What is the angle of sharpening the chainsaw chain

Why do you need chain sharpening? When to sharpen your chain?

The chain saw is an indispensable tool for both construction work, logging and household use. And like any instrument with a complex mechanism. it requires constant care. Each part has its own service life, as well as the number of hours after which it is worth doing prophylaxis or replacement. One such component is the chain. Since it is she who takes the brunt of wear during operation. Timely maintenance will allow you to keep the tool working for many years, and the chain is always sharp. Depending on the frequency of use. check should be done more or less frequently between work cycles. A dull or defective chain is characterized by atypical working behavior, as a result of which you have to spend much more energy on sawing.

To understand that it is time to do the maintenance of your chain and send it for sharpening, pay attention to the following signs:

- when working, you need to put more effort;

- the saw often wedges, as the chain stretches and sags, which does not allow the tire to function normally;

- the sawing process itself increases over time, and the productivity decreases accordingly;

- it is worth paying attention to the shape of the sawdust: at a sharpened saw. the shavings look the same in size and have an even rectangular shape;

- the appearance of smoke during work;

- fuel consumption increases by 20-30%.

If you ignore these factors, then in the end it will lead to a breakdown, not only of the chain, but of the entire chainsaw. It should be borne in mind that all components of the saw are subject to increased stress, and this accelerates its wear. As a result, costly breakdown or even injury from faulty equipment.

Stages of work:

- Preparation of the chain saw and tools for work;

- choice of method;

- sharpening cutting teeth;

- stitching the stopper;

- checking the correctness of the work performed.

How to sharpen your chain the right way on a STIHL Chainsaw

Sharpening with a manual machine

The safest and most effective way is to use a special machine for sharpening teeth. These machines are divided into:

The main difference is the price of the device and the level of accuracy.

Hand-held machines to some extent resemble templates in terms of the principle of operation and operate on the principle of a bow saw. Electric ones use special circles. They allow you to clamp the chain in the desired position and bring the disc to the sharpened edge as accurately as possible.

The most common problems after sharpening the chain:

Cause: Incorrect sharpening angle.

Consequences: aggressive, labor-intensive cutting, short service life, high saw chain load.

How To Fix: Auxiliary Sharpeners Should Be Used To Get The Correct Sharpening Angle.

Cause: Incorrect file operation or incorrect selection of the file diameter.

Consequence: Labor-intensive cutting, short service life, high risk of kickback.

How to fix: use auxiliaries, place the file higher, select the correct diameter.

Cause: Incorrect sharpening angle.

Consequences: low cutting power, high feed force.

How To Fix: Use Sharpening Aids to Form the Correct Angle.

Cause: Incorrect file guidance, incorrect file diameter.

Consequences: low cutting power, high feed forces, high energy consumption and wear.

How to fix: use additional devices such as templates, set the file deeper, use a smaller file.

Cause: Incorrect file guidance, different pressure.

Consequences: cut deviation, saw jamming when cutting.

How to fix: use auxiliary sharpening devices, ensure uniform pressure.

Reason: different material removal during filing.

Consequences: cut deviation, saw jamming when cutting.

How to fix: Find an approximate tooth and sharpen all cutting teeth according to its size.

Cause: Incorrect file stroke.

How to fix: use auxiliary sharpening devices, observe the correct sharpening angle for all cutting teeth.

Depth gauge distance too short

Cause: The distance of the depth gauge after sharpening has not been checked.

Consequence: Despite a sharpened saw chain, low cutting performance.

How to fix: modify the depth gauge, while using the filing gauge corresponding to the chain pitch.

Depth gauge distance too far

Cause: The depth gauge distance is too great.

Consequence: sticking when cutting, high risk of kickback and chain breakage.

How to fix: If possible, sharpen the cutting teeth, otherwise the saw chain should be replaced.

Different distances of depth gauges

Reason: different material removal when sewing.

Consequence: sticking when cutting, chain deflection.

How to fix: find the shortest depth stop; grind all cutting teeth so that they correspond to the shortest distance of the depth gauge; correct all depth stops.

Chainsaw chain device

The parts are teeth and connectors. The teeth are along the entire chain and alternate on a turn to the right and left. The links are made of a special steel material and the teeth are hard chrome plated for a longer service life.

Note that the STIHL company has succeeded in producing quality products more than others. STIHL chains are manufactured in Switzerland, are tested many times and, using induction hardening, increase the wear resistance of the entire bearing surface.

So, the chain consists of the following elements:

- leading links (1);

- connecting links (2);

- left cutting teeth (3);

- right cutting teeth (4);

- lumpy drive links (5) for low kickback chains.

The cutting tooth itself also consists of separate areas:

- tooth base (1);

- depth gauge (5);

- tooth scapula (2);

- end side (4);

- top blade (3).

The peculiarity of the tooth is that it is not sharpened from one side, but from several at once and at the same time are formed:

- angle for cutting the upper blade into wood (1);

- the back angle of the end blade (2);

- the front angle of the end blade (3); different circuits have 60-85 degrees;

- the rear corner of the upper blade (4); the value varies between 50-60 degrees;

- sharpening angle (5); 25-35 degrees is optimal the higher the angle. the softer the wood for cutting;

- depth gauge distance (6);

- tooth scheme (8).

What is needed to sharpen the saw?

To start sharpening the chain directly, you need to make some preparations:

- when sharpening, the chain must be tightened tighter than normal in order to maintain the correct sharpening angle;

- first find the shortest cutting tooth; make a mark on it, according to its size, all the other teeth of the saw will be grinded;

- the canvas is best clamped in a vice or stribucine. fixing the position during work;

- set the marked tooth in the sharpening zone and then turn on the chain brake;

- sharpening requires tools: flat file, round file, holder, template, sawdust hook.

The main types of chains

The main and main parameter when dividing. this is the step of the chain. Pitch is the distance between the teeth links and is measured in inches. It is calculated according to the size of the drive and driven sprocket.

Note that the file diameter is larger the larger the pitch. The main step values followed by the world’s leading companies:

- ⅜ “picco”. very popular, mainly used for softwoods. For sharpening, use a round file up to 4 mm in diameter;

- 0.325 in. complete both household and professional saws with a power of 3.5 hp. File for sharpening 4.8 mm;

- 0.375 (⅜). used only in expensive professional saws. A 5.2 mm file will work best;

- 0.404. if the previous 0.375 pitch was used for expensive saws, then this is only for professional sawing equipment. A file for sharpening is fine. 5.5 mm.

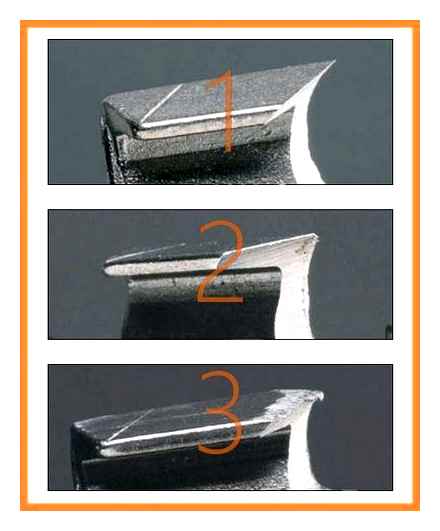

External signs of a blunt cutting edge of a chainsaw tooth

Recall that the chainsaw tooth has a complex configuration (see Fig. 1), which also depends on the direction of chain movement. It has two working edges: the side one, which is located perpendicular to the axis of movement of the links, and the upper one, located at a certain angle to the direction of movement of the chain. In addition, a limiter is provided on each tooth, the parameters of which determine the height of the removed chips. Since the main cutting force falls precisely on the working angle, then all subsequent work with the tool will depend on which angle to sharpen the tooth.

Figure 1. Functional parts of a chainsaw tooth and their appearance

How to use the best and easiest Stihl 2 in 1 chainsaw sharpener

Before starting long-term work with a chainsaw, she needs to inspect and perform test cutting, as a result of which:

- Visually establish the presence (or absence) of a tapered section adjacent to the corner of the tooth, as well as radius curvature on it. the main signs of bluntness (see Fig. 2).

- Check the feed force at which the tool runs stably, with a fast cut. For sharp teeth, the initial moment of penetration of the tooth into the wood occurs quickly, and without significant material resistance.

- Find out the presence of chain vibrations during a steady cut. if they are noticeable, then the teeth must be sharpened.

- Inspect the appearance of the just cut end (especially if the tool is used for ripping). In the presence of rough chips and dents, the chainsaw chain must be sharpened.

Chainsaw chain sharpening template

When purchasing a chainsaw, it is advisable to acquire a special template (see Fig. 3), with which you can easily set the optimal values of the tooth angles. With its help, the values of the rear angles of the upper and end blades are controlled, as well as the leading edge angle (it is indicated in the manufacturer’s instructions, and can vary within 65 80 °).

It is especially important to use a template to estimate the value of the clearance angle of the upper blade. This angle of sharpening of the chainsaw chain is very difficult to determine otherwise, but meanwhile it must be maintained within rather limited limits. from 50 to 60 °.

Measurement of the sharpening angle is performed by determining the angle between the upper cutting edge and a line perpendicular to the chain guide.

How to sharpen your own chainsaw teeth for less than 40

The angle of sharpening of the chainsaw chain can be changed, depending on what kind of work will be done. As the hardness of the wood increases, its value should be lower. In general, it is considered the optimal value of the angle 10 12 °. with a longitudinal cut, and 25 30 °. with a cross cut.

Figure 3. Appearance of the template for sharpening the teeth of a chainsaw

Sharpening can be done manually using a round file with a working diameter of 4 5.5 mm, or on a machine. In the first case, it is extremely important to correctly position the tool in relation to the sharpened tooth. The upper edge of the working part of the file is approximately one fifth higher than the upper edge of the tooth. The tool is positioned perpendicular to the chain axis, and at an angle of 25 30 ° to the upper edge of the tooth

One round file is not enough. You will need a flat file to sharpen the limiter, and a hook that removes the resulting sawdust to clean the work area. There are also special holders on the market, on which the mowing line is graduated with the direction of movement of the file relative to the axis of the chain. As can be seen from Fig. 4, the holder can be mounted on top of the tooth and rest on its upper edge. Since the height of the holder is adapted to a certain chain pitch, it should be selected in relation to chainsaws of specific models and brands.

The minimum required set in order to obtain the correct sharpening angle of the chain by hand is shown in fig. five.

Figure 5. Set of sharpening tools and accessories

First, the teeth are sharpened in one direction, and then in the other. Start with light pressing of the tool away from you, gradually increasing the load. During sharpening, the round file is periodically rotated along its axis.

Chainsaw chain sharpening angle. How to choose the right one?

Even the popular STIHL does not last forever: once the teeth of a chainsaw wear out, which is easy to determine by the nature of the generated chips. With a blunt cutting edge, the chips are small, because the working edge does not cut, but crumples the wood. Naturally, the effort expended by the operator increases dramatically. It’s time to sharpen the saw. How to do this correctly. choose the optimal technology, establish what angle of sharpening the tooth should be and how to check it?

Chainsaw sharpening angles and tooth configuration

The cutting edge of a tooth is characterized by the following parameters:

- Width;

- Thick;

- Sharpening angle.

In addition, each tool model has its own tooth pitch, the value of which for household and semi-professional models is associated with the power of the chainsaw and the torque that the drive develops. For example, for rip sawing, the pitch is taken less (for example, 0.325 inches). In this case, the productivity of work will decrease, but the required effort will be significantly lower. The upper values of the steps for household chainsaws are extremely rare, mainly when felling trees with a large trunk diameter. In this case, the motor power should not exceed 2500 W.

The thickness of the cutting edge for most manufacturers of chainsaws is set the same, and equal to 1.3 mm (there are also edges with a thickness of 1.1 mm, but, firstly, they are extremely difficult to sharpen at home, and, secondly, such links are extremely not very functional: they can only be used for cutting thin branches).

The height of the chain profile can be either 0.625 mm or 0.762 mm, and in most cases it is a low profile that is used for household gasoline-powered tools. When sharpening the limiters, this parameter is very important, because with a decrease in the height of the above-permissible values, the vibration of the tool during operation increases, although the quality of the cut remains satisfactory. Therefore, you should not get carried away with lowering the height of the limiter when sharpening a tooth.

The sharpening angle of the chainsaw chain depends on the main purpose of the tool. for transverse or rip sawing. Since the resistance of the wood is always noticeably higher when ripping, the edge of the tooth must also be very sharp. It is recommended to do it in the range of 6 12 ° (for comparison. with the prevalence of cross-cut. up to 25 30 °). Naturally, in the first case, sharpening should be done more often, and especially carefully, since an unacceptably small angle of inclination of the tooth contributes to its rapid chipping during the operation of the chainsaw. This is especially important for links that are made of structural alloy steels containing silicon and manganese, for example, 40KhGS or 35KhGSA.

Mechanized sharpening on the machine

Sharpening on the machine is much more convenient and does not require high qualifications of the performer. Such machines are electrically driven and equipped with special grinding wheels.

For a household workshop, it is worth purchasing compact units that do not take up much space during storage and are suitable for quick and high-quality sharpening of chainsaw chains from different manufacturers. Such units must operate from a stationary power supply with a voltage of 220 V, have low power consumption (up to 100 W) and be easy to install on a circuit.

When choosing a machine, you need to pay attention to its following technological characteristics:

- Possibility of processing teeth with different thickness of the upper edge and different chain pitch;

- The ability to adjust the sharpening angle, within the limits specified earlier;

- Availability of replaceable grinding discs;

- Constant value of the cutting width.

The design of the machine is simple, and includes a drive motor, a shaft with a seat for a sharpening disk, a handle with controls, a device for attaching the machine to a chain. The adjustment of the pressing force on the sharpened element is provided by a spring clamp. Modern models of sharpening machines are equipped with a differentiated clamp, which provides for the self-centering of the product on the machine. For the convenience of working on the clamp body there is a measuring scale.

Optionally, the machines can also be equipped with a miniature electric lamp that illuminates the working area, as well as a hydraulic booster that makes sharpening easier.

Safety of work is ensured by a folding safety guard.