How to remove a carburetor on a walkbehind tractor. Features of adjustment in different brands

Carburetor of the walk.Behind tractor

What should you pay attention to during the interruption of the motor? If the carburetor malfunction occurs, the first thing you need to check the fullness of the fuel tank and the oil level. If the fuel and oil are enough, then they proceed to the examination of the candle

To do this, it is unscrewed and the spark is checked by ignition. Next, test gasoline to the carburetor. For this purpose, the hose is removed from the fitting and monitor the fuel intake. If the fuel does not appear, then, most likely, the filter mesh mesh is required. For this, the fuel valve is unscrewed and all the parts are washed with gasoline. The same thing is done with the potpel jet.

Carburetor cleaning is as follows. To clean the device, to start it, you need to remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the details on which it holds.

So, remove the carburetor and pour gasoline out of it. Gently separate all the details of the device (nozzle, float) for further purge and cleaning. This manipulation is performed by a special cleaner.

After cleaning, thoroughly dry all the details and boldly proceed to the assembly. After assembly, adjust the carburetor for the walk.Behind tractor.

Install the cleaned device using the standard pad, and fasten it with nuts. Do not forget about the air filter, revolutions and a gasoline supply hose.

Farmall H and McCormick w4 Governor Set up

The tuning of the motorogue carburetor is to adjust it. In order to independently adjust the carburetor, you need to take the following steps:

- Small and full gas screws need to be twisted all the way.

- Turn the screws of small and full gas for one and a half turn (set the throttle to the shutter in such a position that the gap of the corresponding size forms between the base and the duct).

- Start the motor and wait until it warms up.

- When working motor, the control lever is put at minimum turns.

- Achieve uninterrupted operation of the engine. To do this, you need to make minimum storage of idle, using the throttle screw screw.

- Set the idle speed to the maximum using a small gas screw.

- Set the idle speed to a minimum with a screw of the throttle.

- Repeat 6 and 7 step until the continuous operation of the engine begins.

- The engine control lever is put on gas.

- If the interruption occurs, unscrew the screw that regulates the quality of the mixture, no more than 2.5 revolutions.

I would like to note that the adjustment of the carburetor on the Neva walkover is made clearly according to the above instructions. Neva installed on the Neva walk-behind device K-45 is a single-chamber and horizontal. The float camera is located in the central part. Throttle. Flat.

On the Neva motornote, the DM-1K engine is used, which is produced at the Red October Neva plant. The manufacturer categorically does not use Chinese.Made engines. This also applies to the production of a motor cultivator.

Repair and maintenance of a chainsaw friendship

Reliable spare parts and durable mechanisms of the chainsaw Friendship are not able to protect the tool from breakdown. Most often, the causes of the instrument malfunction are incorrect handling it or banal wear of mechanisms.

To reduce the risk of premature breakdown of the chainsaw, you should use high-quality gasoline of the brand not lower than the AI-80, in which oil should be diluted for 2-stroke engines. The proportion of gasoline and oil should be 1:25, that is, in 1 liter of fuel, 40 ml of motor oil should be diluted.

The oil lubrication should also have high quality. In no case do not pour in the oil tank of the chainsaw Friendship spent material, otherwise this will lead to a breakdown of the tool lubrication system. So that the chain of the chainsaw does not succumb to excessive friction, use only fresh oil from trusted manufacturers.

It should be noted that the use of high.Quality fuel mixture and lubricant does not yet guarantee the constant uninterrupted operation of the chainsaw friendship. However, even if you find a malfunction, do not immediately be upset. Some breakdowns are quite easy to eliminate with your own hands. Below we list typical malfunctions of the domestic instrument and ways to independently eliminate them.

How to Rebuild a Ford 8N, 9N or 2N Carburetor, Marvel Schebler

Adjustment of the carburetor of the chainsaw friendship

- To search for the highest revolutions of the motor in idle mode, it is necessary to slowly turn the screw that has marked “L” clockwise. As soon as you find maximum speed, turn the same screw back. If after that the chain on the tire continues to rotate, then turn the screw with the marking “T” against the hand arrows until the saw element is completely stopped;

- Turning the screw indicated by the letter “h” will allow you to configure the necessary power and speed of speed. To do this, you need to connect a tachometer to the chainsaw and by turning the screw “h” to find the optimal number of revolutions indicated in the instructions. Immediately after that, turn the “H” screw for ¼ turn against the hand of the watch;

- Then it is necessary to perform accurate adjustment of the engine speed at idle. For this, the screw “t” should be turned until the rotation of the saw chain starts. Immediately after that, turn the screw “t” in the opposite direction until the circuit is completely stopped.

The adjustment of the carburetor performed by the instructions will allow you to reduce the fuel consumption of a chainsaw, and protect its details from excessive wear.

How to set a ignition on a chainsaw friendship?

To correctly repair the tool, you need to carefully study the guide to its operation. According to the instructions for the repair of the chainsaw of friendship, to install the ignition, it is necessary to remove the cover to which the starter is attached, and turn the magneto so that the marks on it and the adapter coincide. After that, the firmica will be much easier.

Features of the device of the carburetor of the walk.Behind tractor

Motoblok is a powerful power miniigate with additional equipment to perform various functions. It is often based on a gasoline engine, less often. Diesel or electric. For ignition of fuel, carburetor is used.

Don’t replace your tractors carburetor until you check this first!!

Two main types of carburetors are distinguished:

- Rotary. It differs in simplicity of the structure, often found in small engines (12-15 cubic meters. Inches);

- Plunger. The multi.Element design is relevant for high.Power motoblocks.

The carbury is performed due to the following details: a piston, fuel tank, Venuria, fitting tube (acts as a connector), high and low speed needles.

The piston moves up, creating a vacuum. The carburetor begins the absorption of air, which moves through the Venturi tube. The created vacuum allows the combustible through the connecting fitting to get from the tank to the engine. Further, the fuel passes around the main needle and through the nest of intake into the Venturi tube.

During pressure on the gas lever, the needle of low revolutions opens access to gasoline, after which the fuel flow is controlled only by the main needle.

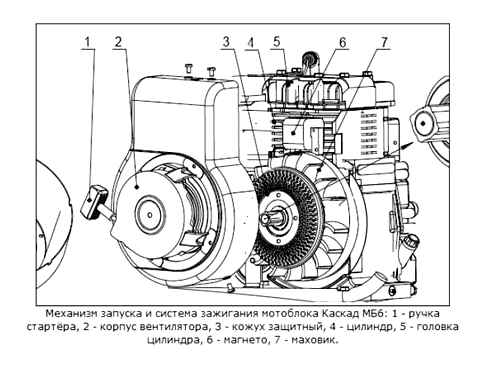

The sought.After agricultural machinery “Neva”, “Agro”, “Ugra”, “Oka” is in demand due to its configuration. When it comes to the carburetor of the Neva Motobogobe K-45, this is a reliable device that is characterized by quality and durability. KMB-5 is a more old carburetor model in Neva units. Before buying, it is worth clarifying this nuance to purchase a really professional assistant. Powerful motors on the MTZ (Belarus-09-N) and Neva MB-2 are supported by the work of reliable carburetors, allowing to withstand heavy loads. On the Kadwa-1 Kadvy technique, Cascade and the Bee Motor cultivator, lightweight models of carburetors to optimize engine functionality.

Carburetor care

It will be possible to prevent a walk.Behind tractor from frequent breakdowns or repairs only with careful tracking of the mechanism

As it has already turned out, it is important to carry out timely adjustment of the idle. In addition, do not forget to clean the carburetor, inspect the condition of the parts, for this you must first remove them, perhaps they need to complete replacement

For example, gaskets often wear out. Due to constant interaction with fuel fluid, air, the engine is strongly contaminated. Filters that are installed on the unit will help to reduce manual cleaning. In this case, they will have to clean them as strong pollution will be.

The composition of the poured fuel affects the state of the equipment. Low.Quality flammable fluid worsens the functioning, the service of parts, the mechanism as a whole. It is for this reason that the masters often resort to the replacement or repair of agricultural machinery. You can purchase new spare parts in automobile markets or in stores where qualified specialists work.

Adjust the device of the Neva brand quite easy even with your own hands. The main thing is to adhere to the above rules. It will not be superfluous to purchase a connection scheme for each part after repair work or setting, since the incorrect installation of spare parts will lead to a malfunction of the equipment. It simply will not start. Try to use high.Quality fuel, adjusting on time, and also do not need to save on spare parts. After all, the work of the entire mechanism depends on each part.

In the next video, you will be cleaned and flushing the carburetor from the Neva MB23 walk.Behind tractor.

Carburetor operation instructions

Gasoline that enters this device should not contain mechanical impurities. All parts are treated exclusively with gasoline. The use of the solvent is not allowed, since the elasticity of the washer and rubber parts is damaged.

To dry the details, use the purge of compressed air. It is not recommended to clean the small holes with wire or needle. Installation after repair or cleaning should be carried out evenly so that there are no bends and deformation of parts.

The float chamber must be connected to the body hermetically. Before operation, you need to check the connection of the air filter. There should not be gasoline leaks.

Before starting the engine, the carburetor should be prepared. To do this, make sure that gasoline does not occur from it. To do this, just open the fuel valve. Block the air damper, and tighten the control lever all the way. Open the throttle to open 1/8. 1/4 from the maximum course.

At a low air temperature (below 5ºС), squeeze the drowner until the fuel appears from the hole.

During the launch, slightly open the air damper, and after warming up the engine, open it completely.

Carburetor operation instructions

In order for the carburetor to work for a long time and without fail, it is important to monitor the quality of gasoline, its purity. It is necessary to change the fuel filter in a timely manner and clean the sump.

It is also recommended to contain all the nodes and mechanisms clean, regularly blow the carburetor with compressed air from dust. It is best to periodically dismantle the part and make complete cleaning with gasoline.

Do not forget about the blockage of an air film

In order for the carburetor engine to work normally, the ratio of air to gasoline in the mixture should be approximately 15 to 1. But starting a cold motor with this composition will not work. For starting, such a mechanism as a throttle is provided, with its help you can “enrich” the mixture by reducing the influx of air entered in the carburetor. This is done manually (using a special lever on the device case).

Cable adjustment on walk behind tractors. Basic

The start of the engine (with normal tuning the carburetor) should be carried out without adding gas.

After the engine is launched and it heated, the throttle must be returned to the usual position, otherwise the fuel consumption will be excessively high.

As a rule, the duration of the carburetor (according to the manufacturer) coincides with the life of the engine until its overhaul. After that, most likely, you will have to replace the product or make its full disassembly and replacement of components using the factory repair kit.

When buying a new carburetor, it is recommended to check it for the presence of cracks in the case, casting defects, and the closing of the throttle closing.

Most models of this manufacturer are equipped by the same principle. They have installed mechanisms of KMB-5. To regulate this fuel node, a number of consecutive actions are performed:

- Drain the remnants of fuel from the float chamber.

- Open a fitting for starting air into the fuel node.

- The throttle of the throttle is tuned so that the gap between it and the duct is 2 mm.

- Clamping bolts that regulate the supply of gasoline.

- The screws are unscrewed alternately until the engine speeds are reduced. You need to do this smoothly and slowly.

- Carefully screw the screws back.

As a result of these actions, you can level uneven operation of the motor, reduce fuel consumption.

DIY starter repair

Bitter failures can also cause engine impairment. Most often there are situations when the screws of mounting the starter body to the engine body are weakened. In this case, the launch cord will not return to its original position. To eliminate the problem, you need to loosen the screws and adjust the position of the cord so that it easily returns to its original position (Figure 6).

Figure 6. Starter repair scheme

In addition, malfunctions in work may be associated with the wear of the starting spring. It is impossible to repair it, so you just need to replace the worn part.