How to sharpen a hand chain of a chainsaw. How to extend the service life of a chain

Sharpening chains for chainsaws with your own hands with photos and videos

In the process of working with a chainsaw in any, even the highest quality tool, the chain over time loses its original sharpness and needs to be pulled. By what signs can be understood that the electric saw circuit or chainsaws dull and it is time to sharpen it?

Below are the main signs that it is time to sharpen the circuit:

- During operation, the saw loses stability, breaks out of the hands and vibrates greatly;

- The chainsaws or electric saw produces shavings only of small sizes, and does not produce large chips;

- The saw part lins in the material, sawing cannot be done efficiently and quickly;

- The deepening of the chainsaw in the wood does not occur on its own, in order to perform the longitudinal cut, the tool has to be “shed” with your hands in the material, putting efforts and pressing the canvas;

- During sawing, a curve cut is formed;

- The chainsaws are quickly and heated hard;

- The wear of the chain occurs much faster;

- Fuel consumption increases.

The original chain of the chainsaw can be sharpened several times, it will maintain all the working properties. The acuity of the cut, the quality of the cut, the speed of rotation along the tire.

A few important tips that will help you do not sharpen the chain on the chainsaw longer:

3 Chainsaw Sharpening Myths

- Do not use a new chain with an old star and vice versa;

- If during the operation of the chainsaw you have already stood two chains, replace the star of the new one;

- The circuit should be running in front of the full operation of the chainsaw with normal load (run.In is carried out immediately before sawing, 1 minute at low speeds, and then 1 minute at medium speeds);

- After cooling the new chain of the chainsaw, the degree of tension should be checked;

- Always use chain grease for the chainsaw, high.Quality oil;

- Keep the normal stretched position of the links, because during operation the chainsaw is often tilted in different directions, which increases the probability of slipping the chain from the tire;

- Control the position and FOCUS of the restore to the depth of the cut, after the 3rd or 4th sharpening, check the parameters of the limiter.

Video

In this video, you can familiarize yourself with the trim process, the most popular ways and tools used for this.

A person who has a chainsaw in his household should know how to sharpen a chain of chainships with your own hands. There are several ways:

- Sharpen with the use of a file (the most common method of sharpening, t.To. Allows you to tighten the tool directly at the place of work on sawing.)

- Silence using a special machine (this method is used in service centers, but can also be used in the personal economy)

- Be sharpened with a grinder. To sharpen this method, it requires certain skills. A little.Won method, t.To. It is difficult enough to sharpen with Ushm correctly.

1 method. File

The first thing you need in order to sharpen the chain, or correct it a little, these are special files.

File

For sharpening and editing chains for saws, two types of files are used. The first, this is a gun file with a diameter of the corresponding diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of a household tool, round Files with a diameter of 4, 4.8 mm, This is due to the fact that they have a small tooth. For professional models, more powerful chains with a large tooth are used, and accordingly, files with a diameter of 5.2, 5.5 mm are needed.

In order to properly sharpen, it is not enough to sharpen only the cutting edges of the tooth, you still need to adjust the restriction of the cut depth of the cut. If this is not done, the chain will not crash into the sawing material to the required depth, which will noticeably reduce the speed of work and in the same way as in the situation with a dumb chain can lead to a saw engine overheating due to a not enough load on the engine. This work is done using a flat file.

Process description

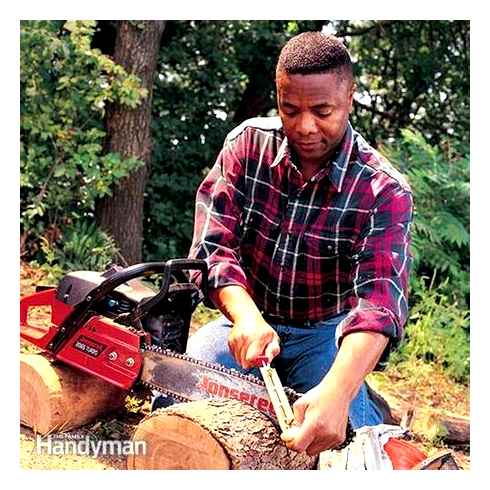

The first where the editing of the saw chain begins on the saw is the installation of the tool on an even platform or table. In forest conditions, for this, a large.Diameter chock is well suited. Next, you need to examine the saw chain for any defects, it can be cracks, completely fragmented teeth. After inspection, you need to install the brake in working condition, thereby blocking its movement along the bus.

The Chainsaw trick NOBODY EVER TOLD YOU!!!

It is advisable to lay a stand under the tire, you can use logs as it, a piece of a branch of suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the tire during the sharpening of the circuit.

STIHL clamp

The circuit is sharpening is carried out by the movements of the file from the inside of the tooth outside. In this case, the file should be located parallel to a special mark on the chain. This label is applied by the manufacturer of circuits to specify the standard angle of sharpening.

The hidden tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process you need to advance the chain along the tire, without forgetting to install the brake in the working position each time.

Ideally, manufacturers advise to conduct the same number of movements with a file for each tooth, but in practice this is not always possible, t.To. Teeth have a different degree of damage to the working edge.

To facilitate the sharpening of a saw chain using a file, special holders can be used, with the markings of the angles applied to them. Markings are made not only for standard transverse cut, but also for longitudinal.

The holders are also convenient to use if you do not have sufficient sharpening experience. Experienced masters for sharpening do not use holders, but can only use special devices that support the file.

Another device designed for sharpening is a manual machine for editing saw chains. As a sharpening tool, it uses a regular file that can independently replace. The machine is mounted directly onto the tire, it also has the ability to adjust the angle of tooth sharpening and a special emphasis that holds the pulled tooth.

Hand machine for sharpening, perfect for beginners. Along with electric models for sharpening, manual has its own undeniable plus in the form of a low price. Depending on the manufacturer of a manual machine, their appearance may vary, but everyone has one principle.

The cut depth adjustment is carried out using a flat file, so that there is a difference between the upper cutting edge of the tooth and a height limiter.

As can be seen from the figure, the depth limiter is flowed in such a way as to bring the clearance indicator to the factory value. Below is a table, which contains the main values of the angles, as well as the clearance for the most common types of circuits.

As a rule, the size of the gap is adjusted using a special dick. It is installed on the circuit during sharpening, after which the depth limiter grows.

DON’T TOSS Your Chainsaw Chain TILL YOU WATCH THIS VIDEO!

Video

In this video, you can familiarize yourself with the trim process, the most popular ways and tools used for this.

A person who has a chainsaw in his household should know how to sharpen a chain of chainships with your own hands. There are several ways:

- Sharpen with the use of a file (the most common method of sharpening, t.To. Allows you to tighten the tool directly at the place of work on sawing.)

- Silence using a special machine (this method is used in service centers, but can also be used in the personal economy)

- Be sharpened with a grinder. To sharpen this method, it requires certain skills. A little.Won method, t.To. It is difficult enough to sharpen with Ushm correctly.

1 method. File

The first thing you need in order to sharpen the chain, or correct it a little, these are special files.

File

For sharpening and editing chains for saws, two types of files are used. The first, this is a gun file with a diameter of the corresponding diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of a household tool, round Files with a diameter of 4, 4.8 mm, This is due to the fact that they have a small tooth. For professional models, more powerful chains with a large tooth are used, and accordingly, files with a diameter of 5.2, 5.5 mm are needed.

In order to properly sharpen, it is not enough to sharpen only the cutting edges of the tooth, you still need to adjust the restriction of the cut depth of the cut. If this is not done, the chain will not crash into the sawing material to the required depth, which will noticeably reduce the speed of work and in the same way as in the situation with a dumb chain can lead to a saw engine overheating due to a not enough load on the engine. This work is done using a flat file.

Process description

The first where the editing of the saw chain begins on the saw is the installation of the tool on an even platform or table. In forest conditions, for this, a large.Diameter chock is well suited. Next, you need to examine the saw chain for any defects, it can be cracks, completely fragmented teeth. After inspection, you need to install the brake in working condition, thereby blocking its movement along the bus.

It is advisable to lay a stand under the tire, you can use logs as it, a piece of a branch of suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the tire during the sharpening of the circuit.

STIHL clamp

The circuit is sharpening is carried out by the movements of the file from the inside of the tooth outside. In this case, the file should be located parallel to a special mark on the chain. This label is applied by the manufacturer of circuits to specify the standard angle of sharpening.

The hidden tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process you need to advance the chain along the tire, without forgetting to install the brake in the working position each time.

Ideally, manufacturers advise to conduct the same number of movements with a file for each tooth, but in practice this is not always possible, t.To. Teeth have a different degree of damage to the working edge.

To facilitate the sharpening of a saw chain using a file, special holders can be used, with the markings of the angles applied to them. Markings are made not only for standard transverse cut, but also for longitudinal.

The holders are also convenient to use if you do not have sufficient sharpening experience. Experienced masters for sharpening do not use holders, but can only use special devices that support the file.

Another device designed for sharpening is a manual machine for editing saw chains. As a sharpening tool, it uses a regular file that can independently replace. The machine is mounted directly onto the tire, it also has the ability to adjust the angle of tooth sharpening and a special emphasis that holds the pulled tooth.

Hand machine for sharpening, perfect for beginners. Along with electric models for sharpening, manual has its own undeniable plus in the form of a low price. Depending on the manufacturer of a manual machine, their appearance may vary, but everyone has one principle.

The cut depth adjustment is carried out using a flat file, so that there is a difference between the upper cutting edge of the tooth and a height limiter.

As can be seen from the figure, the depth limiter is flowed in such a way as to bring the clearance indicator to the factory value. Below is a table, which contains the main values of the angles, as well as the clearance for the most common types of circuits.

As a rule, the size of the gap is adjusted using a special dick. It is installed on the circuit during sharpening, after which the depth limiter grows.

Beliebte Modelle Preiswerter Schärfmaschinen

Bekannte Harsteller Günstiger Kettenschärfmaschinen: Dnipro, Einhell, Sadko, Vitals, Forte, Intertool, Eltos, Zenit, Grand, Stern, Temp.

Unter Der Vielzahl von Modellen Kann Jeder Besitzer Einer Motorsäge Oderktrosäge Das Für Ihn Passende Werkzeug Auswählen. Nachfolgend Finden Sie Eine Rangliste Der Besten Preiswerten Kettenschärfgeräte Für Kettensägen. Diese Maschinen Haben Viele auszeichnungen von denmern Eigalten. Wie viel wird dieses gerät kosteen? Die Kosteen Für Maschinen Dieser Kategorie Reichen von Klein Bis Mittel. In Dieser Preisklasse Gibt Es Viele Modelle, Die Ketten Für Elektro- und Benzinsägen Hervorragend Schärfen.

Weiterlesen: überprüfung der Kettensäge Husqvarna 435. Beschreibung, Spezifikationen und Benutzerbewertungen

Wir Bieten ihnen Eine Kurze Bewertung von Maschinen Zum Schärfen von Kettensägenketten aus der Kategorie Preiswert:

- Professionelle Maschine zum Schärfen von Ketten Scheppach Woodster CS 03, Hersteller Deutschland, 220 Volt, Leistung 180 W, maximaler Schleifscheibendurchmesser 100 mm, Scheibendicke 3,2 mm, Scheibensitzgröße 10 mm, Maschinengewicht 3 kg, 1 Jahr Garantie, Preis 1125 UAH

- Haushaltskettenschärfgerät Dnipro-M NSM-550 (Budget-Elektroschärfgerät), Hersteller Ukraine, Leistung 550 W, Schleifscheibendurchmesser 108 mm, Scheibendicke 3,2 mm, Scheibensitzgröße 23 mm, Gewicht 2 kg, 3 Jahre Garantie, Preis 740 UAH.

- Professionelle Schleifmaschine Vitals Professional ZKA8511s, Hersteller Lettland, Leistung 85 W, Schleifscheibendurchmesser 104 mm, Scheibendicke 3,2 mm, Schleifscheibensitzgröße 22,2 mm, Gewicht 2,6 kg, Garantie 1,5 Jahre, Preis 1093 UAH.

- Maschine zum Schärfen von Kettensägenketten Oregon 106550, Maschinenleistung 85 W, US-Hersteller, Schleifscheibendurchmesser 105 mm, Scheibensitzgröße 22,3 mm, Scheibendicke 3-4,5 mm, Gewicht 2 kg, Maschinenpreis 7 UAH. Das Teuerste Dieser Geräte, Erhielt Viele Gute Kritike, Ein Beliebtes Modell in Russian Und Der UcRain.

Alle Beschriebenen Modelle Sind Für Kettenschärfgeräte an elektrosägen und Motorsägen Geeignet. Zum aufstellen der Maschine ist ein Kleiner arbeitsplatz eerforderlich: Ein Stabler Tisch und Eine Stromquelle, Um Das Gerät Mit Dem Netzwerk Zu Verbinden.

Kettensägenschärfer Oregon. Video Mit Einer übersicht über Die Bedienung des geräts. Das Oregon-Werkzeug Eignet Sich Zum Schärfen von Ketten des Typs 91vx; 91vpx in.325 ″ und 3/8 ″ Teilung; LPX In.325 ″ und 3/8 ″ Teilung; BPX In 3/8 ″ Teilung, LGX.

Video über die Maschine Dnipro-M NSM-550

When to be sharpened and how to find out about it

After examining the saw chain, the master makes a decision about whether it is time to sharpen the tool or not.

As a rule, the saw chain loses its operational properties with intensive work. It may come to the point that in one day the chain will have to be dragged several times. The reason may be the contact of the saw with the soil. In fact, quite several times to struggle with a saw chain on the ground and you can stop all the work. Chainsaw will just stop entering a tree. By the way, one of the signs of a sawing saw is the appearance of small shavings.

The sooner measures are taken to pull the chain, the longer it will last longer. Understand when you need a renewal is quite simple. There will be a change in feed. The chain, with properly sharpened teeth, will get involved even with a slight effort, but if you have to provide a greater effort effort during operation, then this means only one thing, the teeth have lost their severity.

The exploitation of a dumb chain is unacceptable. By the way, this is a safety requirement. And the process will require significant muscular efforts from the lumberjack. As a result, this will lead to a decrease in the quality of the cut, an increase in the amount of fuel used and the accelerated production of the chain.

How to find out that it’s time to hide the chain

It is time to understand what has come for a chain, you can, according to characteristic signs, such as the irreplaceability of a tool that constantly gets stuck in a tree and the appearance of dust instead of traditional shavings. Also indicates a decrease in the severity of the teeth of a difficult deepening and the need to make serious efforts for sawing wood, which occurs extremely slowly. However, it is possible to see that the chain needs sharpening, it is possible by a number of external signs that are observed during visual examination:

There are a number of recommendations on how to sharpen a chain of chainsaws to avoid typical errors characteristic of beginners:

- It is necessary to make the same number of movements for each tooth;

- It is required to make equal efforts for all teeth to avoid unevenness;

- If the chain is too dull, then the file for work is not suitable and it is recommended to use an electric machine;

- The angle is set taking into account the direction in the future will be sawing the logs.

Using the file, it must be borne in mind that it removes metal chips from the chain when it moves forward.

Video Description

Watch in the video how to sharpen the saw with a grinder:

It is recommended not to touch them the surface of the teeth, when performing a return movement back. Mostly all chains sharpen at an angle of 30 °, but after the completion of the procedure, they should be checked by a template. Do this to the subsequent algorithm:

- The template is superimposed on the chain;

- It is checked how the depth limiter acts;

- The limiter is trimmed with a flat file.

Typically, the distance of the depth of the limiter is 0.65 mm, but in general, if necessary, it is allowed to vary within 0.45. 0.80 mm.

Business Service: tool sharpening

Have you ever thought about how much scissors, ax or saw chain costs to sharpen. We will answer right away. Such a service can cost from 20 to 100 rubles. Then another question arises: does it make sense to open your own workshop?

Let’s take a closer look at this business in more detail. It is clear that here the entrepreneur does not make money in certain major transactions, but on the back. Therefore, such a workshop can be profitable only in cities and villages, where there is a large private sector, which means that many tools are used, including electrical and chainsaws. We’ll make a reservation right away. You must offer the widest range of services: the workshop should have a machine for sharpening manicure scissors and equipment for repair and restoration of professional tools.

Necessary tools in the workshop:

- Electrical sharpener with a set of special nozzles;

- Automatic machine for sharpening circuits of electrical and chainsaws;

- Clamps and a vice of different sizes;

- Set of locksmith tools, measuring instruments;

- Locksmith furniture for the equipment of the workplace;

- Special lamps;

All equipment for such a workshop can cost up to 1,000. Additionally, the expenditure article should include utility bills, rent and taxes. At the same time, your monthly turnover in the city, with a population of 150-200 thousand inhabitants, can be about 1,500 monthly.

Thus, if your city does not have high competition in this business segment, then it makes sense to open your own business and earn on sharpening various tools.

Mechanized sharpening by car

Special tools that can be used to simplify the procedure are quite widespread. Such machines are equipped with a special electric drive and grinding circles with increased wear resistance.

For use at home, a small tool is suitable. Such devices can eat from the 220 V network, and at the same time, the electrical consumption indicator is 100 W. The installation of the chain is quite simple, the sharpening procedure can be carried out even without special preparation.

When choosing a machine, attention is paid to the points below:

- Adjusting the angle of sharpening in a certain required range.

- The ability to process the chain with a different step and thickness of the cutting edge.

- Features of the procedure for changing grinding disks.

- Control of the value of the cut width.

- The power of the installed electric engine and the energy consumption indicator.

In addition, it is recommended to devote the popularity of the brand, since the service life depends on this and many other points.

In conclusion, we note that errors at the time of sharpening can cause increased wear of the chain. That is why, with frequent use of the tool and the absence of a required carriage machine, it is recommended to entrust the work to professionals who provide appropriate services.

Tools for the garden: how to sharpen a chain of chainships with your own hands

Each owner The chainsaws should be able to independently sharpen the chain of its apparatus. After all, there are situations when there is nowhere to wait for help in this matter: to call the master is expensive, or to go far to him. In this case, our recommendations on the sharpening of the chain of the chain of the chain will come in handy.

A guarantee of the long work of your saw is proper care. Only high.Quality gasoline and oil need to be poured, as well as monitor the sharpness of the teeth of the chain. When she dumber, the saw begins to vibrate more and more, and this does not affect the entire design of the device. In addition, you can see that small sawdust fly out from under the saw, and this is one of the main signs of a dumb chain. If the teeth are sharp, then the sawdust will be large.

Also, one of the signs of dumb chain is black sawdust. The reason for this.Small fires of wood particles due to the low severity of the teeth. The saw is very overloaded, and you yourself must feel it. When the teeth are sharp. Practically no effort is required to cut the deck. At the same time it goes a little more fuel and the efficiency of the process decreases. In conclusion, you can add that to sharpen the chain It is necessary regularly, Sometimes two or three times a day-then you and your device will be easier to work.

The correct and timely sharpening of the chain of the chainsaw will add to your device for several years of life. According to professionals, an acute chain is more important than a good engine.

First about horror stories

You will saw a dumb chainsaw, get three negative factors:

- Reduce the efficiency of your process. For example, instead of two cubes, drink one (at the same time);

- You will subject the mechanism to intensively wear, with the risk of destruction of the leading stars and tires;

- Receive increased fuel consumption;

There is another fourth, perhaps not such a significant factor. A “torn” cut cut.

And of course, you’ll get tired more, you will (possibly) be angry with yourself, such as “What a fool to me, do not sharpen in advance, now suffer”

Here you have a test (photo on the right). Guess which shavings “came out” from under the sharp and dumb chains? (The answer will be lower).

How to understand that the chain has become dull

- Increased physical efforts;

- Sagging (stretching) of the chain;

- Vibration and “inhibitory” passage of the saw;

- The inaccuracy of the saw and a change in the type of sawdust (they become uneven with sharp “needle” edges, small and dusty). This is Already aboutR tweet on the test.

“According to experts and in my opinion, too: well.Sharpened teeth, more important than the power of the engine.””

Why is it stupid? The reasons, in general, are known, but I will name the main ones:

- Intensive or volumetric work;

- Random contact with stone, earth, hard bitch, etc.P.;

- Inept appeal (broad concept).

What tool tools exist

To start work, it is necessary to stock up on tools that are divided into two types.

Hand tools

A set of tools necessary for sharpening the teeth of the saw:

- Flat file that they are taught to use in school lessons. With it, the depth limiter is stuck.

- Round file of a certain diameter necessary for processing the cutting tooth. An additional device is attached to it. A holder with lines that suggest how to properly keep the tool in relation to the chain. The holding is placed on the tooth of the saw, taking into account the guide lines, the position of the file. Under the cutting surface.

- A template that serves to edit and comply with the parameters.

- A hook is necessary to remove the sawdust from the circuit.

Sets of various configurations can be purchased in a specialized store

Metal sharpening templates help calculate the depth of sharpening

Manual and electric machines

How to sharpen a chain of chainsaws if the cutting edge of the tooth has absolutely lost its shape due to long.Term work? You can use files, but the process will be unproductive and taking a lot of time. The best option is the use of machines, and here you will have to choose, because the machines are different. Manual and electric.

Manual machine for sharpening chains of STIHL brand

Parameters are exhibited before the work, and the processing process takes place much faster than with the help of files: 2-3 movements are enough to sharpen each tooth. Electric machines also have a complex setting, while working quickly and accurately.

An electric machine allows you to reduce a lot of time, but not everyone is ready to pay a round sum for it

Why is the chain of the chainsaw is stupid

The chain of the chainsaw can quickly swell for the following reasons:

- If you work with a saw too often;

- When the operator presses greatly on the saw when sawing;

- If the chain is made of poor.Quality metal, or steel has passed the wrong heat treatment;

- With a frequent cut of raw or tarry wood;

- When sawing trees with solid wood, such as: oak, Karelian birch, cherry, acacia, elm, ash and others;

- If the chain meets on the way of barriers in the form of sand or stones;

- If the chain is incorrectly sharpened or has insufficient tension during operation.

Description of the sharpening process

Consider in more detail how to sharpen a chain of chainsaw. The first thing to do is to prepare a place for installing a clamp, or if the process goes without it, it is convenient to use a regular log as an stop for fixing the tire in a horizontal plane. The chainsaws are installed on a flat surface, the log is placed under the tire, the brake is turned on.

The next stage is direct sharpening of the tooth. To do this, with a round file, movements are made from the inside of the tooth to the external.

It is very important at this moment to maintain the right angle of sharpening. The standard angle is thirty degrees from the perpendicular location of the file to the tire plane. How to arrange it correctly shown in the photo below.

In the process of sharpening a chainsaw for non.Standard cut, for example, longitudinal. The sharpened angle changes to a less acute. As a rule, it is no more than 10 °. It is in such cases that a holder, manual machines or sawing calibers are used to control the angle of sharpening.

Some manufacturers of chain chains, to facilitate sharpening, as well as to indicate the maximum possible sharpening, make a special label on the upper surface of the tooth.

How to Sharpen a Chainsaw?

Holding the file parallel to the mark, you can be sure that the correct angle is observed.

In the process of editing the chain, it is customary to sharpen the teeth on one side first, and then on the other, it is convenient. To. There is no need to constantly change your location in relation to the chainsaw.

After the working teeth are sharpened, it is necessary to adjust the height of the restrictive tooth a flat file. To do this, the supporting caliber is laid on the chain so that the restrictive tooth coincides with its slot, after which the protruding part is grown by a file. This procedure is performed for all restrictive teeth.

The use of roller devices

Sharpet device, with which you can quickly and efficiently correct the teeth consists of a small guide template, on which two videos are installed.

By installing the adaptation on the tire, you can sharpen the teeth of the chainsaw, without even the experience of conducting such operations.

How to sharpen a chain for a chainsaw?

How to sharpen a chain for a chainsaw with your own hands? For a person who often uses this tool, this issue is especially relevant, because contacting a specialist is expensive every time and takes a lot of time. It is better to learn how to do it yourself and always solve the problem as soon as it arises.

The most popular are the three main ways to sharpen the chain of the chainships: using a file, grinder or machine. Consider each in detail.

Video about sharpening chains for chainsaws

Ivan, Poltava:

“During the use of a chainsaw, I realized that no machine could sharpen better than hands! I have been with saws for 20 years, but I sharpened the machine only when I need to quickly and without norms in acuity. He began to work with the Urals and the taiga, even worked on a roll of forest, and after now I am engaged in log cabins and in general wooden buildings. All of these machines of bullshit, especially when the turnover is large and the circle is spinning in one direction. “.