How To Set Up A Stihl Chainsaw

Removal and installation algorithm

In cases where it is necessary to clean the Stihl 180 carburetor or disassemble it, first you need to remove the assembly from the chainsaw. This must be done in compliance with a certain algorithm of actions:

- Put the protective cover for the chainsaw on the tire.

- Remove the top cover of the chainsaw.

- Remove the two nuts securing the air filter and carburetor.

- Remove the air filter housing.

- Disconnect the wire from the engine control lever.

- Carefully remove the lever from its seat in the housing, while simultaneously disconnecting the choke rod from it.

- Pull the carburetor towards you and disconnect the fuel supply as well as the throttle rod.

To facilitate dismantling, you can additionally untwist the rear handle and disconnect the throttle rod first from it, and then only from the carburetor. This may be required, because without some experience, disconnecting the rod from the carburetor is quite problematic and it is easier to first disassemble the handle.

To install the part in place, follow the reverse order of the algorithm.

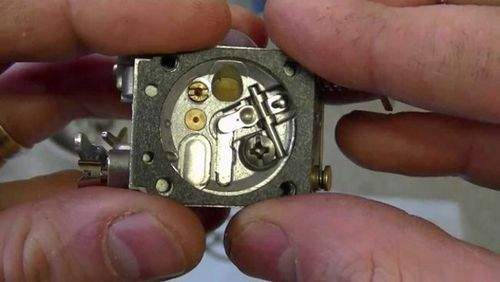

Dismantling the carburetor Stihl 180

In order to purge, change the gaskets or the needle valve, the carburetor must be disassembled. To do this, unscrew 4 screws on the expansion joint cover and one on the fuel pump.

Having opened the case, you should be extremely careful, because if debris gets inside the carburetor, it will make its work impossible. The thickness of the channels in it is comparable to the thickness of a thread or even a human hair.

For repairing a Stihl 180 carburetor, you can see below. In it, the wizard talks in detail about the problems and clearly demonstrates the entire repair process.

Distribution chamber

In the distribution chamber, as in the fuel pump, there is also a membrane that opens and regulates the fuel supply by pressing a special rocker, while raising its needle valve.

The chamber cover is the compensator body, which is attached to the carburetor with four screws; a gasket is installed between the body and the cover, which increases the height of the chamber and is responsible for sealing.

Frequent breakdown of the Stihl carburetor and how to avoid it

A common reason for the failure of the carburetor on the Stihl chainsaw is a sticking valve in the nozzle. The reason for sticking is a violation of the storage of the chainsaw, or rather the instructions of the manufacturer Stihl 180 for proper preparation for storage.

As follows from the instructions, before long-term storage, it is necessary to drain the fuel from the tank, then start the saw and burn the gasoline from the carburetor. Failure to comply with this elementary rule entails the following consequences. The forsknui valve, being in direct contact with the fuel, sticks to the body, since the gasoline evaporates little by little and only sticky oil remains. It is impossible to replace the nozzle, because they are not in the repair kit, you can only try to knock it out and rinse it, which is not always possible to do without damaging the nozzle.

Chainsaw Stihl 180. device and carburetor adjustment

The stihl ms 180 chainsaws are designed in such a way as to make their operation as easy as possible for inexperienced users. To this end, some of the settings available on the more powerful Stihl models were abolished in the saw carburetor. But there is still an opportunity to configure, and repairs, as well as adjusting the carburetor of the Stihl 180 chainsaw with your own hands, is possible.

Adjusting the Stihl 180 carburetor

The carburetor of the Stihl 180 chainsaw, indiscriminately, can only be adjusted by the number of idle revolutions. It is impossible to increase or decrease the fuel supply in different modes using special screws. The manufacturer restricts access to adjustments and does not install these screws. How to adjust the carburetor to the correct idle speed is described in great detail in the manufacturer’s instructions.

In the event of certain malfunctions, and with experience, you can increase or decrease the fuel supply by increasing the clearance when opening the needle valve.

To increase the flow, the rocker arm of the needle valve in the distribution chamber must be bent up, and to decrease, down. This regulates the stroke of the needle and, accordingly, the throughput of the valve.

Need for adjustment

Throughout the entire operation process, the need for additional adjustment and ensuring the correct supply of the fuel-air mixture periodically arises. How to determine exactly when and what setting needs to be done for the equipment to function normally? There are characteristic signs when the mechanism, according to the behavior of individual parts, itself tells when adjustment is necessary.

First of all, each time before starting the engine again, it is necessary to check the color of the spark plug electrodes.

By changing it, you can make a decision on the need to adjust, adjust work processes, improve the quality of the combustible mixture:

- Black electrodes covered with soot or carbon deposits indicate an over-enriched air-fuel mixture entering the engine.

- Brick-gray electrodes indicate that the mixture is ideal in its composition and no additional adjustments are required.

- White coating on the electrodes of the spark plug indicates that the mixture is lean.

The signs stated in points 1 and 3 indicate that carburetor adjustment is extremely necessary for the Stihl 250 chainsaw.

Precise settings will allow you to achieve maximum performance of the unit while reducing the external necessary conditions for its operation. Successful debugging of operating conditions prevents oil starvation and engine failure due to insufficient lubrication. After all, the lubricant enters the saw cylinder along with a lean air-fuel mixture.

How to adjust the carburetor Stihl ms 180 what are the min and max rpm? Also similar about adjusting on my channel: https.

To adjust the stihl MS 180 carburetor:

The MS 180 annotation describes how to set idle speed on a chainsaw as standard:

Conclusion

In order for the chainsaw to work properly, you need to carefully perform work on adjusting the carburetor in exact accordance with their sequence. If there are any irregularities in the functioning of the device, it is necessary to completely disassemble it yourself. In most cases, replacement of any parts that have become unusable is required.

With constant checking of the quality of carburetor settings and taking timely actions to improve its operation, problems with the chainsaw do not arise.

About which chainsaw to choose. read here.

For the small, compact mechanism of the Stihl 250 chainsaw, the correct carburetor setting is key. All well-coordinated work, all load modes and its trouble-free operation directly depend on the adjustment of the fuel supply systems, the quality and quantity of the fuel-air mixture. This article describes how to adjust the carburetor for the Stihl 250 and set up all of its dosing systems.

The main stage

The engine starts at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed must move clockwise. It is released only when the engine comes into stable operation. It is necessary to check that the chain does not move during this process.

In idle mode, the engine may stall (the reason is here). In this case, immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

We turn the idle speed adjustment screw counterclockwise until it goes tight, then turn it two turns clockwise. Voila! Configured.

If your saw has very low idle speed, then we carry out the following actions:

- We turn the adjustment screw clockwise until the chain starts moving along the bus.

- Rotate the screw half a turn counterclockwise.

If you have the highest RPM and the chain keeps spinning:

- We turn the idle speed adjustment screw counterclockwise until the chain stops moving.

- Turn the screw another half turn counterclockwise.

For which the design is intended, if it is not possible for you to adjust the idle speed without the help of others, then you need to contact a special service center.

Chainsaw carburetor tuning. Or how not to pay repairmen!

Owning a chainsaw makes life much easier even for an amateur, and in some professions this tool is virtually indispensable. However, like any relatively complex device, a chainsaw requires periodic maintenance. Due to untimely or poor quality maintenance, as well as as a result of the impact of both planned and excessive loads, all sorts of malfunctions may appear. For professionals, interruptions or erratic saws reduce efficiency or can lead to a ruined working day. One of the fairly common malfunctions is the incorrect setting of the chainsaw carburetor, which gets lost due to unsuccessful attempts to adjust or displace the adjusting screws for other reasons.

Husqvarna Saw Carburetor Adjustment.

For the break-in mode, so that the parts receive sufficient lubrication, the carburetor setting of the Husqvarna chainsaw is made so that the maximum speed is 600-700 rpm. Below working. If it is not possible to set the operating maximum frequency using the tachometer, you should not change the presets with the H screw. It is forbidden to exceed the value of the maximum number of revolutions by the manufacturer. If, after completing the adjustment, the saw chain moves when the engine is idling, turn the screw T counterclockwise to bring it to a complete stop.

For accurate adjustment, the saw must be warmed up for at least 10 minutes, set on a flat surface. The tire should point away from the person making the tune. At the initial stage, the highest idle frequency should be found. To do this, screw L is smoothly turned first from left to right, then vice versa. When the maximum revolutions are found empirically, screw L should be unscrewed counterclockwise by a value from 1/8 to a quarter of a full revolution.

The idle speed is adjusted by the nozzle marked with the letter T. It must be turned from left to right until the chain starts to move. Then push slowly in the opposite direction until the chain stops rotating. Screw H is considered to be installed correctly if the noise of the saw at full throttle without load remains small. If the exhaust is too smoky and the saw makes a lot of noise, the mixture is too rich. Turn the H jet clockwise until the correct sound is set. How to properly tune the carburetor can be seen below.

Chainsaws Partner and Stihl, their adjustments.

In Stihl and Partner chainsaws, the proportion of air and gasoline in the mixture is set with adjusting screws H and L. When the screws are loosened, the mixture is enriched, the revolutions increase. Screwing in leads to a leaner mixture and, accordingly, a decrease in engine speed.

Setting the carburetor of the partner’s chainsaw to idle is carried out with the T screw (Stihl marks this adjustment with the letters LA). Basic tool setting is done in the factory during final testing. In most cases, the carburetor is adjusted to deliver a slightly richer air-fuel mixture than the optimal design. The factory-set settings must be saved during the first few hours of operation, during the running-in period. After that, a finer adjustment can be carried out, although this is not necessary, the saw will work normally on the basic settings.

For fine adjustment of the carburetor, a tachometer is required, in addition, technical documentation will be required in order to carry out work in strict accordance with the manufacturer’s requirements. The best solution would be to entrust the jewelry tuning of the fuel equipment to specialists.

If, nevertheless, it is decided to adjust independently, you should start with screw L, then go to the nozzle H, and then set the idle speed by rotating the screw T (or LA. if it is a Stihl saw).

By smoothly turning the screw L in both directions, a position is sought at which the idle speed will be maximum. After this point is found, it is required to unscrew the screw L by 1/4 turn. If the chain continues to move with the engine running at idle speed, the T (LA) screw is slowly unscrewed until the chain stops.

After setting the maximum speed with screw H, the value of their frequency is checked by the tachometer. If the speed at maximum does not correspond to the values indicated in the documentation, the adjustments are repeated. If the mixture turns out to be too rich at maximum speed, too much smoke comes out of the muffler, when the mixture is poor, the saw makes a squealing sound and the engine is too hot. The adjustment ends by setting the idle speed. the position is considered correct if the engine runs exactly at the minimum speed and the chain is at a standstill. The idle speed setting can be viewed in the following.

Purpose, design and principle of operation of the carburetor.

The carburetor is needed to prepare the air-fuel mixture to power the engine. If the proportions in this mixture are not correct, the motor will malfunction. If the proportion is not observed in the direction of increasing the amount of fuel, the mixture is called oversaturated, if, on the contrary, there is little fuel, it is called lean. Both of them do not affect the engine operation in the best way.

In different models of chainsaws, carburetors differ in design, but they are similar in principle of operation. The air stream moves at high speed through the air channel. A damper blocking the channel allows you to change the speed of the air stream. The fuel is fed through the nozzle into the channel, where it mixes with the incoming air, forming a fuel-air mixture. The resulting mixture enters the engine.

The pressure in the float chamber, where the fuel is located before mixing, is practically equal to atmospheric pressure. But a vacuum is created in the air channel, due to which the fuel is drawn into the air stream. The more the damper is opened, the faster the air moves, and the amount of fuel also increases. the engine speed increases. So you can simplify the principle of the carburetor.

Chainsaw carburetor adjustment is required for efficient, smooth operation of the tool, getting maximum output and at the same time economical fuel consumption. Before adjusting, the fuel and air filters must be checked. they must be clean. On most chainsaws, adjustment is carried out with three screws: idle, high speed, low speed. The following signs indicate the correct setting of the carburetor:

- The chain does not move when idling.

- The engine accelerates smoothly and quickly.

- The sound of the engine running is smooth, similar to the sound of a four-stroke engine.

Adjusting the carburetor must be treated with all possible care, because errors in the settings can lead to very serious consequences, up to the occurrence of engine malfunction. If you are not completely confident in your abilities, you need to contact the service center.

Symptoms of malfunctions and breakdowns in which carburetor adjustment is required.

The following signs and malfunctions indicate the need to adjust the carburetor:

- The engine starts up with an effort and stalls almost instantly;

- Gasoline consumption is too high, the exhaust is too thick, the combustible mixture in the cylinder does not completely burn out;

- The factory settings of the chainsaw carburetor are knocked down (due to vibrations or unsuccessful attempts to regulate);

- Malfunctions of the air cleaning system, which led to the ingress of debris particles into the mechanism for distributing the fuel mixture;

- Significant wear of the piston group. setting the carburetor in this case acts as a temporary measure.

It is clear that if dirt gets into the fuel system, one setting cannot solve the problem. you need to flush it. If the piston is worn out, a major overhaul is required. However, in all these cases, the carburetor is also adjusted.

Tuning the carburetor of a Chinese chainsaw

The position of the screw L, at which it is loosened by one and a half turns from the fully clamped position, is considered standard for "Chinese" carburetors. For screw H. one revolution from the same state. On many people, the L screw is called the quality control of the mixture, and the H screw is called its quantity. Idle speed is adjusted in the same way as described above with a warm engine.

When is adjustment necessary at all?

Specifically, adjusting the carburetor of a chainsaw is required in rare cases, more often problems arise related to the flow of fuel or wear of parts. But sometimes "symptoms" indicate that it is necessary to precisely adjust the mechanism. Here are some signs:

- After the engine starts, it immediately stalls. Alternatively, it won’t start at all. The reason lies in the excess of air and fuel shortages.

- Increased fuel consumption and, as a result, a large amount of exhaust gases. This is due to the reverse process. oversaturation of the mixture with fuel.

The reasons for the adjustment failure can be mechanical:

- Due to strong vibration, the protective cap is damaged, as a result of which all three bolts lose their established fixation.

- Due to wear on the piston part of the engine. In this case, adjusting the carburetor of the chainsaw will only help out for a while, it is better to replace the worn part.

- Due to clogging caused by low-quality fuel, scale or damage to the filter. The carburetor requires complete disassembly, flushing and adjustment.

If the chainsaw suddenly stops working, you need to disassemble it to find out the reasons

Step by step instructions for disassembly

The carburetor device of models of different brands is almost the same, so take the Partner chainsaw as an example. We carefully remove each element and put it in order, so that later it would be easier to assemble.

Chainsaw carburetors from different manufacturers, if they differ, it does not matter

The top cover is removed by loosening three screws. Followed by foam rubber, an integral part of the air filter.

The arrows indicate the bolts that must be unscrewed to remove the cover

Then we remove the fuel hose, followed by the drive rod.

The upper arrow points to the fuel hose, the lower arrow points to the drive rod

Next, remove the tip of the cable.

The arrow shows the end of the cable to be removed.

On the left from the fitting we pull off the gasoline hose.

We also carefully remove the gasoline hose indicated by the arrow

We finally disconnect the carburetor, it is ready for adjustment. Its mechanism is rather complicated, therefore, if further disassembly of the carburetor is required, the elements should be removed very carefully. they are small, so they can be lost.

The carburetor consists of many small parts, which should be laid out in order during disassembly.

Chainsaw carburetor adjustment: we analyze all the technical nuances of the work

Summer cottage construction and repairs are not complete without the use of a chainsaw, as well as garden maintenance. Due to a malfunction of the tool, all work can get up, so it is so important to be able to disassemble it yourself, find problems and fix them. With enough experience and dexterity, it is even possible to adjust the carburetor of a chainsaw. a complicated procedure, or rather, jewelry. How to carry out the adjustment procedures, we suggest you disassemble today.

Chainsaw carburetor device

Not a single repair event is complete without knowledge of the basics of the mechanism. By understanding the constituent elements and the principle of operation, it is easier to determine the cause of the breakdown.

Any malfunction in the carburetor threatens to stop the engine

The carburetor is one of the main functional parts of the engine, which serves to prepare and supply a fuel mixture consisting of certain proportions of fuel and air. As soon as the proportions are violated, the engine starts to "junk", or even stops working altogether.

You can achieve the correct operation of the carburetor by examining its "filling":

- Cross flap tube for air flow regulation.

- Diffuser. Constriction to increase air flow, located near the fuel inlet.

- The atomizer from which fuel comes (fuel needle in the diagram).

- Float chamber that regulates the fuel level at the entrance to the channel.

This is how it looks in the diagram:

The diagram shows the interaction of fuel and air flow

How it works: A jet of air in the diffuser atomizes the fuel, creating a mixture that flows into the cylinder. The more fuel is supplied, the higher the engine speed. Different carburettors work in the same way.

Features of setting and adjustment

To find out how to adjust the carburetor on a chainsaw, you should learn to distinguish between three screws (some models have only one).

The L and H screws are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- "L" is for setting low rpm;

- "H" is needed to adjust the upper speed;

- "T" is needed to adjust the idle speed (models with one screw only have it).

The factory setting is optimal, and with the help of the screws they adjust the engine operation in special situations (work associated with different climatic conditions).

The diagram shows the outputs of the carburetor adjustment screws with the lid closed

To set up the chainsaw, use a special tool

Adjustment is carried out only with screws L and H. To increase the speed, turn them clockwise. To decrease. counterclockwise. The sequence of using screws: L. H. T.

If you have doubts about the adjustment, it is better to contact a specialist, since an incorrect setting can damage the engine.