How to cut an outside thread on a pipe

Instructions for threading with a hacksaw

The tap (flare) is a metal disc with a round petal hole in the center. The blades have cutting edges that cut into threads of a specific size and shape. The blades are made of metal that is harder than the pipe material. This is high speed steel or alloy steel.

- Preparing the pipe. Cleaning off dirt, degreasing the surface.

- Clamping in a vise. When working on the location of the pipe use a gas wrench.

- Flank chamfering. Do not undercut the pipe at right angles to its axis. The chamfer is removed with a grinding wheel or file.

- Lubricate the cutting point with technical oil.

- Cutter is inserted into the holder, screws are tightened, providing its fixation.

- Place strip perpendicularly to pipe axis, do not twist it. Smoothly rotate the strip in a clockwise direction by applying gentle pressure. The first grooves will help anchor the tool, then the process will be easier.

- Slow cutting, with even pressure. A high speed will not speed up the process, but may reduce quality. get the right settings by running the cutting edges along the full length of the die.

- Do not allow the threading surface to become free of grease. if necessary, spray it with oil from a spray gun.

- After obtaining threaded line of the required length, remove the strip by turning it, clean the surface from chips with a rag, brush or brush with soft lint.

The work can be done in two steps. A roughing die is used first, then a finishing die is finished. Working principle corresponds to the one mentioned above.

How to thread and what tools are required for tapping

Without using special tools, it is not possible to thread the pipe. In locksmith stores, the pipe threader is presented under the name of a pipe threading set. Often such kits include rather unusual tools. cloppers.

Externally, it is the same threading die, but consists only of the main functional element. This round frame takes the form of a short cylinder: it is made mainly from tool steel. Cutters of this tool have considerable strength and durability. The kits also contain holders (ratchet or simple) and a few extra fixtures like pliers, clamps, etc.п.

When threading the pipe by hand, the following points must be observed:

- The pipe must undergo mandatory preparation. The area where the thread will be cut is cleaned of dirt, rust and paint. It is important to remove everything, until a metal base appears.

- When threading the pipe, be sure to lubricate the working surfaces and cutters of the tool used. This is done with liquid grease. It is applied at the beginning of work, and in the course of work. Wipe the grease off well with a rag when the procedure is complete.

- The face of the workpiece is first freed from the outer chamfer.

- It is important to use a well sharpened, serviceable tool to achieve good quality.

In addition to understanding the process, it is also important to be able to choose the right tool. The threading can be done not only with the already mentioned dies and dies, but also with a tap. They make it possible to get an internal thread by cutting grooves for the chips. To thread the surface of the pipe, two similar tools with different depths of cut are used at the same time:

Threading dies can be round, sliding, split or solid. As for the clevis, its design is equipped with a guide that allows you to center the cylinder and cutter inside the pipe. Just having information about the list of tools needed is only half the battle. It is also important to be guided by the requirements of GOST for the size of pipe threads, which will facilitate the choice of the most appropriate hand threading tool for pipes. “Tube Threading Rules. Possible Options”.

How to thread externally

External threading is done with round or sliding dies, as well as screwing boards. Threading can be carried out either by machine or by hand.

Threading with round dies.

A round dies (lerki) is a disc with a threaded hole. Several chip holes are made in the die to divert chips and form cutting edge feathers. Dressers are inserted into the tool holder and clamped with screws

frame; 2. handle; 3. clamping screw.

Diameter of threaded rod is smaller than outside diameter of thread and is sawn off conically for lance entry. Metric or inch threaded rods are available as shown in Table 22. 1:

How to Cut Pipe Threads Hand-Cutting Pipe Thread | Iron Wolf Industrial

Table 1. Rod diameter for threaded bolts.

| Metric thread | Inch thread | ||

| Outer diameter in mm | Core diameter in mm | Outer diameter in inches | Rod diameter in mm |

| 5 | 4,89 | 1/4 | 6,19 |

| 6 | 5,86 | 5/6 | 7,7 |

| 8 | 7,83 | 3/8 | 9,3 |

| 10 | 9,8 | 7/16 | 10,8 |

| 12 | 11,7 | 1/2 | 12,4 |

| 14 | 13,7 | 5/8 | 15,6 |

| 16 | 15,7 | 3/4 | 18,7 |

| 20 | 19,6 | 7/8 | 21,8 |

| 22 | 21,6 | 1 | 25 |

| 24 | 23,6 | 1 1/4 | 31,3 |

| 27 | 26,6 | 1 1/2 | 37,6 |

| 30 | 29,5 | 1 3/4 | 43,8 |

| 36 | 35,4 | 2 | 50 |

Sliding strips (Fig. 3, a) consist of two prismatic halves with a tapped hole. A groove is made in the middle of the hole of the die, which forms the cutting edges.

Noodle threading tongs.

Clamp with rectangular or diagonal frame is used for fastening the dies The clamp prism is inserted into the slots of the dies and the dies are pressed on the sides by bolts.

frame; 2. handle; 3. clamping screw.

To avoid a direct press of the screw on the dies, a so called “blocking screw” is placed between the dies and the screw (see “Thread cutting dies” on page 31). figure. 3, b) which has a slots shape.

Threading procedure with a tap.

Cutting with a prismatic dagger dies is different from cutting with a crowbar. When cutting with dies, the rods are not tapered, but the dies are pulled apart. Then they are clamped onto a ram, the end of which must be in line with the top plane of the dies. Threading is carried out by turning the tool slightly to the left and right. The position of the tool holder and the clamp is set strictly perpendicular to the rod to be cut, otherwise the thread will be oblique and one-sided.

Cooling and Lubrication for Tapping.

When threading with taps and dies, it is necessary to use grease. Common emulsion can be used as a lubricant, dissolving one part emulsion in one hundred and sixty parts water. In addition, it is possible to use: for cast iron, lard and kerosene; for steel and brass, boiled and bitter oil and lard; for red copper, lard and turpentine; for aluminum, kerosene.

It is not recommended to use machine and mineral oils for threading, because they increase threading resistance, do not produce clean holes and lead to fast wear of taps and dies.

Tapering boards.

Tapping boards are used to thread screws up to 6 mm in diameter. There are several tapped holes of different diameters with chip grooves on the screwing boards, two for each hole.

Threading with dies is carried out in the same way as tapping. The rod is firmly clamped in a vice, lubricated with oil, and then the claw with dies is put on the rod, clamped with a screw and rotated a full turn in one direction and half a turn in the other direction. If a shank is thicker than needed, it needs to be filed.

Bolt threads measured with a ring gauge or a thread gauge.

Threading pipe and fittings.

Pipes and fittings (pipe fittings) are cut with a special tool and fixtures.

Tube Threading Clupper.

Pipes are threaded with a special clupping tool The pipe threading clupping tool is not the same as the ordinary clupping tools. Four steel combs are inserted into the slots of its cage. They can be pushed together or apart by turning the upper handle. Therefore different diameters can be cut with one claw. The claw also has guides that can be adjusted with the lower handle. Threading guides help keep the tool in the right position when threading pipe.

Pipes are clamped with a special pipe clamp when threading. The clamp consists of a bed, in which are placed dryers with cutouts for pipes of different diameters.

Threading of fittings is done in the same way as for tapping holes. Only the fitting tapping tool has pipe threads, with two taps included in the pipe tapping kit.

Tools used for threading

Before proceeding to perform the work, it is necessary to prepare a tool for threading pipes, which includes the following devices:

- Measuring tape, pencil, and vernier. The assembly of the pipeline occurs according to a previously prepared scheme. The first step is to prepare pipes of a certain length, shown in the diagram. A tape measure and a pencil are used for marking. A caliper is used to measure the diameter of the pipes and select the right tool;

Measuring tape and vernier for measuring pipe

Metal pipe threading tools

A tool that clamps the pipe in a certain position

- machine oil or any other lubricant. Threading pipes by hand will be much easier if the tool and the end of the pipe are lubricated with special products;

- eye protection goggles. Any work must be carried out, observing all safety rules. When threading, metal shavings can enter the eyes and cause severe damage, so protection in the form of goggles is required;

- a pipe threading tool. It can be one of three options:

- tongs;

A set of crescent rollers for tapping threads in different sizes

Tools for tapping internal threads

Using an electric tool

With an electric thread cutter, the planned work can be carried out several times faster, and the quality of the final product will be much higher. The sequence of work will be as follows:

- The pipe is cut to the required size. The most acceptable result is obtained by using a sabre saw with a guide.

- It is not necessary to remove the chamfer, as with a coping tool. This is also valid, by the way, with the manual clupping machine.

- A special holder is put on the socket. It acts as a guide. It is important to clamp it well.

- The power tool is fitted and inserted into the toolholder. The tongs is put on the pipe.

- Lubrication is accomplished with a special compound.

- The machine does everything automatically.

Maevsky pipe threading tongs for tapping pipes

It is not uncommon to use such equipment as a Maevsky clapper. In this instrument there are split dies, consisting of two parts. Individual part of the dies corresponds to a certain size of pipe. The dies are mounted into the socket of the body with screws according to the marks on the dies of the required size and on the body, depending on the number indicated in the socket and on the die. A stopper cap is placed on the dies and screwed on.

This equipment is available in two sizes: for threading 15 and 20 millimeters in diameter and for threads of 25 and 32 millimeters in width.

Such a device has the following advantages: low weight, easy design and maintenance, the possibility of rapid replacement of dies.

Tools

All the necessary tools and equipment for cutting must be prepared in order to carry out the work. In each specific case, the pipe threading set will differ in composition, but for manual use it consists of dies, clevis, and holder with ratchet. The composition of the set is also additionally equipped with a pipe cutter, a gas wrench, file, hacksaw, angle grinder, lubricants and other tools. For those who do not want to work in the old classic method, there is an alternative. the power tool.

The main requirements are the quality of the tools used and the preparation of the work.

The cutting itself is carried out with dies. Some are sliced on one side only, others on both sides.

For internal threading, the set can also include several taps with different depth of cut. Some are used for roughing internal surface of the pipe, other. for finishing. This equipment is represented as a screw with chip grooves. It is fastened in the collar by means of the tail part.

The tap is used to cut internally in several passes. Their number depends on the material being worked on. For example, special sets of several taps are used for threading in titanium alloys.

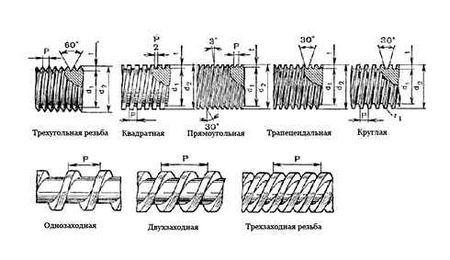

A die, a runner or a lerka is used to make threads of various shapes on pipes. It is a steel nut with a cutting base inside, which has special holes. grooves for waste. Dressers are available in tubular, hexagonal, round and square. Their body modification comes in one-piece, slit and sliding.

Sliding (prismatic) models are also called half-blades. They are fixed in the clupp with screws and a special gasket, a driftwood block. This is necessary for uniform pressure distribution on the screw. The dies are used to thread cylindrical, tapered, round or metric threads. Accessories of the die. special screwdrivers and chucks, with which it is attached to the body of the frame.

The cluppe consists of a frame in which the cutting elements. dies. are fastened. Each mandrel is provided with four steel dies. The clupp is also equipped with a special handle with a ratchet. Only one die can be inserted in the clamp holder, several dies can be inserted in the clupp. The hand clapper is capable of cutting two types of threads: 0.5. 1 ¼, 1 ½. 2 in.

The hand clipper generally cuts small-diameter pipes. They are equipped with a special handle. holder. They can also be used with a suitable pipe wrench. It is small, simple, and easy to use.

A claw with a holder and ratchet is a modification of the design with a toothed mechanism designed to make threads larger than one inch in diameter. The ratchet is an indispensable mechanism. Left- and right-handed ratchets make it easy to work in hard-to-reach places, such as close to walls. Use the ratchet lever to quickly remove the clevis from the thread by turning it in the opposite direction, providing a reciprocating method of threading.

Conventional, oblique and Maevsky clups are used in practice.

The bevel claw is called an angled claw because it adjusts the distance between the sliding dies. This tells the diameter of the slicer. This kind of constructions are the easiest to use.

Maevsky’s pliers of a more complex design, used to make pipe threads. They contain three sets of interchangeable dies and specialize in thread diameters up to 2 in. This type of design is used for threading pipes with a small diameter.

Threading on large-diameter pipes is performed on an industrial scale. For example, in order to thread a seamless pipe with a diameter of 219 mm, a special automatic threading machine is required. Casing pipes (columns) are cut only on special machines in special conditions, while observing all safety measures.

Detailed table of pipe thread sizes with inches and mm

Individual components of water and gas pipes are connected by threaded joints. Such a joint provides a strong and reliable assembly, guaranteeing durability and tightness of the entire engineering network.

The proposed review article contains complete information about popular types of joints used in the home and repair and construction work. Any home handyman, plumber. amateur after reading the article will get comprehensive answers to all questions on pipe threading.

What tool is needed

Threading on pipes will require mandatory availability of the following tools:

- Measuring tape, pencil, caliper. To assemble the pipeline, it is necessary to develop a scheme in advance. First take a pipe with a specified length: the marking is made with a tape measure and a pencil. A caliper is used to measure the diameter and the selection of appropriate devices. When marking it is important to observe considerable accuracy and precision, since any deviation from the specified size leads to a breach of the correctness of the entire construction. As a consequence, in such cases, it is often necessary to redo the entire pipeline.

- angle grinder. This tool is used to cut the pipes according to the marks that have been made. These functions can be performed also by a simple hacksaw for metal.

- Vise. During cutting, the pipe must be held securely in a horizontal position.

- Machine oil or other grease. Lubrication of the tool and the area to be threaded by hand is practiced in order to facilitate manual threading.

- Threading tools. Pipe threads can be cut with a club, die or tap. Which tool to use depends on the type of thread to be cut and the preferences of the performer. Different pipe threading kit is used for different jobs, depending on the situation. The external thread is cut with a die, held by a club or die holder. Taps are needed for tapping internal threads.