How To Cut Pvc Panels

How and with what to cut PVC panels? Choosing a tool and learning to cut plastic correctly

PVC panels are a modern finishing material that has successfully and deservedly gained popularity in the field of interior decoration. They attract buyers with their price, ease of maintenance, stylish appearance, and most importantly. simple installation technology that can be done independently. Many people prefer them to tiles when decorating the walls and ceilings of bathrooms and toilets.

Choosing the right tool for cutting plastic panels

- What tool is suitable for cutting plastic panels?

- How to cut PVC panels correctly?

- Safety engineering

- -instruction

The only problem that the user faces during installation is that the standard panel length is 3 meters, while the ceiling height in panel houses is usually about 2.5 meters. And then the question arises. how and with what to cut PVC panels without damaging them? We will consider the answer to this question in the article.

How to cut PVC panels correctly?

To successfully cope with the task, it is worth knowing some secrets of cutting plastic. This will significantly reduce the number of rejected and damaged panels, and save a novice craftsman from wasting time, money, and, above all, from injuries.

- If you are finishing during the cold season, do not cut panels that have just been brought from the street. Let them warm to room temperature. The best option is for them to stay at room temperature for at least 1 night. Otherwise, plastic, which becomes brittle in the cold, will break off in large pieces, cracks may appear along the entire length of the panel.

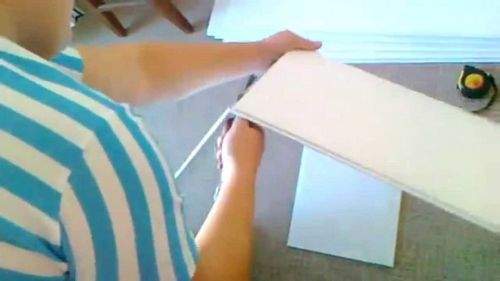

- Regardless of which cutting method you choose, place the panels face up (photo above), otherwise the panel may deform and its installation will cause difficulties. In addition, if you make an incision from the inside out, the front side may become covered with microcracks, which will manifest themselves only over time, finally ruining the design. It will not be superfluous to mark the cutting line in advance, for this a simple pencil or felt-tip pen (which can be easily erased from the surface after finishing work) and a student’s ruler are suitable.

- To cut several PVC panels at the same time, you need to stack them and make a two-point support for this stack so that the panels do not sag. It is also worth resting the opposite edge of the stack against the wall, otherwise the panels will move during cutting and as a result, parts of different lengths will be obtained.

What tool is suitable for cutting plastic panels?

In the arsenal of finishing masters, there are many ways to cut plastic. And everyone who is engaged in repairs on their own can choose any of these methods, use a professional tool or improvised means, based on their needs and capabilities. Let’s take a closer look at all the pros and cons of each method:

-

Plastic cutter

Hacksaw. For plastic, a tool with small teeth is suitable, pay attention that the teeth on the blade are not spread in different directions. So the cut will turn out to be even, smooth, the plastic will not crumple. It is convenient to cut several panels at once with a hacksaw, stacking them on top of each other.

Electric jigsaw. With it, the process of trimming panels will be much faster than with a hand tool. But there are some nuances of working with a jigsaw:

1. Switch off the pendulum motion immediately. 2. Use a file with fine teeth. 3. Adjust the speed of the file (choose the lowest one so as not to melt the cut). The jigsaw will perfectly cope with the task of cutting stacked panels, the main thing is that the stack height does not exceed the length of the file.

Angle Grinder

Angle Grinder. The most convenient tool for cutting PVC panels, using an angle grinder with a cutting disc, you can make both straight and curly cuts. It must be remembered that when cutting plastic, the tool must be operated at the lowest speed, otherwise the cut edge will melt and the panel will be damaged.

Knife

Knife. In the absence of a more convenient tool, you can use a simple kitchen or office knife. The narrower the knife blade is, the easier the cutting process will be. A loaf knife with a serrated blade is ideal, it leaves an even edge without breaks and fraying.

Safety engineering

When cutting plastic panels, especially with an electric tool (jigsaw or angle grinder), there is a high probability that sawdust and debris will fly off the material. Therefore, it is worth purchasing protective glasses and gloves in advance, which will protect your eyes from injury, and it is recommended not to take them off until the end of the work.

Regardless of which tools you decide to use, the above tips will help you avoid the mistakes of most inexperienced finishers and create a cozy interior that will delight for many years.

What is needed?

Currently, a huge number of tools have been created, thanks to which it is possible to shorten the length of a particular material. When working with plastic panels, it is necessary to take into account many factors, among which the main ones are practicality, cutting speed, surface quality, as well as ease of use.

How to cut PVC panels: tool selection

- Application of panels

- Cutting rules

- What is needed?

- Cutter

Undoubtedly, tiles are considered to be a classic material for finishing a bathroom, however, PVC panels have an increased installation speed, and additional care of this material is not required, because neither soap nor water is deposited on their surface. Initially, plastic panels worked well due to their ease of installation. To carry out such work, you will not need help from specialists and a complex tool.

Cutting rules

For safe work, you must clearly follow the following rules:

- When working with panels that were brought in from the cold, you must wait a short period of time. This action is necessary in order to warm the material. If you do not heed the advice, then the plastic panels will break during the cutting process, thereby losing their neat appearance. There are often cases when cracks appear on the surface that is cut along.

- In order to obtain several planks of the same length, it is necessary to lay them on at least 2 supports. This protects against sagging or displacement. It is recommended to rest the edge of the element that is not pruned against the wall. Thanks to this action, you can secure against their shift.

- You can make the process easier by marking with a pencil or felt-tip pen.

- It is necessary to cut correctly with the wrong side of the panel down, because during processing under the influence of a load, the profile of the strip changes and causes some inconvenience during the installation process. Microcracks often appear on the front surface, which appear in the future.

- When using a power tool, use protective goggles and gloves that can protect against debris and sawdust flying in different directions during the cutting process.

Hacksaw

A hacksaw is considered more practical to use, and it does not matter whether it is for metal or for wood. The only requirement when using a hacksaw for wood is the presence of small teeth, which should not be divorced, because this way the surface of the material that needs to be cut into pieces is destroyed. Such a tool is often used for cross-cutting.

The advantage of this tool is the ability to cut multiple panels simultaneously. For this operation, you will need to stack the material.

For convenience when cutting, it is better to have the planks facing the performer. When subjecting the length of the panels to a decrease, care must be taken not to apply enormous forces when pressing the tool, because this can break the PVC sheets.

Cutter

This tool has proven itself well due to its low cost. Perfect for home use.

The tool has excellent performance and the cut surface looks smooth. It should also be highlighted the fact that no special physical effort is required to carry out the cutting. A huge advantage can also be called its compactness, in which it does not take up much space during its storage.

Application of panels

In the process of sheathing, it is necessary to initially determine the tool used for cutting the plastic panels. This material is widely used for decorating balconies or bathrooms, because it has an excellent set of properties. It is also impossible to forget about its practicality, which makes it even more popular. Plastic panels also attract buyers with their low cost and excellent appearance.

Each owner can independently finish the bathroom at home and at his discretion, because there are a huge variety of panel options that can be used for this. All PVC panels are manufactured with a standard length of 3 m.This is not always practical, because it needs to be cut into pieces to obtain the desired size.

What are they made of?

The raw material for PVC wall panels is polyvinyl chloride, which is poured into a die (casting mold) under high pressure.

This method is called the extrusion method. To add color, ground natural chalk is added to the composition of the material, the amount of which is, as a rule, no more than 40%.

In addition to painting, panels are decorated using thermal printing or offset printing, but the latter method is used less often due to its higher cost.

Thermal printing is applied on a special machine using a hot roller, which presses the thermal film to the surface of the product. Thus, it is possible to achieve a quick transfer of the pattern and a clear and bright print, and the panel itself does not need to be varnished, in contrast to the use of offset printing.

Cutter

This device is used by experienced craftsmen who are professionally involved in finishing work.

The use of the cutter provides a perfectly smooth cut and allows you to shorten PVC strips without much physical effort.

Having bought such a tool, you can be sure that there will be no problems with high-quality cutting of panels.

Hacksaw

This tool is present in any home workshop. For those who are not ready to spend money on purchasing a cutter, using a hacksaw may well be an option for solving the problem of cutting panels.

Yes, this method will take a little longer, but with a small amount of work, this will not greatly affect the period of wall cladding.

It is important to note that a hacksaw for metal is best for cutting panels, and if you use a tool for wood, then the blade should have fine teeth. for cross-cutting.

Several options are possible here:

Simple kitchen knife

Although this tool is the least suitable for cutting PVC products, one or two strips can be cut in case of repair and replacement of panels. But with large-scale work, it is impractical to use it. the process will take a long time and painfully;

Construction knife

Stationery knife

It is often used for cutting panels. Using a square or a flat wooden plank used as a ruler, it is possible to achieve an even cut.

Jigsaw and angle grinder

Using a jigsaw is a quick, but not too high-quality way. It is unlikely that it will be possible to achieve an ideally even cut with its help, moreover, chips often form along the edge of the panel, so it is best to abandon this option, preferring the same angle grinder.

Using this tool will ensure an even cut, but only due to high speeds, the panel begins to emit an unpleasant odor and poisonous substances.

Facing surfaces with PVC panels is a finishing method that many people choose today as the most optimal. It’s fast, simple and relatively inexpensive.

But in the course of the work, the question always arises: how to cut the PVC panel? Several methods are possible here, after considering which you can choose the most acceptable option for yourself.

The better to cut?

Different tools can be used to cut the panels. These include both special professional devices and ordinary hand or electric tools used in everyday life for various purposes.

Hacksaw

If, when performing finishing work, the question concerns how to cut the panels exactly, then for such a case, it will be correct to use a hacksaw. When the edge of the panels is hidden from the eye by the starting or corner finishing profile, then a hacksaw is used for wood. In case the cut off section will remain in sight, then use a tool for metal.

When choosing what to cut plastic panels, they pay attention to the convenience of work. When using a hacksaw on wood, the workpiece will vibrate strongly and must be held firmly. And when using tooling for metal, the vibration effect will be little noticeable, but the tool will need to be held almost parallel to the workpiece plane. This is due to the thickness of the blade holder, which is larger than the blade.

In both cases, the panel is placed facing the cutting tool so that all chips and imperfections remain on the wrong side.

How to cut PVC panels

Among the variety of finishing materials used in construction, plastic panels occupy a separate category. It is a modern coating used for interior and sometimes exterior walls. They are made from polyvinyl chloride by extrusion. Before performing installation work, it is important to decide: the better to cut PVC panels. The assortment of tools and accessories offered on the market is full of offers, both general and special. Among all the inventory, you can choose what will cut the plastic panels.

Construction knife

In any household, you can find a kitchen knife, sharpen it and use it to solve the problem than to cut off a plastic panel. But, to get a high-quality cut, it is better to use a construction or clerical knife. Replaceable blades that come with the tool will allow you to get a flat, smooth surface. Cutting with a knife is faster than using sawing devices. But, when you have to deal with the cellular structure of plastic panels, the use of such a tool becomes inconvenient.

When using a construction or clerical knife, the panel is marked out, then laid on cardboard or the cut part is left hanging. After that, pushing through the front and back sides of the finishing material, they separate unnecessary parts. If a large area of unclaimed plastic part remains, then it is better to place or substitute a support under it, in order to avoid kinking or skewing the workpiece.

Jigsaw

Using such a power tool will help you cope with cutting panels and reduce labor intensity, compared to a hacksaw or a construction knife. Convenient to use a jigsaw when preparing a large number of workpieces.

When performing work, the place of the cut is first marked on the front surface, and then smoothly cut to the required size, passing the tool along the marking mowing line. Cellophane or other material is placed under the jigsaw support foot, which will prevent the possibility of scratching the PVC panel. In the case of simultaneous cutting of several blanks, they are fastened with plastic clamps or wrapped with transparent tape. At the same time, it is better to isolate the front surface from the adhesive tape (lay a sheet of paper).

How can PVC panels be cut

Plastic finishing material can be cut both lengthwise and across. Of course, the main blanks are cross-cut. When you want the sewn surface to be completely covered, you have to use a longitudinal cut. Before starting work, it is determined how to cut plastic panels at home or at an industrial facility. The number of blanks required for wall cladding is of no small importance.

Using many years of experience in using PVC materials in interior decoration, we will highlight what can be used to cut plastic panels:

- Construction knife;

- Hacksaw for metal;

- Angle Grinder;

- Jigsaw;

- Cutter;

- Hacksaw for wood.

The use of any of these tools will help solve the question of how to cut PVC panels, but each of them has features that must be taken into account when performing work.

Cutter

Such a device is convenient when speed and high-quality cut of the end face of the workpieces are important for solving the problem. The speed of such a tool is high, while the quality is better than any of the above. But, when working, you need to carefully inspect the panel for possible chips and lay it inside out to the cutter, and face down to the supporting surface. This is due to the fact that the cutter can push the surface of the PVC workpiece by 2-5 millimeters.

The tool simplifies and speeds up installation work. Buying a cutter will forever close the question of how to cut off a plastic panel, and other methods will no longer be relevant. When using it, it is important to remember that such a tool will not be able to trim in place with such a tool.

Basic cutting rules

So that the efforts on cutting PVC panels are not wasted, and the result of the work meets expectations, experts recommend adhering to a number of rules for working with plastic. These little secrets will help not only to significantly reduce the amount of spoiled material, but also save the master from unnecessary financial expenses and injuries.

When carrying out work in the heated season, do not start cutting panels that have recently been brought into the room. The plastic should naturally warm up to room temperature, which is achieved in at least 12 hours. The fact is that at low temperatures, the plastic panel becomes fragile, and therefore it can crack and break off in large fragments.

Regardless of the chosen method of processing the material, it should be placed with its front side facing you, which will avoid deformation of the panel and difficulties during its further installation. When cut from the seamy side, you can find microcracks on the front part, which will manifest itself over time and significantly spoil the interior.

It is necessary to mark in advance the straight line of the planned cut, which can be done with a simple pencil and a clerical ruler.

To speed up the process of preparing the material for installation work, you can cut or saw several PVC panels at the same time. To do this, simply stack them in a pile and create a two-point support. It is best to rest the opposite edge of the stack against the wall, which will help avoid shifting the products, respectively, as a result, parts of the same length will be obtained.

Material features

PVC panels are one of the modern types of finishing materials that are made by extrusion and are used both in the bathroom and in the living room. The main raw material in the production of such products is polyvinyl chloride, which is used to fill the mold. To give the panels the desired color, a certain amount of crushed natural chalk is added to their composition.

Decorating PVC panels can be done in one of the following ways:

- Staining;

- Thermal printing;

- Offset printing.

Thermal printing is applied to the plastic surface using a special roller heated to high temperatures, which presses the film to the surface of the product. Thanks to this technology, it is possible to quickly and clearly apply a pattern without losing the brightness of the image. The panel itself does not need additional varnish. Offset printing is used much less frequently due to its high cost.

Hacksaw

One of the universal devices for cutting any material is a hacksaw, which is sure to be found in the arsenal of any master. It is she who will help, if necessary, cut the plastic wall panel. This work will take longer than using a special cutter, but with significant volumes of cladding, this will not significantly affect the total repair time.

When using a hacksaw, it is worth listening to the following recommendations of experts:

- For working with plastic finishing materials, you should use a tool with small teeth, which is usually designed for working with metal or wood;

- To shorten the PVC panel, there is no need to apply strong physical force, which can damage the material;

- You can cut several parts at once with a hacksaw by folding them in a pile and securing them to avoid bending or displacement.

To prevent the cut from being serrated, it is not recommended to use a tool with teeth set apart in different directions.

Power tool

For quick sawing of PVC panels, a power tool at hand is best. For this purpose, you can use almost any device, which will help to significantly reduce the time spent on preparing for installation.

Often, cutting is performed using the following devices:

- Electric jigsaw;

- Angle Grinder;

- Circulars.

To work with plastic material, it is allowed to use only low revolutions, because with significant heating it begins to melt and release fumes that are toxic to the human body, and the cut in this case will turn out to be torn.

Using a jigsaw will help to make the process of preparing PVC panels for installation much faster than in the case of using hand tools.

However, with this method of processing, the following nuances should be taken into account:

- Before starting work, you must turn off the pendulum stroke;

- A file with the smallest teeth should be used;

- It is necessary to set the lowest speed of movement of the file, which will avoid excessive heating of the plastic at the cut.

Using a jigsaw is very convenient to cut stacks of panels, but it is worth making sure that their height does not exceed the length of the file installed in the tool.

The angle grinder is recognized as the most convenient and practical power tool for cutting PVC wall panels. By installing a cutting disc, you can make not only straight, but also curly cuts on the surface of the plastic. When processing plastic with a circle, the angle grinder turns on only at low speeds, which will avoid damage to the material due to melting of the edges.

In the absence of more practical and convenient tools, PVC can be cut with a knife.

To solve this problem, the following types of cutting products are suitable:

- Kitchen knife. This tool is suitable for cutting multiple panels in the process of repairing or replacing them. For large-scale wall decoration, such a procedure is unnecessarily long and painful.

- Construction knife. Among hand-held cutting tools, such a device is one of the best options for achieving an even cut with relatively little effort.

- Stationery knife. Using a wooden ruler or square, this tool allows you to achieve a perfectly even cut of the panel, therefore it is often used to cut them.

How to cut PVC panels?

- Material features

- Choosing a cutting tool

PVC panel is one of the most popular materials for interior decoration. Its use in the interior attracts not only by its appearance, but also by its affordable price, ease of maintenance and installation. Due to the listed characteristics, many people prefer PVC panels, rather than tiles, when decorating personal hygiene rooms.

Choosing a cutting tool

Specialists in the implementation of repair work, who have to carry out the installation of PVC panels in their professional activities, know many secrets regarding the correct cutting of plastic materials up and down. After analyzing them, each owner who wants to make repairs on his own will be able to choose the most suitable professional tool for him or use the tools at hand.

The choice of a method for cutting panels usually depends on the tasks and capabilities of the master. Below are the types of cutting materials.

How to cut plastic PVC panels

Plastic panels have a number of advantages that make them an indispensable material for quick and inexpensive renovation of bathrooms, toilets, loggias and garden houses. The panels are impervious to moisture, are low-combustible materials, resistant to mechanical abrasion, have a long service life and are relatively cheap. They can decorate both walls and ceilings. The technology of mounting plastic panels is simple and does not require preliminary surface preparation.

One of the essential stages in the installation of plastic panels is their cutting to the required size. The complexity of this stage depends on the condition of the surface to be finished: if the wall, for example, is straight and even, then you can prepare the entire volume of plastic panels required for it in advance. If the wall has different heights, complex shapes or includes architectural elements (windows, doors, ledges, etc.), then you will have to cut the panels along the way, which, of course, significantly increases the installation time.

How to cut plastic PVC panels?

It should be noted that plastic panels are quite easy to process, and they can be cut using a wide variety of tools. Most often, hacksaws for metal or wood with small teeth are used for this. The advantage of this method is that they can simultaneously cut several panels. It is necessary to saw the panel face up, at a slope, avoiding strong pressure. If you use a saw for wood, it is better if it has teeth for cross or mixed sawing, if possible, not set apart. such a saw will leave an even cut without scoring. You can also use a jigsaw, but when cutting, they need to strictly dose the pressure, otherwise the panels can simply break. Some people use an "angle grinder" and circular saws to cut panels to speed up the process, however, in our opinion, such methods have several disadvantages: firstly, plastic is quite fragile and light material, and careless handling of it can lead to the fact that the panel will simply break; secondly, from heating when cutting with a tool at a high rotation speed, the panels heat up and begin to release toxic compounds.

There are several rules to follow when cutting panels. If you brought the panels from the cold, let them “warm up” at room temperature for several hours: cold plastic becomes brittle. Before cutting the plastic panels, mark them to the size you need. It is convenient to do this using an ordinary felt-tip pen. it leaves a well-visible mark on the panel and is easily erased. Safety precautions must be observed when cutting panels. It is advisable to wear safety glasses and gloves. Remember that when the panels are broken, sharp splinters are formed that can injure.