Fixture for angle grinder for wood cutting

How to choose a disc on the angle grinder on wood

Angle grinder, which is more commonly referred to as an angle grinder, is a worthy and versatile tool. Thanks to this equipment is performed cutting, grinding, polishing and sawing of many materials. If the angle grinder must be used for woodworking, then you should provide an appropriate disk on the angle grinder on wood.

It should be remembered that processing metal and wood requires different types of cutting tools, the use of which requires a specific approach.

Disc for angle grinder: study the range

Different types of discs, which are divided by shape and composition can be used for absolutely different types of work. The size of the disc for the angle grinder is determined by two values, for example, 130 x 25. so the diameter is indicated on the outer and inner circle of the disc. Disc thicknesses also vary, but in most cases this does not play a major role.

Every wheel has a limited function, so selecting the right tools allows you to do the right kind of work. Because of the wrong approach can cause equipment failure and even serious injury. Cutting tools for angle grinders have quite a variety of models. In today’s market there are a variety of accessories for the angle grinder:

- Disks that have an abrasive coating. The characteristic of these consumable tools is quite universal, so that any workpiece can be qualitatively cut and sanded. In addition, there are opportunities to perform polishing work. Abrasives are among the most reliable tools.

- Circle for angle grinder, which has a diamond coating. The most common construction tool. This product can be segmented or solid, with each option, peculiar to its narrow purpose. When using it, you can achieve high-quality and precise cutting of durable material, which includes stone, metal, concrete monoliths Represents a special wheel, which is used for sawing and performing various tasks with wood. Kind of resembles a circular disk. The main difference is the materials and alloy used for its production. It is worth noting that previously the prevalence of the product was relatively low, but now the demand for this type of cutting tool is increasing every year. One of the best options for such a disc for an angle grinder is tungsten carbide.

Given the fact that modern products are very diverse, you should not make dangerous manipulations with the circular wheel, trying to install it on the angle grinder, deciding to make a circular grinder from the angle grinder. This blade is not designed for this kind of high RPM work. Because of this, there is a high risk of it breaking and flying debris in the process.

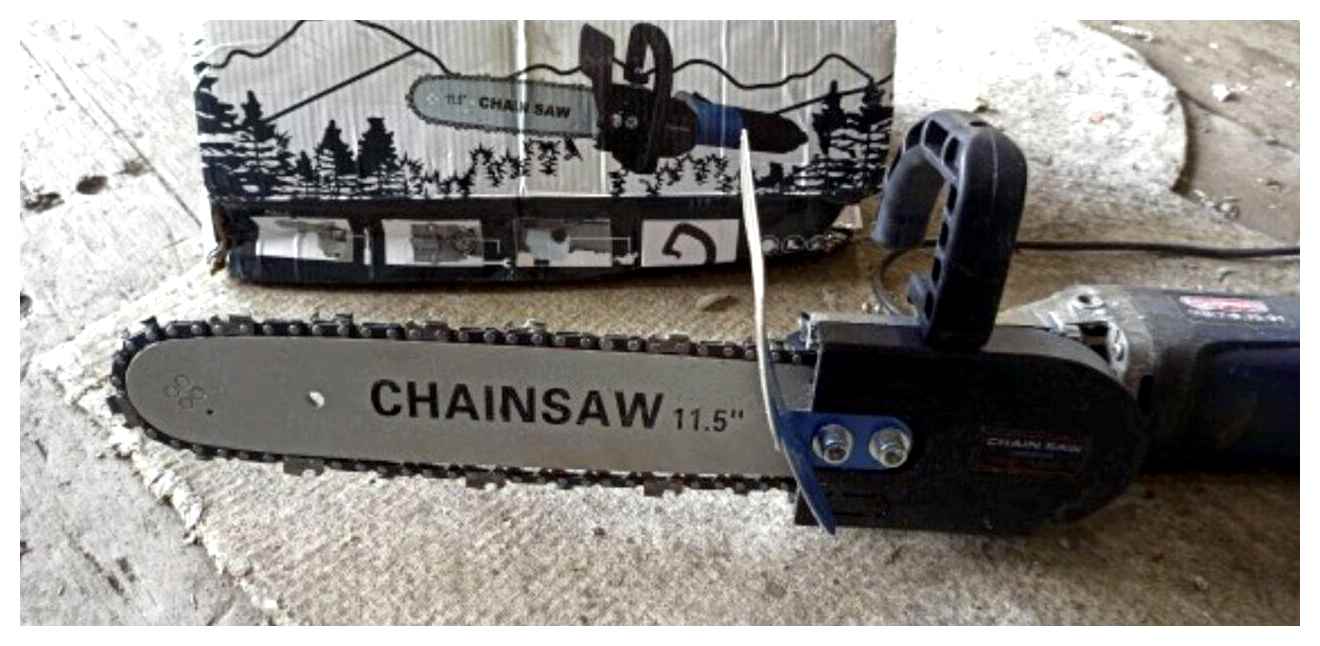

Chain saw arm

This removable tool will be useful in conditions of a private home, cottage, small workshop. Its installation transforms a common “angle grinder” into a power saw capable of cutting dried out wood or sawing thick logs. (A cumber can be sawn both crosswise and lengthways).

The chain saw bracket is easily mounted on the “angle grinder” and disconnected from it. It is designed to be connected to the grinders, which are designed to work with discs 115mm and 125mm in diameter.

The power of the chain saw depends on the power of the “angle grinder”, to which it is connected.

Angle grinder abrasive brush attachment

This attachment allows the angle grinder to be used for cleaning wood, stone, and metal surfaces. It is good for removing rust, old paint, any other stale and persistent contamination. This brush can also be used for cleaning weld seams.

The body of the abrasive brush is made of metal. It itself is made of a polymer material. Which provides a gentle effect on the surface to be cleaned and allows you to work with materials that respond differently to mechanical stress.

The nozzle is designed to work with “grinders”, the speed of which does not exceed 8500 rpm. Recommended speed. 4500 rpm.

Below you can see an example of wood processing with this nozzle

Chain saw blades for wood: advantages of use

In this case the saw blade is made with a chain from a chainsaw. This nozzle is the most suitable for working with wood, because it has the highest efficiency. Wood chain wheel for angle grinder is also considered the safest. Its use significantly reduces the risk of injury should the tool become jammed.

If the circular saw blade hits a hard wood component (e.g. a knot) during operation, the chain is not destroyed. This is accomplished by turning the base plate. These attachments are very popular for removing bark and knots from the trunk of a tree.

Chain saw blades are considered the most suitable for wood

Wood circular saw blades for angle grinders with chainsaws are used for all kinds of work. They can be used to remove tree branches as well as to cut small boards. The functionality of chain saws can be used as skinning tools. They are excellent for removing bark.

With the help of a saw blade you can perform a straight cut of parquet board, plywood, fiberboard, chipboard, as well as conventional unedged and trimmed wood products. It is important to remember that the thickness of the material, which will be processed by such a nozzle, should not be more than 4 cm. Otherwise, there is a high probability of overheating the device.

Wood cutting disc for angle grinder: features

A special material. tungsten carbide. is used to manufacture such products. This is explained by the following: when working with an angle grinder there is a probability that it will tear out of his hands, so the material of the circle should have high strength characteristics. The use of tungsten carbide significantly increases the safety of work, but the cost of such products is quite high.

Cutting discs for angle grinder have a wide variety of types

Discs of this type can have a different arrangement of teeth. The variety of products in this category allows you to choose the most suitable head for the given situation. The shape and frequency of the teeth also play a very important role. The most common size for working with wood is 125 mm. If you want the most universal cut-off saw blade for the 125 mm angle grinder, it is advisable to buy a product with beveled teeth.

Useful information! Wheels that are straight toothed are best suited for work with soft types of wood. Softwood boards can also be machined with these tools.

These products may have teeth that are shaped like a trapezoid. They have a wider service range and are used for cutting boards of medium density. The following materials can be cut with this disc:

The most universal cut-off saw blade size is 125 mm

Wood saw blades for angle grinder of this type have some design features, which are caused by their purpose. For example, during operation, the products are easily overheated, so they have special slots, which can be empty or filled with copper. Such a measure allows you to compensate for the thermal expansion of the metal that occurs at high speeds. The width of such slots may vary, but not more than 2 mm. As for their depth, it does not exceed 20 mm.

Why it is difficult to process wood with an angle grinder

First of all, it should be noted that the high speed of rotation of the disc distinguishes the angle grinder from the circular saw. And even the presence of an expansion ring, which is included with the disc, does not completely solve the problem. But if your angle grinder has a speed control, then it partially facilitates the task.

You can adjust the tool so that its speed corresponds to the speed of the circular saw, this will also reduce the injury risk of the process

But the main difficulty is not this, but in the structure of the wood itself, often heterogeneous and knotty. There is resin in the wood, along with multi-directional fibers, and possibly pellets or embedded wires you might not immediately notice. In general, wood is an unpredictable material. As you work, you may encounter an unexpected obstacle and, as a result, a jerk that can knock the tool out of your hands and steer it along a dangerous vector.

If the blade comes in contact with a piece of metal, a tooth can fly out of it and, like a bullet, also go in an unpredictable direction. You’ll be lucky if a guard gets in the way

If you intend to saw wood in the yard with an angle grinder, you will need to keep it horizontal. This makes the grip uncomfortable and increases the risk of injury.

Important! It is categorically not recommended to saw wood with a tool that does not have adjustable speed and attachments not designed for this purpose.

What attachments can be used for working with wood

As already mentioned, not every attachment is suitable for this task. Don’t take any chances with saw blades not designed for woodworking. Possible nozzle options are listed below.

A chain drive or a cutter

This attachment has a device that allows the chain block to rotate even if it jams, eliminating the possibility of sudden jerk.

With such a cutter you can make notches in the log, remove bark, saw complex relief on the surface

In principle, you can saw with a chain disk, if it has a diameter of 23 cm, but such a tool will cost a lot.

A saw blade with a small number of teeth

Pay attention that on the surface of such a disc the manufacturer puts information about the maximum number of permissible turns.

Large spacing between the teeth makes working in wood safer

Such discs, in addition to wood, cope well with aerated concrete blocks.

Tungsten carbide discs

Such nozzles appeared relatively recently and have already become very popular. The reason is that they can easily cope with small metal inclusions at high speeds.

This is probably the only option for an attachment that can accurately cope with sawing, without any unpleasant nuances

For your information! In great demand are the Rotarex discs, which can be used for sawing wood.

In addition to the actual disc for woodworking, there are other attachments for the angle grinder.

The accessories for wood sanding

Since the machine is called a sanding machine, it should not have any problems with sanding. For this purpose, in working with wood, use the attachment holder, on which the abrasive wheel with a grain from large to fine.

Choosing the right angle grinder for cutting and woodworking

If you have to saw wood material, you can do it with an angle grinder, but with the right tool. angle grinder available in different sizes and capacities, which depends on the possibility of using a diameter of 115, 125, 150, 180 and 230 mm. angle grinder for 115 mm wood cutting discs is not the best solution. This is due to such disadvantages:

- The tool is equipped with a small-sized disk, which is practically impossible to saw or process anything

- The inconvenience of working with a small angle grinder when processing large surfaces

The best solution for cutting wood with an angle grinder is the 125 mm wheel. It not only allows you to carry out effective sawing of the material, but is also considered the safest. However, they are not so safe that they can even be used by beginners. Tools under 150, 180 and 230 circles is better not to use for cutting wood, because the high power of such grinders requires a lot of effort.

This is interesting! angle grinder. it is not a chain saw, and not an electric saw, so without proper skills it should not be used for sawing wood.

The safest option is considered an angle grinder under the circles with a diameter of 125 mm. This is the kind of machine you should use when you need to use a tool to cut woodworking materials. Before you buy a tool bit with teeth for wood cutting, you need to consider not only its outer diameter, but also the inner diameter. the seating hole. For modern standard tools, discs with a diameter of 22.2 mm are available.

angle grinder and accessories for them we recommend to buy in online store https://molotokrus.ru/. There are many tools for every taste.

Roughing disc is designed to remove the bark of the wood and roughing the workpiece

If you have certain skills in solid wood with such a disc can perform sampling. When building a log cabin, a grinder with a roughing head is a good alternative to the usual axe.

You can also use a router blade to cut a board, but it will have a larger kerf width and produce more sawdust.

Milling bits

There are two types of attachments: discs and cutters.

discs are made in different versions. The main difference is the grain size of the abrasive material

Such blades are similar to the surface structure of manual rasp, the difference being their cutting speed. With skill and experience, they can be used for fine woodworking.

There are a large assortment of wood cutters. They differ in size, position and shape of teeth

- It is forbidden to remove the guard when working with a router.

- Only use the cutter for the work specified in the instructions for the cutter, at the recommended rotational speed, and other guidelines.

The main purpose of angle grinder initially is grinding, as evidenced by its correct name. angle grinder. Therefore, wood sanding as an operation for angle grinder suits best. Consider the main attachments for angle grinder, which is used to grind wood.

Corded brushes are mainly used for initial sanding of wood, when it is necessary to level out surface irregularities.

The name of the end discs tells about their function. They are used for grinding the ends of wooden workpieces. Grinding discs are especially suitable for fillet cuts.

Petal nozzles are used in a particular sequence of machining operations. That’s why it is necessary to have several of them, a separate nozzle for each operation. Grinding begins with a coarse disc, then the abrasive size is reduced, and set the nozzles with a finer abrasive grain.

Sanding discs are a universal attachment to the sanding machine. One wheel is enough for all sanding steps. Such a wheel is made of a metal base, on which the circles with different abrasive grit are fixed. When the wheel wears out, it can be easily replaced with another one. it is an expendable item. The base of the nozzle can work for a long time.

- Sanding surfaces before painting.

- Finishing of ends and edges.

- Sanding parquet floors.

- Sanding wooden surfaces.

Wood polishing pads

For polishing wood, discs and brushes are used. Their working parts are made of fine sandpaper, felt, sponge, and other materials.

Recommendations for use of nozzles

- Do not use discs from the circular saw with an angle grinder when fitting parts before grinding, as the angle grinder is a high-speed tool. In this mode of operation, the saw’s teeth can not withstand prolonged use and are destroyed, flying apart at high speed. It is a safety issue.

- Some circular saws are large, so masters remove the protective cover, which is also very dangerous.

- Frequent mode changes contribute to the overheating of the electric motor of the grinder, so you should take breaks in the work to cool it.

- Because of the friable structure of the wood, the saw blade can jam. Therefore, there is a possibility that the angle grinder will escape from the hands, which could lead to personal injury.

Discs for milling and deburring on angle grinder. purpose and types

The capabilities of angle grinders do not end at cutting, sanding and polishing wood. To expand the Spectra capabilities of the tool, manufacturers produce attachments on the angle grinder for milling and deburring wood materials. Deburring nozzles are designed to remove bark and paint from wooden surfaces. There are different types of deburring discs available, and they differ in design, shape and purpose.

- With edge. their main purpose is to remove the top layer of wood, as well as grinding the end part of wooden products. The carbide-applied edge gives the bits a long service life. After processing wood with such nozzles, it is necessary to carry out additional grinding and polishing of the surface

- Spiked. and they are divided into products with large and small spikes. Fine-tipped bits remove paint from the surface of wood, and larger tapered bits remove paint from the surface of wood for smoothing. If the wooden floor has a defect in the form of a different location of the boards on the height, then roughing discs with large spikes can quickly and effectively smooth the surface

- With a working part of the wire or brush. such nozzles are used not only for processing metal, but also wood. Tumbler disc with angled wire is used for paint removal from large surfaces. End-facing wire nozzle for removing paint layer in places with limited access, for example, in the grooves of treated wood constructions. Another type of nozzle used by craftsmen to work with wood is a brush with a thin wire. Used for roughing out wooden surfaces

- A planer disc is an alternative to a usual manual or electric planer. The disadvantage of the first option is that it takes a lot of effort and time to complete the job. Buy electric planer is rational only in the case when a large amount of work is performed to remove the surface layer. To help the home handyman came special discs on the angle grinder, replacing the electro-grinder. The nozzle is a solid circle with three flat knives. It is designed to remove bark from wood, and the end result is very fast. Blunt knives can be sharpened

A special class of accessories for angle grinders are milling discs. Special discs, driven by the spindle of the angle grinder, are used for sawing and cutting grooves of different widths. It is also worth noting that the use of milling attachments on the angle grinder is not safe. Every year the number of options for milling circles on the angle grinder is increasing, but with such attachments need to work with extreme caution. Consider popular options of milling circles on the angle grinder:

Production of various attachments for angle grinder to process wood allows you to significantly expand the functionality of an indispensable tool in the economy. angle grinder today replaces most hand and power tools, so every craftsman necessarily present at least one type of this tool.

Block: 6/7 | Number of characters: 3711

Gentle machining with grinding wheels

Special nozzles are used when performing sanding work:

- Petal tools. They are used for grinding solid wood, making a soft finish. The surface of such a bit has a large number of trapezoidal sandpaper petals. They, like fish scales, overlap each other. Thanks to this the durability of the nozzle is high. There are different grit sizes. Speed and quality of work depend on this characteristic. It is desirable to have discs with both coarse and fine grit. It should be taken into account that the work with petal nozzles requires some skills. So it is necessary before the responsible task to practice as much as possible. It should be emphasized that the petal discs have a long service life. They are available in sizes from 115 mm to 230 mm. One circle is enough to treat 10 sq. м. wood.

- Disks with velcro. For grinding and polishing wood, as well as stone, metal and other materials use grinding discs with velcro. The diameter of the working pad is mostly 125 mm. But you can also find larger ones on the market. The corresponding discs are velcroed to the base. There are accessories made of emery cloth that allow you to carry out sanding work. They can have different grit sizes: both coarse and fine. On sale they are in the form of sets, each of which is 5 discs. A polishing disc, usually made of felt, may also be attached to the base. It is also fastened with Velcro. With such a tool you can work with metal, plastic, plexiglass, marble, polishing them to a shine. Work on metal with special Gauy paste. It is applied to the disc. The polishing pad can also be made of sheep’s wool. It achieves a fine polish to a mirror polish.

- Diamond flex grinding disc. Used for polishing marble, granite. The grit size of these bits ranges from 30 to 3000. It is desirable to work with an angle grinder, in which the speed can be adjusted. the ideal speed for the job. 2.

Recommendations for selection

When selecting a polishing wheel on the angle grinder, there are several factors to consider:

- outer diameter (larger sizes accelerate the machining process and increase the service life);

- seating diameter;

- thickness (the thicker it is, the longer the wheel will last);

- grit size (it is necessary to choose it, taking into account the type of processing: coarse abrasive for rough work, fine abrasive for soft work).

When selecting a wheel, it is also necessary to consider the size of the tool. The wheel is fastened with a special nut. When working with the angle grinder is important to strictly follow the safety. Wheels should be chosen from the factory.

Pendulum-type cut-off saw

The platform for the machine is made of sheet steel. For the pendulum arm, a profile tube is suitable, to which a cross shaft is welded strictly perpendicularly. Two bearing assemblies are pressed firmly onto the shaft at both ends. Then the pendulum is welded on.

Metal cutting machine scheme of the pendulum type

The bracket for fixing the gear case of the universal joint machine is made of the steel strip. Holes are drilled at the edges and in the center for mounting. To provide rigid fixation of the body to the pendulum a collar is made of a steel rod. Metal clamping strip is fastened with bolts. Prepared U-shaped bracket is mounted on the bracket.

The cantilever with a clamp and a mount for the angle grinder is welded to the pendulum lever, and a protective cover is installed at the same time. For automatic return of the angle grinder to the starting position a return spring is used, which must be matched to the weight of the angle grinder.

After the machine is assembled, it should be turned on and idle to check for vibrations, backlash. Then use a cutting wheel of maximum thickness to cut a slot for the cutting tool. On the platform bolts are mounted on the stops for the main directions of the saw. 45 ° and 90 °.

Circular saw attachment

It helps to modify the power tool and is indispensable for professional repairmen and builders.

Chainsaw from angle grinder

Made from quality and durable materials, the chain saw attachment is durable and resistant to wear and tear. Suitable for making quick cuts in wood and allows working with many different materials. With its help you can:

Attachment “chain saw

It will help modify the power tool and will be indispensable for professional repairmen and builders.

Chainsaw from angle grinder

Made from quality and robust materials, the chain saw attachment is durable and resistant to wear. It is suitable for the quick sawing of wood, with the ability to work with a variety of materials. With it you can:

Machine for cutting sheet steel

The angle grinder for cutting sheet metal

For cutting sheet steel, long sheets of textolite, chipboard with an angle grinder requires a different design. In this case, the angle grinder must be able to move along the material to be cut. This is made possible by attaching the angle grinder to the sliding carriage.

The carriage can be made on the basis of roller door blocks. Angles or small channels are used as guides. They are welded strictly parallel to the base. Instead of welding, a screw connection to the platform is possible, but the screws must be countersunk, the nuts secured with Grover washers or locknuts.

Directly on the carriage the angle grinder can be fixed rigidly or on a pendulum lever. The guides should be set so that there is a gap between them and the working table to position the material to be cut on the table.

Creating a milling and copying machine at home

Rules for selecting an angle grinder for the home

Cutting wood, is it worth it to start?

Young masters are always interested in whether it is possible to saw boards with an angle grinder? I’ll tell you right away.no! Although many such an operation is acceptable, but it should be very carefully, because any breach of caution, neglecting the rules of safety, can lead to a fracture of the disk, followed by a flight of particles in an unpredictable direction.

Why you shouldn’t do it as a beginner? Naturally, following the law of meanness, this direction can be your face or other body parts. The speed of the angle grinder’s wheel spinning can give the flying splinter a lot of acceleration.

Let’s consider at once the most frequent and fraught mistakes of beginners:

- Using an angle grinder without a hood, the removal allows you to better control the direction of the cut, but completely removes all insurance against a broken disc, or flying splinters;

- Using a non-standard disc for the angle grinder, most often beginners try to use a heavy circular, which is also dangerous and can lead to irreversible consequences;

- Grasping the tool in the wrong place can cause the angle grinder to slip out of their hands.

Shocking photos on the Internet and equally creepy eyewitness accounts on forums confirm the dangers of using an angle grinder to cut wood. These are the people whose failure to follow TB has resulted in amputations, severe injuries, and even death.

The following information contains comprehensive tips to prevent accidents like those inexperienced guys.

I also recommend reading my books on woodworking so you know all the ins and outs of the job. Read more about the book in the “Books” section on the top menu of the site.

It is for the angle grinder there is a special wood disc, designed for sawing wood at high speed. You don’t often find one on the market.

Do not remove the guard! It is the only barrier between your skin and the highspeed saw blade.

Large angle grinders will not cut well. Because of the speed of the angle grinder, it is unlikely that the teeth of the wheel will catch on the tightly pressed fibers of the wood.

Gloves when working. a must. Better yet, get a device to hold the saw firmly in place. This will turn the angle grinder into a full-fledged machine, protecting you completely from ripping out, in case of quality installation of the design.

Do not use discs with large teeth, they are even less likely to snag the angle grinder, especially on firewood. The possibility of wrenching increases many times over.

When adjusting the number of revolutions on the machine, set the minimum value. Unfortunately, most grinders just don’t have this feature.

You should put the tool at a right angle, you can cut the workpiece, relative to the plane to be cut. Any misalignment can be dangerous. Tilting the machine is also highly discouraged.

If there is a button lock, do not use it. In a critical situation, you will not be able to turn off the device, trying to minimize the damage.

Despite all the tips and rules, the process of sawing wood with an angle grinder can be so accidental that following all the above precautions, can not guarantee the safety of the craftsman. This is due to the fact that the angle grinder is not a target tool for such tasks.

Therefore, if you have any alternative in refusing to use this tool in favor of a stationary machine. immediately decide to use it, even if its transportation will take a lot of effort and time. In any case, health as well as your own life is more expensive.

The advice of many experts is a categorical rejection of this tool for this purpose. If there is a large amount of work to be done, the choice must fall on the jigsaw, which will never be superfluous in the household.

Milling with an angle grinder

Another operation that many experienced craftsmen successfully perform with this tool is milling. Unlike the cutter, it will not be possible to perform a really high-quality processing. However, to make a groove, as well as to cut a part of small size. it will turn out quite well.

Again, this operation is dangerous. Recommendations for general action with the help of this tool I have already written, so follow exactly them. the angle grinder needs a thick and high-quality cutter. Immediately discard the possibility of using homemade nozzles, give your choice to an older brand, insured against chipping and breaking.

Even with all the tips, a beginner should not start milling on his own without the supervision of a more experienced craftsman. As mentioned above, accidents happen all the time and masters of their craft, given the instability of the tool.