How to tighten the clutch on a chainsaw. Clutch clutch

How to remove and change the clutch on a chainsaw with your own hands

In devices released in the near future, a single.Cylinder two.Stroke carburetor engine is installed. It contains several devices that work harmoniously. The main components of the motor:

Read adjusting the carburetor of the chainsaw Energomash

How to remove

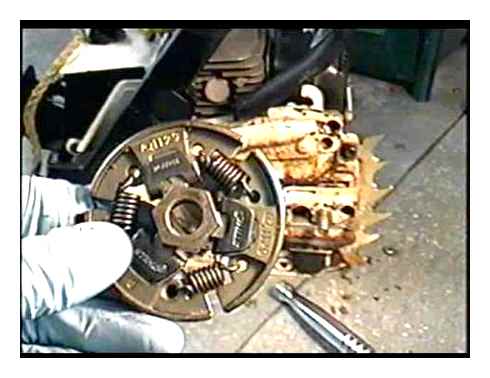

The leading star serves at the same time and the drum. One of the main circumstances of the breakdown of this block is to steal the teeth of the star. In the whole version of the drum, the chain can cut out a star during operation. Such a mechanism asks for substitutions. In the case when there is a replaced crown on the drum, it must be removed and changed during service. After which the drum can continue to work.

Когда появляется потребность в ремонте следует обращаться за помощью в сервисный центр, где работают бывалые спецы. But if this is not close to the question. How to remove the clutch without the help of others? If there is a necessary set of tools, you can easily perform a mystery. Naturally, there are some differences in the models of various companies, but the disassembly scheme remains constant:

- At first, the brake brake cover is removed by turning the lever. Nuts are slightly twisted to loosen the tension of the chain. After weakening, you can completely turn the nuts and remove the lid;

- Disassembling the chain and guide tires, also cleaning the mechanism from pollution;

- The candle of the cylinder head is twisted and the piston is fixed. To do this, the crankshaft should be twisted until the exhaust hole is overlapped, and later a segment of the rope is placed in the cylinder to lock the piston. After the end of the work, the rope is removed from the mechanism;

- The nuts are unscrewed on the clutch with a special key from the kit. In this mechanism, they are made with left thread, and this must be taken into account when dismantling. After which the mechanism is disassembled, and all its details are examined for damage. Worn parts must be removed and changed to new.

After the repair and substitution of parts, it is necessary to assemble in a revolutionary sequence. In more detail, the disassembly process is presented at.

So that without the help of others to repair such chainsaws as STIHL, Husqvarna, Partner, GoodLuck, you should know some features of models. For example, a puck was installed on some varieties of saw (between the cup of the leading star and the engine). During the assembly, it must be installed in its former place.

If the model has a special spring that transfers rotation to the pump drive, then its correct installation is very fundamental after repair. In an unpleasant case, the device may seriously suffer. After preventive and repair work, you need to check whether the mechanisms work properly.

Device and principle of operation of the clutch clutch of chainsaws

Modern chainsaws are equipped with centrifugal clutch couplings. This means that their work entirely depends on the torque of the motor, which at a particular moment in time gives out a saw.

Homelite Chainsaw Clutch Replacement #310510001

Its main constructive elements are:

The principle of operation is as follows. When the saw is launched, the elements that are freely move in the radial direction, with the springs are tightened to the axis of the shaft. In this case, the torque does not enter the drum, which means to the asterisk and the guide. At the moment when the centrifugal force prevails over the power potential of the springs, the adhesion elements are weakened and compressed at the inside of the drum, initiating it. Together with him, the rotational cycle passes to the asterisk and the tire-like headset itself.

The main advantage of the clutch of this type is its slippage when the cutting part is suddenly inhibition, which does not stop the engine. As a result, the “heart” drank. The engines remain intact and preservation.

Frequent clutch malfunctions

Regardless of the reliability of the manufacturer, malfunctions and minor problems in the work of the clutch node are inevitable. The clutch is subjected to a huge load and periodically requires preventive repair. Most often, the cause of the breakdown becomes:

- The natural wear of the entire node (the spring bursts, the clutch slips);

- Clutch breakdown (while the engine works unstable, and the chain is constantly spinning);

- Chill of pieces of clutch fist due to overheating and overload (this is evidenced by the appearance of extraneous noise when the node is operating);

In these cases, it is necessary to remove the clutch from the chainsaw, adjust or completely replace the node. Over, the owners of the instrument can even eliminate the problems even with their own hands. Without involving specialists.

How to remove clutch from a chainsaw: detailed report

The process of repairing the clutch coupling is composed of such operations:

- Dismantle the chain headset, the airfilter shutters and the clutch itself;

- Stop the crankshaft. For this it is enough just to unscrew the spark plug;

- Unscrew the clutch with a special key with strong movements of software or counterclockwise (different models of saw can have either the left and right threads). Usually, a tool in order to remove the coupling is included in the completeness of chainsaws;

- Proceed to the disconnection of the drum and stars;

- If during the inspection of the clutch coupling one or more cracked springs was found (there may be several, for example, the Huskvarn chainsaws. 3.). We need to replace the spring that failed, with a new one;

- Collect clutch on a chainsaw, put it in place and screw it up. Do not forget that the crankshaft should still be motionless;

- Aggregate the removed parts in the sequence, reverse disassembly;

- Fix the coupling. Send the handle of additional braking forward, start the device and carefully remove from the inertial brake.

In order to remove the clutch from the chainsaw, you should first be careful and careful so as not to damage anything superfluous.

This operation should be performed according to this algorithm:

- Remove the saw and chain. To do this, unscrew the manual brake of the chain, pulling the handle over yourself. Then dismantle the tire, remove the pollution.

- Remove the casing from the air filter and clutch.

- Blok the crankshaft. This is a mandatory procedure to avoid its rotation during operation. To do this, unscrew the spark plug, fix the piston at the lower “dead” point and put the rope into the candle hole.

- Using a special key, remove the clutch. You need to unscrew it clockwise, because it usually has left thread.

- Replace damaged parts. Collect the clutch of the chainsaw should be in the reverse order in which the analysis was carried out.

Clutch drum is simultaneously a leading asterisk.

The position of the file when sharpening the chain of the chainsaw.

The main reason for the failure of this node is the wear of the sprocket teeth. If the drum is monolithic, then in the process the chain cuts out the star. Such a drum should be replaced. On some devices of the drum, there is a replaced crown and during the repair it is replaced, and the drum is used further while maintaining the normal state.

At the first stage, it is necessary to remove the brake lid. For this purpose, you need to pull the handle over yourself. This is done so that the tape does not contact a clutch cup. After that, the nut nuts and the chain tensioner are weakened.

The weakening of the tensioner allows you to weaken the chain and the tire. After the nuts of the brake cover are unscrewed, after which the lid is completely dismantled.

At the second stage, the guide tire and chain, the removal of pollution is carried out.

The next stage of disassembly is to turn the candle of the cylinder head. Then the piston is fixed in the cylinder. For this purpose, the crankshaft rotation is carried out and after blocking the exhaust hole, a piece of rope is lowered into the cylinder, which prevents the further movement of the piston. After the repair, the rope is pulled out for the second end outside.

After unscrewing the nut, you need to disassemble the clutch and inspect the drum with the leading star for wear. Then, after the inspection of the drum and sprocket, the condition of the needle bearing is examined. If necessary, worn elements are subject to replacement.

The assembly of the tool is carried out in the reverse order.

There are several nuances that you need to know when repairing the clutch:

- On some modifications and models of the chainsaws between the clutch and a cup of the leading star there is a puck. In the case of disassembling this element, it is necessary to install the washer in the position in which it was previously. This washer can sometimes be installed between the engine and the cup.

- Some models of oil pump drives have a special spring. She transfers rotation from the asterisk to the oil pump drive. The correct installation of this spring is very important when assembling the device. With improper installation, the oil pump stops supplying oil to lubricate the circuit. What can lead to expensive repairs.

After the repair work before using the chainsaws for the intended purpose, it is required to check the operation of the oil pump and the supply of oil to lubricate the saw chain and the mechanisms of the guide tire.

How to tighten clutch on a chainsaw

Clutch is a connecting link located between the power unit and the cutting organs of the chainsaw. Its main function is the transfer of a rotational force created by the engine to the saw set. Most modern household and professional chainsaws are equipped with reliable metallic clutch details, but they eventually completely fail. You can eliminate the breakdown of the node at home, however, for this it is necessary to carefully study the order of disassembly and features of replacing the adhesion elements with your own hands.

Most high.Quality chainsaws of well.Known brands are originally equipped with centrifugal clutch. It is distinguished by high reliability, an increased working resource and works in automatic mode, that is, it independently works when the power unit reaches the necessary speed of rotation.

The device of the factory centrifugal mechanism constructively includes durable friction linings, a clutch drum for a chainsaw and return steel springs. The friction pads of the mechanism can move radially. They are pulled up to the crankshaft springs when the internal combustion engine is at low speed. At the same time, a standard metal drum is acted, which is initially connected to the star of the cutting circuit. When typing a fairly high motor speed, the force of built.In springs in relation to the created centrifugal force decreases. This makes the springs press against the inner surface of the drum and put it into effect. At the same time, an asterisk starting to rotate, responsible for the work of a saw chain. In different types of clutch chainsaws, it can be located behind the clutch mechanism or in front of it.

This principle of centrifugal adhesion has one important advantage. The mechanism automatically slips when jaming the cutting circuit. Thanks to this, the power unit does not stall, but continues to work further.

Video review

STIHL chainsaw repair overview

A review of the replacement of the burned clutch of the chainsaw

Vladimir Khlestov, 44 years old, Armavir

“After six months of operation, the chain on the chainsaw began to spin constantly. I decided that the problems with idle. No carburetor adjustments helped. They dismantled the workshop. It turned out to be bursting the spring on the clutch. Changed everything in 10 minutes, and I could not find a malfunction for two months. The main thing is the correct diagnosis of a malfunction.””

Yaroslav weekly, 31 years old, Vinnitsa region

Chainsaw Clutch Fitting | How to Re-Assemble A ChainSaw Clutch | Easy Way To Fit Chainsaw Clutch

“I can drink mainly solid wood of wood. Quite often you have to sharpen the chain, and the leading star wears out. The first time I took off the clutch. I had to sweat. The metal tightly seized. Not unscrewed. He sprayed with kerosene. Did not help. Only after use in the kids managed to disrupt. And all because the oil flowed somewhere, so the coupling was welded to the asterisk. I think so.””

Andrey Kosuglazov, 23 years old, Primorsky Territory

“After three months of operation of the chainsaws, a longitudinal groove appeared in the asterisk. Everything works, and the chain does not rotate. Said that the problem is in the clutch. It is not at all difficult to make it out, the main thing is to find a puller and not forget that the nut of the coupling has a left thread. In short, unscrewed and changed everything without problems. It works fine, and there was nothing complicated there, only carefully needed.””

The principle of operation of centrifugal automatic clutch of the chainsaw.

Когда бензопила работает на холостых оборотах, грузы сцепления, хоть и вращаются вместе с коленвалом, но не касаются барабана сцепления (в народе — чашки сцепления) так как стянуты пружиной и, соответственно, не передают крутящий момент от двигателя на пильную гарнитуру. When the engine speed reaches 4000 rpm, the clutch loads under the influence of centrifugal force are unclenched and resting their external friction surface on the inner surface of the clutch drum, they begin to rotate it, thereby transmitting the torque from the engine to the saw headset. When the chain stops abruptly during operation (for example, it jammed) the clutch will not allow the engine to stall, since the friction loads at high speeds will be drunk in the drum, and at speeds below 4000 cargo will already squeeze the spring.

In the design of modern gasoline saws, the clutch is responsible for the continuous connection of the engine and the saw headset of the garden tool. Like any other mechanism, adhesion during the operation of the saw lends itself to intensive friction and increased loads. This accelerates the wear of the node, as a result of which cracks, chips and other defects appear on its main details. A thorough inspection of the mechanism and the timely replacement of its faulty parts will help to eliminate the breakdown.

Clutch removal on chainsaws Stil and Dolmar

Surely you noticed that the chainsaws can have different designs of gearboxes. Above is the instructions for removing the coupling with a drum on which the asterisk is located on the inside. Such a device is most of the chainsaws, but not on the instruments of the STIHL brand. The chainsaws of the famous manufacturer are equipped with a drum that has an asterisk from the outside. It looks as follows, shown in the photo below.

Another location of the asterisk does not mean at all that the tool is equipped with a different adhesion mechanism. However, this suggests that the principle of lifting the clutch differs from the above instructions. Therefore, we will find out how to remove the coupling on the chainsaws of STIHL, Dolmar and others, on which the asterisk is located on the outside.

- First you need to remove the casing and the tire to provide access to the clutch

- Unscrew the candle and lock the piston using a special key or cord

- Next, we proceed to the removal of a star and drum. To do this, with a screwdriver you need to put a locking ring and extract it

The installation of a new or repaired part is performed in the reverse order of removal. The procedure is practically identical with the first option, with the exception of some features. If it is necessary to replace only the drum or asterisk, then it will not be needed to dismantle the coupling, unlike the option with the internal location of the star.

It is interesting!If the drum is replaced, then it is also recommended to change the clutch mechanism itself. If the drum changes due to its overheating, then there is a high probability that the mechanism also has the property of damage from exposure to high temperature.

Reviews of the owners

“After six months of operation, the chain on the chainsaw began to spin constantly. I decided that the problems with idle. No carburetor adjustments helped. They dismantled the workshop. It turned out to be bursting the spring on the clutch. Changed everything in 10 minutes, and I could not find a malfunction for two months. The main thing is the correct diagnosis of a malfunction.””

Yaroslav weekly, 31 years old, Vinnitsa region

“I can drink mainly solid wood of wood. Quite often you have to sharpen the chain, and the leading star wears out. The first time I took off the clutch. I had to sweat. The metal tightly seized. Not unscrewed. He sprayed with kerosene. Did not help. Only after use in the kids managed to disrupt. And all because the oil flowed somewhere, so the coupling was welded to the asterisk. I think so.””

DIY How To Remove Chainsaw Clutch without Specialty Tools. Saw Repair. Poulan Husqvarna STIHL Echo

Additionally: what gap should a chainsaw have a gap

“After three months of operation of the chainsaws, a longitudinal groove appeared in the asterisk. Everything works, and the chain does not rotate. Said that the problem is in the clutch. It is not at all difficult to make it out, the main thing is to find a puller and not forget that the nut of the coupling has a left thread. In short, unscrewed and changed everything without problems. It works fine, and there was nothing complicated there, only carefully needed.””

Clutch for the chainsaw

Clutch is a connecting link located between the power unit and the cutting organs of the chainsaw. Its main function is the transfer of a rotational force created by the engine to the saw set. Most modern household and professional chainsaws are equipped with reliable metallic clutch details, but they eventually completely fail. You can eliminate the breakdown of the node at home, however, for this it is necessary to carefully study the order of disassembly and features of replacing the adhesion elements with your own hands.

Most high.Quality chainsaws of well.Known brands are originally equipped with centrifugal clutch. It is distinguished by high reliability, an increased working resource and works in automatic mode, that is, it independently works when the power unit reaches the necessary speed of rotation.

The device of the factory centrifugal mechanism constructively includes durable friction linings, a clutch drum for a chainsaw and return steel springs. The friction pads of the mechanism can move radially. They are pulled up to the crankshaft springs when the internal combustion engine is at low speed. At the same time, a standard metal drum is acted, which is initially connected to the star of the cutting circuit. When typing a fairly high motor speed, the force of built.In springs in relation to the created centrifugal force decreases. This makes the springs press against the inner surface of the drum and put it into effect. At the same time, an asterisk starting to rotate, responsible for the work of a saw chain. In different types of clutch chainsaws, it can be located behind the clutch mechanism or in front of it.

This principle of centrifugal adhesion has one important advantage. The mechanism automatically slips when jaming the cutting circuit. Thanks to this, the power unit does not stall, but continues to work further.

How to Re-assemble a Chain Saw Clutch

Value and device of adhesion

All the latest generation chainsaws are equipped with a centrifugal type adhesion mechanism. The coupling transfers torque from the crankshaft of the engine engine to the saw. The element works exclusively in automatic mode, which helps to prevent excessive voltage of the internal combustion engine. Basic clutch elements:

- Drum. Can have a removable or fixed asterisk, is a transmitted mechanism.

- Friction linings (counterweights). They move under the influence of centrifugal force, there is always a smooth connection with the drum.

- Springs. They provide tight pressing to the crankshaft.

Figure 1. Clutch device

After the start of the chainsaw, the crankshaft set in motion. The coupling is attached to it, from which the leading star of the chain leaves. When working in idle, friction linings are clamped, thanks to which the torque is not transmitted to the drum. After increasing speeds, they move and set in motion a rotating star.

Common breakdown of the clutch of the chainsaw

Types of malfunctions do not depend on the chainsaw model, since the structure and principle of the clutch operation is the same on almost all modern power units. Chainsaw operators know that a slight problem from this node requires immediate active actions. The breakdowns are inevitable, since the clutch collides with not the most intensive operation of the tool with a large load. Often problems are related to:

- The wear of the node as a whole (it may burst the spring or the mechanism will begin to slip);

- Damage to the spring (the chain will rotate, the engine to work, but unstable);

- Sticks formed on the clutch fist due to a large load or overheating (it is enough to listen to the node during its operation, an extraneous noise indicates a malfunction).

It is not necessary to consider instructions for such a type of work for a single model, because for everyone one universal is used, which allows the dismantling of this unit on modern benzo tools.

If there are any distinctive nuances, then they relate to separate traction details. For example, some brands create one spring with two sections in the design of this node, which must be taken into account when the component is completely replaced (it must be replaced when the spring is damaged, due to which the circuit will rotate, and the engine will demonstrate unstable operation).

To dismantle the clutch, we adhere to such an algorithm.

- We dismantle the entire headset. Also remove the cap placed on an air filter and clutch.

- Manually stop the crankshaft so that it does not rotate. It is more convenient to do this, using a rope that is threaded through the candle hole, while removing the candle itself. Do not forget that for this you need to reliably fix the piston in one position. Alternatively remove the starter cap and entrust a couple of bolts into the rotary mechanism of the ignition system.

- Using a special key, which is usually included in the tooling of the tool, unscrew the clutch (you need to unscrew with movements against the course of the clockwise). No need to be afraid to make efforts, usually the fasteners of this node on modern chainsaws are strong.

- Remove the drum and the leading star.

After that, you can install new spare parts (which needed to be replaced). Twisting fasteners, we make movements along the time of time. Do not forget about the crankshaft where the starter is placed. It needs to be stopped.

When assembling, we adhere to the same algorithm of actions, but in the reverse sequence.

By screwing the knot manually, use the brake of the SAW ELREANT to fix for fixing. Tilt the tool forward, try to start it, remove the unit from the brake.

Speaking about the complete replacement of the clutch, do not forget that experts recommend changing the knot after two replacements for the guide. You need to take into account when servicing couplings and such nuances:

- On some saws there is a washer located in the gap between the clutch and an asterisk (sometimes a motor and asterisk), this must be taken into account during repair work;

- Disassembleing the tool, dismantling the clutch, try not to damage the special spring of the oil pump (the drive of this node), do not try to put it in its original position, otherwise this will cause the causes with the supply of lubricants.

We recommend that you look

- How to make a grinder from a chainsaw?

- Where is the bench on the chainsaw?

- Longitudinal sawing of a chainsaw: which nozzles to use?

- Nozzles for a chainsaw of a calm 180 and other models

- The most powerful chainsaw in the world: TOP 4

- Which chainsaw is better and which company? The best rating

Now they read: Kolner circular saws in Moscow-buy at a low price in the online store Leroy Merlin

The clutch of a modern chainsaw has a fairly simple device, so with its independent repair there should not be problems even for novice users of garden equipment. The most frequent breakdowns of the mechanism include:

- Wear of the leading star. During the operation of the saw, the star plays the role of an intermediate link. She gets an effort from the drum and transfers it to the saw headset of the gas instrument. Accordingly, the leading star is in constant rotation mode. In moments when the saw set cuts hard wood, the star amenable to increased loads. Over time, they lead to deformation or the appearance of cracks on the teeth of the part. Even worse, if a plastic sprocket includes a clutch device-it is not able to withstand even 5-minute work in high load mode. In this case, it simply breaks into small parts. The result is “idle” by pressing gas lever, in which the tire and chain do not respond to the manipulation of the operator. To solve the problem, you will need to completely replace the leading star of the clutch of the chainsaw;

- Damage to the drum. This element is the first to accept the rotational effort from the engine and stabilizes it for further transfer to the leading star and the saw headset. The clutch drum for a chainsaw is a composite metal washer, inside which a spring is placed, and a leading star is attached over the puck. Due to constant rotation and friction with the star, the metal case of the element is intensively heated. Because of this, scuffs and burrs are formed on its surface, which will stop the asterisk and the saw headset. To get rid of this problem, you need to replace the clutch drum on a chainsaw, without waiting for its further deformation;

Why is the chain on the chainsaw

The adjustment of the chain stretch takes only a few minutes without experience, and with experience. Less than a minute. Monitor the correct stretch not to monitor, and not to monitor. It is more expensive for yourself.

How to change a star on a partner?

The video will help you change the host Partner of the chainsaw, We will show how easy and fast untie.

The connective traction mechanism is quite complex. It is the Partner 350 chainsaw. Its malfunctions are often accompanied by the loud operation of the engine. It should also be noted that when the crooked mechanism breaks down, the carburetor often goes out. In this case, the repair of the chainsaw “Partner 350” with your own hands is more advisable to start with checking the ignition module. It will also be necessary to completely check the clutch. In particular, the state of the centrifugal coupling deserves attention.

To check it, you need to remove the top cover. The clutch in this model is located near the carburetor. To achieve a centrifugal coupling in the saw, the flywheel is removed. Then the head of the carburetor is disconnected

In this case, it is important not to damage the fuel system. Installed centrifugal coupling on bolts

You can disable this part using the key. If the cracks are visible under the cylinder, then the coupling should be changed. However, some experts advise not to rush. If the cracks are shallow, you can try to wrap the surface a little with a file.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.

Reviews of the owners

“After six months of operation, the chain on the chainsaw began to spin constantly. I decided that the problems with idle. No carburetor adjustments helped. They dismantled the workshop. It turned out to be bursting the spring on the clutch. Changed everything in 10 minutes, and I could not find a malfunction for two months. The main thing is the correct diagnosis of a malfunction.””

“I can drink mainly solid wood of wood. Quite often you have to sharpen the chain, and the leading star wears out. The first time I took off the clutch. I had to sweat. The metal tightly seized. Not unscrewed. He sprayed with kerosene. Did not help. Only after use in the kids managed to disrupt. And all because the oil flowed somewhere, so the coupling was welded to the asterisk. I think so.””

Andrey Kosuglazov, 23 years old, Primorsky Territory

“After three months of operation of the chainsaws, a longitudinal groove appeared in the asterisk. Everything works, and the chain does not rotate. Said that the problem is in the clutch. It is not at all difficult to make it out, the main thing is to find a puller and not forget that the nut of the coupling has a left thread. In short, unscrewed and changed everything without problems. It works fine, and there was nothing complicated there, only carefully needed.””