will get the second side of the rectangular triangle. Marking all the boundaries and cutting out the workpiece, get the right angle. Written down parts can be mounted immediately or wait until the whole kit is made.

In practice, you can easily mark a separate rafter, putting it on the design position. To do this, set the beam so that its lower part is flush with Mauerlat. Draw a horizontal fishing line for a trimmer from the corner to the lower part of the rafter, it should be strictly parallel to the wall. Now you can calmly saw off any improvised tool and install the part. The rest will serve as a template for the remaining rafters only if the base is even.

Knowledge of geometry helps not only in determining the angle of the rafter leg, but also in determining the height of the roof, the length of individual elements, and so on.

Full video report on the assembly of the rafter system

This film takes a little less than an hour, but the message is demonstrated from beginning to end with many details. The roof is placed on a frame house, but when installed on buildings of a different type (except wooden houses) there is no difference.

Light leg and tattoo rafters

When erecting holly roofs and roofs with yendov, rafters are installed, which are directed to the external and inner angles of the walls. Such rafter legs are usually called diagonal or somewhat. Contact rafters in length larger than usual, in addition, they serve as a support for shortened rafters of slopes, named people. That is why tattoo rafters in most cases take a load of approximately one and a half times larger than the standard type of such products.

The length of the clock rafters exceeds the usual length of the boards, so they are made paired. This solves several problems at once:

- Double section can withstand an increased load;

- Building boards allows you to create a long unpromitable beam;

- Mating of boards leads parts to one size.

Important! Drafts of rafters allows you to use the same boards for the device of a match type that are used for ordinary rafters. Simply put, the use of boards equal to the height to create all elements of the rafter device greatly simplifies the design of the structures of the holly roof nodes.

For a multi.flower row, one or two supports are installed under the diagonal leg. This type of rafters can be represented in the form of a bifurcated and tilted skate. Along the length of the board, they are spent so that the joints are at a distance from the center of supports equal to 15 percent of the span length, above which is the joint. That is, the length of the boards to create a match rafter must be selected, given the length of the span and the number of supports.

Popular BC released the application, officially download 1xbet on Android, by clicking on the link without registration and absolutely free.

Support for the bottom rafters

The support for the diagonal rafter leg is a standard subcase, it can also be a stand from a beam or two paired boards. The stand rests through a wooden lining and a waterproofing layer straight to an overlap made of reinforced concrete plates. The gear is installed at an angle of 45–53 °, and its bottom rests on the water.

Important! The angle of installation of a strut is not so important, the main condition is to maintain a sling of the rafters in the place of maximum load.

Continuated rafters made from two sections of ordinary rafter legs withstand the load calculated for ordinary products. If they overlap the flight to 7.5 meters, then they should be supported by the subskosta only in its upper part. When the tattoo rafter is longer and overlaps to 9 meters of span, in the lower part of it, another support is installed in the form of a rack or a sprenigel farm. Under the rafter more than 9 meters long, it is advisable to install the third support in the center, here you can only introduce a rack. Reinforced concrete overlap should withstand this, otherwise a beam is turned on in its design, which could lean on.

Sparengel farm is a beam of a beam, boiled along the overlapping external walls onto the corner. So that the beam does not bend much, the stand (sprengel) crashes into it and two struts are installed. Most often, during the construction of suburban houses of small sizes, this farm does not need to be calculated, because its components are accepted standardly from paired boards or beams with a total section of 100 x 100. for racks, 50 x 100. for struts and 100 x 150. for beams for beams.

The way the clock rafter leg is rested in the skate will depend on the quantity and location of the intermediate supports and the device of the main layered rafters:

- In the option with one run in the middle of the hip roof, the base rafter leg is based on the run console. Consoles are issued 10-15 centimeters for the undergrowth frame, because then the excess then it is much easier to saw off than to build up the missing in the process;

- In the case of two runs and a rafter system, a sprayel structure for runs is installed from the boards. It consists of a rack, with diagonal rafters attached to it at the top, and a horizontal beam;

- In the case of two runs and a design of bars, a warrior is sewn to the rafters in the skate (a short board with a thickness of at least 5 cm), on which tattered legs are rested.

Important! The bottom of the clock rafters when installed on a sprenigel, a subsurrent or run console should be pleased with the horizon and attached with nails. If necessary, such rafters are additionally attached to the supports with tight wire twisting or metal clamps.

Contact rafters, which are located in the valleys, can not be propped up with a sprenigel farm, because the angle of the walls that forms is internal, so that they are propped up with struts or racks. In this case, in contrast to the clock system, the maximum load falls on the lower part of the leg. It is here that it is necessary to put a subcase. But the angle of inclination of the strut, which is rested with the bottom into the lying, is too sharp, which is why the gear is either resting in the corner of the walls, or two struts are installed (one from the corner of the walls, the other from the head) with the upper part of them into each other. The point of maximum load is sometimes ignored and one subcuts at an angle of 45–53 degrees to the horizon are installed from the lieut.

The latter option may seem incorrect, because here the shock supports the rafters, it would seem, at all in the place where it is necessary. However, do not forget that when the third support is introduced under the beam of the third support, it becomes uncertain and two-span, which increases its bearing capacity. Therefore, the installation of a slope according to the latter option is quite often enough to ensure the necessary bearing capacity of the entire diagonal rafter of the double section, which is especially convenient with the planned increased load from the roof.

Important! Narodnets shame the layered rafters with an ordinary nozzle. they drink the upper part of the nuisor in one plane to the part, join and sewed with two or three nails.

Depending on the selected calculated scheme: spacer or brainwash, the bottom of the same rafter legs is emphasized directly in the Mauerlat or in the beam laid on the angle of the walls, or rests on them. This rafter system is similar to the usual. as well as standard rafter legs made with two or three degrees of freedom, they can be transmitted or not transferred to the walls to the walls. The angle of inclination of the base rafter leg, as is commonly believed, changes relative to the angle of inclination of ordinary rafters. This is true if we consider this rafter leg as a separate element. But if you project it to the rafters of the slopes united in turn, you can see that the angles formed by projections are equal to the angles of the slopes.

Important! If necessary, the upper plane of the base rafters laid on the rib of the holly roof can be stuck at an angle, and the rafters located in the yndovo, the crate is laid on them.

The installation between standard rafters of the surfs can create a “Danish roof”. If necessary, the places of fasteners of the saps to them should be supported by struts (undergone legs), the lower part of which rests on a rack or a lying. Or instead of ordinary ones, an enhanced (paired) pair of rafter legs is installed. In those places where the subway intersects with one or two racks, it is attached to them with nails and is propped up with trimming boards. The vertical plane obtained as a result on the hip roof is sheathed with leaf or chase material and, in most cases, are used to arrange in the attic under the skate of the window.

When you need to drink rafter legs?

The main supporting elements of the roof that provide its slope perceive the loads from:

Rafter Step Off Method. Made Simple

- crate;

- finish coating;

- snow;

- winds;

- spot efforts created by maintenance personnel, for example, when cleaning snow, performing inspections and minor repair.

The listed loads are distributed to the supporting enclosing structures, as well as on internal capital walls through racks with braces with large (more than 6 meters) spans of single.sided roofs. The walls of most modern buildings are designed for the perception of vertical loads and to a very small degree of lateral, most often arising from strong winds.

Therefore, the tasks included in the functions of designers and architects include ensuring measures to reduce the impact of such loads both on the enclosing structures (walls) and on the entire structure in general.

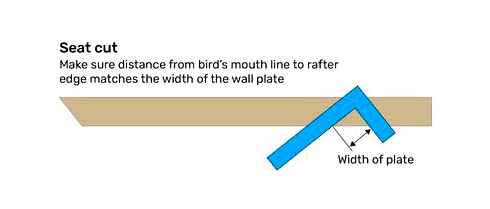

In order to ensure the decomposition of efforts in the supporting parts of the rafter legs so that the lateral (horizontal) force strives for its smallest value, and most of it has to be vertical load, special recesses are made, rectangular shape that crash into redistributive elements.

- In the brick, stone and concrete walls in the cornice parts of the supporting walls from the inner (attic) side, a special neckline is arranged, sometimes called a quarter in which a rectangular beam is laid. Mauerlat (in the simplest case, it can be a stroked simple log).

- In frame buildings, the horizontal strapping of the upper parts of vertical racks is used, most often consisting of two boards with a thickness of at least 3 cm each, knocked down by nails.

- In log cabins of a calibrated log or beam, this is usually the highest crowning reinforced element of the wall.

Wright should be such that, regardless of the slope of the roof, it had a horizontal and vertical platform.

How not to make a mistake with the size?

In order for the cutting of the rafter legs of the single.sloping roof to correctly redistribute the loads that affect them, they usually perform a not too complicated calculation using the recommendations of building codes and rules (SNiPs) in modern relevant editions of such as “loads and influences”, “wooden structures” and others.

For the same purposes, many different recommendations, instructions, methodological instructions related to the device of single.sided roofs are written.

How to cut it correctly?

The angles of the junction of the rafter legs are marked with the help of the Svenson zvens and the. Roofers have rules that they adhere to when cutting and fastening the rafters of a hip roof. This includes such nuances:

- It is important to maintain a single fishing line for the trimmer of the position of the rafters, for this you can use the template;

- As a template, you can use a piece of boards or plywood, where a fishing line for a trimmer from the lower edge will be drawn to a third part of the width of the rafter;

- A similar line is carried out on all the bars that plan to file.

Subsequently, the marking is transferred to the rafters, checking the accuracy of the finished product. Pass throughout the roof and check the degree of adjoining along the entire length of the Mauerlat. Drops of 2-3 mm are acceptable, if necessary, make adjustments.

Frequent errors and recommendations for construction

The hut roof is considered a complex design, so errors often occur during work. If you follow the recommendations of experienced builders, then errors can be avoided:

- use boards and a beam of one section for rafters;

- perform preliminary calculations before proceeding with work;

- All nodes of the rafter system should be reflected in the design documentation;

- The section of the rafters is selected in accordance with the roof material and its area;

- it is better to perform work with an assistant, since the long elements are not able to install one.

Without a project, proceeding with the design of the rafter system of the holly roof is not recommended.