Sharpen a fine-toothed hacksaw on wood

Canvas material

The blade of modern hacksaws for wood is made from high-quality tool (alloy) steel with increased carbon and silicon (65G, 8HF, U7. U10). The hardness must be at least HRC 45. There are also models that use a combined, more wear-resistant blade with a cutting part (teeth) with increased hardness (HRC55. 60).

By type of cut and purpose

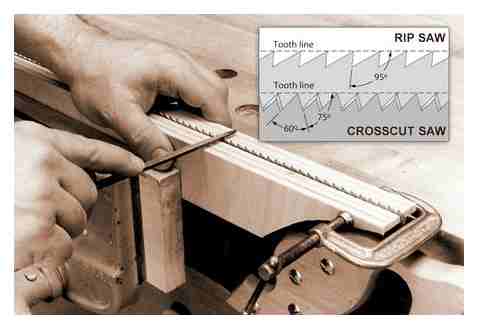

Hacksaws can be designed for cross-cutting, longitudinal (sweeping) or universal. Between themselves, these types differ in the shape of the teeth.

The teeth of saws intended for longitudinal cutting of wood have the form of an oblique triangle. The angle between them is from 45 to 60 °, which allows you to cut wood in only one direction, while ensuring a precise and even cutting line. Most often they are used in the manufacture of furniture.

Hacksaws with teeth resembling an isosceles triangle are used to cross-cut wood. Sharpening at an angle of 45-55 ° makes it possible to cut workpieces both in the forward and reverse direction. This saw works most effectively on dry wood.

The universal hacksaw has two types of teeth. triangular and semicircular (while semicircular more than triangular). When the saw moves forward, long teeth set the direction, and wider, triangular teeth widen the cut, which allows sawdust and shavings to exit freely. The smaller the angle between these teeth, the more accurate the cut is.

Depending on the purpose of the hacksaws for wood, there are classic, circular and spike. Classic saws are used for longitudinal or cross-cutting of wood. Circular hacksaws for wood are designed for cutting holes. With the help of tenon saws, elements are formed for connecting individual parts.

Types and characteristics of hacksaws for wood

It is impossible to imagine a professional joiner or carpenter without a hacksaw for wood, and in everyday life it is used quite often. The widespread use of this tool has contributed to the emergence of its various types, designed for certain operations.

To choose the right hacksaw, you should study its characteristics, imagine what exactly needs to be cut with it and how often it will be used.

- Views

- By type of cut and purpose

- Tooth size

- Classification by construction

- Other varieties

Like any common tool designed to perform a large amount of work, a hacksaw for wood is classified according to several parameters.

Classification by construction

Structurally, hacksaws for wood are:

how to sharpen pruning saws.wmv

- narrow;

- standard;

- with backing;

- with an award;

- onion;

- folding.

They cut workpieces with narrow hacksaws, the thickness of which does not exceed 10 cm. They are also used for sawing branches in the garden, cutting out curved parts and other work. Structurally, these saws are a narrow blade with triangular teeth, connected to the L-shaped handle.

The blade of a standard hacksaw (GOST 2615-84) can have any kind of teeth. Often they are equipped with sets of interchangeable blades designed for a wide variety of carpentry and joinery work.

When processing hardwoods, the blades of the hacksaw can bend strongly. Saws are spared from this drawback, the blades of which are equipped with a backing that acts as an additional stiffener. However, its presence does not allow making the cut deeper than the width of the blade itself.

A hacksaw with a reward looks like a plane. It has two handles and is used when it is necessary to make grooves or tenons. over, the depth of these elements can be different.

Bow saw is a canvas stretched over a base made in the form of a large arc. It is connected to the handle by means of a threaded or tension connection, which makes it possible to use different types of blades during operation. In turn, this makes it possible to single-handedly cut workpieces with complex mowing lines sawing.

On the market you can also find folding hacksaws for wood. They are very light and small in size when folded, which makes it possible for outdoor enthusiasts to take them with them on a hike or fishing. This saw has a short, pointed blade with small teeth.

Main settings

- the material from which the saw blade is made;

- blade length and shape;

- the size and shape of the tooth;

- handle view.

When choosing a tool, you need to pay attention to each element of the characteristic. Only in this case you will not have to regret the purchase.

Other varieties

There are other types of wood hacksaws. Among them, a garden hand saw is distinguished, equipped with a narrow blade, for the manufacture of which chromium steel is used. It is equipped with widely spaced teeth, angled towards the handle. It is convenient to work with such a tool in cases when the emphasis during cutting has to be done on oneself.

There is a two-handed saw with which it is convenient to cut large logs or cut trees. Two people should work with it.

A hand chain saw is a short chain with hardened teeth and two handles at the ends. It is compact and suitable for hiking trips. You can work with her as one person or together.

A modern and versatile tool is an electric hawk, with which you can perform a large amount of various works. In some cases, it completely replaces the circular. Changing the canvases, it is used to cut not only wood, but also plastic, metal.

Length and shape of the blade

In the domestic market, you can find hacksaws for wood with a length of 250 to 650 mm in increments of 25 mm. This parameter is specified by GOST 2615-84 and depends on the distance between the teeth.

Note! It is necessary to choose a saw, guided by the rule: “The length of the blade should be 2 times the thickness (diameter) of the workpieces”.

Otherwise, it will be uncomfortable to work with a hacksaw, since the short blade will jam inside the solid wood.

As a rule, hacksaws with a narrow blade are no more than 350 mm in length and have a large number of small teeth. Universal tools are completed with blades about 500 mm long with medium-sized teeth. Hacksaws with a wide blade are made with large teeth located at a great distance from each other (coarse pitch), their length can reach 650 mm.

Traditionally, a saw for wood looks like a triangle narrowed on one side. This tool can work with any type of wood. In addition, there are hacksaws adapted to work, for example, with tree branches or other objects located at some distance from the sawer. They are rounded and lightweight.

Handle type

The type of handle and the material from which it is made largely determine the convenience of working with a hacksaw on wood. It is best to work with a saw that has a one-piece plastic handle with rubberized finger grips. The two-piece handle is less comfortable as it does not have sufficient rigidity.

There are also hacksaws with flip handles. They, as a rule, are equipped with universal and bow saws, in which in the process of work you can change the blades.

Training

To sharpen a hacksaw for wood, you need to prepare all the necessary tools. Then eliminate possible types of contamination to a clean metal and evaluate the possibility of restoring the web. Based on the inspection, a method of sharpening is selected.

How to sharpen a hacksaw on wood

Tooth setting

So that the tooth does not break during wiring, do not bend it completely.

Before sharpening the cutting element, it is necessary to check and correct the setting of the teeth. The quality of the wiring is checked visually and by measuring the width of the wiring.

The teeth of the hacksaw are diluted using a special tool. setting. Basic wiring is a small metal plate with a handle. A slot is made in the plate, a bit wider than the thickness of the hacksaw blade. To improve the quality of breeding, use a set with an emphasis, which, using a wing nut and a screw, is set at the desired distance and, thus, controls the amount of bend.

The breeding of the teeth itself is carried out in the following sequence. The saw is clamped in a vise so that only the teeth are above the vise jaws. They are alternately captured in the routing slot and bent in the middle at a predetermined angle in the desired direction. When using a set with a stop, the teeth are first bent to one side. Then the emphasis is rearranged, and the other group is bent in the opposite direction. The bending of the tooth is made in a smooth motion.

The quality of the tooth setting is checked visually and by measuring with a vernier caliper. A simple test is recommended to check that there is no excessive bending of individual elements. The saw, after setting, is pulled between the jaws of the vice, spread apart to a width equal to the setting width. Excessive bending of the tooth will prevent the blade from moving.

Tooth setting

The setting of the teeth is required to prevent the blade from getting stuck in the cut. The process consists in bending the teeth relative to the blade in two directions at the same angle and distance. As a result of correct routing, free gaps should be formed, which will help to simplify the movement of the blade in the cut when cutting.

The standard is considered to be wiring at a distance of no more than 2 mm. Depending on the features of the application, the bend is made as follows:

- for processing dry wood. from 0.3 to 0.5 mm;

- for raw wood. from 0.5 to 1 mm.

The selection of the bend angle is carried out on the basis of the following principle: a larger angle will allow you to cut with a wide kerf, and a smaller one. with more effort, but a smaller cutting width.

For bending, special devices are used. The canvas is clamped in a clamp, installed on the work surface. Then the teeth are carefully bent with a metal die to such a distance so as not to break them.

The wiring is done step by step as follows:

- Cuts are made as marks to determine the thickness of the web.

- The prong is fixed in the hole made and bent with a die to the marked stop point.

- A similar procedure is performed with all remaining teeth.

Briefly about the main thing

To sharpen a saw designed for sawing wood, it is first clamped in a vice. Then the teeth are set. Then they are aligned in height. Next, they take a triangular file and sharpen the prepared teeth with it, first from one and then from the other side of the hacksaw.

When using an angle grinder, the saw is secured with clamps on a fixed surface. The plane of its canvas should be horizontal relative to the ground. In this case, a disc with a minimum thickness is installed on the angle grinder. They sharpen the saw teeth at an angle of 15-30 °.

For sawing wood, a classic saw is often used. There is also a reward, fillet, plywood, trigger, with two handles, butt hacksaw for wood. Each of them consists of a canvas and at least one handle.

How to set the teeth

Any sharpening of a hacksaw, be it a two-handed or one-handed saw, begins with a set of teeth 1.5-2 mm in different directions from each other. This layout will serve as a larger cut and faster removal of sawdust outside, without clogging the work surface.

How to set the teeth

It is necessary to do the wiring at the same distance from each other with a special device, which looks like a metal plate with a slot. In this case, the blade should be clamped in a vise so that the teeth barely protrude from the vise. The slot in the fixture is dimensioned to prevent incorrect bending of the teeth. It is enough to put the slot on each tooth in order, with further bending in the required direction (opposite to the chamfer on the tooth. it should look inward).

The nuances of sharpening a hand saw

When sharpening a hand saw for wood, each master follows a number of rules:

- The most reliable attachment of the hacksaw to a workbench or other fixed base is carried out using a vice or clamps. This will sharpen the saw and reduce the likelihood of injury.

- Provides good illumination of the work area so that even very fine teeth can be clearly seen.

- The movements are carried out with a sharpening tool exclusively in one direction, if the process is carried out with a file.

In addition, sunlight is used to quickly check the sharpening quality. When exposed to rays, the teeth begin to shine if the sharpening process is performed correctly.

Link Height Alignment

All prongs must be the same height.

Uneven edge results in uneven loading and greatly reduces working efficiency.

Requirements for setting the teeth of the hacksaw

Bending the cutters through one on both sides of the blade, observe a certain value, which can be set on a homemade device.

The width of the set depends on the type of wood.

Soft and damp wood requires a higher incline angle than dry wood.

Generally, hand tools work effectively with an average of 0.2-0.3mm.

At the same time, the total value should not exceed the width of the web.

In addition, the same bend pattern is observed on each side.

The hacksaw set is checked visually or with a vernier caliper.

Pay attention to the size of the tooth. the height of the incisor is especially important.

How to sharpen a hacksaw with your own hands

How to properly sharpen a hacksaw yourself, if the need arose?

First you need to decide what material the working blade is made of.

Ordinary steel can be corrected independently, and teeth with victorious solders can only be processed on specialized industrial machines.

Some craftsmen, at their own peril and risk, undertake to sharpen a hacksaw with an angle grinder. but this is an unreliable and dangerous way.

To tidy up an ordinary hand hacksaw for wood at home, you need to determine the shape of the teeth, prepare everything you need, and be sure to observe safety precautions.

Hacksaw teeth set

The movement of the blade must be free, for which the saw teeth are set by the same amount.

To reduce the coefficient of friction and the clamping of the hacksaw in the cut, its width must be greater than the thickness of the working blade, otherwise the metal heats up and expands, which leads to the saw to jam.

HANDSAW SHARPENING how to

The setting of the hacksaw teeth is performed by bending the cutters to the sides.

Using pliers does not allow you to get the same angle of inclination. such a tool can only cut firewood.

To spread the cutters evenly and get an even, neat cut, use a homemade setter.

To make it, you need a metal plate of arbitrary shape with a thickness of 2-3 mm.

In a simple version, several slots are made to indicate the thickness of the blade.

The prong is gripped into the hole and bent back until it reaches the selected stop.

In the second version, a cut is cut in the bar with a metal file, and two holes are drilled to install the limiter.

Turning the sector to the sides allows you to adjust the bend angle.

The figure shows a simple model and wiring with emphasis.

The diagram of the device is intuitively easy to manufacture and use.

It should be noted that the bend width has its own parameters.

How to sharpen a hacksaw with a file

The use of a file is still relevant today, so let’s try to figure out how to properly sharpen a hacksaw at home.

Let’s start by installing the canvas.

It must be fixed, as already mentioned above, in a clamp or vice.

The vise cheeks must be made of wood, with a jaw width of at least 200 mm.

The movement of the file should be uniform, and the pressure on the teeth is made only when moving “forward”.

It is necessary to move the hand with the tool to the starting point freely, without effort on the incisors.

In one working pass, an even layer of metal is removed, this will preserve the step, height and profile of the edge.

The sharpness of the cutter can be reduced by the formation of burrs on the surface and irregularities after the passage of the abrasive.

A file cannot perfectly sharpen a hacksaw, but you can get high quality. after sharpening, the smallest file or a file and a touchstone will come in handy.

Burrs are removed by selective cleaning with a fine abrasive, and the edges are smoothed with a wet donor along the side base of the blade.

Having set a goal to sharpen the hacksaw correctly. pay attention to the preservation of the tops of the teeth.

The same cutter height, correct setting affect tool wear resistance and cut quality.

How to determine when it’s time to sharpen a hacksaw?

How to tell if it’s time to sharpen your tool teeth.

An experienced owner knows when and how to sharpen a hacksaw, but it is not difficult for a simple layman to determine this moment on his own. Typically, the operating sound and the color uniformity of the cutting edge change.

Sharp cutters feature even cutting edge wear.

The following signs indicate the need to “correct” the saw:

sawing is hard and uneven;

the cut is uneven;

the web often gets stuck;

it becomes difficult to maintain a given trajectory.

In addition, a blunt hacksaw often gets stuck and requires a lot of effort to complete the process.

General requirements for sharpening

Not every garage or workshop has a special machine for sharpening hacksaws, but it doesn’t hurt to tweak the tool with your own hands.

There are, of course, exceptions. hardened teeth cannot be sharpened.

Diamond drills and other tricks won’t help.

Such a saw has an increased resource and cannot be repaired, but replaced with a new one.

It is easy to identify hardened steel. it is black with a blue tint.

A grinder or a file and file is usually used as a hacksaw sharpener.

A prerequisite is to first perform the correct setting of the teeth, because the thickness of the hacksaw blade affects the cutting width, so the edges must be bent to the required width.

Hacksaw teeth shape

According to GOST 26215, adopted in the USSR back in 1984, the teeth of a hacksaw have a configuration depending on the type of blade:

for cross cutting. in the form of an isosceles triangle or with one cutting edge;

for longitudinal. as an oblique triangle;

for universal. in the form of an inclined or right-angled triangle.

Each type has its own secrets and rules on how to sharpen the cutting edge.

Japanese hacksaw Wolfcraft 6951000

Hacksaws for wood with a large tooth or a small one? Shape and angle of sharpening.

The parameter that is decisive when choosing.

Large models are preferable for soft and damp wood, for example when installing formwork panels or dismantling old structures with residues of earth and paint on the surface.

For dry hardwood and for work where cut quality is important, use a fine-toothed tool.

The design of the teeth of different hacksaws is significantly different (shape, height, pitch, taper angles and the size of the gaps between them for removing waste from the cut). The nature of the direction of movement also depends on them: in both directions, towards oneself, from oneself.

To keep the saw moving easily, not getting stuck in the cut, and the carpenter wasting less effort, the Teflon coating of the side walls was not enough. The teeth should be alternately bent to the sides from the middle (the cut is wider than the thickness of the blade), their tops are sharpened and be on the same mowing line.

Heat treatment of a good hacksaw for wood is performed in such a way that only the edge along the perimeter of the cutter has a higher hardness of 65–66 HRc, and the base of the tooth, like the entire blade, is less than 48–52 HRc. Then, when hitting a self-tapping screw or a nail, a chip will not occur. Tempering is indicated by the characteristic dark shade caused by the appearance of tarnishing colors.