DIY Tiller Oka mini tractor

Mini tractor from Tiller Agro

Before you start reworking the tillers of this brand, you should stock up on material and the necessary tools. To work you will need:

- stainless steel sheets and profiles;

- seat and steering wheel. can be removed from an old car;

- a pair of wheels. their diameter should not exceed 15 ”;

- a set of fasteners;

- angle grinder and electric drill;

- hammer and welding machine.

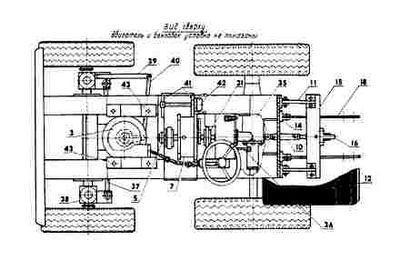

After preparing everything you need, we advise you to study the diagrams that will tell you the correct procedure for installing tractor elements.

We also advise you to see photos that will certainly help you in the manufacture of an agricultural unit.

Unlike the tillers of the manufacturers listed above, the Agro brand equipment has one significant drawback, which must be taken into account when converting a tiller into a mini tractor. It lies in the fact that the tiller axis has very weak fracture strength. This kind of fracture will certainly affect if you exceed the maximum permissible load on the mini-tractor frame. To avoid further malfunction, the mini tractor will need to be equipped with wheel gears.

The procedure for assembling the unit is as follows:

- The first step is to weld a sturdy tractor frame. To do this, use steel profiles and pipes. Be sure to keep in mind that the heavier the frame made, the better the adhesion of the minitractor to the ground will be. At the rear of the supporting structure, weld the tow hitch, which is required to hitch the trailer to the unit;

- Then proceed to the manufacture and arrangement of the minitractor undercarriage. To do this, you can purchase a pair of ready-made front wheels, as well as hubs equipped with brakes. After purchasing the parts, attach the hubs to the steel pipe, and drill the holes in the front of the frame that will be required to mount the hubs to the mini tractor. Next, install the steering rods using a worm gear for this. After the rods, secure the steering column and rear axle. When installing the latter in the bushings used for mounting, press in the bearings. Install a pulley on the rear axle and secure the wheels securely;

- Then mount the engine to the front of the frame. We advise you to do this by means of an additional frame placed on special shock absorbers. this will avoid strong vibrations at high loads on the motor;

- Next, install the driver’s seat on the mini-tractor, connecting it to the frame through the springs. thanks to them, it will be much more convenient to work with the mini-tractor.

If you wish, your hand-made compact tractor can be equipped with a canopy that protects you from rain and sun. To make it, 4 steel pipes must be welded to the frame next to the seat and steering column, to which a steel sheet must be fixed by spot welding. As a result, you will get a reliable unit for a summer residence, which will quickly cope with all the tasks assigned to it.

Avito mini tractor with their own hands with an engine from a tiller. Mounting the engine and hydraulics

The most profitable option for converting a tiller into a homemade tractor is a single-cylinder water-cooled diesel engine. this is usually installed on Chinese scout, Bison and Russian Neva tillers. A single-cylinder diesel engine is economical, therefore, the operation of a mini-tractor produced on its basis will not be invoiced. It is typically placed on the front of the frame, allowing the small tractor to maintain optimal balance when operating with additional tools. At the location of the motor, a mounting system is installed, which is better to make “floating” (sliding) in order to simplify the adjustment and tension of the belts.

The transfer of power from the motor to the rear wheels of a homemade tractor is organized using a belt drive. The PTO transfer case, like the gearbox, can be used from a decommissioned GAZ-53 vehicle. The homemade power unit is mounted in such a way that the PTO pulley is located in the same plane with the pulley located on the rear axle of the minitractor. At the same time, they outline the location for the clutch pedal. The belt drive is covered with a protective cover to avoid slipping during operation and to make its service life longer.

After completing the main work, a hydraulic lift is installed on a homemade mini-tractor with an engine from a tiller. The rework hydraulics kit should include an oil pump, oil reservoir, hydraulic cylinder and distributor. All components of the system are connected by flexible oil-resistant hoses. It is advisable to make the hydraulics in a floating mode. this will ensure the full operation of the tractor hitch.

Equipment running-in

After completing work on the creation of a mini tractor, you need to treat the body with an anti-corrosion agent and paint it. Next, the equipment needs to be run in, so the operator can make sure that all mechanical components are working.

Once the technique has already been tested, it can be supplemented with a head light, canopy, hydraulics and other devices.

Operator’s seat and steering rack

After completing the manufacture of the frame with a body for homemade equipment, the operator’s seat should be attached to the structure. Here you can use the driver’s seat from any vehicle. It must be installed in such a way that the driver can easily adjust himself to the position of the seat. the height and angle of inclination. The steering wheel is created according to the principle of building the installation in karting. But here you need to strengthen and shorten the traction.

Mini tractor from Tiller Agro

We prepare a few basic parts in advance: steering, braking system, additional wheels, hydraulic system. Hydraulics are needed for the system to work normally in combination with attachments. Extra wheels are easy to get from a regular car.

If the Agro engine is located in front of the mini tractor, then it will be necessary to strengthen the front axle shafts with gearboxes. To avoid unnecessary work and parts, you can mark the motor at the back. the load will be evenly distributed. The rest of the assembly process is similar to other tiller models.

How to assemble a homemade tractor from a tiller or a car: our point of view on the question

Many tiller owners often think about upgrading their agricultural equipment. In fact, it will not be difficult to improve the available unit and make a full-fledged mini-tractor out of it. However, you will be required to study the recommendations and follow the procedure. this will give you the opportunity to get an effective homemade mini tractor that will be able to solve absolutely all the tasks assigned to it.

Materials for building a mini tractor:

- ICE from Tiller Centaur with a capacity of 9 hp.

- Gearbox from GAZ-53 with output for power take-off shaft.

- Bridge from Moskvich 412 shortened.

- Steering from Tavria.

- Rear wheels from Moskvich.

- Front wheels from the cultivator.

Photo of a homemade mini tractor.

Mini tractor from Tiller Neva

Converting a tiller into a small tractor may be slightly different. It all depends on the design features of the tiller and his abilities. Consider the principle of making a mini-tractor from Neva tillers.

As in the first case, before making a minitractor, you need to study the diagrams. They detail the dimensions of the elements and the order of their installation during assembly. The procedure for rework will be as follows:

- The frame is made in the same way as in the first case. To create it, use pipes of different sections. Fastening of the frame elements is carried out by means of bolts and welding;

- Next, proceed to the manufacture and installation of the chassis. To mount the rear wheels, use an additional axle, which can be made from steel pipe. Press the bearings and bushings into both ends of the latter, which will be equipped with the rear wheels;

- Next, a tractor from Tiller Neva must be equipped with a motor. over, the engine can be installed both in the front and in the rear of the frame. In the second case, the front and rear wheelbase of the minitractor will need to be expanded;

In the end, the self-made unit will remain equipped with a driver’s seat, lighting devices and side lights. Due to its small size, the finished tractor will have high maneuverability, which will allow it to be used effectively in hard-to-reach places.

Do-it-yourself mini tractor from a tiller. manufacturing procedure

Before you start making a mini tractor based on a tiller, you will need to prepare the materials necessary for work. The conversion kit includes:

- welding machine;

- screwdrivers and wrenches;

- an electric drill and a set of various drills;

- angle grinder and a set of discs for working with metal;

- set of nuts and bolts.

Suitable drawings will help to correctly assemble a tractor from a tiller. In them you will find information about the order in which to connect the parts and what method of fastening is suitable for their reliable installation. Converting a tiller into a mini tractor is performed in the following order:

- A mini tractor based on a tiller must be equipped with a strong, reliable frame. It must withstand an additional pair of wheels, plus the load transported in the tractor will press on the supporting structure. For making a solid frame, pipes or metal corners are best. Be sure to keep in mind that the heavier the frame, the better the adhesion of the mini tractor to the road, and the better the plowing of the soil will be. The thickness of the frame walls is also not very important. the main thing is that they do not bend under the pressure of the transported cargo. You can cut the blanks for making the frame using an angle grinder. Then all the parts are connected to each other, first by means of bolts, after which they are finally welded to each other. To make the frame stronger and more reliable, equip it with a crossbeam;

- Immediately after the frame has been manufactured, it can be equipped with a hitch, by means of which the small tractor will be equipped with additional accessories. The hitch can be installed both in the front and in the rear of the supporting structure. If in the future the minitractor being manufactured is planned to be used in tandem with a trailer, then a hitch should be welded to the rear of its frame;

- At the next stage, the homemade product is equipped with front wheels. For this, the mini-tractor being manufactured is best equipped with two ready-made hubs with brakes provided on them. Next, you need to fix the wheels themselves. To do this, take a piece of steel pipe, the diameter of which fits the front axle. Next, attach the wheel hubs to the pipe. Drill a hole in the central part of the pipe, which is necessary for mounting the product to the front of the frame. Then install the tie rods and adjust them in relation to the frame by means of a worm gear. After installing the gearbox, install the steering column. The axle at the rear of the manufactured tractor is mounted through pressed-in bearing bushings. Wheels used should be no more than 15 inches in diameter. Smaller parts will lead to the “burying” of the unit with the front part, and larger wheels will significantly impair the maneuverability of the mini tractor;

- The next step is to equip the minitractor with a tiller engine. It is best to mount the motor at the front of the machine, as this will improve the balance of the agricultural machine when operating with a loaded trailer. Establish a secure mounting system to mount the motor. When installing the motor, do not forget that the power take-off shaft must be secured coaxially with the pulley located on the rear axle of the mini-tractor. The force on the wheels must be carried out by means of a belt drive. details about converting a tiller into a mini tractor will be described in the video.

A self-made tractor will remain equipped with a reliable braking system and a high-quality hydraulic valve, which is necessary for the proper operation of the unit with attachments.

Mini tractor from a tiller: 4 do-it-yourself manufacturing option

Many tiller owners often think about upgrading their agricultural equipment. In fact, it will not be difficult to improve the available unit and make a full-fledged mini-tractor out of it. However, you will be required to study the recommendations and follow the procedure. this will give you the opportunity to get an effective homemade mini tractor that will be able to solve absolutely all the tasks assigned to it.

Mini tractor from Tiller Bison

Tillers of this brand have a reliable and powerful enough motor, the presence of which allows the unit to be converted into an all-wheel drive minitractor. Before starting work, be sure to study the detailed drawings, and also buy steel sheets, pipes and corners. The procedure for manufacturing a mini tractor is as follows:

- When arranging the frame, you will need to expand the existing tiller frame. This is necessary in order to install additional wheels. Cut the corners and pipes into suitable pieces, then weld them to each other;

- The front beam on the mini tractor is mounted by means of a ready-made hub equipped with brakes. Wheels in the front of the unit must correspond to the size of the rear wheels, or be slightly larger than the latter. this will prevent the mini-tractor from “burrowing” when driving over rough terrain;

- Then install the tiller motor. It is best to mount it at the front to achieve the best balance of the overall structure;

- Weld the towbar to the rear of the finished mini-tractor. it will be required for mounting the trailer.

A home-made mini-tractor, made on the basis of the Zubr tiller, will be able to cope with a number of the most difficult economic tasks: plowing the soil, mowing grass, collecting and transporting crops.

How to make a mini tractor from MTZ tiller?

To remake Tillers of this brand, you should also take into account their design and capabilities. MTZ units have a sufficiently high power, which makes it possible to make a full-fledged tracked mini-tractor out of them. It will be distinguished by high cross-country ability and excellent grip, due to which the quality of plowing the soil of such a machine will be several times higher than that of wheeled mini-tractors.

Before starting work, be sure to study the drawings, in which you will find all the information required for the alteration. The procedure for assembling a mini tractor is as follows:

- First put the tiller in mower operation;

- Then completely dismantle the front platform of the unit;

- Install a caterpillar drive in the front of the mini-tractor being manufactured;

- Install an adjusting rod in the niche for mounting the steering rod. This element will increase the rigidity of the entire structure;

- Weld the driver’s seat to the top of the frame;

- Next to the motor, arrange a platform for mounting the battery and hydraulic valve.

Such a manufacturing method is suitable for converting MTZ 05, MTZ 09 and MTZ 12 tillers into small tractors. Each of them has a sufficient power reserve to work together with a trailer and attachments at the same time.

Mini tractor from Tiller Agro

Before you start reworking the tillers of this brand, you should stock up on material and the necessary tools. To work you will need:

- stainless steel sheets and profiles;

- seat and steering wheel. can be removed from an old car;

- a pair of wheels. their diameter should not exceed 15 ”;

- a set of fasteners;

- angle grinder and electric drill;

- hammer and welding machine.

After preparing everything you need, we advise you to study the diagrams that will tell you the correct procedure for installing the tractor elements. We also advise you to see photos that will certainly help you in the manufacture of an agricultural unit.

Unlike the tillers of the manufacturers listed above, the Agro brand equipment has one significant drawback, which must be taken into account when converting a tiller into a mini tractor. It lies in the fact that the tiller axis has very weak fracture strength. This kind of fracture will certainly affect if you exceed the maximum permissible load on the mini-tractor frame. To avoid further malfunction, the mini tractor will need to be equipped with wheel gears.

The procedure for assembling the unit is as follows:

- The first step is to weld a sturdy tractor frame. To do this, use steel profiles and pipes. Be sure to keep in mind that the heavier the frame made, the better the adhesion of the minitractor to the ground will be. At the rear of the supporting structure, weld the tow hitch, which is required to hitch the trailer to the unit;

- Then proceed to the manufacture and arrangement of the minitractor undercarriage. To do this, you can purchase a pair of ready-made front wheels, as well as hubs equipped with brakes. After purchasing the parts, attach the hubs to the steel pipe, and drill the holes in the front of the frame that will be required to mount the hubs to the mini tractor. Next, install the steering rods using a worm gear for this. After the rods, secure the steering column and rear axle. When installing the latter in the bushings used for mounting, press in the bearings. Install a pulley on the rear axle and secure the wheels securely;

- Then mount the engine to the front of the frame. We advise you to do this by means of an additional frame placed on special shock absorbers. this will avoid strong vibrations at high loads on the motor;

- Next, install the driver’s seat on the mini-tractor, connecting it to the frame through the springs. thanks to them, it will be much more convenient to work with the mini-tractor.

If you wish, your hand-made compact tractor can be equipped with a canopy that protects you from rain and sun. To make it, 4 steel pipes must be welded to the frame next to the seat and steering column, to which a steel sheet must be fixed by spot welding. As a result, you will get a reliable unit for a summer residence, which will quickly cope with all the tasks assigned to it.

Do-it-yourself mini tractor from a tiller!

Many often ask the question: how to make a more functional and easy-to-use unit out of your tiller? The specialists of our service center will try to explain all the nuances of converting a tiller into a motorcycle tractor, but first, let’s figure out what a tiller is.

The tillers, which are essentially light two wheeled tractors, have become excellent helpers for the villagers. With their help, they cultivate the land, plant and harvest potatoes, harvest hay, transport goods, and in winter they clear snow. These functional units have an affordable cost and many advantages, but they have one serious disadvantage, difficult operation for a beginner and tedious work for a specialist. In response to this problem, from the beginning, enthusiasts, and then industrial enterprises, began to produce kits for converting tractors into tractors.

At the moment, there are several types of kit kits on the market, they are different in design and are designed for different types of tillers. For an uninitiated person, it is quite difficult to figure it out, so we decided to write an article that will help in choosing. To begin with, we will simply look at the needs of buyers and identify the basis for choosing, and then we will consider technical solutions for converting a tiller into a tractor. There are two types of tillers, with an air-cooled engine and a water-cooled engine, respectively, and the kit must be selected for the type of tiller.

For simplicity, we will represent models from the Forte company into a group of light tillers, since they are most often converted into a motorcycle tractor. The easiest way is to buy a towing adapter. Suitable for both light and heavy tillers, it is the most affordable way to get your tiller four wheels. Such an adapter is attached to the rear of the tiller through the trailer assembly, turns are carried out using the tiller handles due to the hinge located in the area of connection of the adapter with the tiller.

The main disadvantage of such an adapter is the impossibility of using attachments that require a drive, therefore such a unit can hardly be called a full-fledged motorized tractor.

Adapters with a steering wheel will be more functional, they can be divided into three types:

- rear adapters without propeller shaft

- rear adapter with propeller shaft

- front adapter

The simplest and most affordable solution for lightweight trailers is to buy a front adapter with a handlebar. Rear-mounted motor and gearbox allow for driven attachments

KIT kits for converting a heavy tiller into a mini tractor.

Conversion kits for heavy tillers are divided into 2 groups.

- KIT with natural gearbox position.

- KIT with deployed gearbox.

A kit for heavy tillers, in which the gearbox is in a natural position, in fact, when converted into a motorcycle tractor, the gearbox is simply rolled into the frame. Our experts note such advantages in this design, a flat plane under the seat, a convenient gearbox movement, the cutter is connected to the fasteners provided by the factory, as well as the possibility of reverse alteration into a tiller. In our opinion, the disadvantage of this design is the low lifting capacity of the lifting mechanism, which is very important for a motorcycle tractor.

A whale set and with an unfolded gearbox, as an example, we will examine a set produced by Chp Kryuchkov, when reworking, the box turns. The advantage of this design is the versatile rear lift with high lifting capacity and the ergonomic position of the gear lever. The disadvantage of such a construct is a relatively complex cutter drive mechanism.

Despite the availability of various options, there is another important factor in the choice, this is the workmanship and the general thoughtfulness of the design, when choosing a particular kit, this is a decisive factor when buying a kit for converting a tiller into a motorcycle tractor. For those who have not quite figured out the kits for converting a tiller into a tractor, we propose to get acquainted with the video, we would also be very interested to know your opinion about each type of whale kits. Share your opinions under the video, give recommendations if we missed a certain type from the field of view, and also ask your questions.

How to make a mini tractor from Tiller Neva

First, we purchase the tiller itself, on which a hook has already been pre-mounted, factory or in the form of a homemade product. Then it will be possible to attach trailers with a body, on which cargo is easily transported, regardless of size. There are other additional details that add comfort when using:

- Brake and gas pedals.

- Seat.

- Steering Wheel.

If you have an electric welding and an angle grinder along with additional tools, you can create a dump truck yourself. The main thing is to give a special design to the frame mount, and to make sure that the mini tractor from the tiller can tilt the trailer, turn it. The controls of these devices duplicate each other, so the tiller can be used separately, simply by disassembling a small tractor.

How to make a PLOW for a mini tractor. Homemade plow

Chinese tillery

Basically, these are copies of Russian models. Their cost is lower, but it is achieved not only due to cheap labor, but also by saving on materials for production, technological equipment. This negatively affects the quality of finished products.

Homemade mini tractor from Tiller “Zubr”

Of the details required:

- Frame.

- Cylinder with brake.

- Foot mechanisms, pedals.

- Steering column, complete with rods.

- Front beam, connects to hubs and discs for brakes.

- Rear fenders.

- Rear linkage with manual lift.

The last step is the joint assembly, using a hammer and a drill, wrenches with a welding machine. Additionally, wheels are installed in front. The engine is attached to the frame at the front, so the mini tractor maintains balance during operation. The power take-off shaft is located on the same axle with the pulley on the rear axle of the vehicle. The belt drive helps transfer force from one part to another. Belt tensioning and adjustment will be easier if the motor mount is floating.

Homemade mini tractors

Ideal for small areas. Almost everyone who understands technology can collect them, even at the minimum level.

Minitractor based on MTZ Tiller

This tiller has one difference from other standard models. it is equipped with a two-cylinder diesel engine. This causes the center of gravity to be in front when the device is actively operating. Because of this, the workflow is noticeably complicated. But you can fix the problem by proceeding as follows:

- We use the mode of operation with mowers.

- The platform in front is fully dismantled.

- It is replaced by a wheel from the front of the motorcycle, for which we use bolts. At the same time, the steering wheel is put on.

- In the upper part of the frame there is a niche where the steering link is installed. Here it is necessary to fix the adjusting rod, then the structure will receive an increase in strength and hardness.

- We connect the platform and the mount for the driver’s seat with electric welding.

- The engine must have an additional platform where the hydraulic valve with the battery is placed.

- The rear part is connected to an additional metal frame for the hydraulic system.

- Front motorcycle seat ideal for handbrake placement.

Let’s get a compact mini-tractor with three wheels.

Do-it-yourself mini tractor from a tiller

The first stage of the work consists in drawing up the drawing. And preparation of equipment. If you have the appropriate skills, you can develop a scheme for demonstrating nodes and mechanisms yourself. If there is not enough knowledge, then it is easy to find specialized images on the Internet.

As for the components, ready-made factory kits are suitable for them. They are still cheaper than the mini tractor itself. But this option is suitable only for those who do not want to save on absolutely everything.

Making a homemade tractor will become impossible without:

- angle grinder and discs for working with metal.

- Fasteners and hardware. The latter designation is used for bolts and nuts.

- Channels and pipes with a metal base.

- Drill coming with drill sets.

- Welding equipment.

- Tool kits.

You cannot do without two suitable wheels, together with a hitch and a driver’s seat, steering gear, pedals, and the tiller itself. It must have a sufficient power level. Heavy duty diesel powered unit. ideal.

Mini tractor from Tiller Agro

As always, we prepare several main parts in advance. these are the steering and braking system, additional wheels, and the hydraulic system. Hydraulics are needed for the system to work normally in combination with attachments. Extra wheels are easy to get from a regular car.

In the case of the Tiller Agro, additional actions will be required to strengthen the driving axle shaft together with wheel gears. Let us assume that the engine is located behind the device. Then the load will be distributed as evenly as possible.

Garden Tractor Ground Ripper Cultivator Attachment Build

Russian products

The optimal solution at an affordable price. Options with a V-belt transmission, or the transmission of torque to a mower, snow blower or brush, have gained popularity among buyers. In any case, the process is not complete without the participation of a special belt.

A feature of our developments is a simple device of the clutch system. This makes maintenance and repairs easier. Of the maintenance procedures, only belt replacement remains. Even Soviet engineers designed a gearbox, which is recognized as one of the most successful on the market. Imported professional motors are used. The units are functional and reliable. They are slightly inferior to imported ones, but in cost they are far ahead.